Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Investigation on Black Cotton Soil Treated with Terrabind Chemical and Glass Powder

Authors: V Ratna Deepika, Ch. Sivanarayana

DOI Link: https://doi.org/10.22214/ijraset.2022.47651

Certificate: View Certificate

Abstract

Objectives: To improve the soil stability of Black Cotton (BC) soil which is abundantly found in East Godavari district and some costal areas of Andhra Pradesh in India as they are susceptible to detrimental volumetric changes, with changes in moisture. Methods: laboratory studies has been carried-out to investigate the influence of chemical called Terrabind on Balck Cotton (BC) soil from Amalapuram, East Godavari, Andhra Pradesh, and further the influence on BC when Terrabind is added in combination with Glass Powder (GP). Basic geotechnical properties like grain size distribution, specific gravity, consistency limits have been determined and engineering properties like Maximum Dry Density (MDD), Optimum Moisture Content (OMC), Unconfined compressive strength, California Bearing Ratio (CBR), and Triaxial compression test have been determined for untreated and treated soil. Swelling properties have been determined by conducting free swell index test and swell pressure test. The laboratory investigations were conducted for different curing days to determine the basic and engineering properties of soil such as Atterberg’s limits, grain-size distribution, MDD, OMC, CBR, Unconfined Compressive Strength (UCS), Strength, Durability, Fatigue and Resilient Modulus (E). Findings: There is no huge soil expansion in the consistency limits for the compound (which compound) treated BC soil. Untreated soil shows LL=63%, PL =32%, and PI =34%. For soil settled with Terrabind, PI has diminished from 28% for one day restoring to 24% for 28 days relieving period. For soil balanced out with Terrabind+GP, PI has diminished from 27 % for one day restoring to 18% for 28 days relieving period. Improvement in dry density of treated soil is peripheral. MDD expanded from 17.6 KN/m3 to 18.4 KN/m3 and 18.7 KN/m3, and OMC was decreased from 16.32% to 16.24% and 16.12% for soil settled with Terrabind and Terrabind + GP for 28 days restoring period individually. Swell strain test results showed that Swell tension diminished from 49.5 KN/m2 to 36.73 KN/m2 and 35.12 KN/m2 for soil settled with Terrabind and Terrabind+ GP tried following 7 days of restoring. Swell tension was decreased by 26% and 29% for soil settled with Terrabind and Terrabind+ GP individually. Novelty: Soil stabilized with Terrabind and GP has showed better results compared to soil stabilized with Terrabind. Percentage weight loss was less than 14% for 12th cycle of freeze- thaw, which shows that the stabilized soil has become durable. Swelling has reduced to a great extent. The swelling of soil stabilized with Terrabind and Glass Powder (GP) has reduced by 100%.

Introduction

I. INTRODUCTION

Stabilization is the most common way of mixing and blending materials in with a clay to work on specific properties of the dirt. The interaction might incorporate the mixing of soil to accomplish an ideal degree or blending of industrially accessible added substances that might modify the degree, surface or plasticity, or go about as a cover for cementation of the clay. Soil Stabilization is the collective term used to mean any physical, texture or organic strategy or any mix of such techniques utilized to work on specific properties of normal soil to make it serve sufficiently for an expected engineering work. A cement material or a chemical is added to a natural soil for the purpose of stabilization. The decreasing availability and increasing cost of construction materials and uncertain economic climates force engineers to consider more economical methods for building any civil engineering construction. When poor quality soil is available at the construction site, the best option is to modify the properties of the soil so that it meets the pavement design requirements.

This has led to the development of soil stabilization techniques. Soil improvement by mechanical or chemical means is widely adopted. In order to stabilize soil for improving strength and durability, a number of chemical additives, both inorganic and organic, have also been used.

A. Uses Of Stabilization

Any civil engineering design is based on the premise that minimum specified structural quality will be achieved for each layer of material in the pavement system. Each layer must resist shearing, avoid excessive deflections that cause fatigue cracking within the layer or in overlying layers, and prevent excessive permanent deformation through densification. As the quality of a soil layer is increased, the ability of that layer to distribute the load over a greater area is generally increased so that a reduction in the required thickness of the soil and surface layers may be permitted.

