Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Assessment of Current Downtime Analysis

Authors: Dipayan Saha, Abhijit Mangaraj

DOI Link: https://doi.org/10.22214/ijraset.2022.41505

Certificate: View Certificate

Abstract

The approach used to calculate downtime for complicated projects is consistent with the literature: simulation. Researchers evaluate current downtime study on Shipping Corporation in this report. As a result, the existing approach for determining downtime for complex projects is untrustworthy; in fact, due to the significant simulation uncertainty, it is highly unsafe to utilise current methodology to make predictions on downtime distribution. We advocate utilising a stochastic metocean condition generator in the simulation to reduce simulation uncertainty. These uncertainties, however, may be managed by the model used, & they can also be quantified. Finally, a comparison1should be drawn between simulation uncertainty in HADDOCK & combined model, parametric, & simulation uncertainty in a stochastic model simulation.

Introduction

I. INTRODUCTION

A maritime operation is an action (for example, hoisting or dredging) that has a1net or 'calm-weather' duration & a set of operating constraints, based on the equipment and the activity performed. As a result, the actual duration of operation is determined by weather conditions at time of execution: if the operating limitations are exceeded, downtime1occurs. The objective for this research is that precise information regarding the projected downtime1during a marine project, such as installation of Offshore Wind Farm foundations, is critical information during the tender process of such a project. Marine shipping corporation has created an in-house software tool to analyse1downtime (HADDOCK), but further study is needed to determine the (AI) validity and completeness of technique, particularly for complicated projects involving several consecutive operations. The goal of this thesis is to provide insight into the available methods for delay analysis in various categories of marine operations, as well as to investigate the applicability of a new stochastic1model to use in downtime simulations, which generates binary1workability sequences based on Markov1theory. Based on1these findings, recommendations1are offered to the shipping firm in order to assist enhance the current downtime analysis process.

The sequence of actions that must be performed, the equipment designed for these processes, and the location of project all lead to deterministic1planning. A deterministic1project plan does not include any1risks that might alter the plan; thus, a probabilistic plan is created using a risk model. A probabilistic1planning will not offer a single project1duration, but1rather a range or probability1distribution of possible durations. It1basically mimics the real project execution, including (some of the) potential dangers, depending on the model's complexity. A cost estimate can also be produced based on the projected time bandwidth. There are several ways for estimating the (risk-adjusted) project1duration. This is historically based on1most likely values. Risks & uncertainty can then be incorporated by raising the deterministic duration by a percentage. This % can be thought of as either a random variable or a1deterministic constant. Another alternative is to perform a Monte Carlo analysis.

The estimated project length can be predicted more precisely with a more specific evaluation of the particular hazards to which the project is susceptible. External (e.g., poor weather, unanticipated occurrences) & intrinsic (e.g., work rates or1engineering complexity) uncertainty of activities can be distinguished. Weather risk is one of external risk variables1that contribute to the overall risk of a maritime project, and it is only risk addressed in this thesis.

A cost/benefit analysis of two choices available to decrease weather risk is one purpose of a weather risk study. These options are to start the project at time that results in the least weather1risk or to employ different equipment.

During project execution, actual length and cost are determined by the (potential) occurrence of risk-marked events. Finally, it is hoped that the project's actual cost and duration would fall within the range predicted by the probabilistic risk model (otherwise1very unlikely events occurred or there would be1something wrong with model).

HADDOCK is1used to estimate the predicted weather downtime during a complicated project, which is crucial information during the bidding phase. Depending on stage or'strategy' of the tender, downtime and/or workability1information is used in various ways. The tender specifics are not yet evident in the high-level plan, and just a workability % is required. As the contract process progresses, the operating cycles become1clearer, necessitating a more complete downtime1analysis. This article focuses on downtime evaluation necessary in a thorough tender strategy.

Table 1: Current Downtimei Analysis Method in Haddock For Each Category of Marineioperations

|

TYPE OFIMARINE OPERATION |

DOWNTIMEIANALYSIS METHOD |

DOWNTIMEIRISK PRESENTATION |

|

Continuous operation |

Joint probability distribution / wave scatter |

% of workability |

|

Single weather window |

Distribution of empirical persistency |

Weather window cumulative probability distributions |

|

Complex project |

Raw data simulation (no stochastic model) |

Project duration or downtime cumulative probability distribution (Pxx values) |

II. REQUIREMENTS

In order for a downtime analysis approach for complicated projects to be beneficial in their operations, Shipping Corporation has established the following conditions.

- The approach should be general, which means that it may be used in a variety of geographical areas and types of maritime activities (e.g. dredging, installation1of offshore wind1farm foundations)

- As a result, the technique should be capable of including several metocean characteristics, such as Hs, Tp, wind speed, end-of-day tides, currents, and air temperature.

