Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Compressor-Powered Tyre Pressure System for Monitoring

Authors: Anush Vivian Crasta, Nash Savio Rodrigues, Nuaim Abdur Rahaman, Mr. Rajeshwari

DOI Link: https://doi.org/10.22214/ijraset.2023.52525

Certificate: View Certificate

Abstract

In the Indian subcontinent, where one in every three houses owns a two-wheeler, around fifteen million motorcycles are sold each year. Every year, the country manufactures 20 million two-wheelers. Severe underinflation can produce mechanical and thermal stress caused by overheating, which can cause the tyre to blow out soon. Failures of this type can lead to hazards and catastrophes that endanger not just the operator but also people around them or her. In accordance with median nation estimations, under-inflated tyres cause separation of the tread and tyre breakdown, leading to forty thousand mishaps, more than 33,000 damage, and over 700 fatal injuries per year. However, when the population of India has been taken into consideration, these percentages may rise due to an abundance of individuals possessing numerous 2-wheelers, getting little opportunity to personally check, as well as being unable to consistently get their automobiles examined at a maintenance facility. The difficulties will occur with greater regularity if the riders are unaware. The goal of this project is to develop and build an immediate tyre pressure monitoring system (TPMS), that utilises a pressure sensor in order to measure air pressure directly from the tyre. When the TPMS detects a low tyre pressure, the motorist doesn\'t have to step out of his motorcycle and physically fill air into the tyres since the TPMS and the compressor module work together to give the air to the tyre. The dynamo or an additional battery provides power to the device. The primary parts must be tuned in order to guarantee uniformity and precision in displaying the pressure and sending sufficient air to the tyre. Despite several challenges and limits, this working prototype is a potential solution for real-world usage.

Introduction

I. INTRODUCTION

Without any uncertainty, the most important component of a car is its safety. Any vehicle can fail for a variety of causes. The primary cause of tyre blowouts is insufficient tyre air pressure. While underinflation is responsible for approximately 75 percent of tyre burst occurrences, overinflation is not a concern. According to research, driving using under-inflated tyres significantly increases fuel consumption and CO2 emissions. Tyre wear is unavoidable during use and is influenced by the type of vehicle, tyre qualities, nature of the road and surrounding conditions, and driving circumstances. A tyre burst occurs when pressurised air rapidly leaks from the tyre. When the tyre's structural integrity is compromised, it cannot contain all of that air within. As a result, the compressed air bursts into flames, severely destroying the rubber surface as it tears through the tyre. All of these difficulties can be mitigated with frequent automobile service; there are several methods for doing so. One of the most important systems (TPMS) is the Tyre Pressure Monitoring System. In reality, lowering the pressure on your tyres can shorten tyre life, reduce vehicle adhesion, increase the distance to stop, and even trigger a sudden tyre rupture. Tyre wear and tear generates enormous waste, and the growing use of polymers that are impervious to the process of hydrolysis decay, and biological deterioration is adding to a worldwide environmental problem. As a result, disposing of most plastics is a difficult task. Tyre waste is classified as a sort of garbage that must be processed industrially.

The world is looking for solutions to increase the safety of tyres and make better use of them. Alongside corner movements and operating speed, driving actions such as accelerating, braking, and failing to keep proper pressure in the tyres had the largest influence on tyre wear. Therefore, it seems as though monitoring tyre pressure while minimising rapid acceleration and deceleration could significantly reduce tyre wear. This explains how our approach for rider and passenger safety is critical. It will also have a compressor device that fills the tyre in the event of an emergency. The combined capabilities by the TMPS and Compressor unit provide the user with a better experience.

II. LITERATURE REVIEW

- The "hybrid" approach utilised in this study measures the pressure of the tyres for every vehicle wheel utilising only one pressure sensor. As a result, such a solution's monitoring effectiveness and system expenses are well balanced. Unlike traditional indirect and direct TPMS, the system that is suggested is based on the usage of only one tyre pressure measurement coupled with the estimator that uses other vehicle data. Unlike regular iTPMS, this method assesses a tire's true pressure in addition to recognising deflation. A drop in tyre pressure can reduce tyre life, impact the vehicle's adhesion, enhance halting distance, and even cause a tyre to break suddenly.

- The newly created wireless tyre pressure monitoring system (TPMS) for an assortment of cars is described in this study. Monitoring information can be utilised to decrease tyre wear. The report compares the research on pressure in the tyres and friction-related groove deterioration for an assortment of cars both with and without monitoring. According to the findings of the research, choosing actions based on information from monitoring reduces wastage in the manner of premature worn tyres. Unmonitored tyre degradation reached 70%, whereas tracked tyre degradation varied between 7% to 13%. Assume approximately 50% of Polish travel companies use the suggested tracking method.