II. METHODOLOGY

A. Methods Used

The basic tests for Grain Size distribution (IS:2720, Part-IV), Specific Gravity (IS:2720, Part-III), Atterbergs limits (IS:2720, Part-V), Compaction characteristics (IS:2720, Part-VII, VIII), UCS (IS:2720, Part-X), CBR (IS:2720 Part-XVI), Permeability Test (IS: 2720 (part XVII), Durability (ASTM D 559, 560), Tri axial test (AASHTO T 307-99), IDT strength (ASTM D 6931) Fatigue behaviour, etc. Were performed.

B. Material

- Terrabind: Terrabind is a revolutionary advanced lignosulphonate liquid ionic organic compound for the purpose of soil stabilization. Terra Nova Technologies is the first company to manufacture this technology in India. Terrabind alters the properties of road base materials (soil/aggregate) at a molecular level thus rendering greater compaction, load bearing and cohesiveness. Organic lignins allow for polymeric binding between soil grains. Electrolyte emulsions attack the clay lattice of soil by altering the ionic charge in clay and breaking down the capillary action of clay soil particles and this makes the soil particles to attract and retain moisture. It is available in the liquid concentration and is to be diluted in water in specified proportion before mixing with the soil. Physical properties of Terrabind are tabulated in Table

Table :1 Physical Properties of Terrabind

|

Properties |

Description |

|

Form |

Liquid |

|

Odor |

Sharp, Sulphurous |

|

Colour |

Dark Amber |

|

Wetting Ability |

Excellent |

|

Boiling Point |

182oC |

|

Specific Gravity |

1.7 |

|

pH |

1 |

|

Wieght per gallom |

14.19lb |

C. Physiochemical properties of BC soil

Black cotton soil consists of clay minerals like Montmorrilonite, Illite and Kaolinite, chemicals like iron oxide and calcium carbonate (in the form of kankars), and organic matter like humus. Montmorrilonite is the predominant mineral of Black cotton soils. The swelling and shrinkage behavior of black cotton soil originate mainly from this mineral are hydrous silicates of aluminum and magnesium .They are made of sheets of silica (tetrahedral) and alumina (octahedral) stacked on above the other forming sheet like of flaky particle. Montmorrilonite has a three sheeted structure with expanding lattices. The structure carries negative charge, due to isomorphic substitution of some aluminum ions by magnesium ions and minerals becomes chemically active

Table : 2 Physical Competitions of Black cotton soil

|

Properties |

Black Cotton Soil |

|

Specific Gravity |

2.7 |

|

Liquid Limit (%) |

68 |

|

Plastic Limit (%) |

27 |

|

SHrinkage Limit (%) |

11 |

|

Max Dry Density |

15.5 |

|

Optimum Moisture Content(%) |

25.21 |

|

Cation Exchange Capacity (Meq/100g) |

41.82 |

|

Specific Surface area |

63 |

|

Fine Sand % |

38 |

Table: 3 Chemical Compositions of Black cotton soil

|

Property |

Value |

|

pH |

2.7 |

|

Organic Content |

68 |

|

CaCO3 |

27 |

|

SiO2 |

11 |

|

SiO2, Al2O3 |

15.5 |

|

Montmorrilonite Mineral |

25.21 |

|

Cation Exchange Capacity (Meq/100g) |

41.82 |

|

Specific Surface area |

63 |

|

Fine Sand % |

38 |

III. STABILIZATION USING TERRABIND CHEMICAL

The need to stabilization of soil in the embankments/sub grade layer is decreased with Terrabind treatment. The response of Terrabind with clay soil makes a super durable response in the sub-atomic design of clay soil particles delivering diminished enlarge potential, more prominent compaction, load bearing and soil molecule cohesiveness. Terrabind will further develop engineering properties (compaction, union, load orientation) of soil and squashed macadam street base plans by 25% - 150%.

Regular soil stabilization methods include synthetic substances particles connecting to clay soil grains. Notwithstanding, these synthetic substances atoms move washed away with rising ground water. Terrabind adjusts the exceptionally atomic construction in this way the qualities of the dirt bang for all time. With terrabind, street designers can lessen asphalt thickness, lower starting development costs, work on calculated effectiveness. Lower life cycle costs and limit human blunder while expanding street base strength and solidness when contrasted with their arranged plan blend. World over, this stabilization innovation has demonstrated its capacity. Land Nova advances makes similar innovation in India at a lower cost.

The science behind reacting clay soil with Terrabind

Terrabind assaults the clay cross section of the dirt which changes the ionic charge in clay and makes a substance connection between the clay particles.

