Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Review Paper on Effective Methods for The Retrofitting of Reinforced Concrete Structures

Authors: Shloka Awari, Khushali Ekbote, Ashlesha Patange , Anushka Surve, Shilpi Bhuinyan, Uttam R Awari

DOI Link: https://doi.org/10.22214/ijraset.2022.44203

Certificate: View Certificate

Abstract

Existing structures are retrofitted to make them more bearable for earthquakes, earth motion, and other natural disasters. Many existing reinforced concrete elements throughout the world are in desperate need to be rehabilitated, repaired, or replaced due to degradation caused by a variety of causes such as corrosion, lack of detail, and failure of beam-column joint bonding, among others. The construction industry has embraced Fibre Reinforced Polymer (FRP) composites as a promising alternative for repairing and strengthening RCC structures. This study observes reinforced concrete beams that have been externally retrofitted with FRP. The goal of this research is to summarise the behaviour beams after they have been retrofitted with FRP. The main objective of the research is to repair structurally weak elements and make them useful in flexure and shear.

Introduction

I. INTRODUCTION

Concrete element disintegration is the main problem for the infra works and bridge industries all over the world. Corroded steel issues, slow loss of strength with aging, high-intensity loading, freeze-thaw cycles, temperature variations, contact with chemicals and saline water as well as exposure to UV radiations are all factors that contribute to the deterioration. This issue, together with structural code modifications required to account for this natural phenomena earthquakes, and environmental disintegrating factors, necessitates the development of viable structural retrofit solutions. Repair/retrofit or demolition/reconstruction are the two choices for structural retrofit. Usually, the latter has been the preferred option. Due to shifting economic and social views against established systems, this solution has become increasingly undesirable. Retrofitting is a method by which we add special functions to existing structures, like heritage sites, bridges, temperature variations, etc. It helps to reduce the vulnerability of damage in case of natural disaster or seismic activity. Retrofitting is done so that the deteriorated concrete structure regains its strength. It also helps to prevent upcoming distress in the elements. This deficiency in the strength of the element could be because of design faults or poor workmanship. There could be another cause for the deterioration like the aggression of harmful agents. Given that most of the buildings need to be retrofitted, therefore it is necessary to provide perfect and practical strategies to safeguard the country's national capital as well as prevent human loss. Hence, once the proper method of retrofitting is prepared and specified, then the required capacity for the concrete element could be regained and it totally depends on the intensity of the damage that happened. This change that can regain sufficient safety and protection against such harmful actions is described as retrofitting.

A. The Significance of Structural Retrofitting

Retrofitting is required to improve the performance of structures that have lost strength due to degradation or have reached the end of their expected life. Repair, refit, refurbishment, and even partial reconstruction are all part of the process. Retrofitting's success is determined by the root cause and the actions taken to prevent further deterioration.

The structures listed below must be assessed and retrofitted.

- Buildings whose serviceability or strength are insufficient to meet the requirements of structural rules or regulations due to overuse, poor maintenance, or aging materials and constructions.

- Buildings with quality or safety issues as a result of design errors or poor construction quality. These issues are common in both new construction and existing structures.

- Structures damaged by disasters such as earthquakes, high in behaviour, and other natural disasters.

- Those historic and memorial structures need to be restored and preserved.

- The structures that will be renovated or have new stories added to them.

II. LITERATURE REVIEW

FRP is now being researched and used for the repair works and strengthening works of concrete elements all over the world. When compared to other repair materials, strengthening with FRP in the form of external reinforcement is of great involvement because of its better performance, such as high strength, stiffness as well as ease of its installation. The materials' non-corrosive and non-magnetic properties, as well as their chemical resistance, make FRP a suitable choice for external reinforcement. Many Researchers have studied flexural and axial RC members, which consists of FRP composite, strengthening technique, experimental study, failure behavior, analytical analysis, failure behavior, and analytical prediction.

Steel-concrete composite jackets incorporating steel fiber are utilized as a part of a new approach for upgrading reinforced concrete beams. Steel fiber-reinforced composite jackets were found to be the late formation of the first crack in concrete and the yield of steel rebars along with confinement, as well as increase the beam's energy absorption capacity depending on the amount of steel fiber used, [1].

The strengthening process of beam element, which is not containing the ability towards shear resistance when the structure faces sudden strokes such as earthquakes. The retrofitted beams were wrapped with CFRP of 0.317N/mm2 thick and fixed externally by epoxy resin and hardener in the scale of 1:5. The beam weak in shear concept was achieved by minimizing the percentage of shear reinforcement.

The failure behavior of beams and ultimate shear load carrying capacity were observed, [2]. Powder Concrete used as a retrofitting material and Nitobond EP epoxy adhesive are for bonding new concrete with previously stored and no deboning is observed during the experimental investigation to achieve a higher ultimate load, [3]. Muktar Nuhu Danraka et. al has considered various aspects like surface preparation, finite element (FE) simulation, adhesive curing, fatigue performance, and the failure modes of RC beams strengthened with FRP as well.

