Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Analysis of Interpretation for Orthopedic Plate with Titanium Alloy

Authors: R. Murali , Dr. R. Rajappan

DOI Link: https://doi.org/10.22214/ijraset.2022.45955

Certificate: View Certificate

Abstract

The bone is considered as a linear-elastic, isotropic, and homogeneous materials. Trauma is a major cause of death and disability in both developed and developing nations. The mainly consider interpretation of accident after healing orthopaedic surgery plate replacement material design, evaluation, machining and optimization can be consider in this project. In this project setup is simply replacement method for three models of healing plate of single hole, four holes and six holes plate design in Solid Works. Evaluation process used in 3D finite element methods for a fractured bone with three models of titanium alloy plates is analysed using ANSYS workbench.

Introduction

I. INTRODUCTION

Patients who continue to suffer inconvenience and discomfort after a healed bone fracture may be better off having any plates, pins and screws removed. Scientific research headed by Dagmar Vos (pictured), who took her doctoral degree at University Medical Centre (UMC) Utrecht, demonstrates that most complaints and symptoms, such as pain and restricted motion, improve after removing these so -called osteo synthesis materials. After a bone fracture has mended, metal implants such as pins, plates and screws (usually made from surgical steel or titanium) are in fact no longer useful. The question then arises: do these implants have to be removed from the bone after the fracture has healed or is it better to leave them in place. Such questions often come from patients or their caretakers, sometimes even before the patient has even had the bone fracture operation. In the medical world a debate is going on as well, not least because – surprisingly enough – little high-quality scientific research has been done in this field this until now. After a bone fracture has mended, patients often experience residual complaints, such as pain or restricted mobility. Patients and practitioners often believe that the presence of osteosynthesis materials is to blame for these complaints. Patients also request to have these materials removed because they experience them as foreign. In the Netherlands, doctors remove the osteosynthesis materials after fracture healing in 30 to 40 percent of the cases, resulting in about 18,000 surgical procedures each year.

II. LITERATURE SURVEY

S N. Fouda, Rania Mostafa, A. Saker (2019), 3D finite element models for a fractured tibia with Stainless Steel (SS) and Carbon/hydroxyapatite (C/HA) bone-plates are analyzed using ANSYS workbench. Plates with different gaps (0.2, 0.4 and 0.7 mm), and a contact plate with no-gap are examined. It is found that SS and C/HA bone-plate materials with a gap value 0.7 mm provide higher compressive stress along the fracture site and the bone than the other bone plate models. C/HA bone plate achieves more increasing of stresses than SS bone plate. Using C/HA plate increasing the average stresses by 16% along the fracture site and by 38% along the bone at the final healing stage compared to SS plate of the 0.7 mm gap model [1].

M.S.El-Sayed,* Ahmed S. A. AbouTaleb,* M.FahmyAly, they introduces an optimal design of a composite bone plate. The optimized design is then tested by finite element method. The results of the optimization work showed that the optimized plate is composed of 5 layers showing the volume fraction, fiber orientation and thickness of each layer. The maximal von-Mises stress on the plate is also calculated using FEA [2].

Yu-Tzu Wang, Shao-Fu Huang, This study performs a structural optimization of anatomical thin titanium mesh (ATTM) plate and optimal designed ATTM plate fabricated using additive manufacturing (AM) to verify its stabilization under fatigue testing. The Taguchi analysis found that the ATTM plate required a designed internal hole distance to be 0.9 mm, internal hole diameter to be 1 mm, plate thickness to be 0.8 mm, and plate height to be 10 mm.

The optimal designed ATTM plate with patient-matched facial contour fabricated using AM provides superior stabilization for ZMC comminute fractured bone segments [3].

Sourabh Suresh Awati1, Sanket Anil Borgave, Metals remain comprehensively used in a erraticism of proposals in the medical field for internal support and biological tissue exchanges, such as joint replacements, dental roots ,orthopedic obsession, and stents. This study examines boundaries of metallic implants and the probability of accepting progressive composite materials to overawed stress shielding effects to match more carefully to the bone [4].

Xiaozhong Chen, Kunjin He, The present study proposes an integrated computer- aided approach combining femur surface modeling, fracture evidence recover plate creation, and plate modification in order to conduct a parametric investigation of the design of custom plate for a specific patient. The proposed approach was tested and verified on a case study, and it could be helpful for orthopedic surgeons to design and modify the plate in order to fit the specific femur anatomy and the fracture information [5].

Ali Mehboob a, Hassan Mehboob, Complications are common during bone fracture healing owing to incompatibility of the implants. Flexible fibrous composite materials are promising materials that offer excellent biomechanical compatibility. A suitable biophysical environment was predicted for successful bone healing. The Twintex [0]2nT IM nail contained 19.57% and 33.44% lower stress than that of the stainless steel at day, reducing the stress shielding effect. The body weight carried by the bone was 72.8% higher in the Twintex [0]2nT nail with a maximum relief of 79.8% in stresses relative to the stainless steel IM nail at final day of healing confirming the maximum healing [6].

