Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Ballistic Impact Analysis of Thin Shell and Curved Surface against Different Projectile Nose Shape

Authors: Vimit V. Kosey, Prof. Harish N. Sayankar , Dr. Vinod. S Gorantiwar

DOI Link: https://doi.org/10.22214/ijraset.2023.49636

Certificate: View Certificate

Abstract

Numerical simulations are increasingly becoming an important tool to obtain efficient designs of protective structures, and the existing literature shows that many phenomena can be accurately described by standard methods and models. This thesis, specifically, focuses on novel methods of modeling and simulating ballistic impact. Experiments are needed to validate such simulations, so numerous tests were studied to investigate how projectile nose-shape, plate layering, target strength, ductility, and work hardening affect the penetration and perforation behavior of various structural configurations. These tests provide new information about the behavior of materials subjected to ballistic impact, and are valuable input for the evaluation of the numerical simulations. As more complex materials systems are introduced in engineering practice, the design engineer faces the of utilizing homogenization techniques or detailed numerical models. The latter offers a number of advantages, such as the ability to introduce separate constitutive laws and failure criteria for each phase, at the expense of computation cost. The aim of this study is to give general information about the most commonly used materials and ballistic test methods. In addition, to summarize the topics related to simulation methods such as FEM and numerical methods which are use most in ballistics.A generalized numerical and experimental formulation is presented for the prediction of ballistic impact behavior on various surfaces against different projectile nose shape. The ballistic resistance, failure mechanism and the energy absorption of the structure was investigated thoroughly through experimentation and numerical simulations. influence of projectile shape, incidence velocity of the projectile.

Introduction

I. INTRODUCTION

Investigation pertaining impact response of the shell has secured its own place in different engineering disciplines like designing of helmet, boilers, compressors, aero plane, naval industry (boat hull) and outer-body shells of automobiles and now in the field of lithium ion batteries. The development of lightweight structures having superior energy absorption characteristics has been drawn the major attention of the researchers over the recent years. In this context, the sandwich structures have played a major role due to their very high stiffness-to weight and bending strength-to-weight ratio. Because of these superior properties, it is widely used for civilian as well as military applications (racing cars, aerospace manufacturing, helicopters, jet aircraft, automobile structures etc.). During their service life, these structures may frequently be subjected to impact load (natural or man made), which can cause local failure and results in terms of catastrophic failure of the structure subsequently. Fiber-reinforced composite and aluminium were extensively used as face sheet material, whereas cellular and porous material was used frequently as core materials.

The development of lightweight structures having superior energy absorption characteristics has been drawn the major attention of the researchers over the recent years. In this context, the sandwich struc tures have played a major role due to their very high stiffness-to-weight and bending strength-to-weight ratio. Because of these superior properties, it is widely used for civilian as well as military applications (racing cars, aerospace manufacturing, helicopters, jet aircrafts, auto mobile structures etc.). During their service life, these structures may frequently be subjected to impact load (natural or manmade), which can cause local failure and results in terms of catastrophic failure of the structure subsequently. In the available literature, the impact response of the sandwich structures have been addressed with varying the material, thickness, and shape of face sheets and core against different shapes, diameters and mass of the projectile. Fiber-reinforced composite and aluminium were extensively used as face sheet material, whereas cellular and porous material was used frequently as core materials

Plenty of numerical and experimental studies have been carried out to explore the ballistic response of sandwich structures against projectile impact [1–8,15–19]. Yahaya et al.

[3] studied the impact response of different configuration of the sandwich structure subjected to foam projectile at different projectile velocity. It was found that for specific impact velocity range low (up to 175 m/s) and high (above 375 m/s) airsandwich outperformed the monolithic plate and honeycomb panel, whereas for medium-range velocity (175– 375 m/s) sandwich structure with honeycomb core showed better performance. Arslan et al. [8] carried out the ballistic performance of functionally graded face sheets with honeycomb-core sandwich structures and found that the linear functionally graded face sheets offered the better impact resistance in terms of less deformation and high damage resistance. Kollop et al. [10] showed that the sandwich panel with the dry fabric face sheet performed

