Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

The Effect of Elevated Temperatures on the Behavior of Concrete Material

Authors: Ms. Harsha R. Dhabale, Prof. Deepa Telang

DOI Link: https://doi.org/10.22214/ijraset.2023.49123

Certificate: View Certificate

Abstract

The purpose of this study was to provide an overview of the effect of elevated temperature on the behavior of concrete materials. The effects of elevated temperatures on the properties of common portland cement concretes and manufacturing materials are summarized. The effect of elevated temperature on conventional concrete, GGBS concrete and BFS concrete is considered and the performance is compared with the strength of conventional concrete. Concrete in case of an unexpected fire, the properties of the concrete will change after the fire. The building must be designed to withstand high temperatures and also mainly fire. When exposed to high temperatures, such as during a fire, the mechanical properties of concrete such as strength, modulus of elasticity and volume stability are significantly reduced. Concrete structure is exposed to high temperatures, it degrades in many different ways, such as color, compressive strength, elasticity, and high temperature affects concrete density and surface appearance.

Introduction

I. INTRODUCTION

The behavior of concrete at high temperatures is influenced by several factors, such as the speed of temperature rise and the type and stability of the aggregate. Sudden changes in temperature can cause spalling and cracking due to thermal shock, and aggregate expansion can also damage concrete [1]. High temperatures also affect the compressive strength of concrete. Above 212ºF, the cement paste begins to dry out (lose chemically bound water of hydration), which gradually weakens the bond between the paste and the paste material. The temperature that concrete often reaches can be determined by observing the color changes in the aggregate. For example, limestone materials turn pink when their temperature reaches about 570º F, which can cause a significant reduction in compressive strength [2]. The thermal properties of concrete are more complex than most materials, because the performance of portland cement-based materials at high temperatures is very difficult, and it is difficult to characterize concrete as a composite material with different properties in its composition, but its properties. also depends on . to ensure moisture and porosity. Exposure of concrete to high temperatures affects its mechanical and physical properties. The changes in properties are due to three processes that occur at high temperatures [3]: phase transformation (eg, loss of free water at approximately 100 ?C, decomposition of calcium hydroxide at approximately 50 ?C, and quartz crystal transformation at 573 ?C. ?C from C temperature - to form), pores structure development (eg, pore volume and surfaces increase to the temperature of an accidental fire, etc.) causes severe damage and undergoes a series of changes and reactions, thus causing a gradual degradation of the cement gel structure, reduced durability, increased tendency to drying and shrinkage, structural cracks and associated overall discoloration [4].

Fire safety measures of structural parts are measured by fire resistance, which is the time during which a structural part lasts in terms of structural integrity, stability and temperature permeability. Concrete generally offers the best fire resistance properties of all building materials. This superior fire resistance is due to the constituents of concrete (ie, cement and aggregates) which, when chemically combined, form an essentially inert material with low thermal conductivity, high heat capacity, and slower loss of strength with temperature. It is this slow rate of heat transfer and loss of strength that allows concrete to act as an effective fire protection not only between adjacent rooms, but also to protect itself against fire damage [5].

The behavior of a concrete structural part exposed to fire depends partly on the thermal, mechanical and deformation properties of the concrete from which it is composed. As with other materials, the thermophysical, mechanical and deformation properties of concrete change significantly in the temperature range associated with construction fires. These properties vary with temperature and depend on the composition and properties of the concrete. The strength of concrete significantly affects its properties both at room and high temperatures. The properties of high strength concrete (HSC) vary with temperature unlike normal strength concrete (NSC). This variation is more pronounced in the mechanical properties, which are affected by strength, humidity, density, heating rate, amount of silica fume and porosity [6].

II. PROBLEM DEFINITION

- Replacement of cement and coarse aggregate with GGBS and BFS increases slack strength. Thus, it is not suitable for massive or rapid construction where early strength is required. e.g. Sidewalk construction.

- Additional costs of quality control. Slow and low hydration, not suitable for prefabricated plants or winter concreting.

- The pore structure becomes coarser.

- Faster carbonation rate reduced service life due to enhanced corrosion. Poor workability and cohesion in fresh concrete.

