Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Enhancing Energy Efficiency in Jet Ejectors: A Computational Fluid Dynamics Investigation

Authors: Bhuvneshwar Tekam, Dr. Aseem C Tiwari

DOI Link: https://doi.org/10.22214/ijraset.2023.56282

Certificate: View Certificate

Abstract

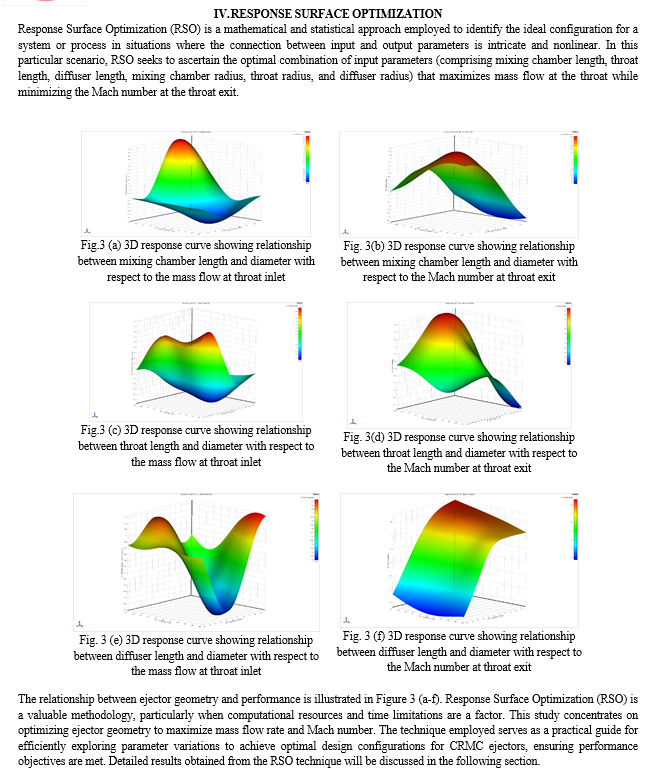

This study investigates the analysis of the operating modes of two distinct jet ejector types, namely, Constant Rate of Momentum Change (CRMC), Constant Pressure Mixing (CPM). Computational Fluid Dynamics (CFD) was employed to thoroughly examine and evaluate their respective geometrical attributes. Through our comprehensive scrutiny, we ascertained the notably superior performance of CRMC ejectors. This superiority is primarily linked to the continuous presence of compression shock waves within the flow processes of CRMC, which consequently lead to comparable or even diminished critical condenser pressures. The core objective of this research is to advance the application of jet-ejector refrigeration technology, especially for the efficient harnessing of low-grade waste heat, thereby contributing to enhanced energy efficiency and sustainable cooling solutions. We concentrated on two operational modes, CRMC and CPM, and employed CFD to analyze the geometry of these ejectors. We found a particular configuration called RSO-2 that demonstrated exceptional performance after carrying out extensive experiments encompassing 53 different parameter combinations using the Taguchi Design of Experiments. With regard to the throat inlet, RSO-2 demonstrated an exceptional mass flow rate of 5.28E+05 J kg-1 and a Mach number of 1.5418 at the throat exit. Furthermore, a strong correlation was found between the diameter of the throat and the radius of the mixing chamber, as revealed by our thorough sensitivity analysis. This discovery offers important new information for the development of jet ejector designs.

Introduction

I. INTRODUCTION

Currently, the dominant approach in cooling and refrigeration technology centers on mechanical vapor compression (MVC) systems. These systems primarily depend on electrical energy, a resource that is both valuable and finite. Regrettably, the heavy reliance on energy generated from the combustion of fossil fuels has significantly exacerbated pressing environmental challenges. These challenges encompass the release of greenhouse gases and the discharge of harmful air pollutants, including nitrogen oxides (NOx), sulfur oxides (SOx), particulate matter, and ozone, into the atmosphere. The consequences of these environmental impacts are far-reaching, presenting significant risks to both human health and the delicate equilibrium of our ecosystem.

