Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Exhaust Power Generator

Authors: Ubaid Khan, Rehan Chaudhary, Thahil Mendon, Yusuf Rehman

DOI Link: https://doi.org/10.22214/ijraset.2022.41120

Certificate: View Certificate

Abstract

In this project, we modify a stationary diesel engine for producing power using turbine. Nowadays in automobile field many new innovating concepts are being developed. We are using the power from vehicle exhaust to generate the electricity which can be stored in battery for the later consumption. In this project, we are demonstrating a concept of generating power in a stationary multiple cylinder diesel engine by the usage of turbines. Here we are placing a turbine in the path of exhaust in the silencer. The turbine is connected to a dynamo, which is used to generate power. Depending upon the airflow the turbine will start rotating, and then the dynamo will also start to rotate. A dynamo is a device which is used to convert the kinetic energy into electrical energy. The generated power is stored to the battery. It can be stored in the battery after rectification. The rectified voltage can be inverted and can be used in various forms of utilities.

Introduction

I. INTRODUCTION

In recent the years the scientific and public awareness on environmental and energy issues has brought in major interests to the research of advanced technologies particularly in highly efficient internal combustion engines. Viewing from the socio-economic perspective, as the level of energy consumption is directly proportional to the economic development and total number of populations in a country, the growing rate of population in the world today indicates that the energy demand is likely to increase. A heat engine is a system that performs the conversion of heat or thermal energy to mechanical work. Examples of everyday heat engines include the steam engine, the diesel engine, and the gasoline (petrol) engine in an automobile. Heat engines are designed to produce useful work only. The efficiency of a modern internal combustion engine is about 37% in a normal spark ignition engine. The energy in the form of heat is rejected by means of exhaust, circulating cooling water, lubrication oil & radiation.

Substantial thermal energy is available from the exhaust gas in modern automotive engines. Two-thirds of the energy from combustion in a vehicle is lost as waste heat, of which 40% is in the form of hot exhaust gas. There are many developments and technologies on waste heat recovery of exhaust gas from internal combustion engines (ICE).

If our idea is implemented effectively, the potential for energy conservation is massive. The report deals into the Working, Hardware requirements, and the advances made so far in implementing the idea. It also hints at future modifications intended.

II. LITERATURE REVIEW

Generation of Electricity by Using Exhaust from Bike by S.Vijaya Kumar, Amit Kumar Singh, Athul Sabu and Mohamed Farhan.P[1]: - According to their study, it has been identified that there are large potentials of energy savings through the use of waste heat recovery technologies. Waste heat recovery entails capturing and reusing the waste heat from internal combustion engine and using it for heating or generating mechanical or electrical work.

Study and performance analysis of charging vehicle battery using bike exhaust gas by K. Kumaravel, P. Bala Shanmugam, and G. Balasubramanian [2], They had done different studies according to their practical inputs. They had approached the problem with different engine RPM. Practically for different engine speeds for different turbine power output were observed.

Power Generation by Exhaust Gases on Diesel Engine by Kranthi Kumar Guduru, Yakoob Kol ipak, Shanker. B and N. Suresh [3]: -. Waste heat recovery entails capturing and reusing the waste heat from internal combustion engine and using it for heating or generating mechanical or electrical work. It would also help to recognize the improvement in performance and emissions of the engine if these technologies were adopted by the automotive manufacturers.

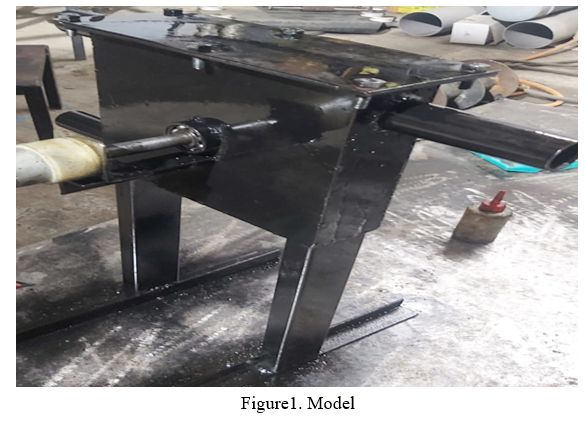

A. Main Components of Model

III. METHODOLOGY

The turbine is fixed to the shaft of the generator. It will be a mechanism of axial high-pressure turbine and backward curved fan blades with an electrical generator. The air will strike on high pressure reaction turbine and the pressure energy will convert into mechanical energy. This shaft will also be rotate fan blade that will increase the discharge rate. The improvement in discharge rate will increase the engine power because high pressure discharge means low-pressure drop-in exhaust system. If the pressure drop will be low the power will increase of the engine. The electrical generator will have rotated by the same shaft and the electricity will be produced by generator. This generator converts the mechanical work into electrical energy This generator is also a DC motor of 12 volts 0.5 MA current This DC motor will give maximum output on 1000 rpm

