Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Estimation of Fatigue and Rutting Life Using Falling Weight Deflectometer of Flexible Pavement Road in Hilly Terrain

Authors: Gagan Sharma, Harivansh Kumar Chaudhary, Akash Malik

DOI Link: https://doi.org/10.22214/ijraset.2022.46968

Certificate: View Certificate

Abstract

Establishing the qualities of the pavement material and its structural capability is the most important step in establishing effective pavement maintenance and management techniques. This can be done by looking at how the pavement reacts to the applied load. The Falling Weight Deflectometer (FWD) is used in this study to assess the performance of a road stretch of the Federal Route in the State of Uttarakhand by measuring deflection in response to the weight applied at various sites along the highway. FWD is used to assess the pavement\'s response to a static load. Using the obtained deflection data, the KGPBACK is used to back-calculate the simulated layers of the pavement. Data is gathered then integrated into the IITPAVE software to create a pavement overlaying design. Flexible pavement is modelled as an elastic multilayer structure to see how bituminous overlay maintenance affected the distress models, and all 4 distress (cracking, rutting, rut depth, and roughness) are shown to be reduced. As a result, the research article provides a methodology that administrators can use to anticipate when and how much financing is needed to preserve and maintain the Indian Highway Road network.

Introduction

I. INTRODUCTION & LITERATURE REVIEW

The proposed road (NH-707A) passes through India's Uttarakhand state. Tiuni, Chakrata, Bhediyana, Mussoorie, New Tehri, and Maletha are all located near Dehradun on the NH707A. The Project Road begins at Tuini at Km 0.00 on NH-707A and finishes at Chakrata Camp at Km 84.0 on NH-707A.In total, the proposed road is 84 kilometers long. The Falling Weight Deflector (FWD) is a simple, reliable, and practical tool for evaluating the structural properties of pavements and runways. Accurate position (velocity transducers) at the loaded region and various distances from the middle determine the pavement deflection and deflection bowl. The deflection levels are unaffected by the loading or recording system design, nor by probable effects of shaky reference points, such as those found in several competing solutions. Observed deflection data from FWD is generally used to assess pavement structural capacity, ease overlay design, and determines whether a pavement is overloaded. FWD data is commonly used to identify whether a pavement is overcrowded, as well as to analyse its structural capability. Depending on its design, a FWD could be restricted to a trailer or built into a self-propelled or say vehicle mounted falling weight deflectometer. A FWD installed in a big truck and a ground-penetrating radar for determination of temperature and an impact absorbent are standard components of comprehensive road survey vehicles. A FWD simulates the loads produced by a rotating vehicle wheel by applying a load pulse on the surface of the pavement during testing. A massive product is present in a "cushion" to change its momentum before being relayed to the highway via a spinning load plate. The deformation of the pavement in response to the load pulse is measured using deflection sensors. The amount of applied load impulse is considered constant by system design in some FWDs. The most common application of FWD data is to evaluate stiffness and its corresponding characteristics of pavement construction. Because there is no closed-form solution, the process of computing the elastic moduli of individual layers in a multi-layer system (e.g., Bituminous concrete is topmost layer, while base course is above of the subgrade) is based on surface deflections is known as "back-calculation. Instead, initial moduli are assumed, surface deflections are determined, and the moduli are changed iteratively until the measured deflections are met. On contemporary computers, this operation is computationally expensive but rapid. It can produce some quite deceptive results and necessitates the use of a skilled analyst. Back calculation software that is commonly used is

- Clevercalc

- Evercalc

- BAKFAA

- KGPBACK

- ELMOD

Singh et al., (2020) The pavement under consideration in this study is part of an in-service segment of a two-lane single carriageway flexible pavement with a 7-meter wide paved/earthen shoulder and a 1.5-meter wide paved/earthen shoulder National Highway in Haryana, India. The information was gathered in analysis to define the origins of multiple kinds of pavement distress over time, as well as suffering caused by design flaws, poor material choices, and faulty construction

Seo et al., (2009) The goal of this research is to use the back-calculation approach to account for the dynamic impacts of the deflection basin from the FWD.

