Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Design and Modification of Forming Tool in Press Machine

Authors: Jayakanth R, Kandasamy R, Selvaraj G, Kannan P

DOI Link: https://doi.org/10.22214/ijraset.2022.45688

Certificate: View Certificate

Abstract

Now-a-days Currently they are using single cavity tool in company by using that we are identified so many problems like high production cost, less production ratio and excess time required for mass production. To solve this problem we are introducing double cavity tool instead of single cavity tool. By using cad software we are designing the double cavity tool. The aim of this project is to increase the production rate and also decrease economically for Pneumatic Press machine. For achieving that, introducing double cavity tool instead of single cavity tool and also fool proof. And analyze those tools by using ANSYS software and manually in industry. This project can be used in industry and also very helpful for unskilled labor to work without mistake.

Introduction

I. INTRODUCTION

Nowadays Currently they are using single cavity tool in company by using that we are identified so many problems like high production cost, less production ratio and excess time required for mass production.

To solve this problem we are introducing double cavity tool instead of single cavity tool. By using cad software we are designing the double cavity tool.

A. List Of Equipments

- Mechanical Presses from 250 Tons to 16 Tons capacity.

- Hydraulic deep draw presses from 250 Tons to 100 Tons capacity.

- Spot & projection welding machines of 50 KVA & 25 KVA capacity.

- MIG Welding, TIG Welding, Serration broaching, machinery.

- Hydraulic & Mechanical Shearing Machine Up to 6mm cutting.

B. List Of Products

EAP is currently manufacturing a variety of sheet metal components and assemblies. The company’s products find ready acceptance in all automotive industries and other industries including white good, Electrical equipment and other miscellaneous equipment.

- Deep drawn brake chamber parts and filter housings

- Dust Covers for commercial vehicle brakes

- 2-Wheeler frame parts, and seating parts

- Cabin trim components for commercial vehicles

- Seat Hinge assemblies for passenger vehicles

- Seat pan and frame parts for passenger vehicles

- Trim components for passenger vehicles

- Air Filter outlet and inlet piping for commercial vehicles

II. LITERATURE REVIEW

From the journals Jong Jin Park, Yung-Ho Kim, (2003) Fundamental studies on the incremental sheet metal forming technique, Journal of material processing technology, 447-453 ,we found the basic things of sheet metal forming technique.

H. Meier (2), C. Magnus, V. Smukala, (2011) Impact of superimposed pressure on dieless incremental sheet metal sheet metal forming with two moving tools, CIRP Annals – Manufacturing technology, 327- 330 , I studied abouth the movement of tool in sheet metal.

Zemin Fu, Jianhua Mo, Pan Gong, (2009) Mould correction for sheet metal multi step incremental air bending forming based of close loop control and FEM simulation, International Journal of Material Science, 732-740 present the results of an experimental modal analysis performed on a tool.

Che-Wun Hong and Tson-Wei Shio (1996) an optimal control strategy designed for an autopilot system to aid driving pattern simulation on tool test stands is described.

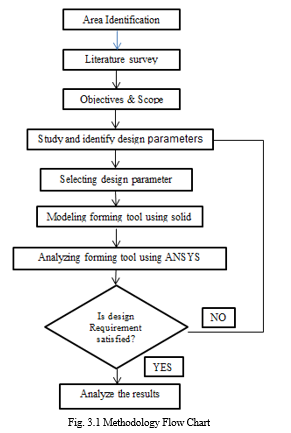

III. METHODOLOGY

A. Definition - Press Tools

Press tools are commonly used in hydraulic, pneumatic, and mechanical presses to produce components at high volumes. Generally press tools are categorized by the types of operation performed using the tool, such as blanking, piercing, bending, forming, forging, trimming etc. The press tool will also be specified as a blanking tool, piercing tool, bending tool etc.

Types Of Press Tools

- Blanking tool

- Piercing Tool

- Cut off tool

- Parting off tool

- Trimming tool

- Shaving tool

- Bending tool

- Forming tool

- Drawing tool

- Progressive tool

- Compound tool

- Combination tool

B. Blanking Tool

When a component is produced with one single punch and die where the entire outer profile is cut in a single stroke the tool is called a blanking tool.

