Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Strength on Polypropylen Fiber Reinforced Concrete

Authors: K. Selvi, S. Karthi

DOI Link: https://doi.org/10.22214/ijraset.2022.48229

Certificate: View Certificate

Abstract

The paper presents research work of experimental investigation on polypropylene fiber reinforced concrete by replacing river sand to artificial sand with and without admixture. Use of fiber reinforce polymer in civil engineering increase rapidly. Various type of fiber is used such as glass, carbon, steel, asbestos, polyester and polypropylene. The various experimental investigations for determination of properties of polypropylene fiber are discussed in paper work. This paper presents the effect of polypropylene (PP) fibers on various properties of concrete such as compressive strength, tensile strength, workability, and fracture properties with various content of fiber(0% ,0.5%,1.0%,1.5%). The result of this present investigation indicates that by adding of 0.5% of polypropylene fiber shows maximum compressive and tensile strength.

Introduction

I. INTRODUCTION

Concrete is one of the most important materials among the building materials in all types of civil engineering works. Since the adaptation of concrete as a building material, lot of researches and studies has been made to improve the quality, strength and durability of it. By the same time efforts are also being made to economize concrete construction compared to other materials. Plain concrete is good in compression but weak in tensile strength with very limited ductility and little resistance to cracking. Internal micro cracks are inherently present in concrete and its poor tensile strength is due to propagation of such micro cracks, eventually leading to brittle fracture of concrete. Generally in case of rigid pavements cracks are formed due to the variation in temperature, shrinkage and heavy moving loads.

II. LITERATURE REVIEW

- B. Vijaya and Dr.S.Elavenil et al.

State that The mix withmanufacturing sand as 100% fine aggregate gives initial workability of 170mm, which is much higher than that of the mixes with 100% river sand(RS) and crusher dust. The standard mix with 100% manufactured sand has exhibited much higher compressive strength 53 MPa. The standard mix with 100% of river sand has exhibited compressive strength of 49MPa, 7.5% lower than that of manufactured sand. Research findings concluded that, compared to concrete made from river sand, high fines concrete generally had higher flexural strength, improved abrasion resistance, and higher unit weight & lower permeability due to fillings the pores with micro fines.

2. Rajendra P. Mogre , Dr. Dhananjay K. Parbat et al.

We concludes that, the replacement of natural sand with artificial sand is fissile and behaviour and strength of reinforced concrete will improved. Also the use of polypropylene fibre will enhance strength and behaviour of reinforced concrete also improves resistance against impact loading and fire. Polypropylene fibers have a positive impact on ultimate strength of heated beams. For a heating duration of 4.5hours, the residual ultimate strength is larger than the corresponding strength of beams without polypropylene fibers by more than 60 %. No sudden failures are observed inall beams containing polypropylene fibers.

3. Roohollah Bagherzadeh, , Hamid Reza Pakravan, AbdolHossein Sadeghi, Masoud Latifi, Ali Akbar Merati et al

The influence of polypropylene fibers has been studied in different proportioning and fiber length to improve the performance characteristics of the lightweight cement composites. Fibers used in two different lengths (6mm and 12mm) and fiber proportions (0.15% and 0.35%) by cement weight in the mixture design. Compared to unreinforced LWC, polypropylene (PP) reinforced Lightweight Cement Composites (LWC) with fiber proportioning 0.35% and 12 mm fiber length, caused 30.1% increase in the flexural strength and 27% increase in the splitting tensile strength. Increased fiber availability in the LWC matrix, in addition to the ability of longer PP fibers to bridge on the micro cracks, is suggested as the reasons for the enhancement in mechanical properties.

All reinforced lightweight concrete specimens display improvement in their mechanical strength as a result of fibers performance in cement matrix. Among all fiber proportions and lengths, only the PP fiber with 12 mm length and proportion 0.35 % performed better in all respects compared to the physical and mechanical properties of reinforced lightweight concrete.

4. James E. Shoenberger, Joe G. Tom et al.

Investigated that PFRC does provide improved impact resistance with increasing volumes of fibers. A PFRC mixture does provide reductions in permeability provided that the water-cement ratio remains below 0.5. Increased percentages of fibers further decreased the permeability provided the mixture remained workable. The study indicates a reduction in plastic shrinkage with increasing amounts of fibers. The polypropylene fibers decrease plastic shrinkage provided the water-cement ratio remains below 0.5. 4. Wear resistance of PFRC has not been widely studied, but one study found an increase in the wear resistance with increasing fiber contents.

5. Roohollah Bagherzadeh, Hamid Reza Pakravan, Abdol-Hossein Sadeghi, Masoud Latifi, Ali Akbar Merati et al.

The influence of polypropylene fibers has been studied indifferent proportioning and fiber length to improve the performance characteristics of the lightweight cement composites. Fibers used in two different lengths (6mm and12mm) and fiber proportions (0.15% and 0.35%) by cement weight in the mixture design. Compared to unreinforced LWC, polypropylene (PP) reinforced Lightweight Cement Composites (LWC) with fiber proportioning 0.35% and 12mm fiber length, caused 30.1% increase in the flexural strength and 27% increase in the splitting tensile strength. Increased fiber availability in the LWC matrix, in addition tothe ability of longer PP fibers to bridge on the micro cracks, is suggested as the reasons for the enhancement in mechanical properties. All reinforced lightweight concrete specimens display improvement in their mechanical strength as a result of fibers performance in cement matrix. Among all fiber proportions and lengths, only the PP fiber with 12mm length and proportion 0.35 % performed better in all respects compared to the physical and mechanical properties of reinforced lightweight concrete.