After turning dynamic deflections into static deflections, the layer moduli were calculated using a pseudo-static back-calculation process called DYN-BAL (Dynamic BALMAT). The applicability and reliability of the back-calculation approach, which can accommodate the dynamic effect, were evaluated in situ. FWD testing was undertaken in fact at a Multi-Depth Deflectometer (MDD) installation. Compared to numerous other computer codes in use, the test findings revealed that DYN-BAL offers the first most reliable outcomes.

Qiao et al., (2020), this paper deals normally planned with historical climate in mind, but future climate change poses a challenge. Quantifying the effects of climate change on pavement service life can help road authorities plan for climate adaptation and, ultimately, incorporate climate resilience into road infrastructure design and management. In this study, a unique data-driven methodology is created to estimate the effects of climate change on the lifespan of the floor service in places was the drop in the FWD data (FWD) was permanently collected, using the following methods:

a. Using previous climate data, maintenance, and traffic patterns as candidate inputs and pavement layer stiffness back estimated from FWD diagnostics are conclusions, train a supervised model (linear regression or Artificial Neural Networks, ANN).

b. Predicting layer stiffness for four future 20-year periods using statistically downscaled future climate forecasts from three Coupled Model Intercomparison Project Phase-5 global climate models and three greenhouse gas concentration scenarios

II. METHODOLOGY

The VMFWD (Vehicle Mounted Falling Weight Deflectometer) has been used to measure deflections along the road surface. To generate the deflections, a target peak load of 40KN is applied to the pavement surface. Sensors are installed at some radial distances such as 0, 200, 300, 450, 600, 900 and 1200mm from the centre of the loading plate to measure the deflections produced. Load and deflection data were recorded for atleast three drops at each test point position. If any data was found to be incorrect or unreasonable at any test location, it was erased, and FWD measurements were conducted again at that spot. The temperature of the concrete topsoil was measured using the vehicle's built-in radar system, which was positioned on the backside. The proposed road (NH-707A) passes through India's Uttarakhand state.

Tiuni, Chakrata, Bhediyana, Mussoorie, New Tehri, and Maletha are all located near Dehradun on the NH-707A. The Project Road begins at Tuini km Towards 0.00 on NH-707A and finishes at Chakrata Cantonment at Km 84.0 on NH-707A. The proposed road is 84 km.

The Pavement Evaluation Report's objective is to use non-destructive testing to validate the structural strength of the new residential pavement.

The report's key goals are as follows: Examine the in-service pavement's structural soundness. Calculate the Pavement's Remaining Fatigue Life in Million Standard Axles backward (MSA). If the pavement's remaining fatigue/rutting life is shorter than the design MSA assessed, an additional overlay should be proposed.

A. Field Investigations

As part of the pavement study, field investigations were conducted to capture the necessary data for pavement evaluation. This research is separated into the following sections, as listed below:

Existing Pavement Crust Layer Thickness

FWD Survey (Falling Weight Deflectometer)

- Existing Pavement Crust Layer Thickness: The following layers and their thicknesses were identified along the road based on historical data:

a. Bituminous Terrain (BT Layer).

b. Layers of Granularity (NBT Layer).

TABLE I

Summary Of Existing Pavement Composition

|

Chainage (km) |

Layer thickness (mm) BT |

Layer thickness (mm) NBT |

Total thickness (mm) |

|

0-52 |

75 |

200 |

275 |

|

52-63 |

80 |

200 |

280 |

|

63-72 |

75 |

200 |

275 |

|

72-74 |

80 |

200 |

280 |

|

74-81 |

85 |

200 |

275 |

|

81-84 |

90 |

295 |

385 |

Visual Condition of Pavement Survey Detailed visual inspection of existing pavement have its own vital role to ascertain the existing pavement condition. It involves the type of distress, quantification of distress type and its severity along the alignment. As per table 1 shown in IRC 115-2014, the alignment of project road is classified as Fair to Poor condition of the road