This method eliminates or reduces the crack development length rate, delays initial cracking, minimizes the stiffness decay with residual deflection, and exceeds the fatigue life of RC beam elements. The best-suited strengthening option in t, in this case, is re-stressed carbon fiber-reinforced polymer (CFRP), [4].

Hu Ying et.al has performed a study on the influence of two retrofitting methods on the behavior of RC beams after the strengthening process. The conventional anchorage method covered adhesive bonding with epoxy and bolting by using anchoring rods or by bolts.

This technique is capable of creating a fully-bonded composite system against bending actions under loading conditions. In a comparison of this with the traditional anchorage system, it is more likely to eliminate the gap span against the deboning failure between both structural components, [5]. J.Jose et.al used GFRP. At that time, observation was the relationship of stress-strain of GFRPs is linear to failure.

The strength of certain GFRP exceeds that of conventional steel. Moreover, it is cost efficient. Therefore, a detailed analysis is done of its properties by retrofitting beam elements. There was an exceedance of the shear load by 9%- 14% and an increase in the flexure by 10%-14%, [6].

Poorna Prasad Rao et.al, investigated Retrofitting of reinforced concrete beams using Rubberized coir fiber, a natural laminate, in both flexure and shear which is subjected to two-point loading.

The test results illustrated that the stiffness of the RCFS retrofitted elements are greatly increased compared to the control beam elements and also the deflections of retrofitted beams were decreased predominantly at the early stages of loading conditions. The ultimate load at failure of the specimen was increased.

Consuelo Beschi et.al studied the effects of HPFRC jacketing on beam-column joint behavior are analyzed, and the experimental results are compared to evaluations of the strength of the retrofitted elements according to the new Italian code, and to the response of the base elements.

The test demonstrated that, with the application of high performance jacket, it is possible to remarkably increase the bearing capacity of the column and the strength of the beam column joint, reaching also an adequate level of ductility with very little visible damage [7].

III. METHODS OF RETROFITTING

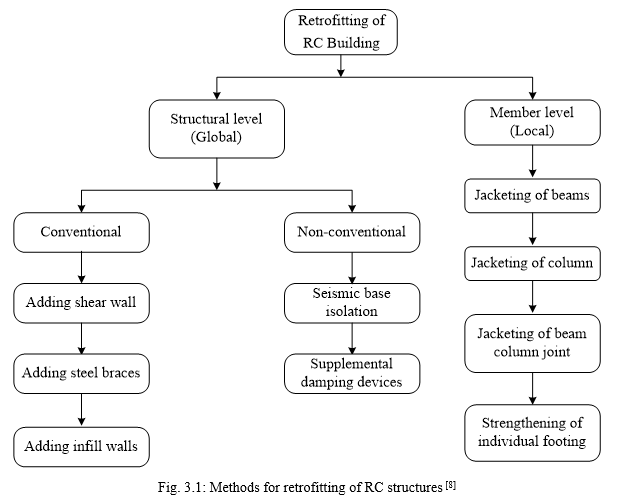

The general methods adopted for retrofitting of RC building are shown Fig. 3.1. As that current study, by Xilin Lu [8], is more focused with local level retrofit, a couple of the approaches employed for the same are addressed below.

- Fibre-reinforced Plastic Bonding Technique: A construction technique in which aramid fibres, carbon fibres, glass fibres, or other continuous fibre (continuous fibre sheets, etc.) are bonded to the concrete outer section, bonding to the existing elements to form a composite configuration, then an organic or other material coating is applied on top, both to prevent the entry of carbon dioxide, chloride ions, and moisture, so on, and to improve performance. FRP improves the shear capability of reinforced concrete elements and increases the ultimate load-carrying capacity of reinforced concrete elements.

- Rubberised Coir Fiber sheet Method: Retrofitting the beams is done with rubberized coir fibre sheet (RCFS). The sheet's physical look is brown in colour. The sheet has a weight of 1 kg/m2, a load of roughly 75 kg/m2, and a thickness of 6 mm.

- Steel Plate Bonding Method: The Steel plates are applied to the outer side of the section of concrete to compensate for inadequacies in the primary or distribution reinforcing of existing beams; these bond to the already existing members to be a composite configuration to gain the desired performance increase. This approach is utilized to construct decks and nearly every other structure concrete.

- Fibre-reinforced Plastic Jacketing Technique: To achieve the desired performance enhancement, continuous fibre sheets, and other fibre materials are applied constantly around existing column members, etc. with insufficient loading capability, and bonding of existing elements to produce a combined configuration. Bridge piers, for example, are constructed using this method. Reactive Powder Concrete method: RPC is an ultra-high-strength concrete prepared by substituting quartz powder, steel fibers, silica fume, and other materials for the typical aggregate in regular concrete. RPC has a high ductility as well as a high strength. It has a value of compressive strength of 200 to 800 MPa. Cement, sand, silica fume, quartz powder, and steel fibres are the main components of reactive powder concrete.

- Continuous Fibre pre-stressing Materials: Continuous fiber retrofitting members that can be used as prestressing materials are referred to as continuous fibre retrofitting members. Uni-directional reinforcing created by impregnating these continuous fibres with fibre adhesiveness and allowing it to cure for use in concrete reinforcement, as well as bundled or woven continuous fibers, are referred to as "continuous fiber reinforcing materials."