6. Priti A. Patel, Dr. Atul K. Desai and Dr. Jatin A. Desai et al.

state that, research program on evaluating the performance of polypropylene fibre reinforced concrete. The presence of fibres in concrete alerts the failure mode of material. It is found that the failure mode of plain concrete is mainly due to spalling, while the failure mode of fibre concrete is bulging in transverse directions. Compressive strength enhancement ranges from 8% to 16% for PFRC. Strength enhancement in splitting tensile strength due to polypropylene fibre addition varies from 5% to 23%. The maximum increase in flexural strength of PFRC is 36%.

7. Slamet Widodo et al.

State that This research conducted to evaluate the effects of polypropylene fiber addition on fresh state characteristics of Self-Consolidating Concrete (SCC)mixes, and investigate the effects of polypropylene fiber on some hardened properties of SCC. In this research, concrete mixes were added with polypropylene fiber of 0%, 0.05%, 0.10%, and 0.15% volume fraction. Tests results indicate tha polypropylene fibers tend to reduce the flow ability and passing ability but will increase viscosity and segregation resistance of SCC. Furthermore, it can be concluded that polypropylene fiber reduce deformability of SCC in the fresh state. After 28 days of curing, concrete specimens’ tests indicate that polypropylene fiber addition up to 0.10% of volume fraction tend to improve the compressive strength, tensile strength, and impact resistance of hardened SCC. It also can be suggested that polypropylene fibers allowed to beadded into SCC mixes up to 0.10% by volume of concrete.

8. A.M.Alhozaimy .et. al

Polypropylene fibers have no statistically significant effects on the compressive strength and toughness of conventional concrete at the volume fractions used in this investigation. The presence of silica fume, however, increased the average compressive strength by 17% and 23% of plain and fibrous concretes. Polypropylene fibers have no effects on flexural strength at the volume fractions used in this study. Polypropylene fibers affect the flexural toughness significantly at 95% level of confidence. On the average, the addition of 0.1%, 0.2%, and 0.3% volume fraction of fibers increases the flexural toughness by 44%, 271% and 387%, respectively. Silica fume increases the flexural toughness by 48% and 79% in the case of plain and fibrous concretes, respectively.

While pozzolans generally reduce the impact resistance of concrete, the positive interactions between polypropylene fibers and pozzolans (fibers are more effective in the presence of pozzolans) lead to enhanced impact resistance of fibrous concrete with pozzolans.

The impact resistance at failure of conventional fibrous concrete was increased by82%, 42% and 90% with the addition of fly ash,

silica fume and slag, respectively.

9. Serkan Tapk?n

The Marshall Tests and repeated load indirect tensile tests have shown that the addition of polypropylene fibers considerably alters the behavior of asphalt concrete. When the polypropylene fiber content increases, an increase in the Marshall Stability index has been observed reaching 58% for the specimens reinforced with 1% of polypropylene fibers.

According to the test results, the addition of 1% of polypropylene fibers prolongs the fatigue life by 27%. Polypropylene fibers have a different specific gravity and size distribution, and because of this ,there are some physical changes in the asphalt concrete and these changes can cause the behavioral differences.

Besides, the polypropylene fiber-bitumen paste shows differences in elastic plastic and adhesive behaviors when compared with natural filler bitumen paste. The different elastic and permanent deformation response of fiber-reinforced specimens can be related to these reasons.

III. CHARACTERISTICS OF POLYPROPYLENE FIBRE

- Polypropylene comes in two forms – straight and special crimped, unlike other manmade fibres. Crimped fibre allows improved interlocking.

- Polypropylene disperses in water within seconds, their by allowing the uniformity in application and properties.

- Polypropylene is produced in fine controlled dimension and gives very high matrix (6-7 times). Such fine fibre and dispersion ensures uniform three dimensional micro reinforcement.

- In construction industry, these fine fibres help the structure take-up thermal expansion and contractions. In RCC and plastering, the fine fibres checks micro cracks. They are also used in cement mix.

- It has excellent UV stability as compared to the Polyester polymer fibres.

- The alkali stability of the fibre in the 2% cement slurry alkalinity shows excellent stability over a period of time.

IV. ADVANTAGES AND DISADVANTAGES

A. Advantages

- Increases tensile strength.

- Greater impact resistance of fibre reinforced concrete.

- Reduces permeability.

- Arrest drying shrinkage.

- Easy to use and mix.

- Controls cracking.

B. Disadvantages

- The fibres form very small lumps while mixing.

- The fibres appearing on the surface of the concrete and are not recommended from the aesthetic views.

V. APPLICATION

- Plain concrete and wall plastering.

