Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Crack Detection in Railway Tracks using Image Processing

Authors: Akshit Jain, Ankit Jonwal, Dishant Doriya, Dev Gupta, Deepak Saini

DOI Link: https://doi.org/10.22214/ijraset.2022.43829

Certificate: View Certificate

Abstract

In this project, a computer-based methodology (i.e. image processing in MATLAB) has been discussed which will helped in detecting the cracks on the tracks appropriately with less human intervention. A system will be there to capture the images of the track and send it to the server .i.e. to the computer of the rail employee. The employee just has to browse that image. However, no special knowledge is required to detect cracks which will definitely help the employees of the railway. Also, the overall cost of the project is less with less maintenance. However, no special efforts are needed to detect cracks which will certainly benefit the employees of the railway. In addition,with less maintenance, the project\'s total cost is lower.

Introduction

I. INTRODUCTION

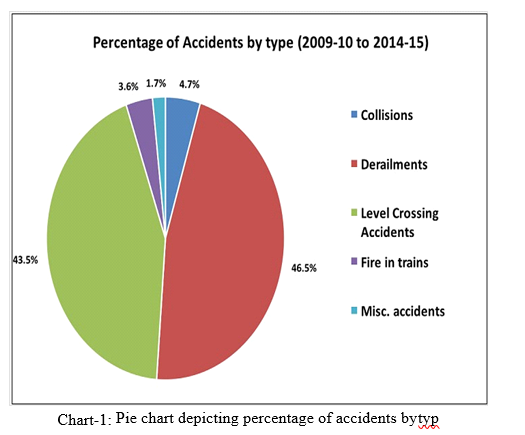

Most of the people travel by railway and also mostly the goods transportation is also done by railway. The railway is faster than the bus and safer plus economical than an airplane and hence mostly used by all and is the biggest means of transportation. But the problems with the railways are the increasing number of accidents which are caused by the number of reasons such as:-

A. Collision Between Trains

Problems occurring in the signaling 3] Obstacles appear on the rail route. 4] Track failures But mostly the accidents occur are due to the track failures means cracks occur in the tracks which leads to the accidents. This cause loss of lives and property. So there is a need to avoid accidents. Reasons for the development of cracks in railway track can be due to Development of excessive thermal stresses in the track due to temperature variation.

Due to excessive wear and tear on account of repetitive mechanical stresses.

Corrosion in track, on account of adverse climatic conditions.

Trains having more weight than weight sustainability of the track due to the passenger overcrowding in the coaches of the train than the real coach capacity.

B. Proposed Method

In this project, we have proposed a computerized method to detect cracks which require very less cost or even we can say that to detect crack we require no cost at all and also no manual inspection to detect the crack.

This method is based on MATLAB. We have use image processing in MATLAB. In this, first of all a reference image without crack is provided in the MATLAB. This image is always same. Then there is a need to capture the image of the track. This captured image is then provided to the server i.e., somewhere in the nearby station where an employee is sitting to monitor the operation.

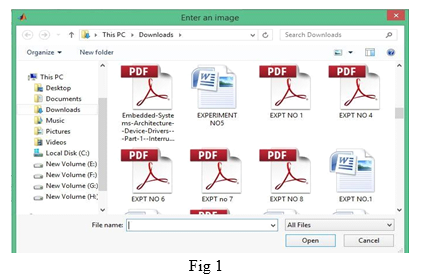

This employee has to do just certain operations such as giving a name to the images or browsing the files of the image which requires no special knowledge. After browsing the images in MATLAB, the program file for the crack detection which is already stored there in MATLAB needs to open. Then the image name only has to put in proper format into that program. We can make another arrangement by writing certain different commands for this due to which there will be no need to write the name every time and then the program is run and browse the file of the captured image. The following figure shows the direct browsing window of the file.

By just clicking the appropriate image file, then open that file. The algorithm i.e., all the operations mentioned in the program are applied to this captured image and show the output result.In this project , we will plot the histograms of the reference image which is without a crack and one capture image which can be with or without a crack. After plotting the histograms for both if both histograms are same then there will be no crack present and if histograms are different then there is a presence of a crack. But the main question arises how to capture the images?

To implement this project there is a need to observe the tracks continuously by’ capturing the images. Also, another need is that we want only the top view of the track. So it s a difficult task to capture images manually.

In this project, we have mentioned two ways to capture images. Both ways use modern technology. To capture images continuously place cameras after certain distance on the poles and allot a particular range for that camera means the range in which only it has to capture images. After capturing the images, the images are then sent to the server. However, this method requires lots of cameras and hence expensive and requires also a lot of maintenance. So we have mentioned this idea but use this when having sufficient budget.