Terrabind lessens psychologist and swell by framing a substance and actual connection between the clay particles that oppose water ingestion. This permits the dampness content of the dirt to settle which diminishes the development of the dirt.

Terrabind separates the narrow activity of soil particles accordingly decreasing the dampness retentive nature of most expansive soil.

Terrabind disseminates the mineral particles uniformly all through the blend, in this way expanding particulate fascination and diminishing voids bringing about expanded material thickness and hardness while keeping up with adaptability.

The communication of its parts enacts and ties the normally happening mineral concretes in soil together to frame a material undifferentiated from most sedimentary rocks.

More compelling than lime in high sulfate soil (lime response in such soil prompts volume development driving

A. Glass Powder

Glass is created by super cooling of dissolved fluid blend involving silicondioxide and soft drink debris which secures the inward design of a fluid as opposed to going through crystallization. The waste glass utilized in the review was gathered from post-customer squander comprising of the remaining parts of glass pieces from window frames and glass contains made of pop lime glass. The soft drink lime glass is made by replacing the soft drink debris utilized as a transition by limestone or dolomite. These sorts of glasses represent right around 80 - 90% of the waste glass delivered in India and the USA.

Squander glass powder is gathered from Glass House, East Godavari, Andhra Pradesh, India. Lime bought from nearby market of Kakinada. The primary advantages of utilizing lime to stabilization of soil particles by give bond strength between squander glass powder and soil, likewise increment strength, and lessening shrinkage and swell qualities. Lime is generally normally added substance for the stabilization of expansive soils. Lime is delivered from modern cycles and is connects with the emanation of ozone depleting substances like carbon dioxide (CO2), sulfur dioxide (SO2) and nitrous oxide (N2O). As indicated by the above writing survey, WGP and lime can be utilized for working on the geotechnical properties of various sorts of soil. The primary target of this study is to find the ideal level of waste glass powder to be utilized for working on the expansive soil.

Different significant tests are act in the laboratory according to the important IS code:

- Specific gravity (IS: 2720 PART III/ Sec I) – 1980

- Liquid limit (IS: 2720 PART-V)-1985.

- Plastic limit (IS: 2720 PART-V)-1985.

- Free Swell index test of Soil (IS-2720-PART-40-1970)

- Standard Proctor Test (IS-2720(Part-7), 1965)

- CBR (California Bearing Ratio) test of soil (IS-2720-PART16-1979)

The grain size dispersion bends for the expansive soil and WGP are displayed in Fig. 4. As per the degree bend of the dirt, around 47% of the dirt is clay, and 82% of WGP is sediment. Moreover, as per the brought together soil characterization framework, the expansive soil, in this review, was delegated low-plasticity clay (CL).

B. Terrabind and Glass Powder (GP)

Terrabind in combination with Glass Powder is highly recommended for use in combination with Terrabind. Terrabind has a catalyst effect when combined in clay soil with Glass Powder. 5%-10% Glass Powder by weight of soil is an ideal range.

C. Terrabind Chemical Constituents

Terrabind is a high level restrictive electrolyte lignin emulsion and a profoundly thought fluid substance. The science behind Terrabind's plan centers around making three essential changes in soil particles;

- Alter the ionic trade liable for water fascination in soil particles.

- Break down hairlike activity answerable for water maintenance (expand/recoil).

- Actuate aluminosilicates inside soil to increment molecule restricting and layer thickness.

IV. TESTS ON BASIC PROPERTIES OF BLACK COTTON SOIL

The results of tests on basic soil properties of BC soil are tabulated in Table 4.

Table: 4 Results of basic soil properties of untreated BC soil.