- Used in footings, foundations and tanks. Pipes, burial vaults, pre-stressed beams etc.

- Roads and pavements.

- Bridges and dams.

VI. MATERIALS USED

A. Cement

Cement is a blend of composites completed by burning limestone & clay composed at very high temperature ranging from 1400 to 1600oc.53 grade Ordinary Portland cement is used as binder, a substance used for construction that sets, hardens and adheres to other materials, binding hem together. The different grades of cement is used they are, 33, 43, 53 grade. The cement specific gravity of cement.

Table 1 properties of cement

|

Property |

Value |

|

Fineness Test |

6% |

|

Consistency Test |

36% |

|

Intial and final setting time |

38min & 460min |

|

Soundness Test |

5.5mm |

B. Fine Aggregate

Manufactured sand is also called as mechanical sand. It possesses similar properties as similar grading as per the river sand. Due to this reason, manufactured sand normal sand. Mechanical sand contains can be used in the region where normal sand limited in availability.

Table 2 properties of fine aggregate

|

`Property |

Value |

|

Specific Gravity |

2.65 |

|

Fineness modulus |

2.7 |

C. Coarse Aggregate

The coarse aggregate for structures consists of materialbetween the sizes of 5 mm and 150 mm. Rocks with a waterabsorption value of more than 3% or a specific gravity of lessthan 2.5 are not known to be suitable for mass concrete. Inpractice, however, mixtures with the same workability for round shaped aggregates needed less water than angularshaped aggregates. The properties of fine aggregate

Table 3 properties of coarse aggregate

|

Property |

Value |

|

Specific gravity |

2.65 |

|

Water Absorption Test |

0.6 |

|

Crushing strength test |

25.45% |

|

Abrasion and Attrition test |

3.5% |

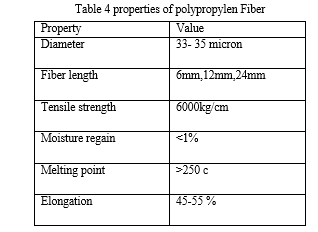

D. Polypropylen Fiber

Polypropylene is an economical material that offers a combination of outstanding physical, mechanical, thermal and electrical properties not found in any other synthetic fibres. There are two general types of fibres currently available in the market. These are referred to as fibrillated and monofilament.

VII. TESTS TO BE CONDUCTED

Fresh concrete tests such as slump cone test, Vee-Bee Test are to be performed. Compressive strength test, split tensile test and Flexural strength test are also proposed to be conducted.

Conclusion

1) Compressive strength properties of polypropylene fibre reinforced concrete increase as the percentage of polypropylene fibre increase up to 0.8% increasing strength and therefore at 1.2% shows decreasing strength. 2) Tensile strength properties of polypropylene fibre reinforced concrete increase as the percentage of polypropylene fibre increase up to 0.8% increasing strength and therefore at 1.2% shows decreasing strength. 3) Flexural strength properties of polypropylene fibre reinforced concrete increase as the percentage of polypropylene fibre increase up to 0.8% increasing strength and therefore at 1.2% shows decreasing strength.

References

[1] Zheng Z, Feldman D, Synthetic fibre-reinforced concrete, Progr Polymer Sci ,vol 20,No3,pp185– 210,1995. [2] A. Naaman, T. Wongtanakitcharoen and G. Hauser, Influence of different fibers on plastic shrinkage cracking of concrete, ACI Mater J, vol 32,2,pp. 102-107,2005. [3] C.Han, Y. Hwang, S. Yang and N. Gowripalan, Performance of spalling resistance of high performance concrete with Polypropylene fiber contents and lateral confinement, Cem Concr Res, vol 35 pp. 1747–1753,2005. [4] M. Zeiml, D. Leithner, R. Lackner and H. Mang, How do Polypropylene fibers improve the spalling behavior of in situ concrete, Cem Concr Res, vol 36 , pp. 929–941,2006. [5] F. Pelisser, A. Into, H. Rovere and R. Pinto, Effect of the addition of synthetic fibers to concrete thin slabs on plastic shrinkage cracking. Constr Build Mater, vol35,3,pp 145-153, 2010. [6] N. Banthia and R. Gupta, Influence of Polypropylene fiber geometry on plastic shrinkage cracking in concrete., Cement and Conceter Research, vol 36 , pp. 1263– 67,2006. [7] Nagarkar P, Tambe S, Pazare D. Study of fibre reinforced concrete; 1987. [8] Won, C. Park, S. Lee, C. Jang and C. Won, Effect of crimped synthetic fibre surface treatments on plastic shrinkage cracking of Cement-based composites, Mag Concr Res, vol 60 , pp. 421–42,2008. [9] IS 516: 1959 Method of test for` strength of concrete [10] IS 2386 (Part I VIII): 1963Methods of Test for Aggregates for Concrete. [11] IS 383:1970 Specification for coarse and fine aggregates from natural sources for concrete. [12] A.M.Neville, Properties of Concrete, Longman Singapore publisher’s pvt Ltd

Copyright

Copyright © 2022 K. Selvi, S. Karthi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET48229

Publish Date : 2022-12-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online