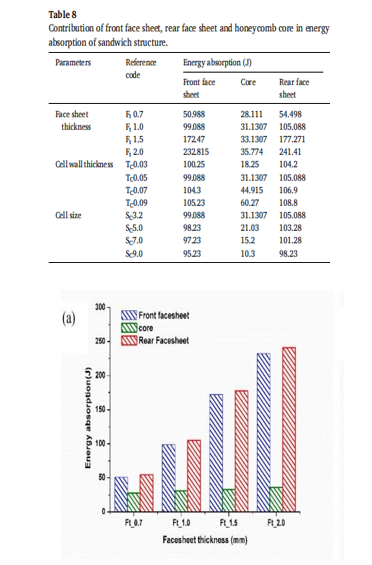

The projectile nose shape strongly influenced the performance of sandwich structures under a distinct range of impact velocity and sandwich parameters such as core density (cell wall size, cell wall thickness, and core height) and face sheet thickness [1–5,16–19]. Flat-ended projectile offered the highest ballistic limit and higher energy dissipation than the conical and hemispherical nosed projectile, whereas the conical nosed projectile required the least energy for perforation [1, 15,17]. Keplar et al. [6] compared the ballistic performance of three different projectile nose shapes (small conical, large conical, and hemispherical) against the sandwich panel and found that both the pointers nosed projectile penetrated the panel easily compared to the hemispherical nosed projectile. Furthermore some researcher found that the ballistic limit of sandwich panel was increased linearly with the increase in the face sheet thickness [1,2,15]. Honeycomb core geometry had a dominant influence on the dynamic response of the sandwich structure. The ballistic limit of the panel increased with the increase in cell wall thickness and decreased with the increase in cell size [2]. The honeycomb structure having thinner cell wall, larger cell size and shorter core height provided higher specific energy absorption [2]. However, the influence of the core height was barely perceptible on the ballistic limit an energy absorption of the structure [1,4,7].

A. Energy Absorption

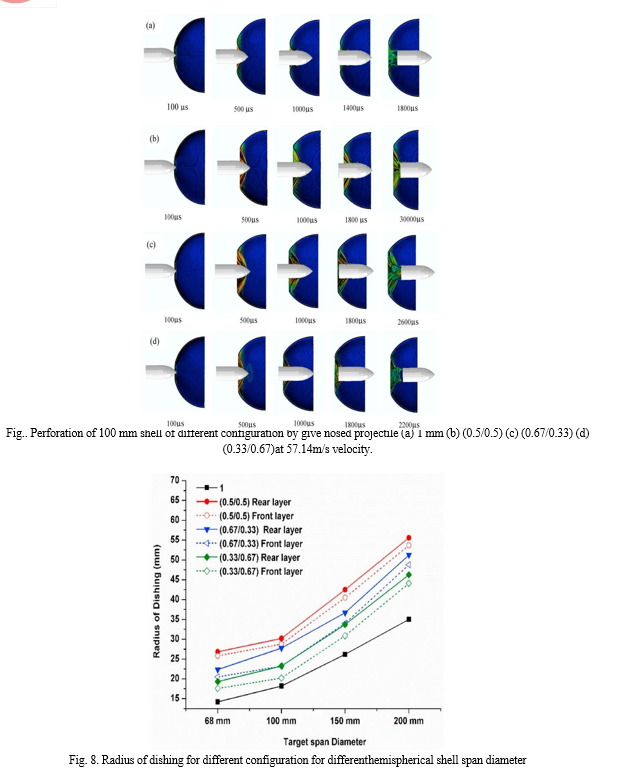

The face sheets were more effective than honeycomb core on the energy absorption capability of the sandwich structure and increase in FML skin thickness can result in a more significant increase in the energy absorption. The absorbed energy of the “2/2- 20” panel is over 60% greater than that of the “1/1-20” panel [14]. Increasing of impact velocity and decreasing of face sheet thickness, core relative density and curvature radius can enhance the energy absorption capability of sandwich shells. The increase of energy absorption becomes slow for the impact velocity below 125 m/s but rapid for the velocity above 150 m/s. This is because the deformation of sandwich shells is dominated by bending of the front face-sheet for the low velocity impact while it is dominated by the global large inelastic deformation with severe local compression of core [18]. The energy dissipation in all the deformation modes increased with increase in span diameter and thickness of shell against both projectiles. The increase was gradual for span diameter and sharp for shell thickness. For a given span diameter and thickness, the energy dissipation was maximum in shear stretching while it was minimum in polar stretching. The energy dissipation in radial and elevation stretching was almost equal for a given span diameter and thickness, and it were found in-between the other two extremes (shear and polar stretching) [29]. Due to their excellent crash worthiness performance and energy absorption ability [43, 44], sandwich structures have become attractive candidates in many engineering applications, including automotive industry [45], aeronautics [46], transportation engineering [47] and personal protective equipment [48]. During the period of their serves, sandwich structures are susceptible to low-energy/low- velocity impacts, such as runway debris, hailstones, tools dropped during maintenance and so on [49-51]. Unlike high- velocity impact, damages caused by low velocity impact are often internal and invisible but can significantly reduce stiffness and strength of the structures, which will result in shortening service life of the structures.