TABLE III

Existing Pavement Condition Of Road

|

S no. |

Chainage (Km) |

Pavement Condition (G/F/P) |

|

1 |

0-10 |

Fair |

|

2 |

10-12 |

Fair |

|

3 |

12-13 |

Good |

|

4 |

13-20 |

Fair |

|

5 |

20-22 |

Good |

|

6 |

22-45 |

Fair |

|

7 |

45-52.5 |

Poor |

|

8 |

52.5-59 |

Good |

|

9 |

59-71 |

Poor |

|

10 |

71-73 |

Good |

|

11 |

73-80 |

Poor |

|

12 |

80-82 |

Fair |

|

13 |

82-83 |

Good |

|

14 |

83-84 |

Poor |

2. Falling Weight Deflectometer for Pavement Evaluation: The pavement was analysed by considering a Falling Weight Deflectometer (FWD) survey on September 17, 2021, throughout the full project stretch (excluding structure locations). The FWD survey followed the instructions of IRC 115-2014, The spacings in the table are based on the premise that the uniform section length is 1 km. By combining the spacing given in the table by the length of the average section, the actual spacing to be used may be determined. The sample size and data intervals for the Project Road (Single-lane two-way carriageway) are gathered depending on the length of the uniform based on the above-mentioned criteria. section computed and pavement section condition, i.e., 'good,' 'fair,' and 'poor' for each lane to acquire a good sample size, a test interval of 500m is used for FWD measurement on a good pavement section, even though the uniform section length is more than 1 km. Along the whole alignment, an FWD survey was conducted upon both LHS and RHS.

Analysis of Data At each test site, the FWD survey principally consisted of peak load and peak deflections at various radial distances. According to Stipulation 4.4 of IRC:115-2014, the measured deflections were linearly scaled to match a standard load of 40.0 KN

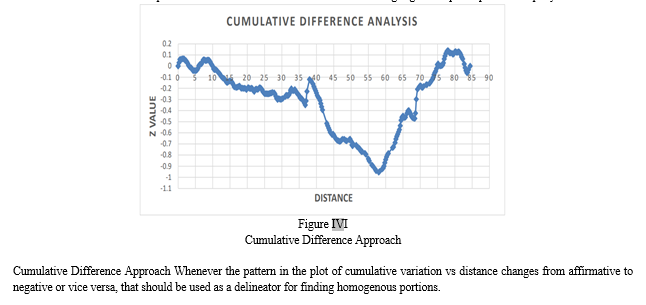

Identification of Homogenous Sections Identification of homogeneous parts of the road is done using cumulative difference analysis according to AASHTO, 1993. The Surface Curvature Index (SCI) variable is used to identify homogeneous sections on the project road. Surface Curvature Index (SCI) is a bowl-shaped characteristic that reflects contribution of higher layers and is calculated at the difference between D0 and D300, where D0 and D300 are the peak deflections in mm measured at the centre of the loading plate and at radial distance of 300 mm is a parameter that describes the form of a bowl and highlights the participation of top layers.

