Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Flexural Behaviour of RCC slab using Epoxy Coated Bamboo as Reinforcement

Authors: Mr. Vivek Sarjerao Chavan, Harshvardhan Vittal Ghorpade, Gourav Shivaji Patil , Pramod Bajirao Jagtap, Shubham Shahaji Patil, Prof. G. S. Kamble

DOI Link: https://doi.org/10.22214/ijraset.2022.45241

Certificate: View Certificate

Abstract

Bamboo is one of the potential material as a substitute for steel reinforcement. Bamboo is very cheap, easily available, and available in ample quantity. Bamboo is cultivated in farm by farmers. Bamboo is having very good mechanical properties which attract many researchers to use it as reinforcing material in concrete. From bamboo small thin strips were prepared. These strips were tied together in two directions to form a bamboo-strip- mat. All these strips while making bamboo-strip-mat was tied together with small thin Mild Steel wire to ensure their position in mat formation. Testing is done using bamboo- strip-mat as reinforcement in cement concrete prismatic section at bottom side. Concrete slab thus produced in laboratory were tested in flexure; results obtained were presented in this project. Bamboo strips were prepared from old age bamboo. Researchers at the Future Cities Laboratory Singapore Zurich achieved the liaison of both the superior physical properties of the bamboo fiber and the extraordinary mechanical properties of polymer resins in a new green and sustainable material technology. The team investigates the potential of high-performance bamboo fiber composite materials to replace steel reinforcements in structural concrete applications. The technology as such is to be considered low-tech with injected high-tech knowledge and components in order to upscale and install it in developing territories. With their fast growing urbanization rates, these areas overlap with the global natural habitat of bamboo, rendering bamboo an affordable and locally available natural resource for a future construction industry. The herein presented newly developed fiber composite materials might revolutionize this industry. In this sense, the research at the Future Cities Laboratory Singapore/ETH Zurich aims to offer a local solution on urban sustainability within a global frame. The construction principles involved in the designing of bamboo reinforced members and structures has been discussed in this document, the use of bamboo in the place of steel as a whole as well as with steel is shown to ensure the reduction in weight, economic advantages with its strength compromised to a slight and safe level. Various researches and study results will be used for the deduction of a method most suitable for the replacement of bamboo as reinforcing material in the right amount and the right proportion and the best possible placement in place of steel and or with steel.

Introduction

I. INTRODUCTION

Concrete is a composite material consisting of fine, coarse materials that are re- tained together by a cement paste that hardens over time. Lime- based cement binders, such as lime putty, were formerly common, although they were some-times mixed with other hydraulic cements, to create Portland cement concrete, use calcium aluminate cement or Portland cement. Asphalt concrete with a bi- tumen binder, which is commonly used for road surfaces, and polymer concretes, which employ polymers as a binder, are examples of non-cementitious concretes that use alternative methods to bind aggregate together. Concrete differs from mortar. Prestressing is a technique that produces known permanent stresses in a structure or element before adding a full or live load. Tensioning the High Tensile Strands, wires, or rods, which are subsequently mechanically fastened to the Prestressed component, produces these stresses. Prestressed concrete is simply concrete in which suitable magnitude and distribution of internal stresses are supplied to counteract the stresses generated by external loads to a desired amount. Cables are made of high-tensile-strength strands that have been bunched together. These wires are typically housed within the High-Tension Cable. TENDON refers to the whole assembly that includes the Anchorage and the High-Tension CableThe use of Reinforced Cement Concrete in structural members with very longspan lengths, low rises, and low structural heights is practically impossible. Prestressing is employed in this example to achieve a light weight, elegantly designed, and cost- effective construction with good durability. As a result, prestressing is commonly employed for long span slab and bridges. The prestressing process is also used very efficiently in building structures to manufacture lighter slabs and slabs, greatly reducing their dead load when compared to R.C.C. Structures. In addition, the use of prestressing in build- ing construction allows for a longer span between columns, resulting in fewer columns. This increases the framework’s adaptability to interior design

II.LITERATURE REVIEW

- Archila H. F. and Kaminski S.[1] This review addresses such ‘bamboo-reinforced concrete’ and assesses its structural and environmental performance as an alternative to steel reinforced concrete. A prototype three bay portal frame, that would not be uncommon in regions of the world where bamboo-reinforced concrete may be considered, is used to illustrate bamboo reinforced concrete design and as a basis for a life cycle assessment of the same. The authors conclude that, although bamboo is a material with extraordinary mechanical properties, its use in bamboo-reinforced concrete is an ill-considered concept, having significant durability, strength and stiffness issues, and does not meet the environmentally friendly credentials often attributed to it.