Most of the impact energy would be absorbed and dissipated during the process while the rest is retained in the impactor as rebound kinetic energy [52]. Afterimpact, an undetectable or barely detectable by visual inspection residual plastic indentation may be left on top face-sheet of the sandwich panel. Indentation characteristics and energy absorption property are basically determined by crashworthiness of the structure, which is extremely sensitive to the mechanical property of matrix material [53]

The impact behaviour of the target was also examined by investigating the energy absorption characteristics of the target plate subjected to projectile impact. Iqbal et al. [19] and Tiwarietal. [20] reported the experimental and numerical study on the energy dissipation character of the thin plates and shells of Al 1100-H12 aluminium and concluded that the maximum energy of the projectile dissipated in tangential stretching of the target.

II. OBJECTIVE

This research aims to optimize the construction of structure by hybridization in order to achieve the improvement of ballistic performance and reduction in weight. To achieve this aim, the research objectives are organized as follows.

- Understanding the ballistic response of structures under impact. This includes different ballistic characteristics, energy absorption, as well as failure modes under ballistic impact.

a. Different ballistic characteristics of each layer will be analyses experimentally and numerically, such as ballistic resistance fracture time, transverse deflection, stress distribution, energy absorption and ballistic limit. This investigation will reflect the different ballistic resistant efficiency of each layer in the panel, through which the mechanisms of energy absorption can be identified.

b. Failure modes are important aspects to reflect ballistic response under impact. It will be systematically investigated through the photographic observations of post-impact panels layer by layer. This work will provide a wealth of physical evidences to reflect different ballistic characteristics of each layer.

2. Optimization of the ballistic structure design. The construction of the structures will be optimized by combining different components of ballistic materials in the most effective positions. To design the hybrid structure, the mechanisms of hybridization will be analyzed and identified before the design principle is put forward.

a. Selection of components for hybridization will be studied. In this research, Metallic materials, composites as well as fibers are studied and will be used as components for hybridization. Ballistic performance of these structures will be investigated on their advantages and disadvantages for ballistic protection.

b. The hybridization effect will be investigated by analyzing the ballistic performance of hybrid structures and hybrid materials. Layering sequences of different components will be explored to determine the better combination manner of materials

3. This study will be carried out using two research approaches, namely the experimental method and the Finite Element (FE) analysis. The experimental studies will be centered on ballistic tests and photographic observations of post impact panels. FE numerical simulation will be used to explore the ballistic response of the structure. These data then helps to find out ballistic resistance, ballistic limit, failure modes and the energy absorption characteristic of structures against different projectile nose shape.

4. Effect of cell wall thickness. Cell wall thickness plays a significant role in enhancing the impact resistance of the sandwich structure. Cell wall thickness 0.03 mm, 0.05 mm, 0.07 mm and 0.09 mm were used to find out its effect on the ballistic performance of the hemispherical sandwich shell structure. Similar to the face sheet thickness, the velocity drop increased with increase in the cell wall thickness, see it was found that with the increase in the cell wall thickness, the ballistic limit of the panel increased.

III. PROBLEM STATEMENT

A major impact phenomena studying is to identify those important parameters of both target and projectile that influence penetration. The most important physical and material parameters that affect ballistic penetration are: impact velocity, hardness and shape of the projectile, hardness, density and toughness of the target facing plate, as well as the rigidity and strength of the backing plate, thickness ratio of a plates, etc. Earlier research was carried out based on a large number of assumptions for simplifying the analysis procedure. These methods provided approximate estimations of mechanical properties, but they cannot be used to analyze variations of mechanical properties with some important architecture parameters due to introduced oversimplified assumptions. On the other hand, due to the immense variety of available composite materials and possible fabric architecture, it is impractical and very time-consuming to obtain material characterizations of various composites by an experimental approach. As a result, there still is a need for comprehensive design modeling tool capable to bridge the gap between composite processing parameters and their structural response on variety of loading conditions, addressing in the same time both geometry and material characteristics.