III. OBJECTIVE

The objectives of the proposed work are as follows:

- The objective of the experimental investigation is to check the effect of different high temperatures on the modulus of elasticity of concrete.

- Evaluate the effect of high temperatures on the elastic layer of conventional concrete at different temperatures.

- To investigate the actual behavior of concrete when cement is replaced by ground blast furnace slag and coarse aggregate by blast furnace slag in different percentages.

- Determines the modulus of elasticity of M-25 grade concrete by replacing cement with ground blast furnace slag (GGBS) and coarse aggregate with blast furnace slag at 10, 20 and 30%.

IV. LITERATURE REVIEW

- Qifang Xie et al. [1] prepared 75 prism samples and divided into four groups (three carbonized groups and one non-carbonized group). The samples were tested at different temperatures (20, 300, 00, 500, 600 and 700 °C), exposure times (3 and 6 h) and cooling methods (water and natural cooling). The surface properties, weight loss and residual mechanical properties (strength, initial modulus, peak and compressive stresses) of the aerated concrete samples were investigated after high temperatures and compared with those of non-aerated samples. The results show that the weight loss of the aerated concrete samples is slightly lower than that of the non-aerated concrete samples, and the cracks increase with increasing temperature. Surface colors of aerated concrete change significantly, but they are not sensitive to cooling methods. When the temperature reaches 100 °C, surface cracks are clearly visible in the carbonized samples. The residual compressive strength and initial modulus of air-entrained concrete after natural cooling are usually higher than those cooled with water. The peak and ultimate compressive stresses of both aerated concrete blocks and aerated concrete blocks increase after heating, but the values ??of the latter are higher than those of the former. Finally, a constitutive equation to predict the compressive behavior of air-entrained concrete after high temperatures was established and confirmed by tests.

- Krishna et al[2] proposed to consider the high temperature exposure behavior of three different concretes M20, M5 and M60. The samples were kept at a high temperature of 100-900 C and cooled by various methods. The greatest deterioration of mechanical properties was observed in the temperature of 100-600 C. High strength concrete has been found to be more vulnerable than normal strength concrete. Mathematical models describing the variation of different mechanical properties of concrete were developed and explained.

- Tiwary et al.[3] The purpose of the experiment was to see how elevated temperature affects the residual properties of concrete, including flexural strength, compressive strength, tensile strength, static and dynamic elastic layer, water absorption, mass loss and ultrasonic pulse velocity. Typical fire behavior of concrete was studied at temperatures of 2000C, 3000C, 6000C, 8000C and 10000C. This study investigated the effects of two cooling methods, annealing and hardening, on the residual properties of concrete after exposure to high temperatures. Replacing up to 10% of cement with marble dust and fine sand when the concrete is exposed to temperatures up to 100? does not affect the behavior of the concrete. However, at temperatures above 100 ?, the decomposition of concrete containing marble dust and foundry sand causes rapid deterioration of the residual properties of concrete, especially due to replacement of more than 10%.

- Jayswal et al.[4] proposed to investigate the effect of temperature on the stress-strain response under monotonic compressive loading for a mixture of two blended high-strength concretes (HSCs, namely high-calcium fly ash HSC (FCHSC) and alkophene-blended HSC (AL-HSC) ). Experimental studies were performed on a 100 mm æ 100 mm æ 100 mm cube specimen and tested after 28 days of curing. Four sets of samples were considered for each mixture, including the control sample and those kept at elevated temperatures of 80 °C, 10 °C and 160 °C for 6 h. The stress-strain behavior of HSC alloys at high temperatures clearly shows the effect of material composition. Increasing the exposure temperature increases the peak voltage of AL-HSC, while it first decreases and then increases for FC-HSC. The results of the study confirm that the elevated temperature contributes to the stiffening of the peak area, but the effect on the peak tension is influenced by the material composition. The effect of elevated temperature on the microstructure change is evaluated by thermogravimetric analysis and the results of FC-HSC and AL-HSC are compared. The weight loss (30160 ¯C) representing the decomposition of calcium silicate hydrate (CSH) decreases with increasing exposure temperature for FC-HSC, while it remains within the range of AL-HSC. On the other hand, the weight loss representing the decomposition of calcium hydroxide (CH) (00500 ¯C) remains within a limited range for FC-HSC, while it increases with increasing exposure temperature for AL-HSC. The observed results suggest that increasing the exposure temperature promotes the degradation of CSH in FC-HSC, while it increases the formation of CH in AL-HSC. The research results provide useful information about the effect of elevated temperature on the stress-strain behavior of HSC mixed with fly ash and alcofin.

