Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design & Fabrication of Mortar Transportation Cart

Authors: Dhyeya Trivedi, Madhav Dive, Shreyas Gajapure , Saurav Mashidkar, Sahil Kshatriya , Prof. P. V. Jadhav

DOI Link: https://doi.org/10.22214/ijraset.2023.53619

Certificate: View Certificate

Abstract

In recent times the assiduity and diurnal routine workshop are set up to be more attracted and enforced through robotization via Robots. The pick and place transport wain is one of the technologies in manufacturing diligence which is designed transport wain operations. The system is so designed that it eliminates the mortal error and mortal intervention to get more precise work. There are numerous fields in which mortal intervention is delicate but the process under consideration has to be operated and controlled this leads to the area in which transport wain find their operations. Literature suggests that the transport wain are designed, enforced in colorful fields similar as; in bottle filling assiduity, quilting diligence etc. The design analysis of an Mortar transport wain has been presented in this design. This work unravels the fact that man would always want to cleave to safety preventives at plant and indeed in its terrain, to be suitable to handle some specific tasks, like transferring the transport vehicle to dangerous terrain to gain samples for chemical analysis. This system comprises of a trolly module which work as the carrier for vehicle.

Introduction

I. INTRODUCTION

Lifting heavy loads like press, fridge, washing machine. Up to 150 kg is not clean job, especially where there are no lifting installations( elevator). likewise, in outside of theHomes inside the pastoral areas does now not have elevators or escalators. In this illustration mortal labours are considered to be the only result. Labour is getting largely- priced each day, wherein increase rate is dwindling. This problem may be answered if a trolley can raise hundreds whilst traveling through stairs. The task introduces a new mongrel for the transportation of the millions over the stair in perpendicular function and weight on identical bottom horizontally. This design deals with the designing and product of a trolley, which could climb stair. The specialized troubles in designing of this trolley are the immutability and haste of the machine at the same time as climbing stairs. still, the steepness of the stairs is likewise the vital concern of this examine. The want for this kind of machine arises from every day conditions in our society. Devices which includes hand trolleys are used for easy lifting of cargo on flat ground still, these trolleys generally fail when it comes to wearing the weight from ground to ground through stairs. Inside the situation of this, the challenge attempts to layout a stair mountaineering trolley which can bring heavy objects up the way with lower trouble as compared to wearing them manually. In our challenge, the trolley is prepared with bus which permit us to hold cargo up and down the stairs. It also eases the movement of trolley in irregular shells like holes, bumps, and numerous others. This trolley is the mongrel of hand trolley and stair mountain climbing trolley which may be employed in each functions i.e. Sporting cargo on equal ground in addition to wearing cargo from stairs.

II. NECESSITY

In this “Domestic Load Carrier Trolley” the aim of this project is to shift domestic load from one floor to anther floor with less efforts and to design a trolley with low cost so that it may be used in rural areas by each and every one. Transport cart is a small transport device used to move heavy loads from one place to another. It is a very common tool used by a large number of industries that transport physical products ,so by making it electric the man power requirement will be less and transportation shall be fast. An example of this logistics in the industrial and civil construction sectors, where agility is required to lift a load of considerable weight, move it from one point to another.

III. PROJECT DETAILS

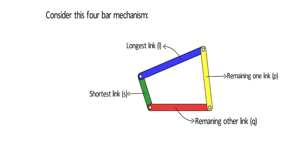

The first time the optimization in this problem is enforced with two styles. In the first system the length are named as optimization parameter whereas in the alternate system perfection point’s distribution is considered as optimization parameter. They been concluded that perfection points as optimization parameters system has produced atomic error, but it couldn't satisfy dimensional constraints.

IV. WORKING

At the beginning the material carrying tub has to be pulled and kept a side.

The three wheel trolley is then fixed with the box.

When the box and trolley are in position, the long handle bar is pulled backward with a little force or efforts So that the upper moving platform or jaws lift the box/ tub to a certain distance of height from the ground surface.

The worker can now move the trolley with the help of the throttle which is connected to the motor to the desired location.

For unloading the tub, the long bar handle is pushed so that the moving platform or jaws drops to their rest position and the tub is pulled down.