- This study provides information on the amount of tyre wear that is released into the environment as well as the significance of the various factors that influence tyre wear. This data is valuable for developing a system for calculating the rate of erosion and determining whatever has to be undertaken to reduce the release of microplastic into the environment. The most damaging impacts on tyre wear were induced by braking and acceleration, cornering motions, and driving speed. Given this, it appears that restricting abrupt acceleration and braking could greatly minimise tyre wear.

- This paper introduces a dual-slope ADC and goes into detail about 13.56MHz transmission. The following drawbacks of employing batteries for TPMS are covered in this essay: limited lifespan of the battery, inability to conduct real-time surveillance, and absence of reliability and stability assurances. These concerns can be rectified without the consumption of batteries by using a full CMOS module. The three methods for implementing a battery-free TPMS are piezoelectricity, electromagnetic coupling, and surfaces acoustic wave wireless sensors. Close coupling, inductive coupling, and electromagnetic coupling systems were only a few of the wireless power transmission techniques that were covered. The inductive coupling in the battery-free TPMS is selected after considering the frequency of operation, transmission range, and consumption of power.

- This project calls for building a suction pre-treatment system, a cooling tower, a refrigerator, and a water-gas heat exchanger. In order to cool the suction of air in the liquid-gas heat exchanger, low-temperature water is produced by the cooling system and refrigerator. The utilisation of innovative frameworks or materials to trap heat from the atmosphere during compressing or to reduce its temperature is emphasised by the most effective compressed air designs now available. For the great majority of applications, the air compressor was developed with the greatest possible load demand in mind. Because it regularly operates at partial capacity, a pneumatic compressor operated by a constant speed motor has an inadequate energy efficiency.

- This study investigates LiFi theory as well as some of the most recent discoveries in this field. LiFi, a sort of wireless optical communication (WOC) technology, can address the challenges that 5th and higher generation mobile networks face. LiFi is a wireless reciprocal communication technology that allows for high speeds up- and down-link transfer at the same time. Although LiFi allows for high-speed data transfer, it has severe restrictions, including coverage. As an outcome, a hybrid WiFi/LiFi system can benefit from LiFi's speed and range. When these technologies are combined, they can compensate for one other's limitations, resulting in improved network performance.

- In this experiment, the negative-pressure system acted as a regulator. Depending on how the entire system is configured, the minute flowing valve that checks flow was selected as a check valve. As the outcome of its complete compression and repair, the tube's material has good physical qualities and resistances. After creating a tube efficiency tester, a CAE (computer-aided engineering) model was created to compare the results. The look of the connection between the tube and regulators has been improved. The concept trial eventually established the investigation's validity. High-performance and secure tyres can be manufactured using existing equipment and technology.

- In order to disclose time-varying frequency features, this study starts with detailed vibro-acoustic investigations of compressor surge evolution. The results demonstrate that the centrifugal compressor output pressure pulsation is primarily responsible for the rise and fall of the overall sound pressure value during deep surge. The causes of the incorrect noise are studied within the near-surge as well as deep-surge zones. The centrifugal compressor's surge is then examined utilising a computational framework model that includes an extra capacity and takes into consideration fluctuations in sound speed.

