Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Enhancement of Cooling Capacity of Refrigerant R-134a through the Addition of CuO and Silica Nanoparticles

Authors: Amit Singh Tomar, Amit Agrawal

DOI Link: https://doi.org/10.22214/ijraset.2023.54242

Certificate: View Certificate

Abstract

This study investigates the cooling capacity enhancement of refrigerant R-134a by dispersing copper oxide (CuO) and silica (SiO2) nanoparticles in the base fluid. The nanoparticles were mixed at different concentrations, and their effects on the thermophysical properties and heat transfer characteristics of R-134a were evaluated. Experimental results demonstrated that the addition of CuO and SiO2 nanoparticles significantly improved the cooling capacity of R-134a, highlighting the potential of nanofluids in enhancing refrigeration systems. The demand for efficient and environmentally friendly refrigeration systems has led to extensive research in the field of nanofluids. This study investigates the cooling capacity enhancement of refrigerant R-134a by dispersing copper oxide (CuO) and silica (SiO2) nanoparticles in the base fluid. The nanoparticles were mixed at different concentrations, and their effects on the thermophysical properties and heat transfer characteristics of R-134a were evaluated. Experimental results demonstrated that the addition of CuO and SiO2 nanoparticles significantly improved the cooling capacity of R-134a, highlighting the potential of nanofluids in enhancing refrigeration systems.

Introduction

I. INTRODUCTION

Refrigeration is a vital process used in various industries, including HVAC, automotive air conditioning, and food preservation. The efficiency and performance of refrigeration systems greatly depend on the choice of refrigerant. Traditional refrigerants like R-134a, though widely used, have certain limitations, including lower heat transfer coefficients and lower cooling capacities. Therefore, the integration of nanotechnology into refrigeration systems has gained attention as a promising approach to enhance their efficiency. This research aims to investigate the impact of CuO and SiO2 nanoparticles on the cooling capacity of R-134a.

II. METHODOLOGY

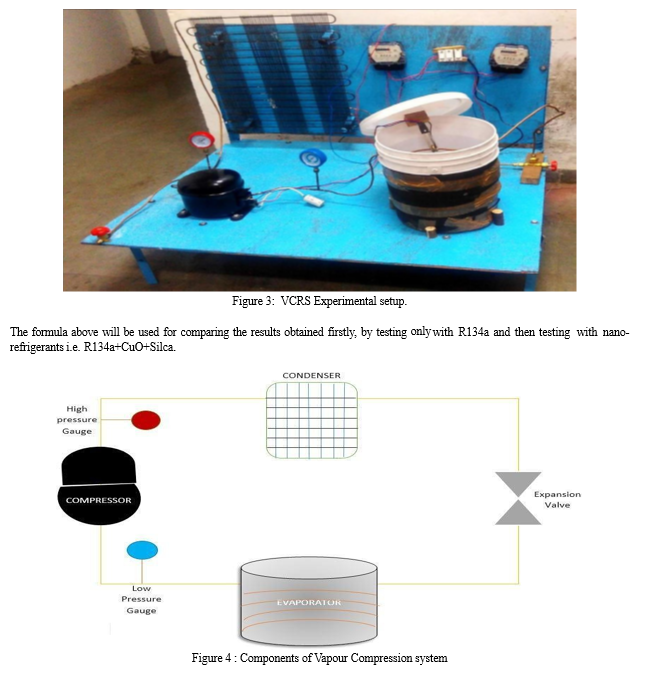

Nanofluid Preparation Copper oxide (CuO) and silica (SiO2) nanoparticles were selected due to their thermal conductivity and stability. The nanoparticles were synthesized through a suitable method and characterized using techniques such as X-ray diffraction (XRD) and scanning electron microscopy (SEM). The nanoparticles were dispersed in R-134a using a two-step mixing method to ensure homogeneity. This portion of the paper describes the testing and condenser quality experiments I conducted. I served as the foundation for the choice utilizing information from the Performance Enhancement of Refrigeration System by utilizing Copper Oxide Nano Particles equipment that was used. According to their requirements, the industry may select testing of nano-particles refrigerant (R134a+CuO+Silca) into the system machine data, which is beneficial. The machine's use and functionality are the basis for this certification. They employed the Taguchi Method to finalize the machine's specification in line with their demands after choosing a decent machine. Any experiment may be carried out using a number of techniques, and the outcomes can also vary widely.

There are several ways to approach this issue. a range of strategies. The procedures listed below can be used to carry out experiments and determine their results.

- Made the decision to run the experiment using the given parameters.

- Based on the literature review investigation, pick the basic metal (R134a+CuO+Silca) first.