|

SL No. |

Property |

Values |

|

1 |

Specific gravity |

2.5 |

|

2 |

Grain size distribution (%) |

|

|

Gravel |

5 |

|

|

Sand |

26 |

|

|

Silt |

54 |

|

|

Clay |

15 |

|

|

3 |

Consistency limits (%) |

|

|

Liquid Limit |

64 |

|

|

Plastic Limit |

31 |

|

|

Plasticity Index |

33 |

|

|

4 |

|

|

|

IS Soil Classification |

CH |

|

|

5 |

Engineering Properties |

|

|

I.S standard Compaction |

|

|

|

|

a) MDD, γdmax (kN/m3) |

16.2 |

|

b) OMC (%) |

20.45 |

|

|

I.S modified Compaction |

|

|

|

a) MDD, γdmax (kN/m3) |

17.7 |

|

|

b) O.M.C |

16.31% |

|

|

|

CBR Value (%) |

|

|

6 |

I.S Standard Compaction |

|

|

a) OMC condition |

25.04% |

|

|

b) Soaked condition |

0.89% |

|

|

I.S Modified Compaction |

|

|

|

a) OMC condition |

28.17% |

|

|

b) Soaked condition |

0.45% |

|

|

7 |

UCS (kN/m2) |

|

|

I.S Standard Compaction |

152.19 |

|

|

I.S Modified Compaction |

268.27 |

|

V. RESULTS AND DISCUSSION

Results of tests performed on bc soil treated with terrabind chemical and terrabind, GP.

A . Plasticity Characteristics

Table shows the variety in consistency limits of mixed soil for various curing period. In the event of soil treated with Terrabind, LL has decreased by 11%, plastic limit has expanded by 9% and plasticity index has diminished by 30% for 28 days curing period and if there should arise an occurrence of soil balanced out with Terrabind and GP liquid limit has diminished by 22%, PL has expanded by 6% and PI has decreased by 49% for 28 days curing period.

Table: 5 Variation of consistency limits of untreated and treated soil for different curing period.

|

Property |

BC soil |

BC+ Terrabind |

BC+ Terrabind+ GP |

||||

|

1 Day |

7 Days |

28 Days |

1 Day |

7 Days |

28 Days |

||

|

LL |

64 |

60 |

58 |

57 |

55 |

51 |

50 |

|

PL |

31 |

33 |

34 |

34 |

29 |

28 |

33 |

|

PI |

33 |

27 |

24 |

23 |

26 |

23 |

17 |

B. Compaction Test Results

Following table shows the IS modified compaction aftereffects of treated and untreated soil. It tends to be seen that there is exceptionally slight expansion in dry density of treated soil. . MDD of soil balanced out with Terrabind for 28 days curing is 18.5 KN/m3 and 18.8 KN/m3 for soil settled with Terrabind and Glass Powder.

Table: 6 MDD and OMC of untreated and treated soil for different curing period.

|

Property |

|

BC+ Terrabind |

BC+ Terrabind+ GP |

|||||

|

BC soil |

1 Day |

7 Days |

28 Days |

1 Day |

7 Days |

28 Days |

||

|

I.S modified Compaction |

a) MDD (KN/m3) |

17.7 |

17.7 |

17.9 |

18.5 |

17.7 |

18.0 |

18.8 |

|

b) O.M.C (%) |

16.31 |

16.31 |

16.29 |

16.25 |

16.31 |

16.21 |

16.11 |

|

Based on Heavy compaction test results (MDD and OMC), UCS tests for untreated and treated soil tests were done and the experimental outcomes are introduced in the Table 5.4. From the outcomes it is seen that the strength of soil treated with terrabind has expanded by 80% and soil treated with Terrabind and Glass Powder has expanded by 73%. Results showed expansion in strength with expansion in curing time for both the blends. The strength of soil settled with Terrabind (1203 KN/m2) was more contrasted with soil balanced out with Terrabind and Glass Powder (971.25 KN/m2).

Table: 7 Unconfined compressive strength results of untreated and treated soil for different curing period.

|

Property |

BC soil |

BC+ Terrabind |

BC+ Terrabind+ GP |

||||

|

1 Day |

7 Days |

28 Days |

1 Day |

7 Days |

28 Days |

||

|

UCS |

268 |

414.68 |

792.23 |

1203.98 |

743.54 |

890.37 |

971.25 |

C. CBR Test Results

The results of the CBR tests are arranged in Table 5.5. It very well may be seen from the table that the CBR of treated soil at unsoaked condition has expanded hugely for both the blends. The unsoaked CBR of soil has expanded by 31% and 48% for soil treated with Terrabind and Terrabind+ Glass Powder separately.

Table: 8 CBR test results of untreated and treated soil for different curing period.

|

Property |

|

BC+ Terrabind |

BC+ Terrabind+ GP |

|||||

|

BC soil |

1 Day |

7 Days |

28 Days |

1 Day |

7Days |

28 Days |

||

|

CBR Value (%) |

Unsoaked condition |

28.17 |

33.09 |

40.25 |

40.69 |

47.4 |

48.74 |

53.66 |

|

Soaked condition |

1.04 |

0.67 |

1.34 |

2.3 |

1.12 |

1.57 |

2.55 |

|

???????D. Triaxial Test

Consequences of Triaxial pressure test have been introduced in the table 5.6. Table shows the variety in attachment and point of rubbing of untreated and treated soil.