III. METHODOLOGY

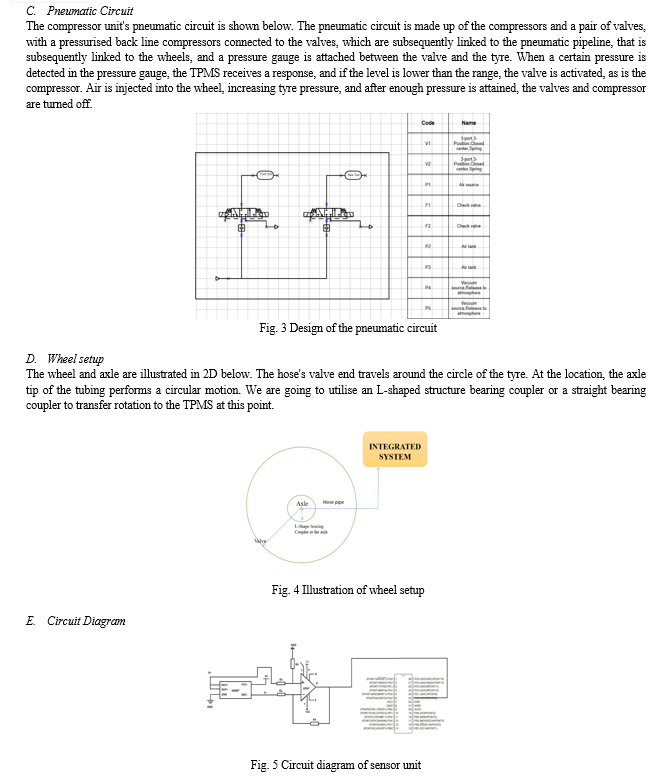

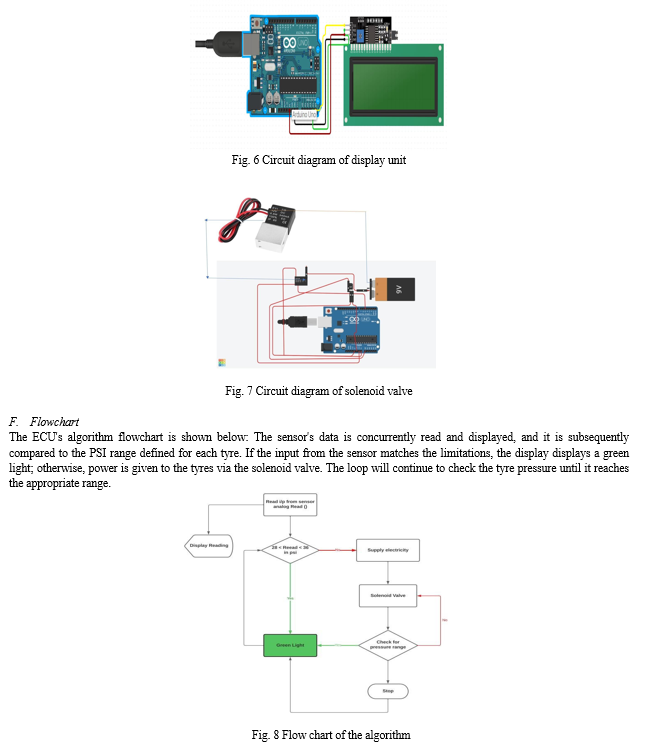

Tyre pressure is influenced by temperature; therefore, the following measures are taken to limit the maximum heat: 1. The front and back tyres' restriction ranges prior to air filling are regulated independently. 2.Display units for monitoring the entire procedure. 3.Buzzer Alarms are mostly used in emergency situations to prevent further consequences. 4. Data collecting, communication, processing, and other uses of pressure sensors. 5. Compressors for filling tyre air. 6.Microcontroller for improved sensor communication.

A. Proposed System

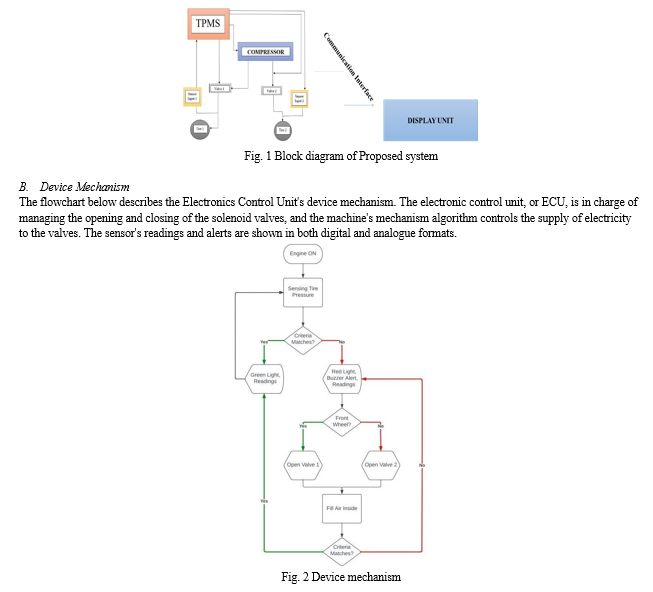

The schematic representation illustrating the transmitter and reception unit is shown below. 1. The TPMS transmitter is linked to the inflation actuators at both the front and the back tyres for continuous monitoring of tyre pressure. 2. The receiver is made up of an indication unit. 3. A wired connection connects the transmitter, receiver, and transmitter.

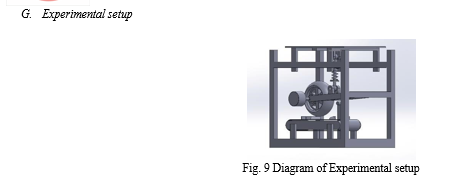

The experimental configuration is made up of a framework on which a supporting arm is attached, which is subsequently connected to a wheel setup.