- Lin et al. [5] This paper presents a comprehensive review of recent research on the fire resistance of FRC 13. In particular, temperature-dependent mechanical properties of 1 steel fiber concrete, polypropylene fiber concrete, and hybrid steel-reinforced concrete are discussed, including of permeability, cracking, compressive strength 16, tensile strength, modulus of elasticity, durability, and mass loss. In addition, 17 currently available FRC residual property prediction equations 18 are summarized and compared.

- Hiraskar et al.[6] suggested that blast furnace slag from the local industry was used in the study to find out its suitability as a coarse aggregate in concrete production. The complete or partial replacement of natural aggregates with slag would result in significant environmental benefits. The results show that the unit weight of Masuunikuona aggregate concrete is lower than that of traditional aggregate concrete. The test result shows that replacing a few percent of natural aggregates with slag aggregates causes a negligible strength reduction. The compressive strength of blast furnace slag aggregate concrete at the age of 90 days was found to be higher than that of conventional concrete. It also reduced water absorption and porosity by more than 28 days compared to conventional concrete using crushed stone as coarse aggregate.

- Singh et al.[7] The present experimental work investigates the applicability of GBFS using natural sand and GGBS as a substitute for cement in concrete. Concrete cubes are manufactured and their compressive strength is tested for M30 concrete. Thus, it can be concluded that GGBS and GBFS can partially replace cement up to 55% and grind up to 50% in concrete without affecting their compressive strength. In this way, carbon dioxide emissions and concrete costs are reduced by 20.25%.

- Chaithra et al.[8] The work deals with the effective use of waste material in the production of concrete as a partial substitute for cement and sand. For quality mix M0, cement is replaced by GGBS at 30%, 0% and 50% of the cement mass, quarry sand at 10%, 50% and 60% of the cement mass. The workability test was performed on the fresh concrete properties, while the hardened concrete was tested on compressive strength, splitting tensile strength and flexural strength. It was found that the partial replacement of cement with GGBS and sand with quarry sand significantly improved the strength of concrete compared to plain mixed concrete. The compressive strength test was performed at 7, 28 and 56 days, while the flexural and split tensile test was performed with a 28-day healing period.

- Marshall et al.[9] The research paper describes the usefulness of GGBS as a partial substitute for cement in the production of self-compacting concrete. GGBS can be used as filler and helps to reduce voids in self-compacting concrete. Standard fly ash is also used in all mixing ratios to increase the powder content to achieve workability. Cement is replaced by GGBS at 0%, 25%, 30%, 35% and 50% of the cement weight for M-30mix, respectively. After repeated mixing of test mixes, the water/cement ratio (w/c) was chosen as 0.0. The compressive, cracking and flexural strength of self-compacting concrete mixtures were prepared, tested and compared with conventional concrete at 7, 1, 28 days. It was found that 25% of GGBS can be replaced and the resulting strength is comparable to conventional concrete.

- Zhang et al.[10] The research examines the effects of individual factors such as stress damage and high temperature and their combinations on the neutralization of concrete structures in order to assess the durability of concrete structures under adverse environmental conditions and to promote the practical use of concrete structures. of concrete with fly ash as a fine aggregate (CFA). The carbonation speed test was used to determine the carbonation depths at different carbonation times and to evaluate the carbonation resistance of the concrete. The results show that the carbonation depth of concrete increases with increasing initial stress damage and carbonation time. In addition, the replacement of fine aggregate with fly ash can improve the carbonation resistance of concrete compared to regular concrete. At high temperatures, the neutralization of concrete is significantly weakened, and the durability of concrete decreases further as the temperature rises. The deterioration of the durability of concrete exposed to the combination of high temperature and stress damage is significantly greater than that of a single factor, which greatly reduces the carbonization resistance of concrete, especially for ordinary concrete.