The method which we are going to use to capture the images is to use Drone camera. The image for the drone with a camera is shown in the following figure:-

The drone will have transmitter-receiver and this transmitter-receiver is used to send information to drone and as well to send images to the server when it captures the image. The camera being used must be powerful with the great image capturing capabilities. For capturing the images at night time is a big task but we will use infrared cameras.

Another question arises that how many drone cameras required? If we consider the railway line of 20 Km and drone have a range to travel 20 km. The drone will first capture the images till first 10 Km and send to the server. Then captures for the next 10 Km and that images send to the server. This drone camera is very useful to capture images because in area likes Mumbai where continuously trains are moving. It is very difficult to monitor tracks manually with a walking stick or inspection vehicle.

Every thirty minutes or before the train moves over the track. This drone camera s operation is also very fast and not involves a lot of machinery. Another advantage of using it is that it can use for other purposes such as security.

This is totally dependent on the railway authority to allot ranges or decide the policy; we have just given a rough idea here.

This drone camera will capture the image and send to the server where the employee is sitting. Hence the employee will put the images in MATLAB and run the program. As soon as he gets the result if the employee finds the crack present, the employee can also be able to find the location of the crack immediately in which range it lies and send information to the appropriate authority.

II. LITERATURE SURVEY

A. Crack Detection System For Railway Track By Using Ultrasonic And Pir Sensor(Alternate Method)

This paper introduces the integration of ultrasonic sensors and PIR sensors for detection of cracks in railway tracks. This project consists of GPS module, GSM modem, IR sensor, PIR sensor for the purpose of communication, crack detection and detection of human beings in the railway track. The GPS module and GSM modem help to find and send geometric parameters of cracks detected to the nearest railway station. In the present day high cost LVDTs are used for measurement of track distance with less accuracy, but for high accuracy, the less cost ultrasonic sensors should be used. According to the recent trends of application the PIR sensors are used to avoid the manual procedures for detection of human beings. This project is applicable for both day and night time detection purpose.

B. Railway Route Track Crack Detection By Microcontoller

This paper proposes a railway crack detection system. This paper presents the detection system that detects any crack in the railway tracks by using a microcontroller. Most of the goods are transferred from one region to another through railways only due to its low transportation cost, fastness, reliability and less chance of accidents. Therefore, it is necessary to provide safety to the railway tracks. Hence an advanced technology capable of locating cracks in the tracks is developed.

C. Railway Track Crack Detection(Use With Raspberry Pi)

This paper proposes a railway track crack detection and object detection system. A Raspberry Pi 3 module is used to control and coordinate the activities of these devices. This project prevents train derailment by detecting cracks in railway track using internet of things technology.

III. FLOWCHART

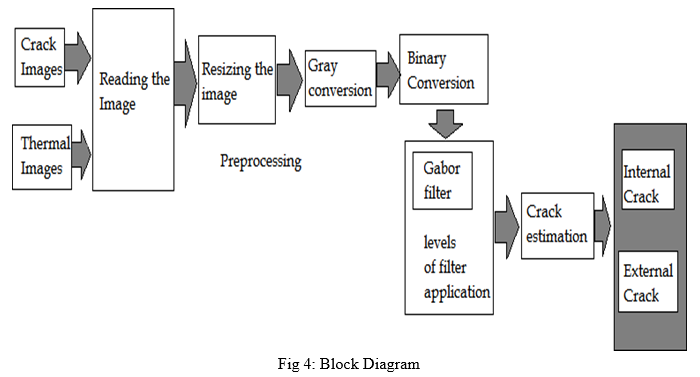

The explanation for a flowchart:-

In this first, the captured image and reference image of the track are browsed into the MATLAB. Then start the writing of the commands in the editor of MATLAB. These images are read into the MATLAB. These images are RGB images.

Now we have to apply the algorithm to these images. The algorithm can only apply to two-dimensional images rather than three-dimensional images in MATLAB.

Since RGB image is three-dimensional image so we cannot apply algorithms to these images and hence we convert these images into grayscale images.

The X-axis is the intensity value from 0 to 255(these images are uint8). The Y-axis varies depending on the number of a number of pixels in the image and how their intensities are distributed.

IV. COMPONENTS OF IMAGE PROCESSING

Image Processing System is the combination of the different elements of digital image processing. Digital image processing is the processing of an image by means of digital computers. Digital image processing uses different computer algorithms to perform image processing on various digital images.