The supporting arm is linked to the suspensions, which are subsequently linked to the load plate. The wheel and engine are attached to the support arm. A treadmill-like contraption is located beneath the wheel. The treadmill and weights are used to simulate real-time performance for analysis.

IV. RESULTS AND DISCUSSION

A. Expected outcome

The technology will be compatible with the majority of two-wheeler vehicles, allowing users to inflate their tyres despite requiring them to go through a lengthy procedure. The system will include alerting elements as well as tyre health monitoring.

B. Market analysis

The Tyre Pressure Measuring System is an electronic gadget that maintains records of the tire's heat and pressure of air while also displaying those numbers on the screen in real time. This alerts the operator of the motor vehicle about an alteration in tyre pressure. Vehicular efficiency, protection, the mileage, and tyre longevity are some of the key factors associated with reduced vehicle pressure. The TPMS system has helped to reduce the incidence of accidents while also enhancing fuel mileage, tyre longevity, and driver handling of the vehicle. TPMS batteries have a lifespan of between six and ten years. The market suffered a drop in manufacturing due to the epidemic. However, the market is again returning to normal, and it is projected that demand will increase more in the years to come. The TPMS industry was temporarily blocked, however various countries have now provided leverage for import-export trading. In 2021, the worldwide marketplace for tyre pressure monitoring systems (TPMS) is expected to be worth $5.67 billion. The market value for TPMS within the Asia-Pacific region is expected to reach 13.60 billion USD by 2027.

C. Barriers to Enter the Market

- Nature or physical barriers: Existing enterprises in India have already made their move into the two-wheeler sector, making entry into the market difficult. Companies who are active in the market have expanded their network to include both high-end and low-end companies. As a result, it may provide us with limited access to the market or the Me network. It will be tough to get control of the raw material network.

- Artificial or Strategic Barrier: When existing enterprises set a cheap price while producing a high output. Profitability will be difficult to achieve in the early phases. To stand out in a crowded market, we must build our brand identity. And for our fifty percent of the target population to accept the motorbike firms' product. Contracts, patents, and licences must comply with government rules and regulations, and obtaining a licence is complex. When established corporations licence more contracts and patents.

- The Technology: How quickly is technology progressing, and will it make our product outdated over the following 5 years? The transition of tyres from puncturable to non-puncturable might emerge as one of society's biggest concerns in the next years. A more compact and user-friendly model identical to our device prior to branding could also pose a danger to our product's advancement.

- Branding: To differentiate ourselves in a crowded market, we must create our brand identity. And for our customer base, the motorcycle companies, to embrace the product.

D. Players in Market

Valour TPMS, Delphi Automotive, DENSO Company, Continental AG ZF TRW.Continental AG will boost India's safety solution in February 2022. Continental is largely focused on supplying modern safety technology, including as ADAS and TPMS, in India, the world's largest two-wheeler market. Continental is releasing an updated combination-tire monitoring device for its Combine Master and Combine Master VF tyres in May 2022. They monitor the pressure on the tyres and temperatures.

Fleeca Kawach, India's first AI-powered intelligent truck tire-pressure monitoring system, was released in the month of February 2022 from Jaipur-based start-up Fleeca India Private Limited. This TPMS systems is a smart device mounted on the wheel's rim that monitors signals from the tyres' outside and also the rate of rotation of the wheel.

E. Target Audience

Because our solution is a combination of a tyre pressure monitoring device and an inflator, the audience would range widely, from the general to the Supplier. Possible buyers include Jawa Motorcycles, TVS, Bajaj, Suzuki Motors, Royal Enfield, Honda, Hero Motocorp, Boom Motors, and others. We can also link it with common motorcycle sale shops to reach a larger audience, as well as sell it individually through online and offline platforms to reach the general public.

Conclusion

To summarise, tyre pressure is a vital aspect of automotive efficiency and performance, and inappropriate tyre pressure can produce heat and mechanical stress, as well as tyre breakdown, posing a risk for both the user and the environment. While placing a system for monitoring in a larger vehicle is straightforward, reducing and mounting one in a two-wheeler without losing efficiency or reliability is a challenge. The proposed gadget would have warning and tyre condition tracking functions to provide owners with a quick and easy way to inflate their tyres. The device is designed to be suitable with the majority of two-wheelers, leading to safer and more efficient travels for riders. Additionally, installing the gadget in 2-wheelers can help to improve overall vehicle stability, cut fuel consumption, and increase tyre life. Furthermore, the device can save riders both time and money by detecting and repairing tyre flaws early on, preventing the need for costly repairs or replacements. Furthermore, the device is simple to incorporate within the current 2-wheeler structure, providing a convenient and cost-effective option for riders. Tyre health monitoring systems can also help motorcycle riders keep track of the condition of their tyres and avoid unforeseen mishaps.