The emission of greenhouse gases, particularly carbon dioxide (CO2), has been a primary contributor to global warming and climate change. The resultant rise in average global temperatures has led to phenomena such as more frequent and severe heatwaves, melting polar ice caps, and rising sea levels. These changes have dire implications for human populations, including extreme weather events, disruptions in food and water supplies, and the displacement of communities due to sea-level rise. Moreover, the release of nitrogen oxides (NOx) and sulfur oxides (SOx) into the atmosphere is linked to the formation of acid rain, which can have devastating effects on ecosystems and aquatic life. It also contributes to air pollution, leading to respiratory diseases and other health issues in humans.

Particulate matter and ozone, both byproducts of fossil fuel combustion, further deteriorate air quality and can harm respiratory health. The accumulation of these pollutants in the atmosphere is a significant concern, especially in urban areas where energy demand is high. In light of these challenges, there is an urgent need to explore and adopt alternative cooling and refrigeration technologies that are energy-efficient and environmentally sustainable. Such innovations can help mitigate the adverse effects on our environment, protect public health, and contribute to the global effort to combat climate change. Furthermore, in the domain of refrigeration and cooling technologies, the traditional use of mechanical vapor compression (MVC) systems has been synonymous with the employment of chlorofluorocarbon compounds (CFCs). Unfortunately, these compounds have proven to be extremely detrimental to the environment. The release of these pollutants into the atmosphere plays a significant role in the depletion of the protective ozone layer in the upper atmosphere, a critical concern that resonates with global efforts to promote environmental sustainability.

In the face of these pressing environmental issues and the ever-growing imperative to enhance energy efficiency, there is an escalating demand for techniques capable of efficiently harnessing low-grade heat. Such methods typically involve the entrainment and compression of low-pressure vapor, raising it to higher pressures, thus rendering it suitable for a wide array of applications. This compression process serves as a foundational element in numerous technological approaches, including absorption, adsorption, chemical, and jet ejector vapor compression cycles.

Among these alternative methods, jet ejectors emerge as a superior choice, primarily due to their inherent simplicity and remarkable effectiveness. Unlike other approaches, ejectors consist of a single unit that connects to motive, entrained, and mixture streams, offering a streamlined and efficient solution for various cooling and refrigeration applications. Jet ejectors provide an elegant and straightforward means of achieving the desired compression, making them an attractive option for industries seeking to improve energy efficiency and reduce the environmental impact of their operations. Their versatility and efficiency make them a promising solution in the quest for more sustainable and environmentally friendly cooling and refrigeration technologies. This streamlined design makes them exceptionally efficient and uncomplicated for use in vapor compression cycles. Moreover, jet ejectors possess a unique advantage in that they operate without the need for intricate components like valves, rotors, or any other moving parts. This inherent simplicity not only enhances their versatility but also makes them exceptionally adaptable to a wide array of sizes, which, in turn, renders them suitable for a diverse range of applications in the commercial sector. From small-scale to large-scale operations, jet ejectors prove to be highly versatile and effective. In the realm of cost considerations, jet ejectors offer a distinctly clear and compelling advantage. Their elegantly streamlined design, devoid of intricate or intricate components, results in not only lower manufacturing costs but also reduced maintenance expenditures. This inherent affordability factor renders jet ejectors an exceptionally attractive choice for businesses seeking to optimize their processes without the burden of excessive expenses.

The simplicity of jet ejectors, both in their construction and operation, significantly reduces the initial capital investment required to implement these systems. Furthermore, their uncomplicated design simplifies the maintenance and servicing procedures, leading to fewer breakdowns and shorter downtime periods. This inherent reliability minimizes the need for costly repairs and spare parts, resulting in substantial long-term savings.

This fusion of simplicity and cost-effectiveness makes jet ejectors a highly valuable asset in various commercial applications. Whether it's in the field of chemical manufacturing, power generation, or environmental control, businesses and industries can harness the economic benefits of jet ejectors to enhance their operational efficiency while remaining financially prudent. In essence, jet ejectors exemplify a cost-effective solution that does not compromise on performance, making them a compelling choice for those seeking to balance economic considerations with operational excellence. They offer a compelling cost advantage both in terms of initial capital investment and ongoing maintenance when compared to alternative configurations [1]. Conversely, the primary disadvantages of jet ejectors encompass the following:

- Ejectors are designed to work best under specific conditions, and moving away from those ideal conditions can cause a significant drop in their performance. Ejectors are carefully engineered to operate most effectively within a particular set of parameters. These ideal conditions ensure that ejectors can efficiently do their job, whether it's mixing or compressing fluids. Achieving this as the outcome of a lot of meticulous planning, considering things like the ejector's design and how fluids behave. When ejectors are used outside of these ideal conditions, it can lead to various issues. Key measures of ejector performance, such as how much fluid it can handle, how much it can compress, and how efficiently it works, can drop significantly. This means that ejectors may not perform as expected, which is a real problem in applications where precision and reliability matter a lot. Ejectors are often used in situations where it's challenging to keep things perfect all the time. This is because operating conditions can change, or there might be factors beyond your control. So, understanding how variations can affect ejector performance and knowing how to keep ejectors working close to their ideal conditions is essential to get the best results. Regular maintenance and adjustments can also help keep ejectors working well over time. In summary, the ideal operating conditions for ejectors are really important. They're like the sweet spot where ejectors work best, and moving away from this can seriously affect how well they do their job. So, understanding and managing these conditions is key for getting the results you want when using ejectors.

- Ejectors exhibit notably low thermal efficiency. Ejectors are known for their limited thermal efficiency. In simple terms, this means that they are not very effective at converting heat into useful work. When ejectors are used to perform tasks like mixing or compressing fluids, a significant portion of the input heat energy is not efficiently harnessed. Instead, it is lost or wasted in the process. This low thermal efficiency can be a concern in applications where energy conservation is critical. In such scenarios, it may be necessary to consider alternative technologies or methods that can provide higher efficiency in converting heat into useful mechanical or fluidic work. In summary, the thermal efficiency of ejectors is an important factor to be aware of, as it indicates their effectiveness in utilizing heat energy. Understanding this characteristic is essential when evaluating the suitability of ejectors for specific applications, especially in situations where energy conservation is a priority. In traditional vapor compression refrigeration systems, the compressor serves as the primary component responsible for reducing exergy. A pivotal approach to elevate the overall efficiency of these systems entails the substitution of electrically-driven compressors with components that function on either waste heat or renewable energy sources. Currently, thermal-driven refrigeration systems fall into three main categories: absorption, adsorption, and ejector cooling systems. These innovative categories represent diverse avenues of harnessing thermal energy to achieve cooling and refrigeration, each with its unique set of advantages and applications. While operating for a long time, adsorption cooling systems may experience system interruptions and have trouble reaching higher refrigeration capacities [2]. Comparatively speaking to their counterparts, the other two cooling methods, absorption cooling systems, exhibit remarkable potential for achieving high system efficiency. They do, however, have some drawbacks, chief among which are high initial investment costs, an expansion in the size of the system as a whole, and the requirement for high cooling temperatures [3]. Here comes the ejector refrigeration system (ERS), a ground-breaking and creative cooling method that emerges as a compelling substitute for traditional vapor compression systems. In order to address the drawbacks of conventional systems, ERS offers a novel perspective on cooling and refrigeration. Exergy losses experienced by conventional compression refrigeration systems are reduced by ERS, which does so by employing an ejector to either recover expansion losses [4,5] or enhance fluid pressure [6,7]. This choice is favored due to the system's uncomplicated structure, cost-effectiveness, and satisfactory performance. Hence, the adoption of an ejector refrigeration system employing R1234yf stands as a promising solution to confront the challenges of energy scarcity and environmental concerns in the refrigeration domain. It's crucial to keep in mind that this system has a limitation in the form of a relatively lower Coefficient of Performance (COP) when compared to its competitors, particularly the absorption refrigeration system, especially when using R1234yf as the refrigerant. The ejector component's subpar performance is primarily to blame for this difference [3]. The importance of the relationship between the cooling capacity of the system and the ejector's entrainment ratio has been recognized, and a substantial body of research has been devoted to increasing the ejector's efficiency. The ongoing study aims to overcome this constraint, improve the system's overall performance, and make it more competitive with other thermally-driven cooling systems. In essence, improving ejector performance is essential for closing the COP gap.