- The experiment looks for effects of the process parameter on the result. - Minitab Software optimizes the process parameter using experiment data. - The findings of the testing of the experiment's required item were documented for a later study and scope.

- The outcomes of the two comparisons ultimately identify the ideal process parameter.

A. Pareto Low

The concept was developed by an economist from Italy named Vilfredo Pareto. Pareto noted that in Italy in 1906, 20% of the population had control over 80% of the country's property. He hypothesised that this ratio may be indicative of a natural norm and said that it might be observable across the physical cosmos.H

E. Permanent Components in Setup

- Copper tubes (25 foot, quarter inch)

- Compressor (hermetically sealed)

- Condenser

- Expansion valve (quarter inch)

- Thermal Insulation

- Energy meters (2 for heater and compressor)

- Refrigerant gas R134a

- Heater (to be applied in evaporator for maintaining temperature)

- Bucket, Electrical wires for connection

- High and Low Pressure gauges

- Temperature sensors

- CuO+silica Nanoparticles

- Shut off valve

- Copper filter

- Relay overload and electrical condenser for compressor

- Flair Nut

F. Equipment& Accessories Required During Construction of Setup

- Brazing Rod

- Brazing Gun

- Flux for preventing oxidation

- Can tap valve

- Gas charging wire

- Brazing Gas

- Dead nut

- Pin valve

- Teflon tape

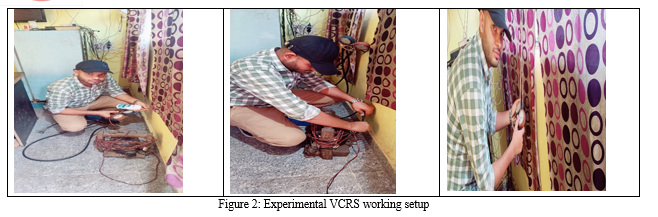

a. Wire insulation insulation tape The true construction begins when the parts are listed and bought, and it begins with building the basis or foundation on which all the parts will be attached. After being divided into 4 equal halves, iron bars are first welded to form the frame's leg. The iron frame is next fitted with hardwood planks that are the proper sizes, and the foundation is complete.

b. The compressor, condenser, evaporator, expansion valve, and energy metres are now all installed on the foundation of the VCRS.

c. All copper tube connections are now formed to complete the VCRS cycle by brazing, and the copper coiling in the evaporator is finished.

d. Next, using T joints, the pressure gauges, both high and low, are carefully inserted into the compressor's input and output.

e. At this point, electrical connections are completed, including the connection of energy metres to the heater and compressor, respectively, and the connection of switches to complete the circuit.

f. The setup is now prepared for testing by placing all temperature sensors at all of the measuring sites.

G. System after Construction and Basic cycle of VCRS

V. FUTURE SCOPES

Nanotechnology will be crucial to the refrigeration sector in the near future. There are several nanorefrigerants, nanolubricants, and perhaps even new nano-based technologies as a result. Future work in the refrigeration business should still be achievable using nanotechnology:

- Different refrigerants and their mixes can be combined with special nanoparticles to create new kinds of nanorefrigerants.

- The usage of nanoparticles with environmentally friendly refrigerants that are less likely to contribute to ozone depletion and global warming should be especially investigated.

- There is a need for a full explanation because there hasn't been much study done regarding the differences in characteristics when nanoparticles are employed with any major refrigerant.

A. Future Scope

- Optimization of Nanoparticle Concentrations: Further research can focus on identifying the optimal concentrations of CuO and SiO2 nanoparticles that provide the maximum cooling capacity enhancement without significantly increasing viscosity or causing issues related to nanoparticle agglomeration.

- Long-Term Stability and Compatibility: Investigating the long-term stability of the nanofluid and assessing its compatibility with various system components, such as pipes, heat exchangers, and compressor materials, is crucial for the practical implementation of nanofluid-based refrigeration systems.

- Cost Analysis: Conducting a comprehensive cost analysis to evaluate the economic feasibility of incorporating CuO and SiO2 nanoparticles in refrigerant systems is essential for commercial viability.

VI. ACKNOWLEDGMENTS

The authors would like to acknowledge SRCEM BANMORE GWALIOR for providing the necessary resources and support for this research project.