It consists of following components:-

- Image Sensors: Image sensors are used to sense the intensity, amplitude, and other features of the images and pass the result to the hardware.

- Image Processing Hardware: Image processing hardware is the dedicated hardware which is used to process the instructions obtained from the image sensors. It passes the result to the general purpose computer.

- Computer: Computers used in the image processing systems are the general purpose computers that are used by us in our daily life.

- Image Processing Software: Image processing software is a software that includes all the mechanisms and algorithms of an image processing system.

- Mass Storage: Mass storage stores the pixel images during the processing.

- Image Display: An image display includes the monitor or display screen that displays the processed images.

- Network: The connection of all the above elements of the image processing system constitutes a network.

- Image Segmentation Techniques: The process of partitioning a digital image into multiple segments is called image segmentation..

V. WORKING

A. Phases Of Image Processing

- ACQUISITION– It mainly involves converting an image into a digital form. The main work involves: i) Scaling ii) Color conversion (RGB to Gray or vice-versa)

- IMAGE ENHANCEMENT–It is used to extract some hidden details from an image and is subjective.

- IMAGE RESTORATION– Restoration is based on mathematical or probabilistic models or image degradation.

- COLOR IMAGE PROCESSING– It deals with full color image processing.

- WAVELETS AND MULTI-RESOLUTION PROCESSING– It is the process of representing images in various forms.

- MORPHOLOGICAL PROCESSING-It deals with tools that are very useful in description of shape.

- SEGMENTATION PROCEDURE-It includes partitioning an image into its integral components.

- REPRESENTATION & DESCRIPTION- It transforms raw data into processed data.

- OBJECT DETECTION AND RECOGNITION-It labels an object based on its descriptor.

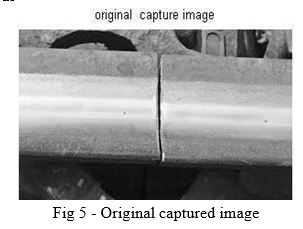

Now load the capture image in MATLAB first and read this image.

The commands for this are as follows:-

[fname, path]=uigetfile('*.*','Enter an image'); fname=strcat(path,fname);im=imread(fname); imshow(im);

title('original captured image');

The result for this is shown in MATLAB as

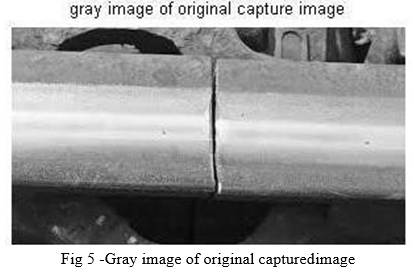

This RGB image is then converted into GRAY image and the commands for this are as follows:-

b=rgb2gray(im);imshow(b);title('gray image of original capture image');

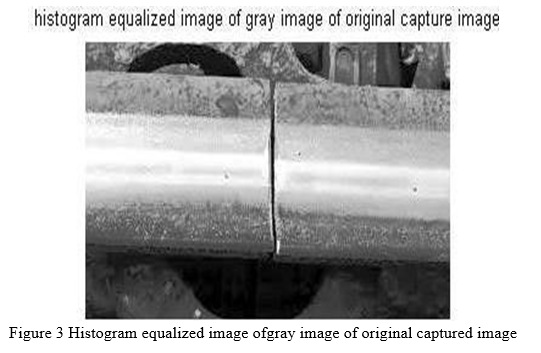

This GRAY image is then converted into histogram equalized image. The need for histogram equalization is that track is brighter than the background due to sunlight. Hence to observe track clearly histogram equalization is required and the commands for this are as follows:-

c=histeq(b);imshow(c);title('histogram equalized of input captured image');