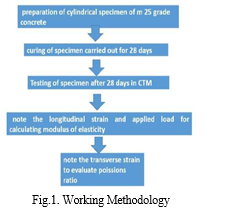

V. BLOCK DIAGRAM

- All the results, including the quality of the materials used in the concrete. It contains information about the different types of tests and their ingredients.

- Test results used to determine concrete mix design for M25 grade concrete. Results such as impact value test, crushing value, specific gravity, sieve analysis, hardened concrete compressometer.

- In addition, it provides the quality of materials, test methods for these materials, and results of tests used in the design of various concrete mixes. In addition, the modulus of elasticity of traditional concrete and its change due to different exposure conditions and their comparison between GGBS-based concrete and BFS-based concrete are presented. Finally, compare the weight of concrete due to exposure to temperature.

Conclusion

The compressive strength of concrete decreases with increasing temperature due to the large dehydration of calcium hydroxide in cement and increased water vapor, which leads to a decrease in strength. In addition, moisture reduces weight when the temperature rises. These are known facts from previous studies. However, the purpose of this study is to obtain a numerical database for Class 0 concrete, which was not included in the previously mentioned work, to guide the design of prefabricated equipment for this class of concrete. For example, at a recommended design age of 28 days for concrete grade 0, a strength loss of 53.7% and a weight loss of .67% at 30 oC were studied. They point to the fact that more research is needed on high-temperature concrete to guide the proper design of facilities where high temperatures are required in places such as nuclear reactor vessels and fire-prone buildings..

References

[1] Xie, Qifang, et al. \"Effects of high temperatures on the physical and mechanical properties of carbonated ordinary concrete.\" Advances in Materials Science and Engineering 2019 (2019). [2] D KRISHNA, A. N. U. P. A. M. A., R. S. Priyadarsini, and S. Narayanan. \"High temperature effects on different grades of concrete.\" S?dhan? 46.1 (2021): 1-12. [3] Tiwary, Aditya Kumar, et al. \"Effects of Elevated Temperature on the Residual Behavior of Concrete Containing Marble Dust and Foundry Sand.\" Materials 15.10 (2022): 3632. [4] Jayswal, S., & Mungule, M. (2022). Effect of temperature on stress strain behavior of high calcium fly ash and alccofine blended high strength concrete. Materials Today: Proceedings. [5] Wu, Heyang, Xiaoshan Lin, and Annan Zhou. \"A review of mechanical properties of fibre reinforced concrete at elevated temperatures.\" Cement and Concrete Research 135 (2020): 106117. [6] Hiraskar, K. G., and Chetan Patil. \"Use of blast furnace slag aggregate in concrete.\" Int. J. Sci. Eng. Res 4.5 (201 [7] Singh, Ashita, et al. \"The study on optimization of cement and fine aggregate by blast furnace slag in concrete.\" AIP Conference Proceedings. Vol. 2158. No. 1. AIP Publishing LLC, 2019. [8] Chaithra, H. L., K. Pramod, and A. Chandrashekera. \"An experimental study on partial replacement of cement by GGBS and natural sand by quarry sand in concrete.\" Int J Res Appl Sci Eng Technol 3.4 (2015): 1539-1544. [9] Raman, J. Vengadesh Marshall, and V. Murali Krishnan. \"Partial Replacement of Cement with GGBS in Self Compacting Concrete for Sustainable Construction.\" SSRG Int. J. Civ. Eng 4 (2017): 22-25. [10] Zhang, Dongsheng, et al. \"Carbonation performance of concrete with fly ash as fine aggregate after stress damage and high temperature exposure.\" Construction and Building Materials 242 (2020): 118125.

Copyright

Copyright © 2023 Ms. Harsha R. Dhabale, Prof. Deepa Telang . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET49123

Publish Date : 2023-02-15

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online