II. LITERATURE REVIEW

In a comprehensive examination of cooling systems tailored for the construction industry, Lei, Y., et al. (2023) [8] introduces an innovative bi-loop double-evaporator ejection-compression cycle that maximizes the utilization of low-grade heat while adapting to varying temperature requirements. This system combines the strengths of a vapor compression system and an ejector refrigeration system, adeptly managing diverse pressure levels and compression ratios while maintaining a common condenser pressure. In contrast to traditional computational fluid dynamics (CFD) approaches, this research employs a wet steam model, accounting for non-equilibrium water vapor condensation, which enhances precision in assessing condensation behavior and its consequences on ejector performance. The incorporation of a wet steam model in this study marks a significant advancement over conventional dry gas models. This innovation results in significantly reduced errors and a closer alignment with experimental data, ensuring greater accuracy. The study extensively explores four crucial characteristics of wet steam, all aimed at elevating the performance and efficiency of the ejector system. It involves the identification of optimal area and primary nozzle diameter ratios for the steam ejector, thus contributing to the optimization of this process. This meticulous optimization process yields substantial benefits, not only in terms of condensation intensity reduction but also in diminishing the liquid mass fraction within the diffuser. These findings offer invaluable insights for enhancing and precisely calibrating ejector performance. Moreover, they underscore the critical significance of incorporating spontaneous condensation behavior into ejector design and modeling practices. This innovative approach not only deepens our understanding of ejector functionality but also provides practical guidance for achieving optimal performance under varying operational conditions. In a similar vein, a study by Borirak Kitrattana and colleagues in 2021 introduced a one-dimensional ejector model. This model takes into account real fluid properties, with a specific focus on the steam-water context. It is grounded in Stoecker's framework from 1958 and has demonstrated its high effectiveness in designing steam ejector geometries and making accurate performance predictions. This research collectively contributes to advancing the field of ejector technology and its application in real-world scenarios. Notably, it highlights the discrepancies between ideal gas-based models and those incorporating condensation in supersonic flows, emphasizing the critical role of condensation in ejector analyses and design considerations.

In an earlier study conducted by A.J. Meyer et al. in 2009 [10], the development of a small-scale experimental steam jet ejector system was reported, marking a significant step forward in the practical implementation and testing of steam ejector technologies. This study contributes to the growing body of knowledge surrounding steam jet ejector systems and underscores the continuous efforts to refine their performance for various applications. This ejector setup featured an open-loop configuration, with the boiler operating within the temperature range of Tb = 85–140 °C. The evaporator's typical liquid temperatures ranged from Te = 5 °C to 10 °C, while the water-cooled condenser operated at pressures between Pc = 1.70 kPa and 5.63 kPa (Tc = 15–35 °C). To power the boiler, two 4 kW electric elements were employed, and a 3 kW electric element simulated the cooling load in the evaporator. The electric elements were controlled using variacs.

The study encompassed a meticulous examination of primary nozzles featuring throat diameters of 2.5 mm, 3.0 mm, and 3.5 mm, with the secondary ejector throat diameter consistently maintained at 18 mm. These deliberate variations in the primary nozzle throat diameter provided a range of options for the boiler's operation within the temperature spectrum, specifically between Tb = 85–110 °C. What emerged from this investigation was the clear relationship between nozzle throat diameter and the minimum attainable boiler temperature. It was evident that an increase in the nozzle throat diameter corresponded to a reduction in the minimum boiler temperature.

As an illustration, a primary nozzle with a 3.5 mm throat diameter was subjected to testing at a boiler temperature of Tb = 95 °C, an evaporator temperature of Te = 10 °C, and a critical condenser pressure of Pcrit = 2.67 kPa (22.6 °C). In this particular configuration, the system demonstrated a coefficient of performance (COP) of 0.253. This meticulous case study is part of a broader investigation into the experimental data of a solar-powered steam jet ejector air conditioner, which has been undertaken with meticulous attention to detail.

The prominence of solar-powered steam ejector air conditioning systems is evident, as they prove to be both technically and economically feasible in comparison to traditional vapour compression air conditioners. The utilization of either flat plate or evacuated tube solar thermal collectors is contingent upon the specific type of solar energy available for the systemIn a noteworthy study conducted in 2015 by B Tashtoush et al. [11], a comprehensive exploration was undertaken to investigate the impact of ejector geometry, refrigerant category, and operational state on the efficiency of the ejector cooling cycle during its pivotal operational phase. This research unveiled intriguing findings, shedding light on the intricate dynamics of these systems.