Conclusion

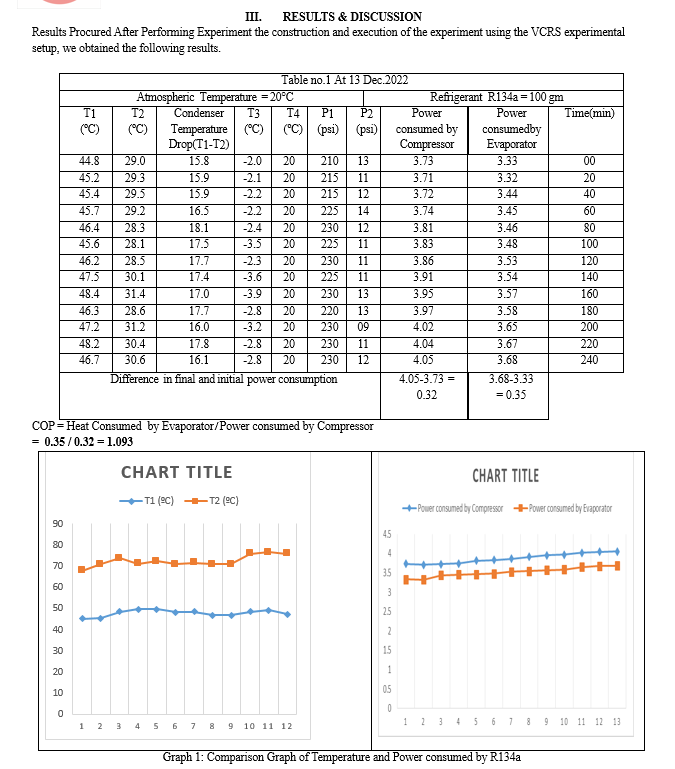

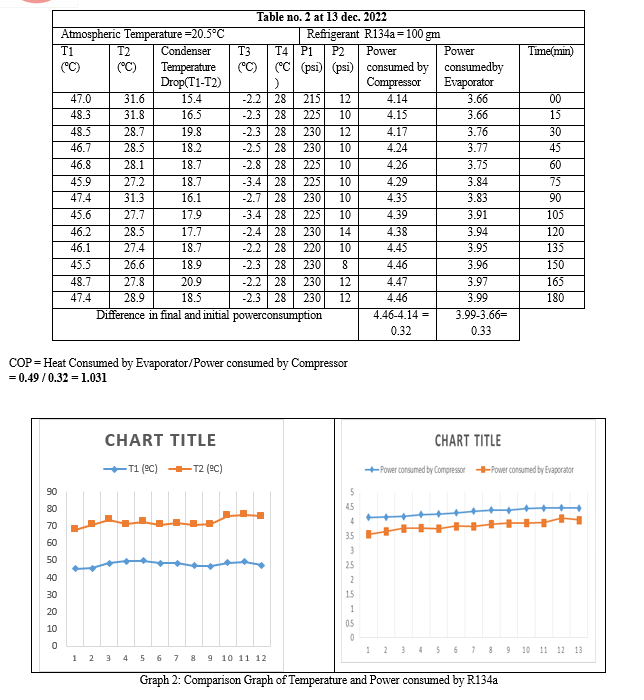

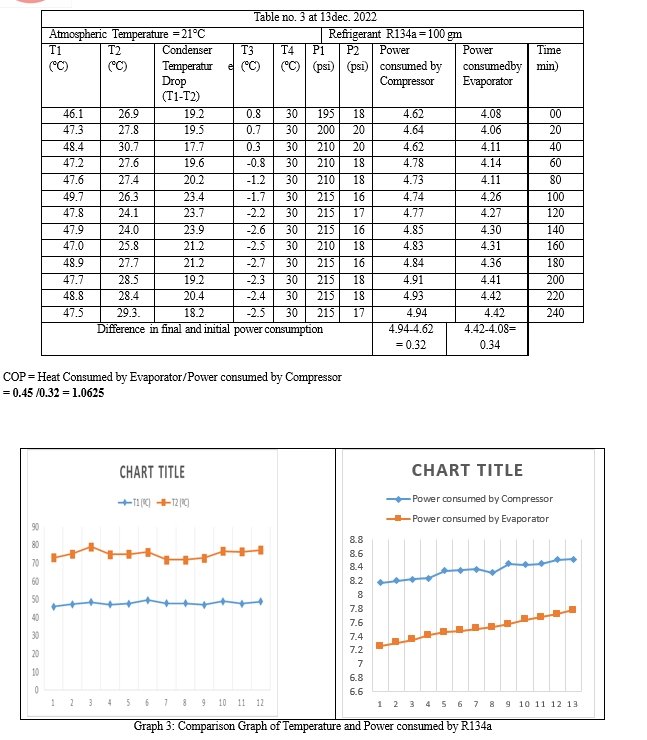

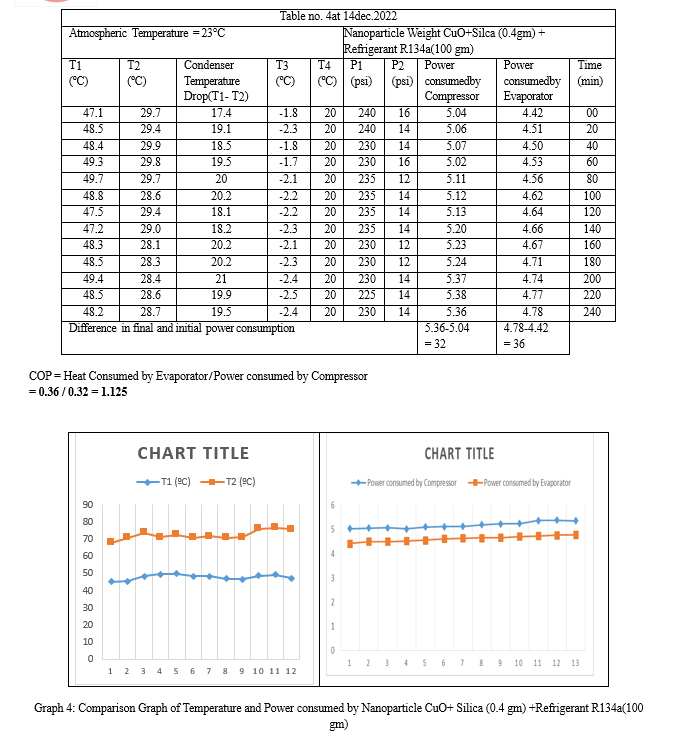

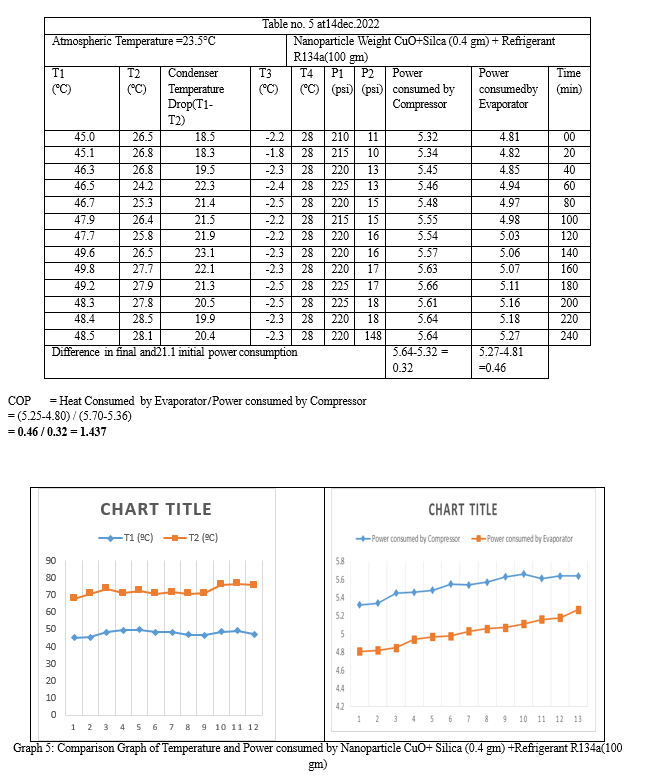

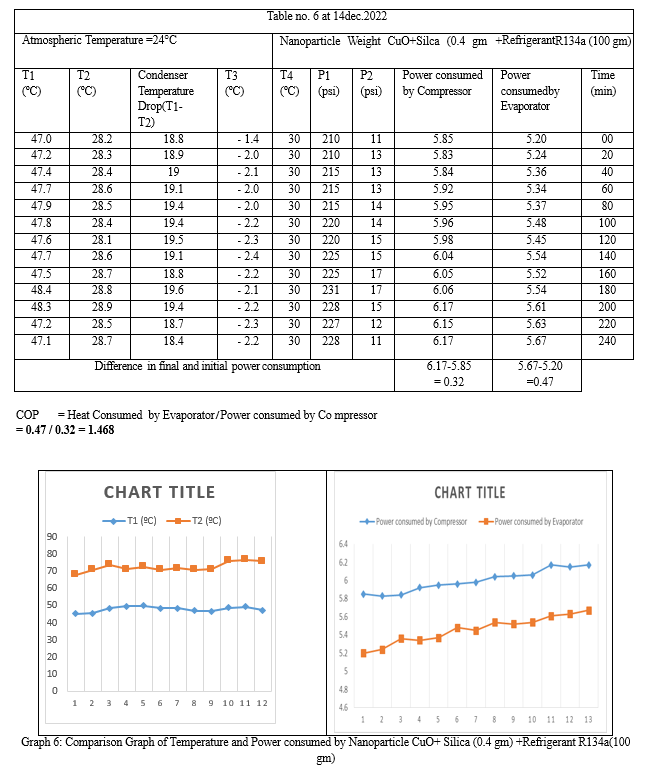

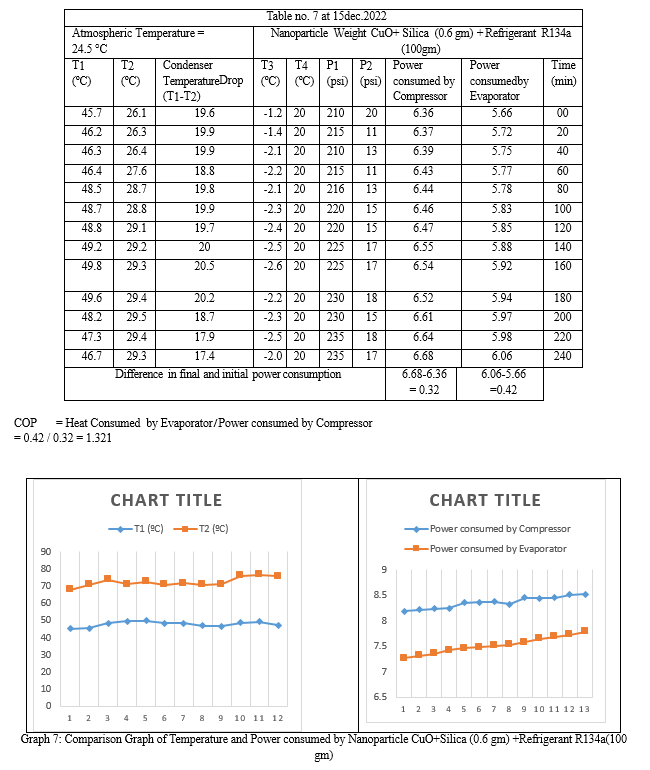

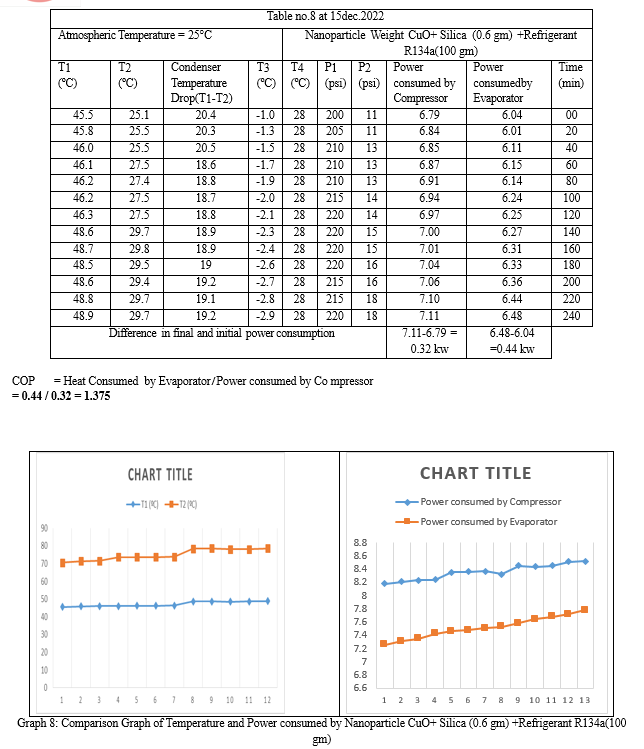

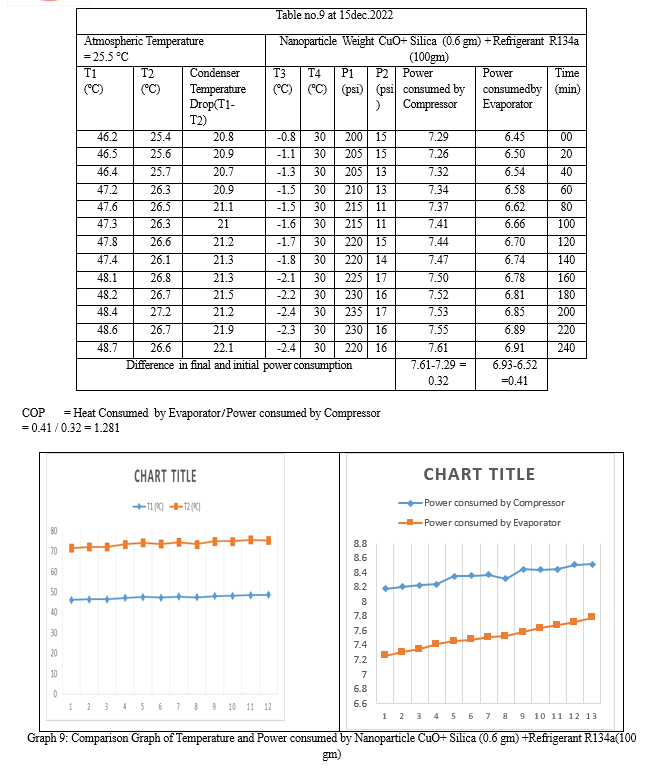

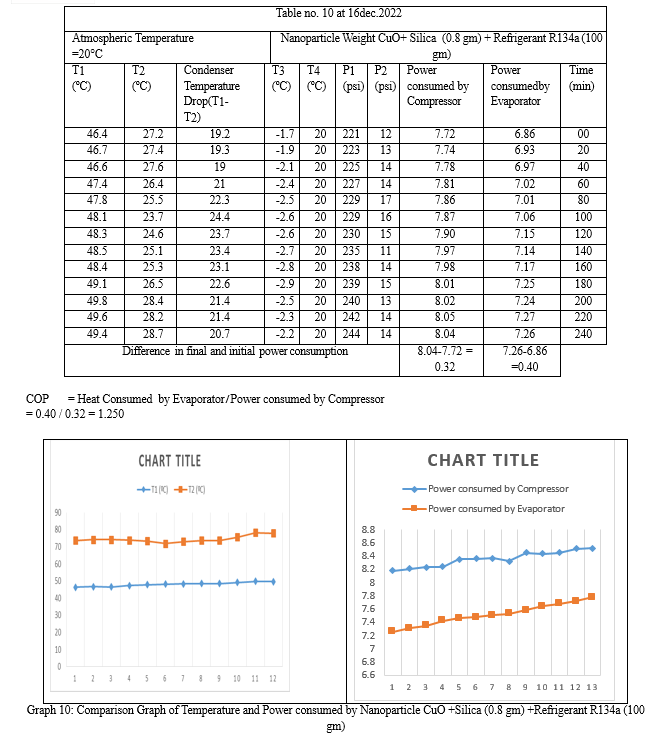

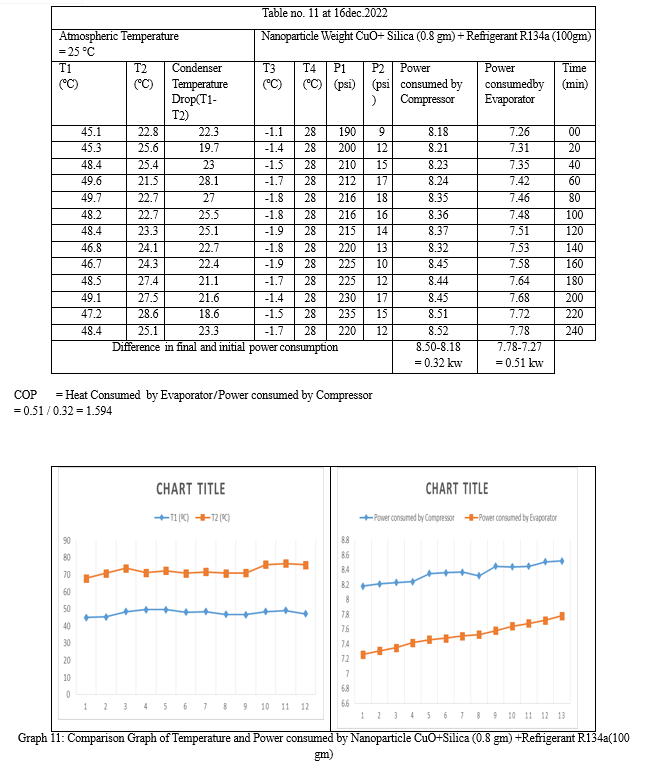

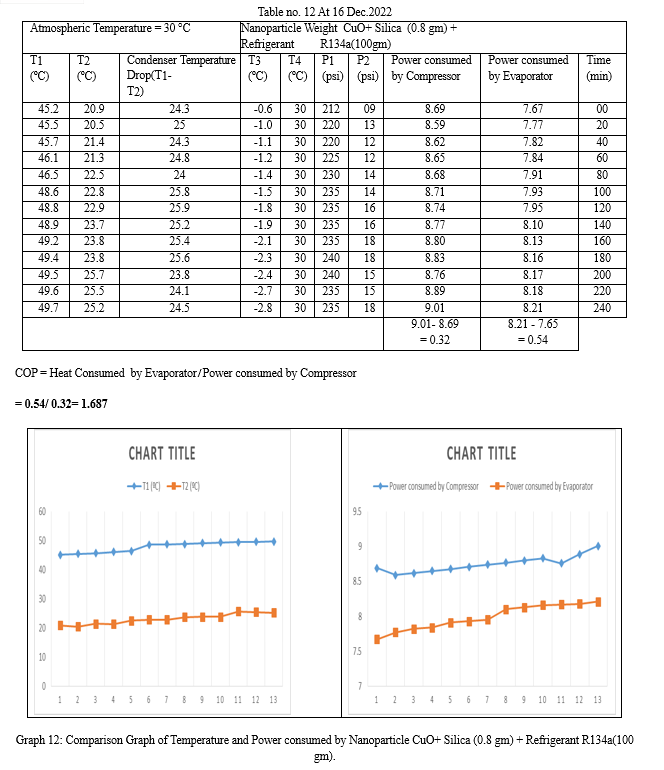

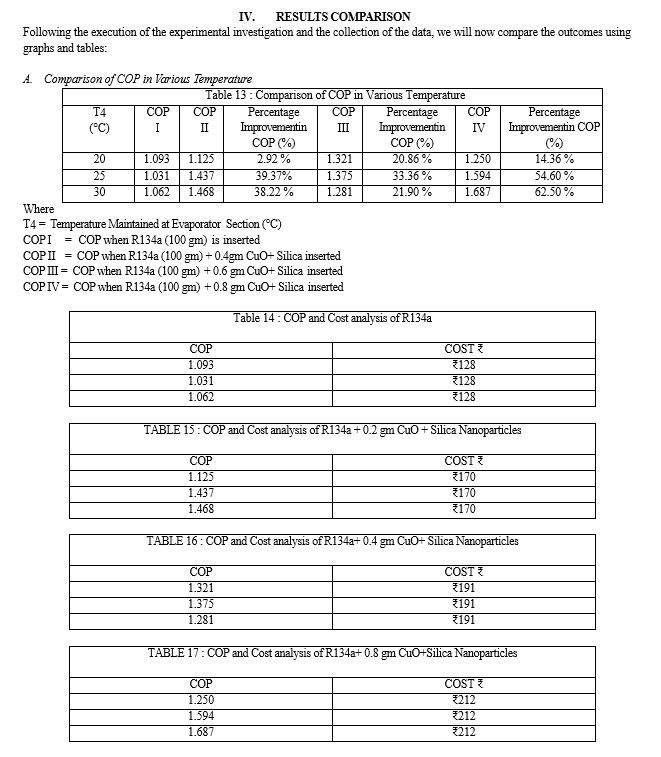

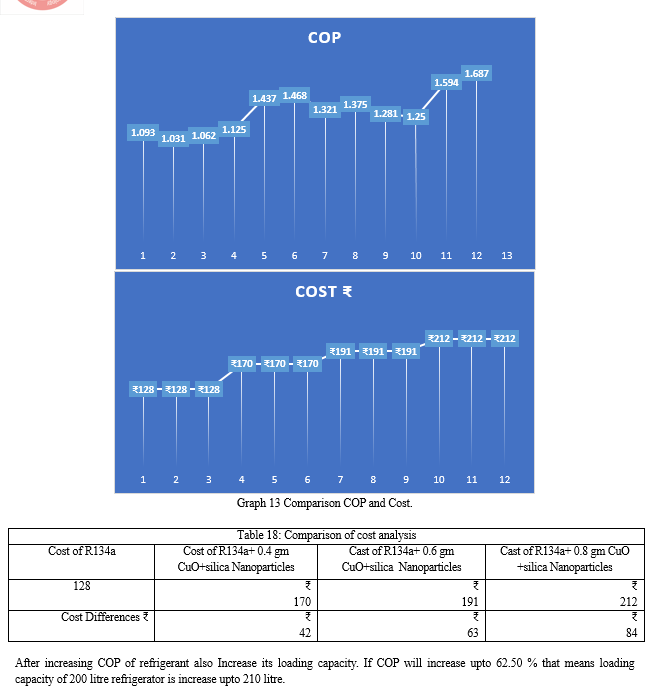

This trial study utilised another performance enhancement of refrigeration system using copper oxide nanoparticles arrangement, and despite having exceptional details regarding its blower type, evaporator shape, size, length of copper tubes used in it, measurement of copper tubes, type of condenser, number of turns in it, length of cylinder and limit of that particular