The result for this is as follows:-

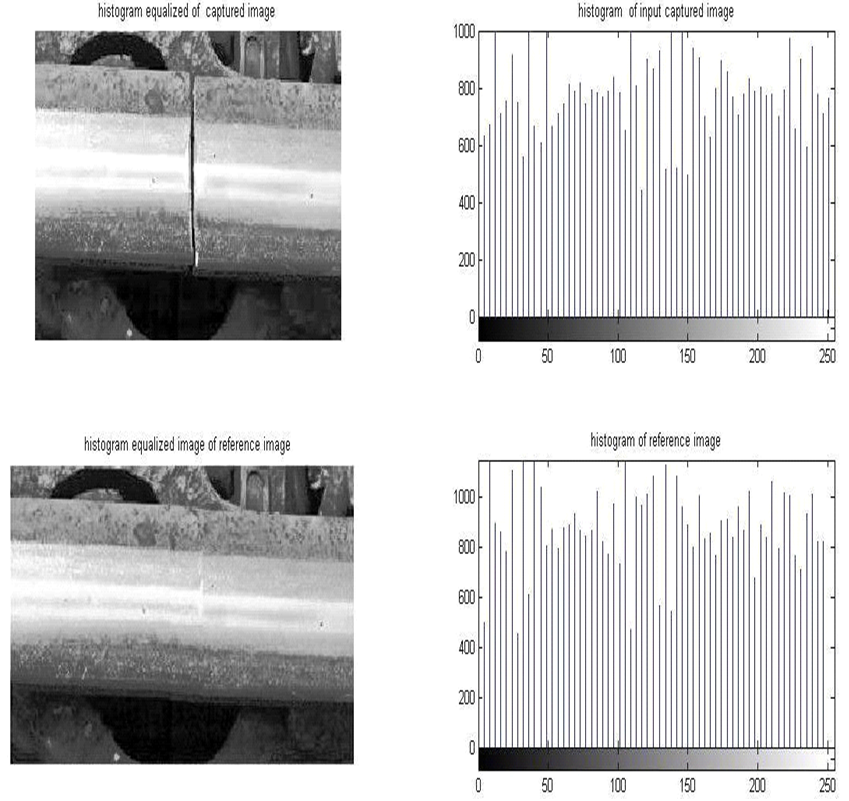

Then the histogram of this above image is plotted. The reference image without crack is provided. Similarly it is converted into gray image and then into histogram equalized image. After this histograms for both images are plotted.

The commands are as follows:- subplot(2,2,2);

imhist(c);

title('histogram of captured image'); REF=imread('rail2.jpg'); m=rgb2gray(REF); n=histeq(m); subplot(2,2,3);

imshow(n);

title('histogram equalized image of reference

image'); subplot(2,2,4); imhist(n);

title('histogram of reference image'); The result for this is follows:-

The whole program is shown ones again:-

[fname path]=uigetfile('*.*','Enter an

image');

fname=strcat(path,fname);im=imread(f name);

imshow(im);

title('original captured image'); b=rgb2gray(im);

c=histeq(b); subplot(2,2,1); imshow(c);

title('histogram equalized of captured image');

subplot(2,2,2); imhist(c);

title('histogram of input captured image'); REF=imread('rail2.jpg'); m=rgb2gray(REF); n=histeq(m);

subplot(2,2,3); imshow(n);

title('histogram equalized image of reference image');

subplot(2,2,4); imhist(n);

title('histogram of reference image');

The result for this is as follows:-

If we observe the above two histograms then it is clear that both are different and hence we can come o the decision that there is a crack on a track. The employee of the railway just has to identify the histograms and then can give the decision about the presence of the crack.

VI. FUTURE APPLICATION AND DEVELOPMENT

This project can be helpful in areas like Mumbai. where crowds of trains are very much high. The above described method is simplest method to detect crack. In future, instead of image processing we can use video processing.Various types of features can be obtained fromthis image processing in MATLAB.

Conclusion

In this paper, a method to detect cracks in railway tracks has been presented using image processing techniques. The proposed method helps to detect cracks with some manual working on the computer. Pictures of the tracks are taken with drone and given as input to the suggested system to detect cracks. This will help to detect cracks immediately and reduce the possibilities of accidents. The proposed method detects cracks with accuracy and hence the utmost efficiency of the system can be ensured. So with the help of image processing in MATLAB, it is able to find the cracks in the tracks easily.

References

[1] Rizvi Aliza Raza, Khan Pervez Rauf, Ahmed shafeeq, crack detection in tracks using MATLAB , International Journal of Advance Research, Ideas and innovations in technology ( VOLUME 3, ISSUE 4). [2] Gonzalez, R. C., R. E. Woods, and S. L. Eddins, Digital Image Processing Using MATLAB, New Jersey, Pearson Prentice Hall, 2004. ’ [3] Image Processing Toolbox User s Guide, version 5, by The MathWorks, Inc. [4] https://www..mathworks..com [5] An Introduction to Digital Image Processing with Matlab, Notes for SCM2511 ImageProcessing 1, Semester 1, 2004, Alasdair McAndrew, School of Computer Science and Mathematics, Victoria University of Technology

Copyright

Copyright © 2022 Akshit Jain, Ankit Jonwal, Dishant Doriya, Dev Gupta, Deepak Saini. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET43829

Publish Date : 2022-06-05

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online