A. Components

- Nozzle

- Turbine

- Dynamo

- A LED Strip

- Mild steel for constructing frames

- Connecting wires

- Sheet metal

- Bearing to mount turbine

- Shaft

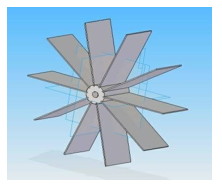

B. Turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. It has almost completely replaced the reciprocating piston steam engine primarily because of its greater thermal efficiency and higher power-to-weight ratio. Because the turbine generates rotary motion, it is particularly suited to be used to drive an electrical generator – about 90% of all electricity generation in the United States is by use of steam turbines. The steam turbine is a form of heat engine that derives much of its improvement in thermodynamic efficiency through the use of multiple stages in the expansion of the steam, which results in a closer approach to the ideal reversible process.

C. Diesel Engine

The diesel engine is an internal combustion engine in which ignition of the fuel that has been injected into the combustion chamber is caused by the high temperature which a gas achieves (i.e., the air) when greatly compressed. Diesel engines work by compressing only the air. This increases the air temperature inside the cylinder to such a high degree that it ignites atomized diesel fuel that is injected into the combustion chamber.

Specifications of diesel engine used:

|

Model |

Tata 407 |

|

Type |

Water cooled, naturally aspirated |

|

No. Of cylinders |

4 in line |

|

Displacement |

2956 cc |

|

Maximum engine output |

72 bhp |

|

Maximum operating speed |

3500 rpm |

|

Idling speed |

600 rpm |

|

Firing order |

1-3-4-2 |

|

Compression ratio |

17:1 |

D. Dynamo

Dynamo is an electrical generator. This dynamo produces direct current with the use of a commutator. Dynamo was the first generator capable of the power industries. The dynamo uses rotating coils of wire and magnetic fields to convert mechanical rotation into a pulsing direct electric current. A dynamo machine consists of a stationary structure, called the stator, which provides a constant magnetic field, and a set of rotating windings called the armature which turn within that field. On small machines the constant magnetic field may be provided by one or more permanent magnets, larger machines have the constant magnetic field provided by one or more electromagnets, which are usually called field coils.

E. Nozzle

Jet nozzles are also use in large rooms where the distribution of air via ceiling diffusers is not possible or not practical. When the temperature difference between the supply air and the room air changes, the supply air stream is deflected upwards to supply warm air or downwards to supply cold air. Nozzles can be described as convergent or divergent (expanding from a smaller diameter to a larger one). A de Laval nozzle has a convergent section followed by a divergent section and is often called a convergent divergent nozzle.

F. Battery

It is a device user to store the power. The power is stored in the form of DC current only. There are many types of batteries are used Lead acid, lithium fluoride and in this work 8Amp current and 12 voltage specification is used.

G. Shaft

A shaft is a rotating machine element, usually circular in cross section, which is used to transmit power from one part to another, or from a machine which produces power to a machine which absorbs power.

H. Bearing

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis or, it may prevent a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the plain bearing, consists of a shaft rotating in a hole. Lubrication is often used to reduce friction. In the ball bearing and roller bearing, to prevent sliding friction, rolling elements such as rollers or balls with a circular cross-section are located between the races or journals of the bearing assembly

IV. CALCULATIONS

A. Exhaust Gas Flow Rate

To determine theoretical nozzle outlet velocity:

Continuity equation,

Q=A1V1=A2V2

Velocity at nozzle outlet,

|

Trial No |

Speed of engine (rpm) |

Velocity of exhaust gas at silencer end (m/s) |

Expected velocity of exhaust at nozzle end (m/s) |

|

1 |

950 |

12.9 |

51.6 |

|

2 |

1120 |

16.1 |

64.4 |

|

3 |

1230 |

18.1 |

72.4 |

Table 4.1 Exhaust gas Velocity test

Flow rate,

Q=A*V

Where A is c/s area of outlet in m2 V is velocity in m/s

A=π*d2/4 = π*(2.5*10-2)2/4 = 4.9087*10-4m2

Therefore,

Q= 4.9087*10-4*51.6 (At an engine speed of 950 rpm) Q=0.0253 m3/s

At an engine speed of 1120 rpm, Q=0.0316 m3/s

At an engine speed of 1230 rpm, Q=0.0355 m3/s

Area Swept,

A= (22/7) x radius of turbine2 Velocity of the Turbine,

V= ((22/7) * D x N)/60

Where D=diameter of turbine

N=number of revolutions per minute Power available at the turbine,

P= (1/2) * Density * (Velocity)3*Cp*Area swept

B. Model Calculation

Swept area by the turbine, A = (22/7) x radius2

A=3.14 x (0.115) 2

A=0.04152 m2

Velocity of the turbine, V= ((22/7) x D x N)/60 V=3.14*0.115*60/60

V=0.3611 m/s

Power of the flowing exhaust gas =1/2*ρ* area x (velocity)3 * Cp

=1/2 x1.23 x 0.04152x (0.3611)3*0.4

=4.8*10-4 Watts

C. Impulse Force Acting on the Turbine

Mass flow rate,

m=ρ*Q

Where ρ is the density in kg/m3

Q is the volume flow rate in m3/s Impulse force,

F=m*V

Where V is the velocity of flow of exhaust gases in m/s

At engine speed of 950rpm,

Mass flow rate,

m=1.23*0.02503

m=0.03079kg/s Impulse force,

F=0.03079*51.6 F =1.588 N

At an engine speed of 1120rpm,

Mass flow rate,

m=1.23*0.0316

m=0.03886 kg/s Impulse force,

F=0.03886*64.4

F =2.503 N

At an engine speed of 1230rpm,

Mass flow rate,

m=1.23*0.0353

m=0.04347 kg/s Impulse force,

F=0.04347*72 F =3.129 N

D. Power Generated by Turbine

Torque,

T=F*R

Where F is impulse force in Newton

R is distance from center of shaft to the point where exhaust gas hit the blades in meter Power generated,

