Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Review on Development of Thermoelectric Air cooler

Authors: Dr. V. B. Vaidya , Roshan S. Janve, Chetan D. Diwate , Yash A. Mankar, Yash S. Thote , Somnath Mukherjee, Prem S. Ingulkar

DOI Link: https://doi.org/10.22214/ijraset.2022.40610

Certificate: View Certificate

Abstract

With rising global temperatures leading to an increase in average temperatures throughout the year making people living in areas with high power outages very busy and difficult. As a modern cooling system that combines Coolers and Air-conditioners does not work in the inverter for energy-saving purposes which makes them useless thus during high temperature hours. Therefore, in terms of combating the problem with portability, savings and cost-effectiveness in the concept of another climate it uses TEC while using the grid and re-charging. Although it is common knowledge that the efficiency of TEC co-operation is low compared to the air-cooled air cooler used today but with advanced production techniques and forced delivery of cold liquid that increase effective device cooling and humidity control using humidity. suction and capillary tube as a heat sink to reduce heat in the hot sink instead of air fin to reduce the surrounding heat radiation. Basically in this study we tried to increase the performance coefficient of Peltier Module using various techniques. The module also does not save energy, so over time we will not be able to use many or two or three and we need to create a cooling effect. So we keep everything in mind using the right module to achieve the goal and make it a mass production model.

Introduction

I. INTRODUCTION

In 1821, Thomas See-beck discovered that there is a continuous flow of energy when two strands of different elements are joined and burned at the end and French physicist Jean Charles Peltier module discovered the Peltier effect in 1834. He found that the use of a. current in the interaction between two different substances the effect of heat dissipation without the use of ozone depleting chlorofluorocarbons [1]. This provided an alternative to conventional air conditioners. The Thermoelectric phenomenon was discovered more than 150 years ago, but has been tested for commercial use in recent decades, correction is not possible [2].

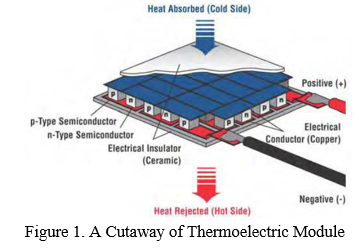

A. Thermo-Electric Effect

The direct conversion of electrical voltage to temperature differences and vice versa with the help of a thermocouple is known as a thermo-electric effect. The voltage is generated by the thermoelectric device due to the temperature differences on each side. Therefore, the applied voltage causes heat transfer from one side to the other which creates a temperature difference. At the atomic rate the difference in temperature used is due to the electrons or holes that separate it from the hot side to the cold side. The thermoelectric effect can be used to generate electricity, measure temperature or can be used to change the temperature of objects. [2] Devices that use thermoelectric electricity do not have temperature controls because heat and cooling depend on the light of the applied voltage.

- See-beck Effect: The electricity produced at the junction of different types of cables due to temperature changes is known as the See-beck effect. In this case the voltage and thermoelectric EMF are created due to the temperature difference of the two different metals or semiconductors resulting in a continuous flow of power to the conductors. The See-beck effect used in a thermocouple to measure temperature differences by setting one part of the known temperature. When more than one thermocouple is connected to a series it is called a thermopile [3].

- Peltier Effect: It occurs due to the presence of heat or cooling in an electrically charged body of two different conductors by a temperature change known as the Peltier effect. The effect will be stronger when two different semiconductors are used instead of conductors in a circuit [3].

- Thomson Effect: Heat absorption occurs due to the flow of electricity per circuit rather than the temperature difference in its length. When heat transfer is forced to produce heat-resistant heat to the currents in the conductors [3].

Technology is used very little compared to steam refrigerator. The main advantage is the lack of movement. So the main advantages of using a thermoelectric cooler.

a. Minor repairs are required because there are no moving parts and we do not use the refrigerator or CFCs.

b. High level of temperature control by changing voltage and current.

c. May not be used in the wrong place for conventional methods.

d. One TEC can create a temperature of 70 ° C between its two sides.

Therefore, if we are able to maintain the temperature of the hot side in the surrounding area or at room temperature then we will be able to produce cooling on the other side of the Peltier module. In refrigeration use, thermoelectric assembly area has 1 / 4th of real Carnot cycle efficiency so it is only used in areas where the solid state exceeds pure efficiency.