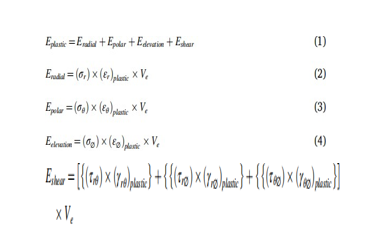

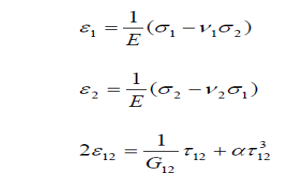

Where ε, σ, ν, τ denote Strain, Principal stress, Poisson’s ratio, Shear stress and subscripts denote the principal directions. The third equation defines the nonlinear shear stress parameter α The fiber matrix shearing term augments each damage mode:

A. Numerical Modelling

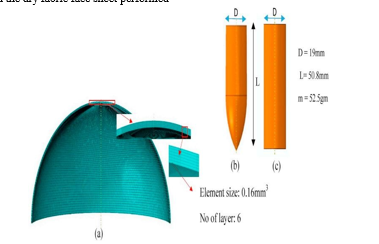

Numerical simulation was carried out through commercially avail able finite element code Abaqus explicit solver. Hemispherical sandwich shell structure consists of two face sheets, the adhesive layer, honey comb core and projectile which has been shown in . Also the different configuration of cell size used in numerical simulation shown The adhesive layer of 0.2 mm was employed between the face sheets and the core. Honeycomb core was discrete using 4 noded shell elements, whereas the face sheets and the adhesive layer were discrete using the 8 nodded solid elements. To capture the accurate result and proper failure mechanism mesh size at projectile - sandwich struc ture contact region was kept finer (aspect ratio 1), however at the non contact region, it was kept coarser (up to aspect ratio 8). For the face sheet and adhesive layer at the contact region, mesh size was kept 0.16 mm3 The number of the element through the thickness for 0.7 mm, 1 mm, 1.5 mm and 2 mm face sheet was kept.

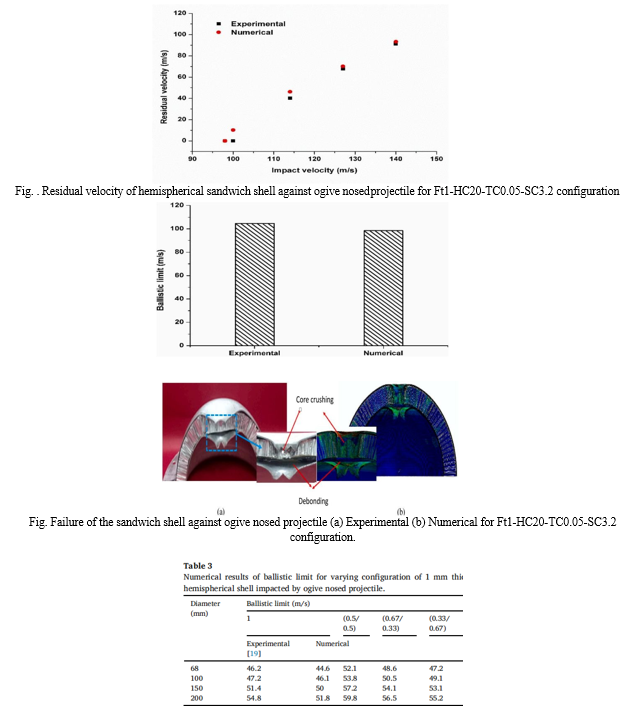

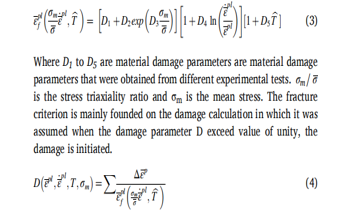

The numerical results corresponding to residual velocities of different configurations (0.5/0.5, 0.67/0.33, 0.33/0.67) and span diameters (68, 100, 150 and 200 mm) of the shells have been presented in Table 2 against ogive nosed projectileimpact. The predicted residual velocity for 1 mm thick monolithic hemispherical shell was quite close to actual residual velocity. Further, the graphical representation of similar results has been shown in Fig. 3 for direct comparison of the monolithic target with different layered configurations of 68, 100, 150

and 200 mm span diameter. All double-layered hemispherical shell configuration offered larger drop in the residual velocity than the monolithic hemispherical shell. Moreover, the double layered configu ration with equal thickness 0.5/0.5 showed highest decrease in the re sidual velocity followed by the 0.67/0.33, 0.33/0.67 and the single layered target, respectively. The maximum deviation in between the experimental and the numerical results was found to be 10.43 m/s for 200 mm diameter. The influence of target configurations was much significant close to ballistic limit which subsequently decreased with increase in the incidence velocity of the projectile, see Fig. 3. Similar trend was found for plastic deformation of the shell with incidence velocity of the projectile. The deviation of numerically predicted results from actual experimental results was quite small.