Xiaozhong Chen, Kunjin He, The experimental results showed that the proposed method could effectively represent femur surface shape features and intuitively construct and edit individualized plates with high-level parameters. The method is competitive in time saving and design convenience and may provide a basic tool for digital restoration of incomplete femurs and the design of patient specific femur plates [7].

Hassan Mehboob, Seung-Hwan Chang, The study aimed to investigate the influence of design factors of a functionally graded biodegradable composite bone plate on the healing of a tibia fracture. To optimize the design parameters of the bone plate and maximize the healing performance, signal-to-noise ratio was used, as a larger signal-to-noise ratio was better. The optimal condition of design parameters was successfully determined by using the Taguchi method, and it was shown to maximize the healing of bone fractures [8].

D. Chandramohan, this paper focuses a new method of using data obtained from CT images combined with digital CAD and rapid prototyping model for surgical planning and this new application enables the surgeon to choose the proper configuration and location of internal fixation of plate on humerus bone during orthopaedic surgery [9].

III. METHODOLOGY

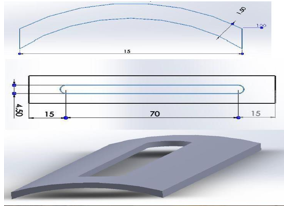

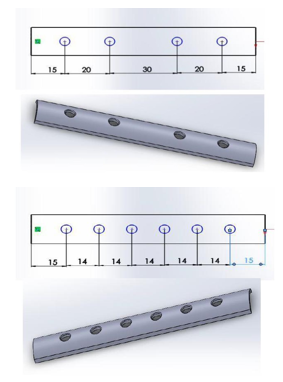

A. Design the orthopaedic plate

Drawings can be created either from single hole, four holes and six holes for 100mm plate parts and assemblies. Views are SolidWorks 2D and 3D models with dimensions generated from the solid model, and notes, dimensions and tolerances can then be easily added to the drawing. The following on design of orthopedic plate’s model and Orthopedic Plate Assemble Parts in Solid Works drawings shown in the figure.

B. Wire cut Electrical Discharge Machine

Wire electrical discharge machining is a high-precision method for cutting nearly any electrically conductive material. A thin, electrically- charged EDM wire held between upper and lower mechanical guides forms one electrode, while the material being cut forms the second electrode. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. As the spark jumps across the gap, material is then removed from the work piece and the electrode. Virtually any conductive material can be cut using Wire EDM. This would include all metals, including steel, aluminum, brass, titanium, and alloys and super alloys of all types. EDM is a thermal material removal process in which material is removed by local melting or vaporizing small areas at the surface of work piece.

Table:1 Input process parameter three levels of data

|

Levels |

Pulse On Time (P On) |

Pulse Off Time (P Off) |

Wire Feed (VF) |

Wire Flow |

|

Level- 1 |

12 |

4 |

7 |

1 |

|

Level- 2 |

14 |

5 |

8 |

2 |

|

Level- 3 |

16 |

6 |

9 |

3 |

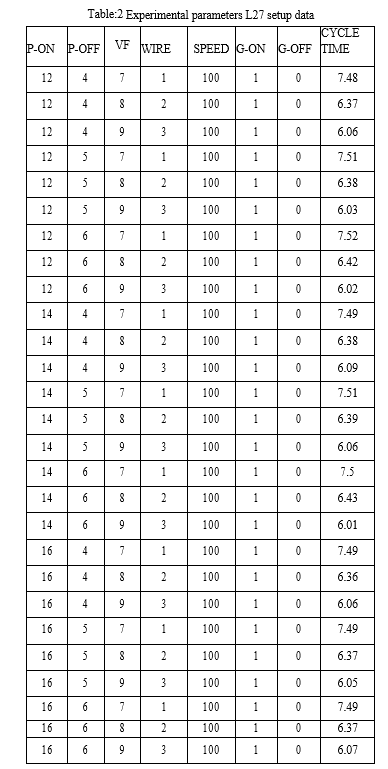

The wire cut EDM of titanium grade-2 specimen with a size of 10x5x3 mm3 has been done with molybdenum wire.The titanium metal has been cut into L27 a sample with different process parameters has been shown in table-2 that the machining setup.