- Because sequence of procedures or operational restrictions may vary throughout the tender process, the technique must be computationally viable. As a result, the model is often run numerous times with new input data, with calculation ideally taking no more than a1few hours.

- To utilise procedure and comprehend the findings, the user should not need a full comprehension of the underlying mathematical1model and/or statistics.

- The approach produces a distribution of project1time duration & a proportion of each operation to overall downtime.

III. PROJECT INFORMATION

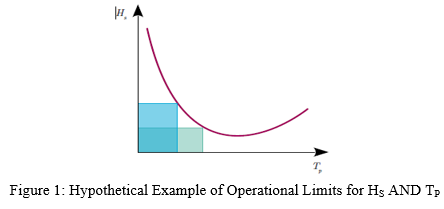

The tender team offers project planning information. This comprises the intended vessel(s) as well as a description of the procedures that must be carried out. Each operation has a net duration, is either linked or uncoupled, and has operating constraints (for example, wave height and/or period limits, wind speed limits). Figure 1 depicts a fictitious example of operational limitations for Hs and Tp, as they are frequently schematized. The purple line represents the equipment's real operating limit, while the blue boxes are two instances of how limits are frequently stated. It is obvious that this method of modelling1operational restrictions understates real workability. On the other hand, operational limitations are often developed from practise and so are not known exactly.

Furthermore, the vessel captain always has the last say on whether or not the procedure is carried out. Some captains in dredging projects take operating constraints with a "grain of salt" and rely on their own1judgement and/or expertise. Exceeding limit will not cause the ship to sink, but it may produce a malfunction in suction tube, which is then captain's responsibility. Because of the greater insurance costs and hazards, the limit(s) specified by the Marine Warranty Surveyor (MWS) are1always observed in offshore projects. All project data is supplied as a Microsoft Excel spreadsheet that can be loaded into HADDOCK.

IV. DOWNTIME CALCULATION

HADDOCK's downtime analysis for complicated projects follows vander Wal and de Boer's [1] approach: a simulation on hindcast1metocean data (i.e. no stochastic data generator). To begin, the workability1per time step is computed (i.e. determine whether or1not each time step in dataset is workable or not for that specific equipment). If time step is deemed practicable, the workability value is one; otherwise, it is zero. Because the project includes many operations & hence more than one operational restriction, this workability is computed for each of the norms. These are combined into a single 'workability-array,'1which serves as the foundation for the subsequent downtime and persistency calculations. A 'workability sequence' is a column from workability-array (excluding the date/time column(s).

Table 2: Example of A “Workability-Array”

|

TIME |

OPERATION 1 |

OPERATION 2 |

OPERATION 3 |

|

0:00 |

0 |

1 |

1 |

|

1:00 |

0 |

1 |

1 |

|

2:00 |

0 |

1 |

1 |

|

3:00 |

1 |

1 |

1 |

|

--- |

--- |

--- |

--- |

V. INFLUENCE OFIPROJECT START DATE ON DOWNTIME

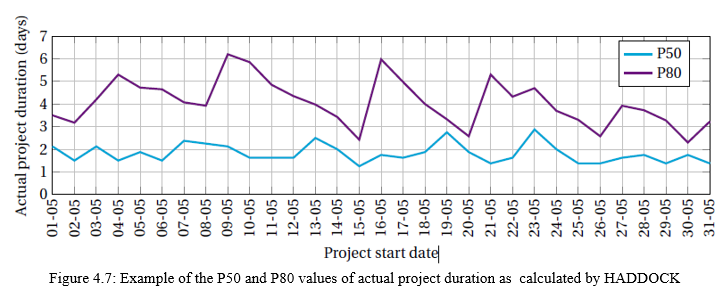

In a tender, Shipping Corporation also wants to know difference in downtime if project begins on a date other than Q, such as Q + 1, Q + 2, and so on. In other words, they want to know what influence a delayed project start date has on downtime. With this information, it is possible to determine the ideal date to begin the project, to minimise amount of projected downtime, 1or to change the project length mentioned in tender to account for additional downtime caused by a delay in start date. Figure 4 depicts effect of project start date on P50 & P80 values of project's actual duration. The picture depicts a'saw-tooth' pattern as a result of the project duration's dependent on dates that are close together (because they will encounter same storm). This may also be seen in "dwt-array," where the actual project length is lowering in expectation of a peaceful phase. This saw-tooth pattern is not practical in terms of project downtime forecasting in the long run. To assess the effect of the project start date on the project duration, sampled project durations must be independent, which current technique does not allow for.

VI. ADVANTAGES OFICURRENT METHOD FOR COMPLEX PROJECTS

A. If the necessary input data set is provided, the model may be applied to any sea on the planet.

B. There is no limit to number of1metocean criteria for operational restrictions or operations.

C. Because the simulation is done using hindcast data, the premise and outcomes of the calculation are simple to comprehend and evaluate.

D. Because the simulation is based on real hindcast data, modelling dependency between metocean parameters is not a concern.