- Blanking is the operation of cutting flat shapes from sheet metal.

- The hole and metal remaining after a blanking operation is discarded as waste.

- Size of blank or product is the size of the die & clearance is given on punch.

- It is a metal cutting operation.

- It is fast process and generally used for medium and mass production volumes.

- It is cheapest process in manufacturing.

C. Piercing Tool

Piercing involves cutting of clean holes with a resulting scrap slug. The operation is called die cutting and can also produce flat components where the die, the shaped tool, is pressed into a sheet material employing a shearing action to cut holes. This method can be used to cut parts of different sizes and shapes in sheet

Metal, leather and many other materials.

D. Cut Off Tool

Cut off operations are those in which a strip of suitable width is cut to length in a single operation. Cut-off tools can produce many parts. The required length of strip can be cut off for bending and forming operations using this tool, we found Single Cavity Forming Tool Parameter Under below given.

- Total length of the tool : 100mm

- Punch height from top plate : 82mm

- Punch thickness : 16.5mm

IV. MODELING OF FORMING TOOL

According to the dimensions, the existing forming has been modified and modeling in a Solid Edge and AutoCAD software. The existing forming tool dimensions are explained in a before chapter.

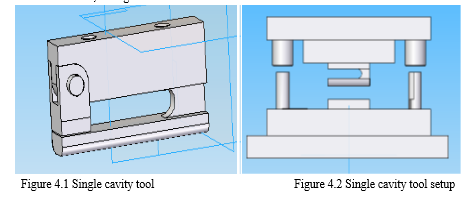

A. Modeling Of Single Cavity Forming Tool

- Total length of the tool : 100mm

- Punch height from top plate : 82mm

- Punch thickness : 16.5mm

According to the above dimensions, the figure is drawn in Pro-E as shown as below

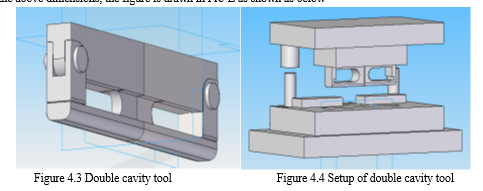

B. Modeling Of Modified Forming Tool

- Total length of the tool : 200mm

- Punch height from top plate : 82mm

- Punch thickness : 16.5mm

According to the above dimensions, the figure is drawn in Pro-E as shown as below

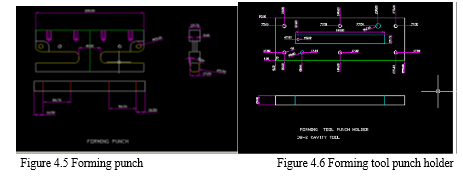

C. Modelling Of Modified Forming Punch & Holder

- It’s used to clamp the Punch

- It’s made up of OHNS (Oil Hardened Non Silicon) material.

- After making operation from Milling, Jig Boring and Surface Grinding, our required size of the forming punch can be obtained.

- After making this component, it should be hardened for to avoid the worn out of the profile.

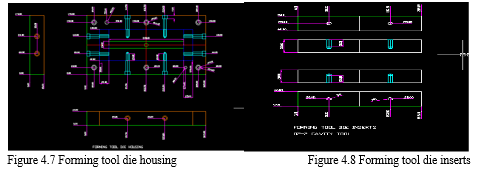

D. Modeling Of Modified Die Housing & Die Insert

It’s made up of OHNS (Oil Hardened Non Silicon) material.

- After making operation from Milling, Surface Grinding, Jig Boring and Heat

- Treated, our required size of the forming tool die inserts can be obtained.

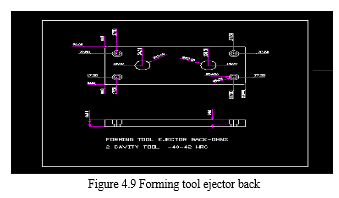

E. Modeling Of Modified Ejector Back

- It’s made up of OHNS (Oil Hardened Non Silicon) material.

- After making operation from Milling, Surface Grinding, Jig Boring and Heat Treated, our required size of the forming tool ejector can be obtained.