condenser, and type of extension valve used, it was still obvious that the results were also exceptional. In order to finish the postulation and the try to make it successful, my main obligation was to build up Performance Enhancement of Refrigeration System utilizing Copper Oxide Nano Particles as perfectly as feasible, which I did with exceptional sincerity and care. After everything was ready, the test was started by including the COP and R134a refrigerant into the framework before being released. The showdown taguchi technique and graphing table give a very clear explanation of how we arrived at the outcomes. The framework was created utilizing cost analysis or energy use experiments. A similar method was applied when micro refrigerants were utilized in the Taguchi framework, and the outcomes were then reviewed. After concentrating on, the theory\'s commitments and outcomes declaration are compacted. 1) COP rose when nano-refrigerants were used in the copper or silica base nano particles\' experimental setting rather than just R134a refrigerants. 2) Compared to employing 0.6 gramme and 0.8 gramme, which had a decent multiplication rate, using 0.4 gramme CuO+silica nanoparticles caused a sudden rise in COP. 3) When nano-refrigerant was employed, an exact improvement of 19.1 percent was seen. At 20, 25, and 30 degrees Celsius in the evaporator, R134a was mixed with 0.8 gramme of CuO + Silica. 4) The condenser temperature reduction increased as a result of the usage of nano-refrigerants, and it continued to rise as a result of nanoparticle fixation. To get the greatest results, the refrigerant R134a was enclosed in a 0.8 gramme nanoparticle. 5) R134a will function more effectively as a compressor for the typical refrigeration system if the minimum price rises. If adjusted appropriately for heavier load refrigeration systems, the COP approaches increase 24.28% with only 84 rupees in additions. If COP rises by 62.50%, the