TABLE VII

Homogeneous Sections Of Road

|

Homogeneous Section |

Chainage |

|

Homogeneous Section 1 |

Km 0.0 to Km 1.5 |

|

Homogeneous Section 2 |

Km 1.5 to Km 5 |

|

Homogeneous Section 3 |

Km 5 to Km 7.5 |

|

Homogeneous Section 4 |

Km 7.5 to Km 14.25 |

|

Homogeneous Section 5 |

Km 14.25 to Km 15.494 |

|

Homogeneous Section 6 |

Km 15.494 to Km 29.25 |

|

Homogeneous Section 7 |

Km 29.25 to Km 32.75 |

|

Homogeneous Section 8 |

Km 32.75 to Km 36.748 |

|

Homogeneous Section 9 |

Km 36.966 to Km 46.742 |

|

Homogeneous Section 10 |

Km 46.742 to Km 49.688 |

|

Homogeneous Section 11 |

Km 49.688 to Km 51.494 |

|

Homogeneous Section 12 |

Km 51.494 to Km 58.242 |

|

Homogeneous Section 13 |

Km 58.242 to Km 66.683 |

|

Homogeneous Section 14 |

Km 66.683 to Km 68.425 |

|

Homogeneous Section 15 |

Km 68.425 to Km 74.953 |

|

Homogeneous Section 16 |

Km 74.953 to Km 76.465 |

|

Homogeneous Section 17 |

Km 76.465 to Km 77.96 |

|

Homogeneous Section 18 |

Km 77.96 to Km 83.468 |

Backcalculation of layer moduli KGPBACK application was used to backcalculate the elastic properties of different layers for existing pavement in compliance with IRC 115-2014. Normalised surface deflections were combined with other inputs (layer thickness and Poisson's Ratio of different layers). Temperature and seasonal variation have been factored into these back-calculated moduli values referenced in the parts that follow. For BT layers, the Poisson's ratio was determined to be 0.5, 0.4 for granular layers, and 0.4 for pavement structure.

Correction of Temperature

E35 = λ X ET

Where,

λ = temperature correction factor.

λ =(1-(0.238Xln))/(1-(0.238Xln))

E35= back-calculation modulus at 35 0C, MPa

ET = back-calculation modulus at T 0C, MPa

The pavement Temperature has its own impact on values of backcalculated modulies in the pavement layer evaluation in FWD survey. As a result, back calculated moduli temperature other than 35°C i.e "T° C" was corrected with the help of given above equations. Temperature adjustment does not need to be applied to back-calculated modulus values for Poor sections, according to clause 6.4.2 of IRC 115:2014. The normal pavement temperature of 35°C will not be applicable in colder places like Chakrata and tuinu with altitudes larger than 1000 m if the average daily temperature is less than 20°C for more than 4 months in a year, according to clause 6.4.3 of IRC 115:2014. When the ambient temperature exceeds 20°C, deflection measurements should be taken.

Correction for Seasonal Variation The strength of granular subbase/base layer(s) and subgrade is affected by moisture content, and these layers are at their weakest during the monsoon period. The FWD investigation for this project took place during the monsoon season's hiatus. As a result, the back-calculated granular and subgrade moduli are not subjected to corrective operation. The elastic layered structure of flexible pavement is simulated. A linear elastic layered model is used to calculate stresses and strains at crucial places (as illustrated in the Picture). Critical metrics for pavement evaluation have been a tensile strain at the beneath of the bituminous layer & a vertical compressive strain at the beneath of subgrade. The pavement's remaining life is calculated using these essential values of tensile and compressive strains.

B. Consideration in Lower and Upper Ranges of Moduli of Various Layers

Based on the range of Moduli parameters supplied as input, KGPBACK will calculate the moduli values for a defined set of normalized deflections.

- For Bituminous Layers

The range for Bituminous layer: thick layers without considerable cracking of 750 MPa to 3000 MPa, according to clause III.8.4 of IRC 115-2014. However, because some sections of the project road were built with DBM and BC with VG-30, the evaluation was carried out using the feasible range values of 750 to 2000 MPa (Table 9.2 in IRC 37-2018). The spectrum for Bituminous layers was in Impaired Condition (Fair to Poor) of 400 MPa to 1500 MPa is used for the analysis, according to paragraph III.8.4, IRC 115-2014

2. For Granular Layers

For granular layers, a lower bound of 100MPa and even an upper limit of 500MPa have been chosen according to clause III.8.4 of IRC 115-2014.

3. For Subgrade

The research is performed using a subgrade range modulus of 20 to 100 MPa. The practical range values determined for km in 180 to km 230 are 50 to 100, and for km 230 to km 265 are 60 to 100, depending upon the age of the pavement, integrity of the pavement, and climatic circumstances.

TABLE VIV

Range Of Moduli For Various Layers

|

Layer Description |

Lower Modulus Range (MPa) |

Upper Modulus Range |

|

BC layer (Good) |

750 |

2000 |

|

BT (Fair to Poor) |

400 |

1500 |

|

Granular (NBT) |

100 |

500 |

|

Subgrade |

20 |

100 |

C. The Pavement's Remaining Life

Because the road is a national highway, a 90 percent dependability factor was used to calculate the estimated endurance and rutting life of the newly constructed/in-service pavement.