- Saheb D.N. and Jog J.P.[2] Tensile tests and micro structural analysis were conducted to investigate the impact of different corrosive environments on the bamboo composite material’s behaviour. The results revealed that the application of epoxy coating successfully protected bamboo composite material’s integrity without substantially affecting its mechanical capacity, particularly in acidic environment. Secondly, bond strength between bamboo composite material and concrete was investigated through pull- out tests. The epoxy coating improved the bond strength, especially with addition of sand particles. The findings of this study suggest that epoxy coating can be an effective approach to simultaneously enhance the bamboo composite material’s resistance towards acid attack and improve its bond strength with concrete for concrete reinforcement application.

- Agarwal Atul and Bharadwaj Nanda.[3] The feasibility for usage of bamboo as reinforcement in concrete is evaluated through a series of experimental investigations in the present study. First of all, tensile test of locally procured bamboo strips are conducted for evaluation of its ultimate strength and engineering properties. Varieties of adhesives such as Tapecrete P-151, Sikadur 32 Gel, Araldite and Anti CorrRC have been used for the treatment bamboo to study their effect on bond strength at the interface of the bamboo concrete composite. From the comparative study the most suitable adhesive has been selected and used further to cast bamboo reinforced beams and columns.

- Sakaray Harish and Reddy Ramana[4] In this paper an attempt has been made for finding bamboo as reinforcement in concrete by determining the various physical and mechanical properties of bamboo. The investigations conducted for the tested types of bamboo are evaluated using the same accept criteria as that of steel. This study investigates the Moso type bamboo tensile stress, compressive stress, Modulus of Elasticity, Water absorption capacity, Shear stress, and bonding stress.

- Ahmad Shakeel and Raza Altamash[5] To see the effect of bamboo fibre on compressive and flexure strength, bamboo reinforced Concrete cubes have been tested. On comparing the results with plain concrete cubes, strength becomes double in 50 days testing. Further singly and doubly reinforced beam with bamboo sticks have been cast and tested in

- Khan Imran and Jibhkate Nitesh[6] Reinforced concrete is most common material in the world but it become expensive when as reinforcement steel is used. So this present paper deals with the utilization of bamboo as reinforcement in place of steel. Cost analysis and limitations of bamboo. The intention of research is to utilize bamboo as a key structural material, for a safe and durable house, which can be affordable by poor people.

- Srivastava Manjesh and Sharma Kuldeep[7] To study the effect of replacement of steel reinforcement by bamboo reinforcement, designs have been conducted on the span of two way slab of size 3650 x 4570 sq-mm with providing beams. The information in this report has been compiled from reports of test programs by various researchers and represents current opinion. In this paper the designs are done on the calculation of loads according to IS 456:2000 and compare the costs of structure by design of structure.

A. Remark on Literature Review

In recent years, it has been noted that researchers are primarily focused on post tensioned systems that are used in slab analysis and design. However, no substantial research has been conducted on the analysis and designof Optimization of slab by post tensioned design in slab. Post- tensioned slab thickness optimization is often done to improve mechanical behaviour, particularly bending moments, as well as to minimise strain energy of the slab, which results ina reduction in the area of the post- tensioned tendons and, as a result, a reductionin construction cost.

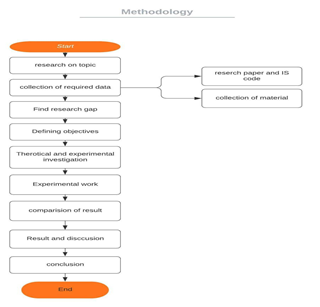

III. METHODOLOGY

A. Experimental Work

The design of RCC slab and PT slab has been carried out in the proposed project work as per Indian scenario. For experimental purposes cast a prototype model which is suitable for casting, handling and testing.

After the casting of all slab specimens are done and reinforced with IS 456:2000 and IS 1343:2012. All the slabs have been designed and tendons are stressed by using prestressing jack andalso testing will be done with loading frame.