V. CALCULATION

A. Material Used And Modification

- Wheels

The indirect element known as a wheel is designed to rotate on a shaft bearing. The wheel is one of the essential factors of the wheel and shaft, which is a simple machine. Wheels and axles enable the movement of heavy particulars while sustaining a cargo or carrying out mechanical work, hence abetting mobility or transportation. A boat's wheel, a hand wheel, a wheel, and a flywheel are just a many exemplifications of the colorful uses for bus. Polyurethane( PUR and PU) is the material. It might be a chemical made up of organic motes linked together by carbamate( urethane) bonds. Although thermoset polymers, which don't soften when hotted , make up the maturity of polyurethanes, thermoplastic polyurethanes are also available. High tensile and tear resistance are both characteristics of polyurethanes. In water, oil painting, or grease, the material parcels of polyurethane can remain stable( with minor lump). In subsea operations, polyether composites can survive for a many times.

2. Axle

An axle is the middle shaft for a wheel or gear that rotates. On wheeled vehicles, the axle is either fixed to the vehicle and rotates around it, or it is fastened to the wheels and rotates with them. Depending on where the axle is supported, bearings or bushings may be installed at the mounting points.

Material: MS METAL

3. Trolley Frame & Handle

Trolley's frame is its primary component, mounted to an axle.Try to keep anything that needs to be transported. Typically, a frame is a structural framework that supports various components of a physical construction and/or a steel frame that restricts the size of the construction.

In building, framing refers to the assembly of materials that provide a structure support and shape. The most common framing materials are steel, wood, or constructed wood. The trolley's handle allows for simple handling of big loads while being moved from one location to another.

Material

Frame: Tin

Handle: GI Pipe

4. Ball Bearing

A ball bearing is a specific kind of rolling- element bearing that uses balls to keep the bearing races piecemeal. Choose a ball bearing with a minimal 12 mm periphery, a minimal 150 kg radial cargo capacity, and a speed lesser than 100rpm. Ball bearing 6202( as per standard periphery of solid shaft is 12 mm).

Rolling resistance determines the stability of rolling wheel.

5. Assembly Of Trolley

- The base plate is first cut to the necessary dimensions of 5486.4 mm × 6096 mm, or period x breadth.

- Next, three rectangular bars measuring 1066.8 mm in length are taken and welded to the body as needed. A rectangular body is also welded beneath the bottom plate.

- The final step is to display the drills at zero to finish the top transferring arrangement. In order to create an inflexible handle, 5 foot on vertical fixed square bars and movable bars are welded together.

- Next, a quasi-star frame is cut with the aid of petrol cutting, and plates are drilled so that a bolt needs to be pushed through to keep the wheel in place between two frames. Two sets of nearly famous wheels are ready, and they are welded using arc welding to the end of the shaft.

- A pillow bearing is geared up with the aid of nut and bolts at the middle of each leaf spring, and two leaf springs are welded on corner vertical rectangular rods.

- A single ratchet is welded into the shaft's centre, and a pawl is fixed to a vertical, rectangular rod with a spring-loaded anxiety.

- A brake lever should be installed on the handle's right side so that it can be used as a grab to clear the trolley's path.

VI. RESULTS & DISCUSSION

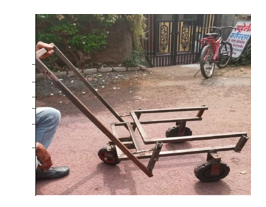

We put the trolley to the test by lifting notable household items, and the results showed that it was simple to transfer items up to 150 kg up stairs, while the horizontal capacity of the trolley on the ground floor was 100 kg. As the load increases, so does the amount of energy needed to lift the object, but as the load decreases, so does the number of people needed to lift the object and the amount of time needed to carry it, which lowers the labour cost for moving household items.

- In the construction and industrial sectors, where dexterity is needed to lift a load of large objects. likewise to transfer it from one location to another.

- In malls, a tub attached to a cart filled with water is used to clean the floor and transport any heavy objects.

- Because it runs on batteries, less effort is required.

- It is a versatile project since numerous accessories may be mounted and various work needs can be satisfied.

A. Project Image

VII. ADVANTAGES

- Manual power is unnecessary.

- Easy to operate and to use as a guide.

- Follow the instructions to run and rotate in any direction.

- Transport greater weight than oneself. (About 20 Kg according to design) and less noisy in operation.

VIII. DISADVANTAGES

- The price of manufacturing is relatively expensive.

- Battery charging requires an external power source.

- Only more complex in design than a hand-driven trolley.