Table: 9 Triaxial compression test results of untreated and treated soil for different curing period

|

Property |

BC soil |

BC+ Terrabind |

BC+ Terrabind+ GP |

||||

|

1 Day |

7 Days |

28 Days |

1 Day |

7 Days |

28 Days |

||

|

Cohesion ( c ) KN/m2 |

45 |

90 |

160 |

320 |

120 |

230 |

350 |

|

Angle of failure(?) in degrees |

35 |

38 |

45 |

54 |

35 |

35 |

36 |

???????E.Free Swell Index

Results of Free swell index test have been presented in the table 5.7. It is observed from the results that the swelling property of black cotton soil has reduced greatly after stabilizing the soil with Terrabind and with the addition of flyash the swelling has reduced to zero with time.

Table: 10 Free swell index test results of untreated and treated soil for different curing period.

|

Property |

BC soil |

BC+ Terrabind |

BC+ Terrabind+ GP |

||||

|

1 Day |

7 Days |

28 Days |

1 Day |

7 Days |

28 Days |

||

|

FSI (%) |

50 |

8.33 |

8.33 |

8.33 |

8.33 |

8.33 |

0 |

F. Swell Pressure

Aftereffects of swell tension test have been introduced in the table 5.8. Swell tension of treated soil is viewed as 49.5 KN/m2.

Table: 11 Swell pressure test results of untreated and treated BC soil.

|

Soil Mix |

Swell Pressure (KN/m2 ) |

|

Untreated soil |

49.495 |

|

Soil +Terrabind |

36.72 |

|

Soil +Terrabind+ Glass Powder |

35.12 |

G. Durability

- Wet and Dry Method: When the samples were immersed in water for the first cycle of wetting, the samples couldn’t withstand and samples got collapsed within a fraction of seconds.

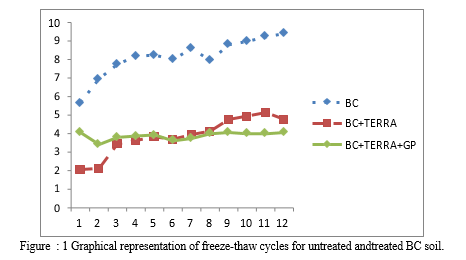

- Freeze and Thaw Test: Results of freeze and defrost test on untreated have been introduced in table 5.9 and results of soil treated with Terrabind and Terrabind+GP have been introduced in table 5.10, and 5.11 separately.

Table: 12 Freeze and thaw test results of untreated and treated BC soil.