Table 3.1 shows the mechanical and thermal properties of the selected materials.

B. Tests on cement

- Standard Consistency Test: (IS 12269-1987): The standard consistency of cement paste is defined as the consistency of cement paste that allows a vicat’s plunger with a diameter of 10 mm and a length of 50 mm to be inserted into thespecimen from the top of the mould.

- Initial Setting Time Test: (IS 12269-1987): The period passed between the addition of water to the cement and the begin-ning of the paste’s loss of flexibility The first setting time is limited to 30 minutes.

- Final Setting Time Test: (IS 12269-1987): It is the amount of time that has passed between the addition of water to cement and the point at which the paste has fully lost its fluidity. This period should not exceed 10 hours.

- Compressive Strength: (IS 650-1991): The most essential property of hardened cement is its compressive strength. The strength test is performed on a cement sand motor in a particular percentage rather than on net cement paste. The compressive strength of three cubes is mea- sured, and the average of the three cubes is taken. Material Properties of Cement Throughout the project, Portland Pozzolana cement (PPC 53 Grade cement) is utilized. Cement that conforms to IS: 12269-1987.

The cement material charac- teristics are shown in the table.

Table 1: Properties of Cement

|

Properties |

Average Values for PPC used in the present Investigation |

|

Specific Gravity |

3.15 |

|

Consistency (%) |

28.75% |

|

Initial Setting Time (min) |

135 |

|

Final Setting Time (min) |

315 |

|

Compressive strength (MPa) 28 days |

60 |

IV. RESULT AND DISCUSSION

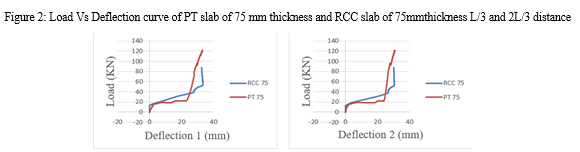

A. Experimental results of RCC and Post- Tensioned Slab

Four-point loading was applied to the slab until it failed. A digital loading frame was used to apply the load. The graphical representation of Load vs Deflection for RCC and post-tensioned slabs with optimization of slab thickness. The results of RCC slab & PT Slab as shown below, Comparison of PT 75 mm slab thickness and RCC Slab of 75 mm thickness Four-point loading was applied to the slab until it failed. A digital loading frame was used to apply the load. The graphical representation of Load vs Deflection for RCC and post-tensioned slabs with optimization of slab thickness. The results of RCC slab & PT Slab as shown below,

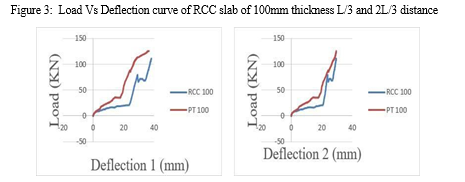

B. Comparison of PT 100 mm slab thickness and RCC 100 mm slab thickness

The maximum load carried by the PT Slab of 75 mm thickness is 121 KN and at L/3 distance, the deflection was measured to be 32.93 mm and at 2L/3 distance, the deflection was measured to be 30.94 mm. Also, the maximum load carried by the RCC Slab of 75 mm thickness is 87.31 KN. At L/3 distance, the maximum deflection was measured to be 32.57 mm and at 2L/3 distance, the deflection was measured to be 30.27 mm.

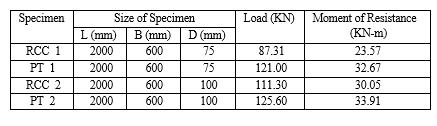

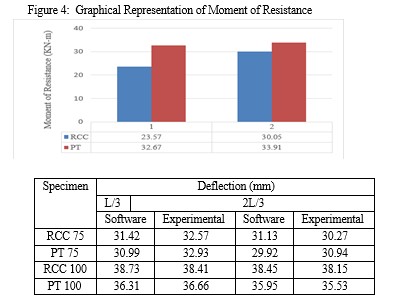

C. Moment of Resistance Results

The ultimate load carried by the slab is used to compute the moment of resistance for all slabs. The graphical representation of moment of resistance, optimization of slab thickness in RCC and post-tensioned slabs. The result of moment of resistance is given as below,

D. Software Results

Etabs 18, a finite element software tool, was used to analyze the specimens. The specimen’s deflection is determined at the ultimate load, which includes two-point load, self-weight, and live load on the slab. The table below shows the variationin findings from software analysis, and experimental program.