VII. LIMITATIONS OFICURRENT METHOD FORICOMPLEX PROJECTS

A. The study is computationally demanding; algorithm computes actual project duration for each time step in dataset, but only a subset of these values may be utilised to generate project duration ECDF.

B. The outcome is an empirical cumulative1probability distribution of project length & downtime per operation, but confidence limits are not tight (high simulation uncertainty) due to limited sample size: ±20 years of data yields ±20 project1duration samples. (This means that condition 5 is only partially met.)

C. Actual project1durations generated for start dates1close to one1other are not independent, resulting in a high sensitivity to project start date due to no generalisation for months/seasons.

Conclusion

The approach used to calculate downtime for complicated projects is consistent with the literature: simulation. However, calculation\\\'s validity is very dependent on available data: because no stochastic model is used, each year in dataset can only offer one sample of project length (since project has a specific start date). This leads in a significant simulation uncertainty: ± 46.58 percent for 17 years of data & a confidence interval of 95 percent. As a result, to address the study question, the existing approach for determining downtime for complex projects is untrustworthy; in fact, due to the large simulation uncertainty, it is extremely unsafe to utilise current methodology to make predictions on downtime distribution. We advocate utilising a stochastic metocean condition generator in the simulation to reduce simulation uncertainty. These uncertainties, however, may be managed by the model used, & they can1also be quantified. Finally, a comparison should be1drawn between simulation uncertainty in HADDOCK & combined model, parametric, & simulation uncertainty in a stochastic model simulation. This is something that needs to be looked at more. Not all weather generators are acceptable since two of requirements are that (1) approach should be able to analyse downtime for all types of maritime projects and (2) numerous metocean characteristics. For example, using multivariate distributions to represent correlations between more than two metocean characteristics might become theoretically difficult (high parametric uncertainty) and hence unsuitable for application in reality. As a result, a probabilistic1Markov model that does not simulate precise values of metocean parameters but simply1whether or not the operational constraints are breached appears to be a possibility. When compared to a model that simulates the real values of the metocean parameters, this1Markov model \\\'abstracts\\\' the actual metocean conditions by providing binary workability sequences, reducing number of parameters that must be estimated (i.e. relatively low parametric uncertainty). We must ensure that this abstraction does not oversimplify environmental1processes, i.e. that model uncertainty is not excessive. Furthermore, it is critical to select a model that generates realistic persistence1because this is a driver for downtime if precise weather periods are required; this also influenced the choice of a Markov process. Such a1model1does not yet exist, which is the thesis\\\'s problem. In the next two chapters, such1a model will be provided, using stages established by Harling [2]: 1) Convert continuous metocean data set to1workability sequences depending on required operational restrictions after reducing the raw data to an acceptable form. 2) Construction of a model of real system that neither oversimplifies system to point where model1becomes trivial, nor carries over so many features of real system that the model becomes intractable. The Markov model will include only seasonality and time-dependence of metocean conditions, as well as coupled operations. 3) In a sampling experiment, combine data and the model, run a simulation1on \\\'new\\\' workability1sequences created by Markov1model, & estimate an ECDF for1downtime based on these1samples.

References

[1] R. J. van der Wal and G. de Boer, Downtime analysis techniques for complex offshore and dredging operations, (American Society of Mechanical Engineers, 2004) pp. 93–101. [2] J. Harling, Simulation techniques in operational research, OR , 9 (1958). [3] R. T. Walker, J. van Nieuwkoop-McCall, L. Johanning, and R. J. Parkinson, Calculating weather windows: Application to transit, installation and the implications on deployment success, Ocean Engineering 68, 88 (2013). [4] M. O’Connor, T. Lewis, and G. Dalton,Weather window analysis of irish west coast wave data with relevance to operations & maintenance of marine renewables, Renewable Energy 52, 57 (2013). [5] J. Dowell, A. Zitrou, L. Walls, T. Bedford, and D. Infield, Analysis of wind and wave data to assess maintenance access to offshore wind farms, in Proceedings of the European Safety, Reliability and Risk Management (ESREL) (2013) pp. 743–750. [6] D. Martins, G. Muraleedharan, and C. G. Soares, Weather window analysis of a site off portugal, (2015). [7] W. Xie, B. L. Nelson, and R. R. Barton, Statistical uncertainty analysis for stochastic simulation, Under review (2014). [8] K. S. Hickmann, J. M. Hyman, and S. Y. Del Valle, Quantifying uncertainty in stochastic models with parametric variability, arXiv preprint arXiv:1503.01401 (2015). [9] G. Leontaris, Design of a probabilistic decision support tool for the cable installation of an Offshore Wind Farm, Master’s thesis, TU Delft (2015).

Copyright

Copyright © 2022 Dipayan Saha, Abhijit Mangaraj. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET41505

Publish Date : 2022-04-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online