D. Requirement for Overlay Thickness based on FWD Analysis

The calculated remaining fatigue and rutting life of the pavement are compared to the minimum needed design life after the analysis has been done using the process described above. If the pavement's remaining fatigued/rutting life is short, a compatible overlay is constructed and evaluated using the IITPAVE software to extend the pavement's life.

III. THE TENDS TO RESULT OF THE PAVING EVALUATION

TABLE V

Design Modulus Values For Various Layers

|

Homogeneous Sections |

15th Percentile Modulus (MPa) |

||

|

Bituminous Layer |

Granular Layer |

Subgrade |

|

|

Homogeneous Section 1 |

1359.925 |

101.62 |

100 |

|

Homogeneous Section 2 |

1444.53 |

175.17 |

100 |

|

Homogeneous Section 3 |

1223.3 |

101.2 |

100 |

|

Homogeneous Section 4 |

1435.1 |

122.565 |

100 |

|

Homogeneous Section 5 |

1419.6 |

101.86 |

100 |

|

Homogeneous Section 6 |

1375.9 |

103.14 |

100 |

|

Homogeneous Section 7 |

1365.125 |

104.115 |

100 |

|

Homogeneous Section 8 |

1368.39 |

101.6 |

99.9 |

|

Homogeneous Section 9 |

1426.015 |

147.3 |

100 |

|

Homogeneous Section 10 |

855.24 |

104.3 |

100 |

|

Homogeneous Section 11 |

1406.04 |

105.68 |

100 |

|

Homogeneous Section 12 |

1411.05 |

109.71 |

100 |

|

Homogeneous Section 13 |

1267.2 |

100.3 |

76.675 |

|

Homogeneous Section 14 |

1329.36 |

100 |

99.89 |

|

Homogeneous Section 15 |

1423.35 |

104.35 |

93.275 |

|

Homogeneous Section 16 |

1456.175 |

116.75 |

75.8 |

|

Homogeneous Section 17 |

1471.5 |

103.8 |

99.775 |

|

Homogeneous Section 18 |

1418.97 |

112.355 |

100 |

On the idea of the above-followed values, the ultimate life (Fatigue & Rutting) has been calculated for the venture avenue in phrases of Million Standard Axles (MSA) and is provided below

TABLE VI

Remaining Life Of Pavement In MSA

|

Homogeneous Section |

Chainage |

Fatigue Life |

Rutting Life |

|

Homogeneous Section 1 |

Km 0.0 toKm1.5 |

0.37 |

0.83 |

|

Homogeneous Section 2 |

Km 1.5 to Km 5 |

1.14 |

1.23 |

|

Homogeneous Section 3 |

Km 5 to Km 7.5 |

0.33 |

0.77 |

|

Homogeneous Section 4 |

Km 7.5 to Km 14.25 |

0.55 |

0.94 |

|

Homogeneous Section 5 |

Km 14.25 to Km 15.494 |

0.39 |

0.86 |

|

Homogeneous Section 6 |

Km 15.494 to Km 29.25 |

0.39 |

0.85 |

|

Homogeneous Section 7 |

Km 29.25 to Km 32.75 |

0.39 |

0.84 |

|

Homogeneous Section 8 |

Km 32.75 to Km 36.748 |

0.37 |

0.83 |

|

Homogeneous Section 9 |

Km 36.966 to Km 46.742 |

0.78 |

1.06 |

|

Homogeneous Section 10 |

Km 46.742 to Km 49.688 |

0.26 |

0.64 |

|

Homogeneous Section 11 |

Km 49.688 to Km 51.494 |

0.4 |

0.86 |

|

Homogeneous Section 12 |

Km 51.494 to Km 58.242 |

0.51 |

1.05 |

|

Homogeneous Section 13 |

Km 58.242 to Km 66.683 |

0.33 |

0.35 |

|

Homogeneous Section 14 |

Km 66.683 to Km 68.425 |

0.35 |

0.81 |

|

Homogeneous Section 15 |

Km 68.425 to Km 74.953 |

0.4 |

0.69 |

|

Homogeneous Section 16 |

Km 74.953 to Km 76.465 |

0.47 |

0.38 |

|

Homogeneous Section 17 |

Km 76.465 to Km 77.96 |

0.42 |

0.88 |

|

Homogeneous Section 18 |

Km 77.96 to Km 83.468 |

0.6 |

2.13 |

IV. ACKNOWLEDGMENT

We are thankful to Department of Civil Engineering of Galgotias University, Greater Noida (UP) for support and their Effort. Special thanks to CB Raman Sir (Partner of MS Park Futuristics & Associates) for Providing Tools and Equipment’s such as VMFWD etc. Thanks to PWD Uttarakhand for providing Necessary data that were required for analysis purpose.