So the main motivation for the project lies in the fact that:

- Reduce carbon footprint by producing more efficient, low-resolution cooling equipment.

- Creating a portable device for use on the grid in areas where standard cooling is not a viable option.

- Build a machine that can be easily made and produced in large quantities when needed for poor people who do not have access to electricity other than sophisticated metals.

The experimental study revealed a payment time of 0.75 years compared to 1 ton of refrigeration that sounded beneficial.

II. OBJECTIVES

It is important to note the key aspects of the project and the final outcome of the project. Therefore, it is important to clearly state and accept the purpose of the project. In all this work, these are the objectives that will illuminate this thesis;

- An in-depth study of the air conditioning system for both advantages and disadvantages.

- Exploring various technical options for changing the existing air conditioning system.

- Study TEC instead of the current air conditioning system that will overcome all the problems of the current air conditioning system.

- Develop a working model of the air conditioning system using TEC.

- Evaluate the air conditioning system using TEC for its efficiency, efficiency, environmental friendliness, comfort and convenience.

III. LITERATURE REVIEW

Huang B J and others. [1] designed a thermo electric cooler. Automatic testing machines were designed and built to reflect testing. The results of the module performance test are used to determine the physical properties and determine the thermal performance of the thermoelectric module. These results are then used in the analysis of the thermoelectric refrigerator system using a thermal network model. Heat sink resistance is selected as one of the key parameters in the construction of thermoelectric cooler. System simulations show that there is a very cheap heat sink for the design of the thermoelectric refrigerator.

Wang Huajun et al. [2] developed a low-power electric cooling coolant. From testing they found that the relative humidity had two phases of acceleration and two phases of reduction. This condition is related to the abbreviated behavior of the cold side heat exchanger and they found that there was a difference in the COP by changing the input power and they found a COP of 0.32 and the corresponding humidity level of 0.0097g / min when the input power was maintained at 6 watt.

Dabhi J B, et al. [3] performed experiments on thermo cooling systems and found the following considerations in the design of thermo cooling system. There are 1. System COP is growing with current growth to a certain extent and continues to decline. 2. The COP is reduced by increasing the input capacity. 3. The COP is reduced by increasing the temperature difference by keeping the temperature constant.

Mayank Awasthi et al. [4] designed and developed a 5L thermo electric cooler with a stored temperature of between 5 ?C to 25 ?C. Their purpose is to keep vaccination, medicine, food etc where electricity is not available for a long time. They used a large battery to power the thermo refrigerator and tested equipment with different power sources.

Onoroh Francis, et al. [5] m?de ? therm? ele?tri? refriger?t?r st?red ?t 40 ?. The results ?f th?se tests indi??te th?t the ??? sh?wing the fun?ti?n ?f the therm? ele?tri? system is ? fun?ti?n ?f the tem?er?ture between the s?ur?e ?nd the sink. F?r m?ximum effi?ien?y the tem?er?ture differen?e must be ke?t ?t ? very l?w level.

Rawat M K, et al. [6] designed a 1L thermo power supply, a temperature drop of 110 C from 230 C in 30 minutes and obtained a COP TE refrigerator as 0.1.

Gaurav Maradwar [7] developed a TE Refrigerator and was tested in two ways namely by fans and without fans and concluded that the cooling effect is higher than the TE refrigerator where the refrigerator contains fans due to forced conversion.

Nilesh Varkute et al. [8] has developed a Peltier air-cooled air-cooled coil to achieve dual moisture removal purposes and rational cooling. The work was intended to conduct a Peltier test to cool the house. The air cooling unit provides cooling up to 26 ° C.

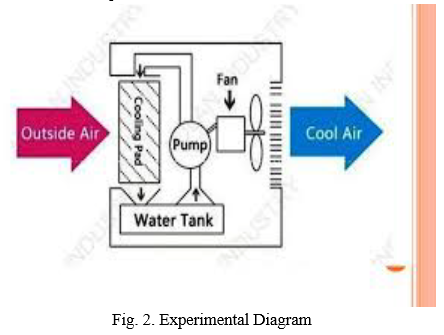

IV. PROJECT DIAGRAM

The performance of a TE cooler is similar to that of a standard cooler. Normal cooling water is distributed without cooling but in this TEcooler water cooled by the setting of the Thermo electric cooling module, this cooling water is distributed over the cooling pad with the help of a pump installed in an aluminum container, for us. the effect of cooling more by circulating cooler water. In the cooling pad of cooling water and warm air from the atmosphere by indirect contact. On the cooling sheet the heat is removed from the air and the cooling air is blown out with the help of fans or blowers.