loading capacity of a refrigerator with a 200-liter capacity will increase to 210 litres. This research study investigated the cooling capacity enhancement of refrigerant R-134a by incorporating CuO and SiO2 nanoparticles. The experimental results demonstrated that the addition of nanoparticles significantly improved the cooling capacity and heat transfer performance of R-134a. The findings suggest that nanofluids have the potential to enhance the efficiency and performance of refrigeration systems. Further research is warranted to optimize the nanoparticle concentrations and explore long-term stability and compatibility with system components.

References

[1] Krishna Sabareesh, N. Gobinathb, V. Sajithb, Sumitesh Das a, C.B. Sobhan , Application of TiO2 nanoparticles as a lubricant-additive for vapor compression refrigeration systems e An experimental investigation, international journal ofrefrigeration35, 1989e1996 (2012). [2] D. Sendil Kumar1, Dr. R. Elansezhian2 Experimental Study on Al2O3-R134a Nano Refrigerant in Refrigeration System, International Journal of Modern Engineering Research (IJMER), Vol. 2, Issue. 5, pp-3927-3929, Sep.-Oct. 2012. [3] R. S. Mishra, Rahul Kumar Jaiswal, Thermal Performance Improvements of Vapour Compression Refrigeration System Using Eco Friendly Based Nanorefrigerants in Primary Circuit, International Journal of Advance Research and Innovation, Volume 3, 524-535, Issue 3 (2015). [4] Sang M. Kwark, Ratan Kumar, Gilberto Moreno, Jaisuk Yoo, Seung M Yoo, Pool boiling characteristic of low concentration nanofluids, Int. journal heat and mass transfer 53, 972-981 (2010). [5] R. S. Mishra, Methods for Improving Thermodynamic Performance of Vapour Compression Refrigeration Systems Using R134a Ecofriendly Refrigerant in Primary Circuit and Three Nano Particles Mixed with R718 used in Secondary Evaporator Circuit for Reducing Global Warming and Ozone Depletion, International Journal of Advance Research and Innovation, Volume 2, Issue 4 , 784-789 (2014) [6] Nilesh S. Desai and P.R.Patil, Application of SiO2 Nanoparticles as, Lubricant Additive in VCRS: An Experimental Investigation, Asian, Review of Mechanical Engineering ISSN: 2249 - 6289 Vol. 4 No. 1, pp. 1-6© The Research Publication,2015 [7] Hao Peng, Guoliang Ding*, Haitao Hu, Weiting Jiang, Influence of carbon nanotubes on nucleate pool boiling heat transfer characteristics of refrigerant oilmixture, International Journal of Thermal Sciences 49, 2428e2438 (2010). [8] Ruixiang Wanga,b,?, Qingping Wua, Yezheng Wu, Use of nanoparticles to make mineral oil lubricants feasible for use in a residential air conditioner employing hydrofluorocarbon refrigerants, Energy and Buildings 42, 2111–2117 (2010).

Copyright

Copyright © 2023 Amit Singh Tomar, Amit Agrawal. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54242

Publish Date : 2023-06-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online