- External Cable Method: To achieve the desired performance improvement, prestressing materials are placed on the external side of the concrete to impart tensile force to the members through an anchorage section or deviator. Those pre-stressing materials can be utilized for the external cable construction technique, in which the prestressing materials are placed on the exterior of the concrete, from concrete prestressing steel or continuous fiber pre-stressing materials. Internal cables are those pre-stressing materials that are installed on the inside of the concrete and are made of concrete stressing steel or continuous fiber pre-stressing materials. Depending on whether or not they are bound to the concrete, these are classified as bonded or un-bonded.

- Anchorage Section: The portion of the Prestressing force transmission system in which anchorage parts are fastened to concrete parts. These are prepared of the anchorage parts and the fastening elements.

- Fibre-reinforced Plastic Jacketing Method: Continuous fiber materials are applied continuously to the whole periphery of the existing column, etc. with insufficient load taking to the existing elements to produce a composite configuration to accomplish the desired improvement of performance. Bridge piers, for example, are constructed using this method. Fiber-reinforced plastic is also known as fiber-reinforced polymer, is a composite material consisting of a matrix of polymer reinforced with fibres. Glass (in fibreglass), carbon aramid, or basalt are common fibers. Other fibres, such as paper, and asbestos or wood, have been utilized rarely. Although phenol formaldehyde resins are still used, the polymer is commonly an epoxy, vinyl, or polyester thermosetting plastic.

- Continuous Fibres Sheet: Continuous fibers organized in one or two directions to be a sheet are used to reinforce materials. Fiber-reinforced can also be made by impregnating continuous fibres with impregnation glue and allowing them to become hard.

IV. DISCUSSIONS

The materials mainly used for retrofitting for any RC members are GFRP, CFRP, RPC, rubberized coir fiber sheets, direct shear anchorage, steel fiber reinforced composite jackets, etc. But the most economical solution for retrofitting is by using FRP. In FRP, GFRP is more economical as compared to the other different types of FRP and CFRP provides more ultimate load capacity for beams. Hence it’s clear that in this technique, the beam retrofitted with a 20 mm thick lay over of RPC is able to regain the attained original strength whereas a 10 mm overlaid beam fails to gain its original strength when compared with controlled beam element.

Conclusion

For strengthening of R C members the material used are chemical-based, hence the research can be extended to understand the effects of FRP on the durability aspects. The Conclusions of using FRP systems can be stated as follows. 1) Easy in application and do not need large number of labour. 2) Corrosion proof. 3) Easy to transport and easily rolled and stored. 4) Higher ultimate tensile strength and Young’s modulus. 5) Negligible and practically no extra weight or volume is added which helps in space management. 6) High fatigue resistance. 7) Light weight, hence very high strength to weight ratio.

References

[1] M. Shadmand, A. Hedayatnasab, O. Kohnehpooshi, “Retrofitting of Reinforced Concrete Beams with Steel Fiber Reinforced Composite Jackets”, International Journal of Engineering Application, May 2020, pp 770-783 [2] P. Vijaya Kumar, P. Poluraju, “Retrofitting of Flexural Deficient Beams Using CFRP”, International Journal of Recent Technology and Engineering, Volume-7, Issue-6C2, April 2019, pp 6-11. [3] S Karthik and Karthik Sundaravadivelu “Retrofitting of Reinforced Concrete Beams using Reactive Powder Concrete (RPC)”, IOP Conf. Series: Earth and Environmental Science 80 (2017) 012038, pp 1-9. [4] Muktar Nuhu Danraka, H. Mahir Mahmod, Ojo-kupoluyi Job Oluwatosin, ‘Strengthening of Reinforced Concrete Beams using FRP Technique: A Review”, International Journal of Engineering Science and Computing, June 2017, pp, 13199-13213. [5] Hu Yinga , Pang Huawei,Quan Xueyoua,Pang Junc , Luo Xiancunc , Pang Qiyuna , Liu Bao, “Performance of Reinforced Concrete Beams Retrofitted by a Direct Shear Anchorage Retrofitting System” 6th International Workshop on Performance, Protection & Strengthening of Structures under Extreme Loading, protect2017, 11-12 December 2017, Guangzhou (Canton), China ,pp 132-140. [6] Poorna Prasad Rao, RamaMohan Rao, “Retrofitting of Reinforced Concrete Beams Using Rubberized coir Fibre Sheets”, International Journal Of Civil Engineering, 2016, pp 20-27. [7] Consuelo Beschi,Alberto Meda, Paolo Riva, “Beam-Column Joint Retrofitting with High Performance Fiber Reinforced Concrete Jacketing”, Applied mechanics of materials,july2011, pp 572-582. [8] Xilin lu (2010), “Retrofitting design of building structures”, Science Press, New York.

Copyright

Copyright © 2022 Shloka Awari, Khushali Ekbote, Ashlesha Patange , Anushka Surve, Shilpi Bhuinyan, Uttam R Awari. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET44203

Publish Date : 2022-06-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online