Conclusion

1) The deflection of the PT slab is optimized up to 5% than RCC Slab. 2) The moment of resistance for PT slab of 75mm thickness is 27.85% increasedthan RCC Slab of 75mm thickness whereas PT slab of 100mm thickness is 11.38 % increased than RCC Slab of 100mm thickness. Hence from proposed size of slab specimen and loading condition PT slab of 75mm thickness is preferable. 3) According to experimental testing of slab specimens the load carrying capac- ity, The PT slab of 75mm thickness is 27.85 % increased than RCC Slab of 75mm thickness whereas PT slab of 100mm thickness is 11.38 % increased than RCC Slab of 100mm thickness. 4) The cost of 75mm thickness PT slab is 65.44 % increased than RCC slab of 75mm thickness whereas the cost of 100mm thickness PT slab of is 69.33 % increased than RCC slab of 100mm thickness. Hence from above reults it is

References

[1] Aalami, B. O. and Jurgens J. D. (2003). “Guidelines for the Design of Post- Tensioned Floors.” 77-83. [2] Abd-El-Mottaleb, H. E. et al. (2018), “Behaviour of Two-Way Post Tension Flat Slab” Applied Engineering, SciencePG, vol. 02, no. 02, 54-59. [3] [Bednarz, K. (2018). “Analysis of the effectiveness of various cross sections in large-span post-tensioned ceilings.” IOP Conf. Series: Materials Science and Engineering, ICMEMSCE, 1-6. [4] Desai, M. V. G. and Shaikh M. J. (2016). “Comparative Analysis of Flat Slab and Post- Tensioned Flat Slab Using SAFE.” International Advanced Research Journal in Science, Engineering and Technology, IARJSET, vol. 03,no. 08, 152-156. [5] Hymans, M. et al. (2018).“Optimization of post-tensioned concrete floor slabs.” International Association for Shell and Spatial Structures, IASS, 1-9. [6] Imran, M. et al. (2017). “A Comparative Study of Flat Slab Vs Post Tensioned Flat Slab.” International Journal for Scientific Research and Development, IJSRD, vol. 05, no. 09, 979-982. [7] Mohammed, A. H. et al. (2017), “Finite element analysis and optimization of bonded post- tensioned concrete slabs” Cogent Engineering, ISSN, 1-16. [8] N. Krishna Raju (2013) “Prestressed Concrete”, Forth edition pp. Prestressing Manual, “The Freyssinet Prestressed Concrete Co. Ltd.”, 1-9Peter J. Blau, “Fifty years of research on the wear of metals”, Tribology international, 1997; 30: pp- 321-337. [9] Rogers J. (2008). “POST-TENSIONED SLABS.” Concrete Construction, 1-4. [10] Sarkisian, M. et al. (2017), “New Methods in Efficient Post- Tensioned Slab Design Using Topology Optimization” Structures Congress, ASCE, 213-224. [11] Szydlowski, R and Barbara Labuzek, B. (2017). “Post-Tensioned Concrete Long-Span Slabs in Projects of Modern Building Construction.” IOP Conf. Series: Materials Science and Engineering, WMCAUS, 1-9. [12] Torok, I. et al. (2019), “Post-tensioned Flat Slabs with Unbonded Tendons for Public Buildings” ScienceDirect Procedia Manufacturing, ELSEVIER, 102–109. [13] IS: 1343-2012 Indian Standard Code of Practice for prestressed concrete, (Sec- ond Revision), Bureau of Indian Standards, New Delhi, India. [14] IS: 456-2000 Indian Standard Code of Practice for plain and reinforced con- crete, (Fourth Revision), Bureau of Indian Standards, [15] New Delhi, India. IS: 10262-2019 Indian Standard Code of Practice for guidelines for concrete mix design proportioning, Bureau of Indian Standards, New Delhi, India.

Copyright

Copyright © 2022 Mr. Vivek Sarjerao Chavan, Harshvardhan Vittal Ghorpade, Gourav Shivaji Patil , Pramod Bajirao Jagtap, Shubham Shahaji Patil, Prof. G. S. Kamble. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET45241

Publish Date : 2022-07-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online