References

[1] S. Formentin, L. Onesto, T. Colombo, A. Pozzato, and S. M. Savaresi, “h-TPMS: a hybrid tire pressure monitoring system for road vehicles,” Mechatronics, vol. 74, Apr. 2021, doi: 10.1016/j.mechatronics.2021.102492. [2] B. Szczucka-Lasota, T. W?grzyn, B. ?azarz, and J. A. Kami?ska, “Tire pressure remote monitoring system reducing the rubber waste,” Transp Res D Transp Environ, vol. 98, Sep. 2021, doi: 10.1016/j.trd.2021.102987. [3] Y. Liu et al., “Impact of vehicle type, tyre feature and driving behaviour on tyre wear under real-world driving conditions,” Science of the Total Environment, vol. 842, Oct. 2022, doi: 10.1016/j.scitotenv.2022.156950. [4] X. Bai, L. Wu, X. Zhang, and C. Jia, “Wireless power transfer and a dual-slope ADC design for battery-less TPMS,” in WOCC2010 Technical Program - The 19th Annual Wireless and Optical Communications Conference: Converging Communications Around the Pacific, 2010. doi: 10.1109/WOCC.2010.5510654. [5] J. Shen, Z. Li, N. Tan, and Y. Xiao, “Design and analysis of a suction pretreatment system for the air compressor,” Energy Convers Manag, vol. 263, Jul. 2022, doi: 10.1016/j.enconman.2022.115675. [6] M. R. Ghaderi, “LiFi and Hybrid WiFi/LiFi indoor networking: From theory to practice,” Optical Switching and Networking, vol. 47, Feb. 2023, doi: 10.1016/j.osn.2022.100699. [7] M. Jun Kim et al., “DEVELOPMENT OF A VALVE AND OPTIMIZATION OF A TUBE FOR SELF-INFLATING TIRE,” International Journal of Automotive Technology, vol. 18, no. 6, pp. 973–981, 2017, doi: 10.1007/s12239?017?0095?4. [8] S. Chen, S. Zuo, Z. Wu, and C. Liu, “Comprehensive vibro-acoustic characteristics and mathematical modeling of electric high-speed centrifugal compressor surge for fuel cell vehicles at various compressor speeds,” Mech Syst Signal Process, vol. 178, Oct. 2022, doi: 10.1016/j.ymssp.2022.109311. [9] T. Kim, S. Yang, and S. Kang, “Numerical Study on the Flow Characteristics of a Solenoid Valve for Industrial Applications.” [Online]. Available: http://cfdlab.donga.ac.kr [10] D. Ma, Z. Liu, Q. Gao, and T. Huang, “Fault Diagnosis of a Solenoid Valve Based on Multi-Feature Fusion,” Applied Sciences (Switzerland), vol. 12, no. 12, Jun. 2022, doi: 10.3390/app12125904. [11] P. Sojka and V. Jaros, “Design of a wireless communication based on low power RF transceivers,” in Transportation Research Procedia, 2019, vol. 40, pp. 505–510. doi: 10.1016/j.trpro.2019.07.073. [12] S. A. Moezi, M. Rafeeyan, E. Zakeri, and A. Zare, “Simulation and experimental control of a 3-RPR parallel robot using optimal fuzzy controller and fast on/off solenoid valves based on the PWM wave,” ISA Trans, vol. 61, pp. 265–286, Mar. 2016, doi: 10.1016/j.isatra.2015.12.005. [13] D. Hu, J. Liu, F. Yi, Q. Yang, and J. Zhou, “Enhancing heat dissipation to improve efficiency of two-stage electric air compressor for fuel cell vehicle,” Energy Convers Manag, vol. 251, Jan. 2022, doi: 10.1016/j.enconman.2021.115007. [14] N. N. Hasan, A. Arif, and U. Pervez, “Tire pressure monitoring system with wireless communication,” in Canadian Conference on Electrical and Computer Engineering, 2011, pp. 000099–000101. doi: 10.1109/CCECE.2011.6030417. [15] C. Saad, E. A. Cheikh, B. Mostafa, and H. Abderrahmane, “Comparative Performance Analysis of Wireless Communication Protocols for Intelligent Sensors and Their Applications,” 2014. [Online]. Available: www.ijacsa.thesai.org

Copyright

Copyright © 2023 Anush Vivian Crasta, Nash Savio Rodrigues, Nuaim Abdur Rahaman, Mr. Rajeshwari . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET52525

Publish Date : 2023-05-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online