P=2πNT/60 watts

Where N is speed of turbine in RPM T is torque in Nm

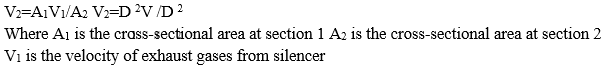

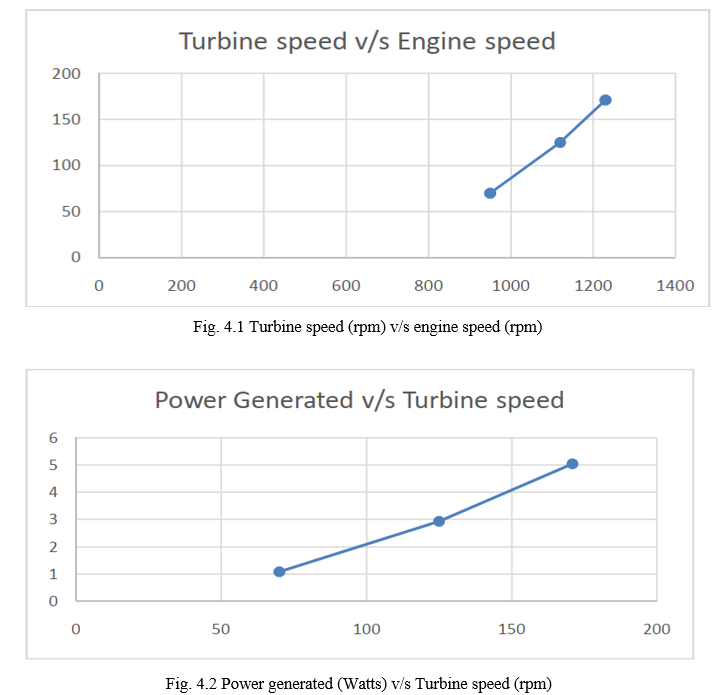

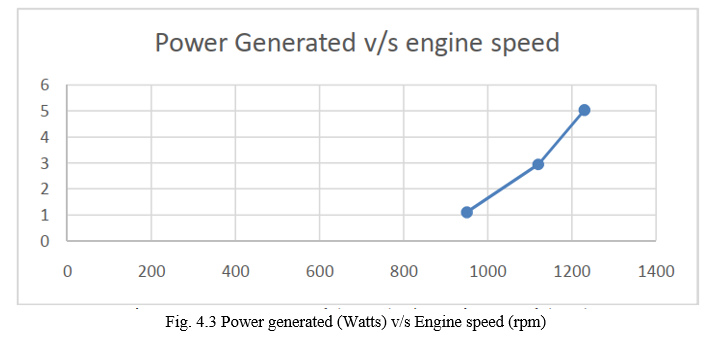

At engine speed of 950rpm,

Torque,

T=1.588*0.09 T=0.1492 Nm

Power generated,

P=2π*70*0.1492/60

P =1.0936 Watts

At engine speed of 1120rpm,

Torque,

T=2.503*0.09 T=0.225 Nm

Power generated,

P=2π*125*0.225/60

P=2.945 Watts

At engine speed of 1230rpm,

Torque,

T=3.129*0.09 T=0.2816Nm

Power generated,

P=2π*171*0.2816/60

P =5.04 Watts

V. RESULTS

VI. FUTURE SCOPE

Generation of Electricity the major goal of Using Exhaust Gases is to design a silencer-based energy generation system-based inverter. Centrifugal force is used to move air forward in most air blowers. The blower in a centrifugal air compressor is a wheel with tiny blades around the circumference and a casing that directs airflow flow into the wheel's center and out toward the edge.

The obtained energy is stored in a battery. The battery power is provided to the pulse generator, which in turn powers a MOSFET that can generate ON/OFF pulses of various frequencies. To generate low voltage AC, this is passed to a step-up transformer. This air conditioner is connected to a power outlet.

Conclusion

From this project, it has been identified that there are large potentials of energy savings through the use of waste heat recovery technologies. Waste heat recovery entails capturing and reusing the waste heat from internal combustion engine and using it for heating or generating mechanical or electrical work. It would also help to recognize the improvement in performance and emissions of the engine if these technologies were adopted by the automotive manufacturers. The study also identified the potentials of the technologies when incorporated with other devices to maximize potential energy efficiency of the vehicles. The project carried out by us made an attempt to generate electricity in engine exhaust unit. This project has also reduced the cost involved in the concern

References

[1] International Journal of Innovative Research in Science, engineering and technology.Vol.4, Special issue 6, May 2015. Generation of electricity by using exhaust gases from bike. [2] Kranthi Kumar Guduru, Yakkob KolIpak Power generation by exhaust gases on diesel engine.ISSN: 0975-5662. Vol.7, Issue 5, December Dipak Patil1, Dr. R. R. Arakerimath2” A Review of Thermoelectric Generator for Waste Heat Recovery from Engine Exhaust” Vol.1 Issue.8, December 2013.Pgs: 1-9 [3] 3. Prathamesh Ramade1, Prathamesh Patil2, Manoj Shelar3, Sameer Chaudhary4, Prof. Shivaji Yadav5, Prof. Santosh Trimbake6” Automobile [4] Exhaust Thermo-Electric Generator Design &Performance Analysis” International Journal of Emerging Technology and Advanced Engineering [5] Website: www.ijetae.com (ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 4, Issue 5, May 2014) [6] 3. R. Saidur a, M.Rezaei a, W.K.Muzammil a, M.H.Hassan a, S.Paria a, M.Hasanuzzaman b,n” Technologies to recover exhaust heat from internal engines. [7] Combustionengines”1364-0321/$ see frontmatter & 2012 ElsevierLtd.Allrightsreserved. [8] 4. Jia S, Peng H, Liu S, Zhang X. Review of transportation and energy consumption related research. Journal of Transportation Systems [9] Engineering and Information Technology 2009;9(3):6–16. [10] Saidur R. A review on electrical motors energy use and energy savings. Renewable and Sustainable Energy Reviews 2010;14(3):877–98. [11] Saidur R, Atabani AE, Mekhilef S. A review on electrical and thermal energy for industries. Renewable and Sustainable Energy Reviews [12] Jahirul MI, Saidur R, Hasanuzzaman M, Masjuki HH, Kalam MA. A comparison of the air pollution of gasoline and CNG driven car for [13] Malaysia. International Journal of Mechanical and Materials Engineering 2007;2(2):130–8.

Copyright

Copyright © 2022 Ubaid Khan, Rehan Chaudhary, Thahil Mendon, Yusuf Rehman. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET41120

Publish Date : 2022-03-31

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online