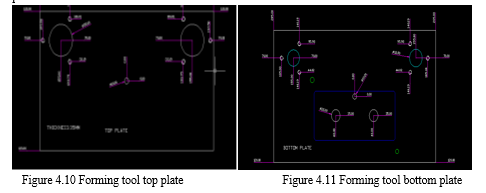

F. Modeling Of Modified Top And Bottom Plate

It’s made up of Mild Steel material.

- By using gas cutting method, cut the shape of the material according to our requirement.

- After cutting the shape, it should be processed under Milling, Surface Grinding and Jig Boring for accurate dimensions and shape of the plate.

V. RESULTS AND DISCUSSIONS

A. PROBLEMS IDENTIFIED FROM SINGLE CAVITY TOOL

- Time is excess for mass production.

- Production ratio is very less.

- There is a high production cost.

- There is no fool proof.

- Component is mixed up while manufacturing the left side and right side component.

B. Problems Rectified After Modification

- Time is low for mass production.

- Production ratio is high.

- There is a low production cost.

- There is fool proof.

- Avoid the mixed of component while manufacturing the left side and right side component.

C. Calculation For Production Cost – Single Cavity

Stroke for one month : 1,04,000 strokes

Then stroke for one day : 4000 stroke (8hrs)

Cost for one stroke : Rs.0.20

Then cost for one day = Cost of per stroke * total stroke for per day

= 4000*0.20

= Rs. 800

Then cost for one month = cost for one day * one month (no.of.days)

= 800*30

The cost for one month = Rs.24,000

D. Calculation For Production Cost – Double Cavity

Stroke for one month : 52,000 strokes

Then stroke for one day : 2000 stroke (4hrs)

Cost for one stroke : Rs.0.20

Then cost for one day = Cost of per stroke * total stroke for per day

= 2000*0.20

= Rs. 400

Then cost for one month = cost for one day * one month (no.of.days)

= 400*30

The cost for one month = Rs.12,000

E. Comparison Results

Table 5.1 Comparison between single & double cavity

|

S NO |

DESCRIPTION |

SINGLE CAVITY |

DOUBLE CAVITY |

|

1 |

Stroke / Month |

104000 |

104000 |

|

2 |

Stroke / Day |

4000 |

4000 |

|

3 |

Cost / Stroke |

0.2 |

0.2 |

|

4 |

Time / Stroke |

7sec |

7sec |

|

5 |

Handling Time |

5sec / job |

6sec / two job |

|

6 |

Total Cycle Time |

12sec |

13sec |

|

7 |

No Of Job / Day |

2240 |

4320 |

|

8 |

Production Rate |

93% |

98% |

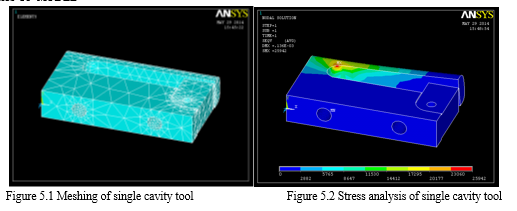

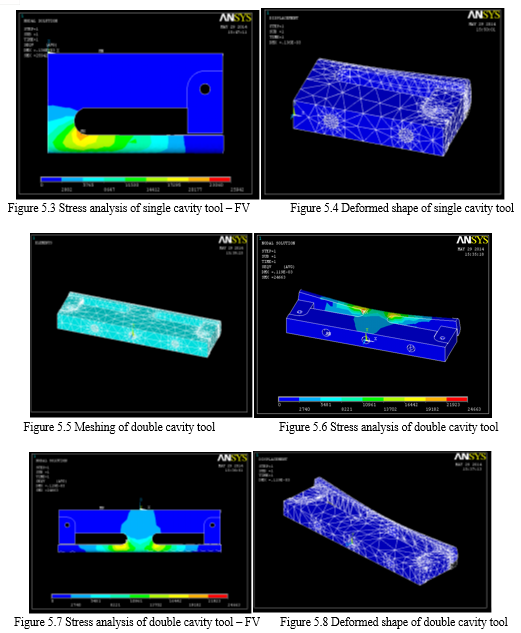

F. ANALYSIS OF MODEL

Table 5.2 Analysis between single & double cavity tool

|

S NO |

DESCRIPTION |

SINGLE CAVITY |

DOUBLE CAVITY |

|

1 |

MATERIAL |

OHNS |

OHNS |

|

2 |

STRESS |

MAX - 25942 N/mm2 |

MAX - 24663 N/mm2 |

|

3 |

DEFORMATION |

MAX - 0.000136mm |

MAX - 0.000119mm |

From the Ansys software, single cavity and double cavity tools are analyzed and the results are shown above table.