Conclusion

The existing pavement remaining life is less than 1 MSA as shown in table VI and deficient in granular layer thickness along the project road. Therefore, Reconstruction of pavement is Recommended. Therefore, the existing layers (like different bituminous layers) crust needs to be remove completely by milling or scarifying machines, and then the pavement is required to built up with the granular layer(s) and bituminous Surfacing. The thickness and composition of pavement layers shall conform to IRC 37:2018.

References

[1] Singh, A., Sharma, A., & Chopra, T. (2020). Analysis of the flexible pavement using falling weight deflectometer for indian national highway road network. Transportation Research Procedia, 48(September), 3969–3979. https://doi.org/10.1016/j.trpro.2020.08.024 [2] Seo, J. W., Kim, S. Il, Choi, J. S., & Park, D. W. (2009). Evaluation of layer properties of flexible pavement using a pseudo-static analysis procedure of Falling Weight Deflectometer. Construction and Building Materials, 23(10), 3206–3213. https://doi.org/10.1016/j.conbuildmat.2009.06.009 [3] Qiao, Y., Zhang, Y., Zhu, Y., Lemkus, T., Stoner, A. M. K., Zhang, J., & Cui, Y. (2020). Assessing impacts of climate change on flexible pavement service life based on Falling Weight Deflectometer measurements. Physics and Chemistry of the Earth, 120(October 2018), 102908. https://doi.org/10.1016/j.pce.2020.102908. [4] IRC (Indian Roads Congress). (2012). “Guidelines for the design of flexible pavements.” IRC:37- 2012, New Delhi, India, 12–18. [5] Deori, S., Choudhary, R., Tiwari, D., & Gangopadhyay, S. (2018). Calibration of HDM-4 models for Indian conditions of flexible pavement having modified bitumen in wearing course. International Journal of Pavement Engineering, 19(9), 772–785. https://doi.org/10.1080/10298436.2016.1208196 [6] Singh, A., and Chopra, T. (2018a). “Development of Pavement Maintenance Management System for The Urban Road Network by Calibrating the HDM-4 Distress Models.” 1–8. New Delhi: CSIR- CRRI, pp.239-248. ISBN: 978-93-88237-20-8. [7] Solanki, U., Solanki, U. J., Gundalia, P. J., and Barasara, M. D. (2015). “A Review on Structural Evaluation of Flexible Pavements using Falling Weight Deflectometer Structural Evaluation of Flexible Pavement using Falling Weight Deflectometer View project A Study of interface bond between Prime coat over granular base, prime c.” Ttea, (January 2014), 1–10. [8] IRC 115. (2014). Guidelines For Structural Evaluation and Strengthening of Flexible Road Pavements Using Falling Weight Deflectometer (Fwd.) Technique. New Delhi. [9] https://pwd.uk.gov.in/files/3530_1.pdf [10] Kurt D. Smith, James E. Bruinsma, Monty J. Wade, Karim Chatti, Julie M. Vandenbossche, and H. T. Y. (2017). Using falling weight deflectometer data with mechanistic-empirical design and analysis, volume I: final report. Report No. FHWA-HRT-16-009. Federal Highway Administration, I(March), 182. [11] https://trid.trb.org/view/795808 [12] Pavement, L., & Program, P. (2006). Performance Program Manual for Falling Weight deflectometer. December.

Copyright

Copyright © 2022 Gagan Sharma, Harivansh Kumar Chaudhary, Akash Malik. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET46968

Publish Date : 2022-10-03

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online