The ballistic limit velocity (V50) was obtained to quantify the per formance of the target against the ogive nosed projectile. It was obtained through the average of the maximum projectile velocity, at which target couldn’t get perforation and the minimum projectile velocity and the velocity at which the target completely perforated. The ballistic limit velocities of different span diameter with varying configurations have been shown in Table 3 which was further represented in Result showed that the ballistic limit of the target was increased with increase in the span diameter of the hemispherical shell. Moreover layering of the hemispherical shell enhanced the ballistic resistance of the shell. How ever, the double layered target (0.5/0.5) showed the highest ballistic limit followed by the (0.67/0.33), (0.33/0.67), and 1 mm monolithic target.

The ballistic limit of the layered hemispherical shell 0.5/0.5, 0.67/ 0.33, 0.33/0.67 for 68 mm diameter was 16.8%, 9.54% and 6.55% higher than the monolithic hemispherical shell, for 100 mm span.

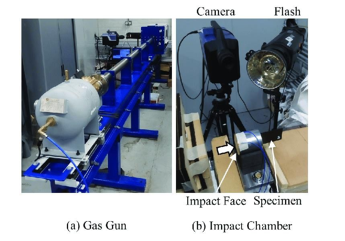

B. Test Procedure

The following is the standard test procedure with proper safety

- Configure/Set up test fixture

- Turn on helium pressure in trailer

- Turn on power to electromagnetic coils and data acquisition system

- If necessary, set up high speed video

- Close trigger ball valve

- Insert projectile into gun barrel

- If necessary, set up gun barrel wire trigger

- Set regulator on nitrogen bottle

- If necessary, turn on lights for high speed video

- Close and lock all test area doors

- Charge helium bottle to desired test pressure

- Turn weapon key lock to “weapon ready”

- Press “system ready” button

- Arm data acquisition system

- Press “test” button

- Press “arm” button

- Activate siren

- After 5 second audible count down, press “fire” button

- Press “end test” button

- Turn weapon key lock to safe position and remove

- If necessary, turn off lights for high speed video

- If necessary, save high speed video recordings

- Record projectile velocities from data acquisitionName:

- Close valves on nitrogen cylinder and helium trailer

- Remove specimen from test fixture

IV. APLICATIONS

Its wide applications such as in aircraft leading edges and flaps, boat hulls, car, and caravan body panels. Moreover, the influence of configuration and core structure against projectile impact has also not been reported in the available literature. Therefore in depth study is required to investigate the response of curved sandwich panel against projectile impact. it is widely used for civilian as well as military applications (racing cars, aerospace manufacturing, helicopters, jet aircrafts, auto mobile structures etc.).

During their service life, these structures may frequently be subjected to impact load (natural or manmade), which can cause local failure and results in terms of catastrophic failure of the structure subsequently.

In the available literature, the impact response of the sandwich structures have been addressed with varying the material, thickness, and shape of face sheets and core against different shapes, diameters and mass of the projectile. Fiber- reinforced composite and aluminium were extensively used as face sheet material, whereas cellular and porous material was used frequently as core materials.

- Automobile Industries and E- Vehicle for Battery blast Protection.

- For Aeroplane Framework and Casing.

- For Electrical Transformer.

- For Bullet Proof Jacket And Military Appliences

- For Marine Vehicles.

- In Defence Industries.

Conclusion

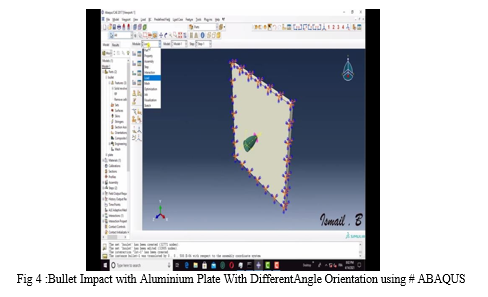

In this study, the ballistic performance of aluminium hemispherical sandwich thin shell structure was studied experimentally and numerically against ogive nosed projectile impact within sub ordnance velocity regime. Moreover, the effect of face sheet thickness, cell wall thickness and cell size on the sandwich shell performance also examined through numerical simulation. Bullet Impact with Aluminium Plate With Different Angle Orientation using # ABAQUS The work in this thesis was mainly on the study of experimental and numerical approach for the prediction of ballistic impact behavior on various surfaces against different projectile nose shape. Little emphasis was put on empirical and analytical modeling. Experiments were designed to serve as a basis of comparison to numerical simulations while still providing useful data to advance the field. The numerical contribution was to use and evaluate rather novel methods to Solve the penetration problem.