|

|

BC Soil |

BC Soil + Terrabind |

BC Soil + Terrabind + GP |

||||

|

No. of Cycles |

weight (gm) |

% weight loss |

weight (gm) |

% weight loss |

weight (gm) |

% weigh t loss |

|

|

1 |

Freeze |

160.7 |

0.31 |

160.0 |

0.06 |

157.1 |

0.2 |

|

Thaw |

152.1 |

5.65 |

156.8 |

2.06 |

151.0 |

4.1 |

|

|

2 |

Freeze |

153.3 |

4.90 |

157.2 |

1.81 |

153.0 |

2.8 |

|

Thaw |

150.0 |

6.95 |

156.7 |

2.12 |

152.0 |

3.4 |

|

|

3 |

Freeze |

151.7 |

5.89 |

157.2 |

1.81 |

153.7 |

2.4 |

|

Thaw |

148.7 |

7.75 |

154.6 |

3.44 |

151.4 |

3.8 |

|

|

4 |

Freeze |

149.7 |

7.13 |

155.8 |

2.69 |

151.7 |

3.6 |

|

Thaw |

148.0 |

8.19 |

154.3 |

3.62 |

151.3 |

3.9 |

|

|

5 |

Freeze |

149.1 |

7.51 |

155.3 |

3.00 |

151.8 |

3.6 |

|

Thaw |

148.1 |

8.13 |

154.0 |

3.81 |

151.2 |

3.9 |

|

|

6 |

Freeze |

148.6 |

7.82 |

155.4 |

2.94 |

151.5 |

3.7 |

|

Thaw |

148.3 |

8.00 |

154.2 |

3.69 |

151.7 |

3.6 |

|

|

7 |

Freeze |

149.3 |

7.38 |

156.7 |

2.12 |

151.7 |

3.6 |

|

Thaw |

147.3 |

8.62 |

153.8 |

3.94 |

151.5 |

3.7 |

|

|

8 |

Freeze |

148.3 |

8.00 |

154.5 |

3.50 |

151.3 |

3.9 |

|

Thaw |

148.4 |

7.94 |

153.5 |

4.12 |

151.1 |

4.0 |

|

|

9 |

Freeze |

149.3 |

7.38 |

155.1 |

3.12 |

151.2 |

3.9 |

|

Thaw |

147.0 |

8.81 |

152.5 |

4.75 |

151.0 |

4.1 |

|

|

10 |

Freeze |

148.3 |

8.00 |

151.2 |

5.56 |

151.5 |

3.7 |

|

Thaw |

146.7 |

9.00 |

152.2 |

4.93 |

151.1 |

4.0 |

|

|

11 |

Freeze |

145.6 |

9.68 |

151.9 |

5.12 |

151.3 |

3.9 |

|

Thaw |

146.3 |

9.24 |

151.9 |

5.12 |

151.1 |

4.0 |

|

|

12 |

Freeze |

147.4 |

8.56 |

152.7 |

4.62 |

150.0 |

4.7 |

|

Thaw |

147.0 |

8.81 |

152.5 |

4.75 |

151.0 |

4.1 |

|

H. Fatigue Test

Results of fatigue test on untreated examples have been introduced in table 5.12 and results of soil treated with Terrabind and Terrabind+ GP have been introduced in table 5.13, and 5.14.

Table: 13 Fatigue test results of untreated BC soil.

|

UCS(31.99Kg) |

Fatigue life(No of cycles) |

|

|

% of UCS strength |

Applied stress(Kg) |

|

|

33.33 |

10.65 |

8422 |

|

50 |

16 |

6612 |

|

66.66 |

21.33 |

3798 |

Table: 14 Fatigue test results of soil treated with Terrabind.

|

Curing period |

UCS (Kg) |

Fatigue life(No of cycles) |

||

|

Total UCS strength(Kg) |

% of UCS strength |

Applied stress(Kg) |

||

|

7 days |

93.61 |

33.33 |

31.17 |

15589 |

|

50 |

46.81 |

12567 |

||

|

66.66 |

62.41 |

10415 |

||

|

28 days |

147.81 |

33.33 |

49.22 |

20449 |

|

50 |

73.91 |

16780 |

||

|

66.66 |

98.54 |

13365 |

||

Table: 15 Fatigue test results of soil treated with Terrabind and Glass Powder.

|

Curing period |

UCS (Kg) |

Fatigue life(No of cycles) |

||

|

Total UCS strength(Kg) |

% of UCS strength |

Applied stress(Kg) |

||

|

7 days |

105.97 |

33.33 |

35.29 |

20119 |

|

50 |

52.99 |

18715 |

||

|

66.66 |

70.65 |

16318 |

||

|

28 days |

115.6 |

33.33 |

38.49 |

23450 |

|

50 |

57.8 |

20570 |

||

|

66.66 |

77.1 |

18560 |

||

VI. DISCUSSION

- There is no huge expansion in the consistency limits for the compound treated BC soil. Untreated soil shows LL=64%, PL =31%, and PI =33%. For soil settled with Terrabind, PI has diminished from 27% for one day restoring to 23% for 28 days relieving period. For soil balanced out with Terrabind+GP, PI has diminished from 26 % for one day restoring to 17% for 28 days relieving period. Measure of clay content assumes a significant part in the variety of consistency limits. Since the tried soil contains just 15% of clay, there is no much improvement in Atterberg's limits. According to IS:1498, "arrangement of swelling soils", the level of development regarding LL has decreased from high to mechanism for soil balanced out with Terrabind and GP and as for PI level of extension has diminished from exceptionally high to mode for soil settled with Terrabind as well concerning soil balanced out with Terrabind and GP.