- From the table it’s the well-known fact that the double cavity tool to minimize the stress and also deformation.

- So there is no wear occur in the double cavity when loads are acted.

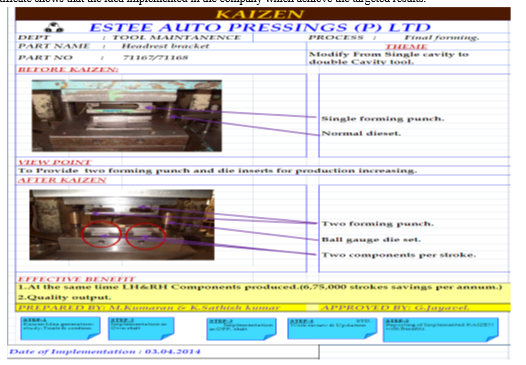

G. Kaizen Implementation

The Toyota Production System is known for kaizen, where all line personnel are expected to stop their moving production line in case of any abnormality and, along with their supervisor, suggest an improvement to resolve the abnormality which may initiate a kaizen. Masaaki Imai made the term famous in his book Kaizen: The Key to Japan's Competitive Success. Apart from business applications of the method, both Anthony Robbins and Robert Maurer have popularized the kaizen principles into personal development principles. In the book One Small Step Can Change Your life: The Kaizen Way, and CD set The Kaizen Way to Success, Maurer looks at how individuals can take a kaizen approach in both their personal and professional lives. In the Toyota Way Field book, Liker and Meier discuss the kaizen blitz and

kaizen burst (or kaizen event) approaches to continuous improvement. A kaizen blitz, or rapid improvement, is a focused activity on a particular process or activity. The basic concept is to identify and quickly remove waste. Another approach is that of the kaizen burst, a specific kaizen activity on a particular process in the value stream

H. Kaizen Certification

Kaizen certificate shows that the idea implemented in the company which achieve the targeted results.

Conclusion

This chapter highlights the summary of information presented in this project that includes discussions of industrial achievement, main findings, advantages and limitation of the varnishing process, and recommendations for future work that can be undertaken. This objective achieved successfully. The summary of project outcomes and their findings are mentioned below. 1) When compared to both the result, the double cavity saves amount of about Rs.12,000 per month 2) Not only that double cavity achieve the production rate of single cavity within 4hours itself. 3) So the double cavity helps to increase the production rate as well as control economically.

References

[1] Jong Jin Park, Yung-Ho Kim, (2003) Fundamental studies on the incremental sheet metal forming technique, Journal of material processing technology, 447-453 [2] Y. H Kim, J. J. Park, (2002) Effect of process parameters on formability in incremental sheet metal forming, Journal of material processing technology 130-131, 42-46 [3] J. Kopac, Z. Kampus, (2005) Incremental sheet metal forming on CNC milling machine tool, Journal of material processing technology, 162-163, 622-628 [4] LI Ju-chao, LI Chong, ZHOU Tong-gui, (2012) Thickness distribution and mechanical property of sheet metal incremental forming based on numerical simulation, TNMS, China , s54-s60 [5] H. Meier (2), C. Magnus, V. Smukala, (2011) Impact of superimposed pressure on dieless incremental sheet metal sheet metal forming with two moving tools, CIRP Annals – Manufacturing technology, 327-330 [6] B. Taleb Araghi, G. L. Manco, M. Bambach, G. Hirt, (2009) Investigation into a new hybrid forming process: Incremental sheet forming combined with stretch forming, CIRP Annals- MT, 225-228 [7] Zemin Fu, Jianhua Mo, Pan Gong, (2009) Mould correction for sheet metal multi step incremental air bending forming based of close loop control and FEM simulation, International Journal of Material Science, 732-740.

Copyright

Copyright © 2022 Jayakanth R, Kandasamy R, Selvaraj G, Kannan P. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET45688

Publish Date : 2022-07-16

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online