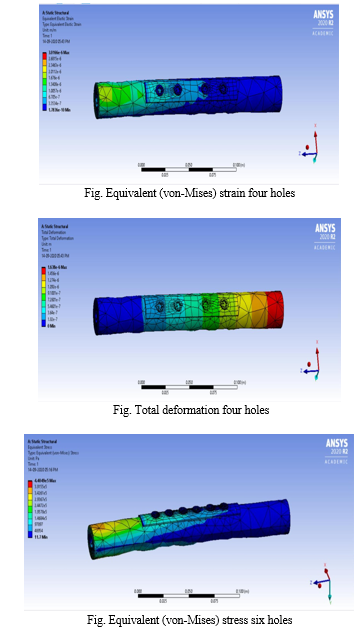

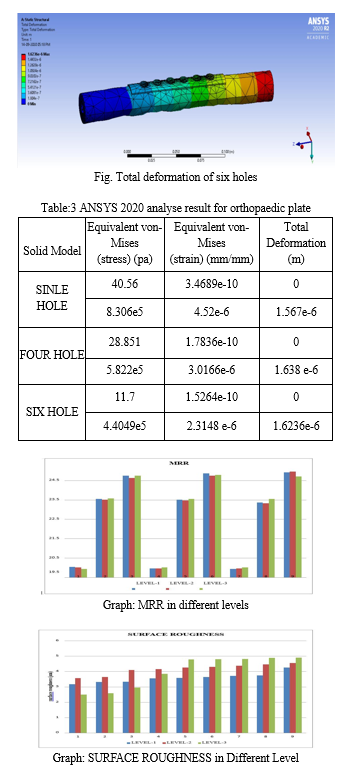

IV. RESULT AND DISCUSSION

3D finite element analyse the stress value are studied along three types of hole model and trabecular bone attach with fastening orthopaedic plate , as shown in Figure. This study is done by selecting the nodes from finite element method as equivalent von-Mises stress and strain, total deformation, in the solution of single tap, four holes and six holes models assembly is interpretation in ANSYS 2020. The following on minimum and maximum of von Mises stress, strain distributed and total deformation through nodes from along with the trabecular bone for each model orthopaedic plate. WEDM working process to L27 work materials is three level of experimentally is cutting. The cutting parameters and output values are optimization of the MATLAB in NNTOOL method. WEDM input parameters are Pulse on time, Pulse off time, and feed rate of machine working condition and output values are MRR, SR and SEM result. The MRR defends on increase the Pulse on time and wire feed rate also increases the MRR.

Variation of Material Removal Rate and Surface Roughness at different a level of process parameters has been shown in the graph 1 and 2. From that, it is observed that level 3 with P-on 16µs gives the best results.

Conclusion

The optimization technique of the WEDM input process parameter is considered on pulse on time, pulse off time, and wire feed rate of machine working condition for improved MRR and SR. The optimization with NNTOOL using the 27 experimental data sets resulted in the get better input process parameter values obtained as pulse on time (16µs), pulse off time (4µs), and wire feed rate (8mm2/min). Also the best input cutting parameters were selected by SEM test. The project has been worked with three types of model analyses in ANSYS 2020. The defined organ system is the single hole to get the best result of orthopaedic surgery plate. The finding process use the finite element methods analyse better maximum stress (8.306e5 pa), maximum strain (4.52e-6) and total deformation (1.567e-6 m).

References

Elsevier Science Direct, Ain Shams Engineering Journal 10, 2019, 481-488. [2] M.S.El-Sayed, Ahmed S. ‘Optimum Design & FEA of Tibia Fractured Composite Bone Plate’ International Journal of Engineering Trends and Technology (IJETT) – Volume57, 2018, 89-97. [3] Yu-Tzu Wang, Shao-Fu Huang, ‘Anatomical Thin Titanium Mesh Plate Structural Optimization for Zygomatic-Maxillary Complex Fracture under Fatigue Testing’ Hindawi BioMed Research International, 2018, 1-7. [4] Sourabh Suresh Awati1, Sanket Anil Borgave ‘Limitations of Current Metallic Bone Plates: towards Development of Composite Bone Plates’ IOSR Journal of Mechanical and Civil Engineering (IOSR- JMCE), 2018, pp. 25-29.. [5] Ali Mehboob a, Hassan Mehboob ‘Effect of composite intramedullary nails (IM) on healing of long bone fractures by means of reamed and undreamed methods’ Science Direct Composite Structures, 167 (2017), 76-87. [6] Xiaozhong Chen, Kunjin He, ‘A parametric approach to construct femur models and their fixation plates’ fracture’ Biotechnology & Biotechnological Equipment Taylor & Francis, 2016, 529-537. [7] Hassan Mehboob, Seung-Hwan Chang, ‘Optimal design of a functionally graded biodegradable composite bone plate by using the Taguchi method and finite element analysis’ Science Direct Composite Structures, 119, 2015, 166–173. [8] D. Chandramohan, ‘Analysis on natural fiber bone plates’, European Journal of Experimental Biology, 2014, 323-332. [9] Lee, H.-H. (2017). Finite Element Simulations with ANSYS Workbench 17. SDC Publications. p. 50. ISBN 978-1-63057-088-0. Retrieved June 9, 2017. [10] Ugrasen G, H V Ravindra, B M Umeshgowda, Y D Chethan and G V Naveen Prakash (2018) ‘Estimation of Machining Performances using GMDH and ANN in Wire EDM of Cu-1Cr-0.1Zr Alloy’ IOP Conf. Series: Materials Science and Engineering 376 (2018) 012132, https://doi.org/10.1088/1757899X/376/1/012132. [11] G.Ugrasen, H.V.Ravindra, G.V.Naveen Prakash, R.Keshavamurthy (2014) ‘Process optimization and estimation of machining performances using artificial neural network in wire EDM’ 3rd International Conference on Materials Processing and Characterisation (ICMPC 2014), Procedia Materials Science 6 ( 2014 .

Copyright

Copyright © 2022 R. Murali , Dr. R. Rajappan . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET45955

Publish Date : 2022-07-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online