It was discovered that, under the same entrainment ratio and coefficient of performance (COP), constant-pressure mixing ejectors tended to exhibit higher backpressure compared to their constant-area mixing counterparts. This divergence in performance can be attributed to the heightened demand for condenser pressure and elevated generator temperatures in the case of constant-pressure mixing ejectors. Consequently, a COP range of 0.59-0.67 was observed at a condenser backpressure of 24 bar, emphasizing the significance of these operating parameters in optimizing ejector systems.

Furthermore, in a significant stride forward, a pioneering scientific prototype of a steam ejector refrigeration system was successfully engineered by Jingming Dong et al. in 2017 [12]. This outstanding accomplishment represents a significant advance in the field of ejector technology, further demonstrating the potential of steam ejector refrigeration systems and their ability to completely alter the market for cooling and refrigeration solutions. This prototype represents an important development in the understanding and practical application of steam ejector refrigeration systems, further validating their potential as effective and environmentally friendly alternatives in the field of air conditioning technology.

The three ejectors were designed and developed using three different constant-area sections and the same fundamental nozzle. The steam ejector refrigeration system comes into its own as a particularly alluring replacement for conventional absorption refrigeration systems as the heat source temperature drops below the 80°C threshold. In this case, a thorough experimental investigation was conducted to delve into the impact of a variable geometry ejector (VGE) design on the operational performance of a smaller-scale solar heat-assisted ejector air conditioning system.

With a nominal capacity of 1.5 kW, this system positions itself as a promising and sustainable cooling solution. This insightful study, conducted by Van Nguyen and their team in 2020 [13], clarifies the practical evaluation of the system's functionality under actual operating conditions. It not only underscores the system's potential as an alternative cooling technology but also highlights the role of innovative design features, such as the variable geometry ejector, in optimizing its performance. These findings contribute significantly to the broader conversation surrounding energy-efficient cooling solutions, particularly in scenarios where lower heat source temperatures are prevalent. This study underscores the practical implications of integrating a variable geometry ejector design, highlighting its potential to bolster the performance and efficiency of solar heat-assisted ejector air conditioning systems.

III. METHODOLOGY

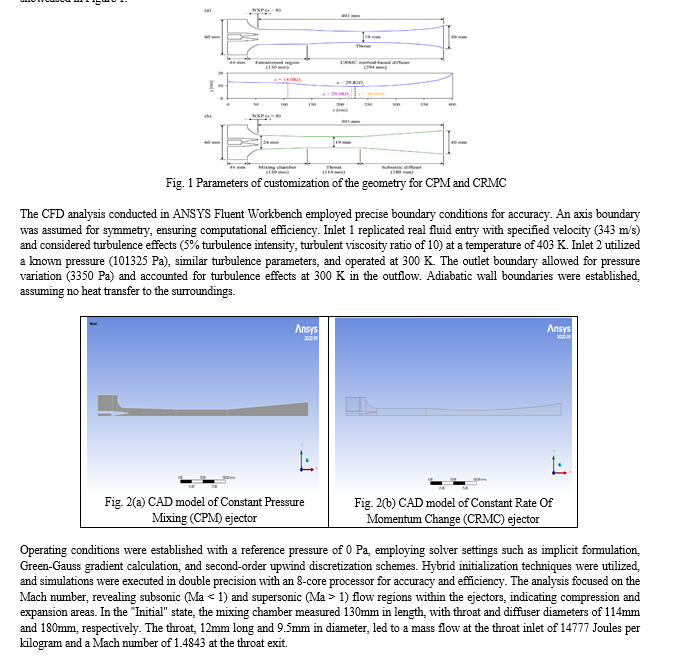

In a comprehensive examination of ejector performance, the study meticulously analyzed both Constant Pressure Mixing (CPM) and Constant Rate of Momentum Change (CRMC) ejectors employing ANSYS Fluent Workbench, as illustrated in Figures 2(a) and 1(b). The methodological approach consisted of several crucial stages. To enhance computational efficiency and simplify intricate geometries, an axisymmetric CAD model of the ejectors was initially created in ANSYS Design Modeler. Subsequently, parameter sets were assigned to pivotal components, enabling customization of the geometry to align with specific design criteria, as showcased in Figure 1.