References

[1] Z. Wang, H. Tian, Z. Lu, W. Zhou, High-speed axial impact of aluminum honeycomb–Experiments and simulations, Compos. B Eng. 56 (2014) 1–8. [2] B.L. Buitrago, C. Santiuste, S. Sanchez-Saez, [3] E. Barbero, C. Navarro, Modelling of composite sandwich structures with honeycomb core subjected to high-velocity [4] impact, Compos. Struct. 92 (9) (2010) 2090–2096. [5] J. Kepler, Impact penetration of sandwich panels at different velocities-An experimental parameter study: part I-Parameters and results, J. Sandw. Struct. Mater. 6 (4) (2004) 357–374. [6] I. Iva~nez, S. Sanchez-Saez, Numerical modelling of the low-velocity impact response of composite sandwich beams with honeycomb core, Compos. Struct. 106 (2013) 716–723. [7] K. Arslan, R. Gunes, M.K. Apalak, J. Reddy, Experimental tests and numerical [8] modeling of ballistic impact on honeycomb sandwich structures reinforced by functionally graded plates, J. Compos. Mater. 51 (29) (2017) 4009–4028. [9] C. Menna, A. Zinno, D. Asprone, A. Prota, Numerical assessment of the impact [10] behavior of honeycomb sandwich structures, Compos. Struct. 106 (2013) 326–339. [11] A. Kolopp, S. Rivallant, C. Bouvet, Experimental study of sandwich structures as armour against medium-velocity impacts, Int. J. Impact Eng. 61 (2013) 24–35. [12] D. Zhang, Q. Fei, P. Zhang, Drop-weight impact behavior of honeycomb sandwich panels under a spherical impactor, Compos. Struct. 168 (2017) 633– 645. [13] Y. Chen, S. Hou, K. Fu, X. Han, L. Ye, Low-velocity impact response of composite sandwich structures: modelling and experiment, Compos. Struct. 168 (2017) [14] 322–334. [15] I. Elnasri, H. Zhao, Impact perforation of sandwich panels with aluminum foam core: a numerical and analytical study, Int. J. Impact Eng. 96 (2016) 50–60. [16] C. Liu, Y. Zhang, J. Li, Impact responses of sandwich panels with fibre metal laminate skins and aluminium foam core, Compos. Struct. 182 (2017) 183–190. [17] W. Hou, F. Zhu, G. Lu, D.-N. Fang, Ballistic impact experiments of metallic sandwich panels with aluminium foam core, Int. J. Impact Eng. 37 (10) (2010) 1045–1055. [18] I. Iva~nez, C. Santiuste, E. Barbero, S. Sanchez-Saez, Numerical modelling of foam cored sandwich plates under high-velocity impact, Compos. Struct. 93 (9) (2011) 2392–2399. [19] C. Liu, Y. Zhang, L. Ye, High velocity impact responses of sandwich panels with metal fibre laminate skins and aluminium foam core, Int. J. Impact Eng. 100 (2017) 139–153. [20] L. Jing, C. Xi, Z. Wang, L. Zhao, Energy absorption and failure mechanism of metallic cylindrical sandwich shells under impact loading, Mater. Des. 52 (2013) 470–480 (1980-2015). [21] L. Jing, Z. Wang, L. Zhao, Response of metallic cylindrical sandwich shells subjected to projectile impact—experimental investigations, Compos. Struct. 107 (2014) 36–47. [22] R. Mohmmed, F. Zhang, B. Sun, B. Gu, Finite element analyses of low- velocity impact damage of foam sandwiched composites with different ply angles face sheets, Mater. Des. 47 (2013) 189–199. [23] S. Long, X. Yao, H. Wang, X. Zhang, Failure analysis and modeling of foam sandwich laminates under impact loading, Compos. Struct. 197 (2018) [24] Eason, B. Noble, and I.N. Sneddon, “On certain integrals of Lipschitz- Hankel type involving products of Bessel functions,” Phil. Trans. Roy. Soc. London, vol. A247, pp. 529-551, April 1955. (references)

Copyright

Copyright © 2023 Vimit V. Kosey, Prof. Harish N. Sayankar , Dr. Vinod. S Gorantiwar . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET49636

Publish Date : 2023-03-18

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online