- Improvement in dry density of treated soil is peripheral. MDD expanded from 17.7 KN/m3 to 18.5 KN/m3 and 18.8 KN/m3 for soil settled with Terrabind and Terrabind + GP separately for 28 days relieving period. OMC was decreased from 16.31% to 16.25% and 16.11% for soil settled with Terrabind and Terrabind + GP for 28 days restoring period individually. Expansion in dry density might be because of the enactment of aluminosilicates inside soil particles which brings about change of the ionic trade liable for water fascination in soil atoms.

- The improvement in UCS esteem is especially reassuring. Terrabind synthetic is viewed as powerful in expanding the UCS esteem. The strength of soil balanced out with Terrabind (1203 KN/m2) is more contrasted with strength of soil settled with Terrabind + GP (971.25 KN/m2). It was likewise found that as the restoring period builds the UCS esteem additionally increments. This propensity might be because of successful cation trade process which for the most part takes longer period. This tremendous expansion in strength is because of Terrabind substance response with the clay cross section of the dirt which changes the ionic charge in clay and makes a compound connection between the clay particles.

- CBR worth of treated soil at unsoaked condition increments hugely for both the blends. The unsoaked CBR worth of soil increments from 28.17% for untreated soil to 40.69% and 53.66% for soil settled with Terrabind and soil balanced out with Terrabind+GP for 28 days relieving individually. From the outcomes got obviously the compound further develops the CBR worth of the unsoaked soil by and large and it is more powerful when GP is added to it. Soil settled with Terrabind+GP shows improved results because of the expansion of cementitous materials like GP with added substance lime which reinforces the dirt further. Terrabind catalyzes the actuation of aluminosilicates in soil alongside the calcium hydroxide presents in cementitous covers, yet in the event of doused condition there isn't a lot of expansion in CBR. The greatest CBR at drenched condition for 28 days relieving period for soil settled utilizing Terrabind and Terrabind+GP lime is 2.3% and 2.55% individually.

- From Free Swell Index (FSI) test it was seen that swelling property of BC soil has decreased significantly in the wake of balancing out the dirt with Terrabind and with the expansion of GP the swelling has diminished to zero with longer restoring time. At the point when FSI test was led following 28 days, the swelling has decreased by 83% and 100 percent for soil balanced out with Terrabind and Terrabind+GP individually. This shows that the synthetic is exceptionally successful in lessening the swelling properties of BC soil and is viewed as more compelling when GP is added. According to IS: 1498 "order of swelling soils", the level of extension as for FSI has decreased from medium to low.

- Swell strain test results showed that Swell tension diminished from 49.5 KN/m2 to 36.72 KN/m2 and 35.12 KN/m2 for soil settled with Terrabind and Terrabind+ GP tried following 7 days of restoring. Swell tension was decreased by 26% and 29% for soil settled with Terrabind and Terrabind+ GP individually. The decrease in swell tension is because of the activity of electrolytic emulsions presents in Terrabind that goes after the clay cross section of soil by adjusting the ionic charge in clay and separating the slender activity of clay soil particles hence diminishing the capacity for soil particles to draw in and hold dampness. This shows that the compound is extremely powerful in diminishing the swelling properties of BC soil and is viewed as more successful when Glass Powder is added.

- From freeze and defrost test it has been seen that the rate misfortune in weight after the last pattern of freezing and defrosting (twelfth cycle) is 8.81%, 4.75% and 4.1% for untreated soil, soil treated with Terrabind and soil treated with Terrabind + GP separately. According to AASHTO, rate weight reduction ought to be inside 14 %. In this way we can say that the settled soil is solid.

- The fatigue investigation directed in light of the UCS test results demonstrate that the fatigue life has expanded enormously in the wake of balancing out the dirt. Soil example blend ready with Terrabind and Terrabind + GP showed sensibly great fatigue life.

Conclusion

The terrabind chemical with combination of glass powder has shown the best results on an index and the swelling soils’ engineering properties were satisfied by the enhanced geotechnical properties of expansive soils. Sample expansive soil from Amalapuram was selected for this study. There is no huge expansion in the consistency limits for the compound treated BC soil. Untreated soil shows LL=63%, PL =32%, and PI =34%. For soil settled with Terrabind, PI has diminished from 28% for one day restoring to 24% for 28 days relieving period. For soil balanced out with Terrabind+GP, PI has diminished from 27 % for one day restoring to 18% for 28 days relieving period. Improvement in dry density of treated soil is peripheral. MDD expanded from 17.6 KN/m3 to 18.4 KN/m3 and 18.7 KN/m3, and OMC was decreased from 16.32% to 16.24% and 16.12% for soil settled with Terrabind and Terrabind + GP for 28 days restoring period individually. Swell strain test results showed that Swell tension diminished from 49.5 KN/m2 to 36.73 KN/m2 and 35.12 KN/m2 for soil settled with Terrabind and Terrabind+ GP tried following 7 days of restoring. Swell tension was decreased by 26% and 29% for soil settled with Terrabind and Terrabind+ GP individually.