???????A. Comparative Analysis

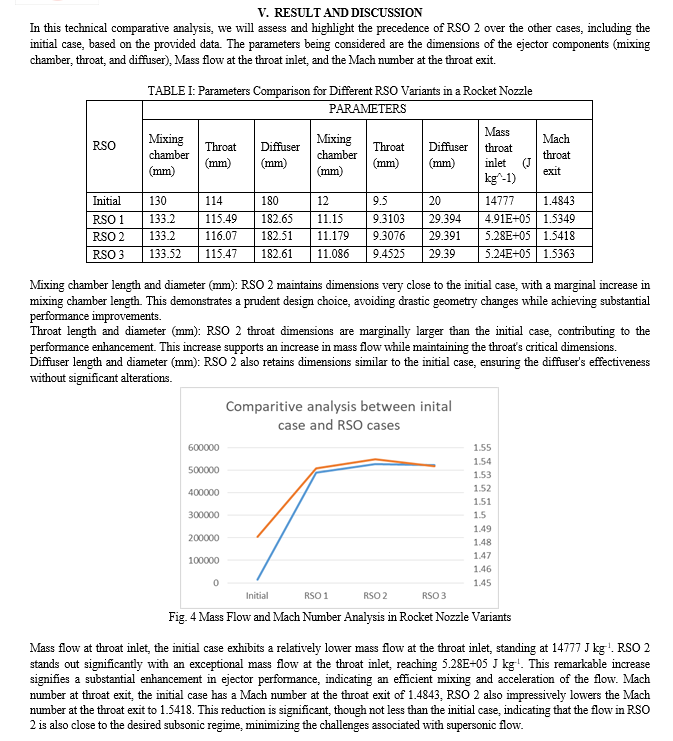

RSO 2 clearly outperforms the initial case and other RSO cases in several critical aspects:

- Mass Flow: RSO 2 achieves an astounding increase in mass flow at the throat inlet compared to the initial case, indicating a much-improved performance in terms of fluid acceleration and mixing.

- Mach Number: RSO 2 not only excels in mass flow but also manages to significantly reduce the Mach number at the throat exit, demonstrating superior control over the flow regime and enhancing the ejector's efficiency.

- Geometry Changes: Notably, RSO 2 achieves these improvements without radical changes in geometry, which is often advantageous for practical applications as it avoids complex manufacturing or design alterations.

In conclusion, RSO 2 stands out as the best-case scenario, surpassing the initial case and other RSO cases in both mass flow and Mach number performance. Its modest geometry adjustments coupled with remarkable enhancements in performance make it the clear precedence in optimizing the ejector's design for improved efficiency and effectiveness.

Conclusion

The effectiveness of jet ejectors operating in two distinct scenarios—constant pressure mixing (CPM) and constant rate of momentum change (CRMC)—is evaluated in this study. To do this, computational fluid dynamics (CFD) is used. The Taguchi method and Response Surface Methodology (RSM), two statistical techniques, are used to optimize the design parameters of CRMC jet ejectors. Out of a pool of 53 Taguchi configurations that involved altering dimensions of the mixing chamber, throat, and diffuser, three optimum configurations (RSO1, RSO2, RSO3) have been identified. A comprehensive comparative analysis has brought to light the exceptional promise of the RSO-2 configuration within the examined geometries. This configuration is distinguished by its ability to generate a high mass flow at the throat inlet while maintaining a low Mach number. The optimized geometry for this efficient CRMC ejector is characterized by specific dimensions, including a mixing chamber length of 133.2mm, a throat length of 116.07mm, a diffuser length of 182.51mm, a throat diameter of 9.3076mm, a mixing chamber diameter of 11.179mm, and a diffuser diameter of 29.391mm.These dimensions culminate in an impressive mass flow rate of 5.28E+05 J kg-1 and a Mach number of 1.5418. Sensitivity analysis has also emphasized the favorable impact of increasing the mixing chamber radius. These findings underscore the immense potential for enhancing ejector designs across a spectrum of industrial applications. It is worth noting that further practical validation and financial assessments are imperative to translate these promising results into real-world solutions. Collectively, this research significantly contributes to the ongoing efforts aimed at bolstering energy efficiency and environmental sustainability.