The test setup shown in Fig. 1 contains the following sections:

- Thermo Electric Module

- Heat sink,

- Protective material,

- Aluminum Sheet and Block,

- Anabond Paste,

- Honey Comb

- MS ubakaki,

- DC fan,

- DC Pump

- Exhaust Fan

V. ADVANTAGES

We believe that thermoelectric cooling offers fewer benefits than traditional cooling methods:

- No moving parts, eliminating vibrations, noise and wear issues.

- No Freon cooler or other liquid or gas is required,

- High reliability and durability.

- Size combined with low weight,

- Low cost compared to high impact,

- Eco-friendly C-Pentane, CFC free installation

- The cooling unit becomes a heater by reversing the current mode.

VI. DISADVANTAGES

- COP is lower than traditional refrigeration systems.

- Only suitable for low cooling capacity.

Conclusion

Thermoelectric coolers are used to remove heat from two watts to a few thousand watts. It can be used for a variety of purposes such as a small refrigerator as large as a submarine. Although TECs are low in health, and their cooling capacity is measured by changes in their AC resistance. But the findings of a product designed in such a way showed a trend that cooling often decreases to higher temperatures which results in the loss of high temperature performance. With the additional problem arising in producing a completely leaky area that is almost impossible for a device with a long cycle while thus leading to certain mechanical problems thus the state of operation of the project is still in the process of being developed due to problems. in production. The following is the future scope of the project: 1) Rust-resistant materials for me selected for easy use of materials such as used aluminum sheets. 2) The need for the development of a highly efficient thermal cooling system to extend the COP of current equipment to compensate for losses in operation at high temperatures. 3) A powerful COP connected to a power controller to increase cooling temperature change with a system power switch.

References

[1] H. B. J. Duang, C. L. Chin, “A design method of thermo electric cooler,” International Journal of Refrigeration, vol. 3, 1999, pp.208-218. [2] W. Huajun, Qi. Chengying, “Experimental study of operation performance of a low power thermo electric cooling dehumidifier,” International Journal of Energy and Environment, vol. 1, no. 3, 2010, pp.25-35. [3] J. B. Dabhi, N. B. Parmar, N. S. Mehta, “Consideration for design of Thermo electric refrigeration system,” International Journal of Advanced Engineering Research and Studies, vol. 1, 2012, pp. 55-62. [4] M. Awasthi, K. V. Mali, “Design and development of thermo electric Refrigerator,” International Journal of Mechanical and Robotics Research, vol. 3, 2012, pp.99-106. [5] Francis, O. Chukuneke, H. Itoje John, “Performance Evaluation of a Thermo electric Refrigerator,” International Journal of Engineering and Innovative Technology, vol. 2, 2013, pp.11-16. [6] Rawat, M. K. Himadri Chattopadhyay, S. Neogi, “A review on developments of thermoelectric refrigeration and air conditioning systems: A novel potential green refrigeration and air conditioning technology,” International Journal of Emerging Technology and Advanced Engineering, vol. 3, 2013, pp.115-124. [7] G. Maradwar, “Fabrication and Analysis of Problems in Thermoelectric Refrigerator,” International Journal of Core Engineering and Management, vol. 1, 2014, pp.72-77. [8] N. Varkute, N. Akshay Chalke, Deepak Ailani, Ritesh Gogade, Ajay Babaria, “Design and Fabrication of a Peltier Operated Portable Air Cooling System,” International Research Journal of Engineering and Technology, vol. 3, 2016, pp.1-6. [9] Signe Kjelstrup,“Dissipated Energy In The Aluminum Electrolysis”,Hydro Aluminum Technology Center, 467-474,(1998). [10] “Thermoelectric Solar Refrigerator” By Sandip Kumar Singh, Arvind Kumar ISSN (Online):2349-6010.

Copyright

Copyright © 2022 Dr. V. B. Vaidya , Roshan S. Janve, Chetan D. Diwate , Yash A. Mankar, Yash S. Thote , Somnath Mukherjee, Prem S. Ingulkar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET40610

Publish Date : 2022-03-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online