IX. APPLICATIONS

Pallets, rolls, racks, carts, and containers are just a few of the many sorts of materials that can be transported using automated guided vehicles. Applications with the following traits benefit greatly from AGVs:

- Moving objects repeatedly over a long distance.

- Stable loads delivered regularly.

- Medium volume/throughput.

- When timely delivery is essential and inefficient deliveries are a problem.

- Activities involving at least two shifts.

X. FUTURE SCOPE

- Internal breaking systems are potentially useful as breaking systems. This trolley can be powered by a motor to lessen the amount of manual labour required.

- There is currently a range of equipment for the extraction, handling, and transportation of coal and ore in both open pit and underground mines.

- There are currently a variety of unique methods and tools for handling materials in large construction projects. It affects how civil engineers design projects.

Conclusion

The design analysis of an Mortar transport wain has been presented in this design. This work unravels the fact that man would always want to cleave to safety preventives at plant and indeed in its terrain, to be suitable to handle some specific tasks, like transferring the transport vehicle to dangerous terrain to gain samples for chemical analysis. This system comprises of a trolly module which work as the carrier forvehicle., it was an experimental design. In all both rolling and climbing modes gives a new transportation mode over stairs and rough shells with maximum inclination angle 44 degree. The main end of this design is easy running, stairs climbing medium for cargo carrier with lower sweats. With conclusion of all papers, we\\\\\\\'ve an idea of accoutrements , specification of comportments and bus. With this we try include one another revision in our trolley.

References

[1] International Journal of Recent Research in Civil and Mechanical Engineering (IJRRCME) Vol. 2, Issue 2, pp: (160-165), Month: October 2015 ,March 2016. By Mulik shriniwas, Salunkhe Rohit, Shaikh Shahrukh, Waghmode Dada, Swapnil Gaikwad B.E Students, 5prof Mechanical Department, S.B. Patil College of Engineering, Indapur, India [2] International Conference on Industrial Engineering and Operations Management Dhaka, Bangladesh, January 9 ???? 10, 2010. By Md. A. Hossain. Nafis, A. Chowdhury, Rubaiat I. Linda, and Shamiuzzaman Akhtar. Department of Mechanical Engineering MIST, Dhaka-1216, Bangladesh. [3] International Journal Of Research Publications In Engineering And Technology [IJRPET] ISSN: 2454-7875 Special Issue , Sept. 2015. By Bhanje V.C., Alzende S. S., Gulik A.T., Kale A. A. Department of Mechanical Engineering, Vidya Vikas Pratisthan Polytechnic, Solapur/MSBTE [4] India Research and Reviews: Journal of Engineering and Technology.Vol.2 April- June 2013. By Avinash V Gaikwad, and Sandip J Kadam Department of Mechanical Engineering, Jawaharlal Darda Institute of Engineering and Technology, Yavatmal, Maharashtra [5] International Journal of Emerging Trends in Engineering and Development Issue 3, Vol.5 (September 2013). By Mr. Pratik H. Rathod, Mr. Ravi R. Mishra, Mr. Nitin A. Waghamare. [6] Md.A.Hossain, Nafis.A.Chowdhury, Rubaiat.I.Linda, “Stair Climbing Vehicle”, Published In International Journal Of Research Publications In Engineering And Technology (2010). [7] Mr. Pratik.H. Rathod, Mr. Ravi.R. Mishra, Mr. Nitin.A. Waghamare, “Stair Climbing Truck”, published In International Journal of Emerging Trends in Engineering and Development, (2013). [8] R.Rajasekar, K.P.Pranavkarthik, R.Prashanth, S.SenthilKumar and A.Sivakumar “DESIGN AND FABRICATION OF STAIRCASE CLIMBING Wheelchair”, published In International Journal of Mechanical Engineering and Robotic Research, (2013). [9] Sunil Kumar K R, Sunitha V S, Suresh K, Udaya Kumar S, “Design And Fabrication Of Stair Climber Trolley” , A Project Report At Anand Institute Of Higher Technology Chennai-603 103 Anna University , Chennai-600 025 , (2014) . [10] Prajan Pradip Gondole, Kamlesh Diliprao Thakre, “Stair Climbing Hand Trolley”, Published In ournal Of Emerging Technologies and Innovative Research (JETIR), (2015).

Copyright

Copyright © 2023 Dhyeya Trivedi, Madhav Dive, Shreyas Gajapure , Saurav Mashidkar, Sahil Kshatriya , Prof. P. V. Jadhav. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET53619

Publish Date : 2023-06-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online