References

[1] Hisham El-Dessouky, Hisham Ettouney, Imad Alatiqi, Ghada Al-Nuwaibit, “Evaluation of steam jet ejectors, Chemical Engineering and Processing:” Process Intensification, Vol. 41, Issue 6, pp. 551-561, ISSN 0255-2701, 2002, https://doi.org/10.1016/S0255-2701(01)00176-3. [2] Pridasawas, W. (2006). Solar-driven refrigeration systems with focus on the ejector cycle (Doctoral dissertation, KTH). [3] J. Deng, R.Z. Wang, G.Y. Han, “A review of thermally activated cooling technologies for combined cooling, heating and power systems,” Progress in Energy and Combustion Science, Vol. 37, Issue 2, pp. 172-203, ISSN 0360-1285, 2011. https://doi.org/10.1016/j.pecs.2010.05.003. [4] Neal Lawrence, Stefan Elbel, Experimental investigation of a two-phase ejector cycle suitable for use with low-pressure refrigerants R134a and R1234yf, International Journal of Refrigeration, Vol. 38, pp. 310-322, ISSN 0140-7007, 2014. https://doi.org/10.1016/j.ijrefrig.2013.08.009. [5] Zhen-ying Zhang, Yi-tai Ma, Hong-li Wang, Min-xia Li, Theoretical evaluation on effect of internal heat exchanger in ejector expansion transcritical CO2 refrigeration cycle, Applied Thermal Engineering, Vol. 50, Issue 1, pp. 932-938, ISSN 1359-4311, 2013. https://doi.org/10.1016/j.applthermaleng.2012.08.022. [6] José Galindo, Vicente Dolz, Luis Miguel García-Cuevas, Alberto Ponce-Mora, “Numerical evaluation of a solar-assisted jet-ejector refrigeration system: Screening of environmentally friendly refrigerants,” Energy Conversion and Management, Vol. 210, pp. 112681, ISSN 0196-8904, 2020. https://doi.org/10.1016/j.enconman.2020.112681. [7] Bernardo Peris Pérez, Miguel Ávila Gutiérrez, José Antonio Expósito Carrillo, José Manuel Salmerón Lissén, Performance of Solar-driven Ejector Refrigeration System (SERS) as pre-cooling system for air handling units in warm climates, Energy, Vol. 238, pp. 121647, ISSN 0360-5442, 2022. https://doi.org/10.1016/j.energy.2021.121647. [8] Lei, Y., Li, S., Lu, J., Xu, Y., Yong, Y., & Xing, D. “Numerical Analysis of Steam Ejector Performance with Non-Equilibrium Condensation for Refrigeration Applications.” Buildings, vol. 13, no. 7, pp. 1672, 2023. MDPI AG. Retrieved from http://dx.doi.org/10.3390/buildings13071672 [9] Borirak Kitrattana, Satha Aphornratana, Tongchana Thongtip, “One dimensional steam ejector model based on real fluid property,” Thermal Science and Engineering Progress, Vol. 25, pp. 101016, ISSN 2451-9049, 2021. https://doi.org/10.1016/j.tsep.2021.101016. [10] A.J. Meyer, T.M. Harms, R.T. Dobson, “Steam jet ejector cooling powered by waste or solar heat,” Renewable Energy, Vol. 34, Issue 1, pp. 297-306, ISSN 0960-1481, 2009. https://doi.org/10.1016/j.renene.2008.03.020. [11] Bourhan Tashtoush, Aiman Alshare, Saja Al-Rifai, “Performance study of ejector cooling cycle at critical mode under superheated primary flow,” Energy Conversion and Management, vol. 94, pp. 300-310, ISSN 0196-8904, 2015. https://doi.org/10.1016/j.enconman.2015.01.039. [12] Jingming Dong, Mengqi Yu, Weining Wang, He Song, Celue Li, Xinxiang Pan, “Experimental investigation on low-temperature thermal energy driven steam ejector refrigeration system for cooling application,” Applied Thermal Engineering, vol. 123, pp. 167-176, ISSN 1359-4311, 2017. https://doi.org/10.1016/j.applthermaleng.2017.05.061. [13] Van Nguyen, V., Varga, S., Soares, J., Dvorak, V., & Oliveira, A. C. “Applying a variable geometry ejector in a solar ejector refrigeration system.” International Journal of Refrigeration, vol. 113, pp. 187-195, 2020. https://doi.org/10.1016/j.ijrefrig.2020.01.018

Copyright

Copyright © 2023 Bhuvneshwar Tekam, Dr. Aseem C Tiwari. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET56282

Publish Date : 2023-10-24

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online