References

[1] Salim, Nahla. (2021). Improvement of the Geotechnical Properties of Expansive Soils Using Fly Ash. Journal of Southwest Jiaotong University. 56. 10.35741/issn.0258-2724.56.1.9. [2] Wang W, Lv B, Zhang C, Li N, Pu S. Mechanical Characteristics of Lime-Treated Subgrade Soil Improved by Polypropylene Fiber and Class F Fly Ash. Polymers (Basel). 2022 Jul 19;14(14):2921. doi: 10.3390/polym14142921. PMID: 35890700; PMCID: PMC9323135. [3] J. Zhang, A. Deng, M. Jaksa, Optimizing micaceous soil stabilization using response surface method,Journal of Rock Mechanics and Geotechnical Engineering, Volume 13, Issue 1,2021, Pages 212-220, ISSN 1674-7755, [4] Wang W, Lv B, Zhang C, Li N, Pu S. Mechanical Characteristics of Lime-Treated Subgrade Soil Improved by Polypropylene Fiber and Class F Fly Ash. Polymers (Basel). 2022 Jul 19;14(14):2921. doi: 10.3390/polym14142921. PMID: 35890700; PMCID: PMC9323135. [5] Turan, C & Javadi, Akbar & Vinai, Raffaele & Cuisinier, Olivier & Russo, Giacomo & Consoli, Nilo. (2019). MECHANICAL PROPERTIES OF CALCAREOUS FLY ASH STABILIZED SOIL. [6] IS: 2720 (part 3)-1980, “Determination of specific gravity, Section-1 Fine grained soils.” Bureau of Indian Standards, New Delhi. /http://hdl.handle.net/10871/38081 [7] IS 2720 (Part 5)-1985. “Determination of Liquid and Plastic limit” Bureau of Indian Standards , New Delhi. [8] IS: 2720 (part 8)-1983, “Determination of water content - Dry Density Relation using Heavy Compaction” Bureau of Indian Standards , New Delhi. [9] IS: 2720 (part 10)-1973, “Determination of Unconfined Compression Strength” Bureau of Indian Standards , New Delhi. [10] IS: 2720 (part 16)-1979, “Laboratory Determination of CBR” Bureau of Indian Standards , New Delhi. [11] IS: 2720 (Part 11)-1971, “Determination of shear parameters by triaxial test” Bureau of Indian Standards , New Delhi. [12] Rao, K., Satishkumar, K. and Blessingstone, T. (2012). “Performance of recron-3s fiber with cement kiln dust in expansive soils.” International Journal of Engineering Science and Technology (IJEST), 4 / https://doi.org/10.22214/ijraset.2022.47340. [13] N. Latifi, F. Vahedifard, E. Ghazanfari, A.S.A. Rashi(2018) ‘’ Sustainable usage of calcium carbide residue for stabilization of clays”, Journal of Materials in Civil Engineering, 30 (6) (2018), 10.1061/(ASCE)MT.1943-5533. 0002313. [14] Al-Rawi, Dr. Orabi & Mohammed, Neimat & Sammarraie, Abdulrahman & Najeeb, Abdulrahman. (2020). Article ID: IJARET_11_06_058 Simulation Model to Predict the Volumetric Changes of Expansive Soils and Factors Affecting them. 10.34218/IJARET.11.6.2020.058. [15] Terra Nova Technologies. (2012). “http://terranovatechnologies.com/.” Thyagaraj, T., Rao, M.S., Sai, S.P. and Salini, U. (2011). “Laboratory studies on stabilization of an expansive soil by lime precipitation technique.”Journal of Materials in Civil Engineering., ASCE publication. [16] Warren, K.W. and Kirby, T.M. (2004). “Expansive clay soil a wide spread and costly geohazard.” Geostra, Geoinstitute of ohe American Society of Civil Engineers.

Copyright

Copyright © 2022 V Ratna Deepika, Ch. Sivanarayana. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET47651

Publish Date : 2022-11-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online