Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Foot Operated Washing Machine

Authors: Omkar A. Mandavkar, Tejas P. Komawar, Dipesh R. Gawad, Shubham V. Gupta, Shaikh Abdul Bari

DOI Link: https://doi.org/10.22214/ijraset.2022.41296

Certificate: View Certificate

Abstract

The foot operated washing machine is a huge innovation all by itself. Foot operated washing machine is especially designed for its use for washing laundry by means of foot application. Today, because of non-renewable energy cries out its basic need to use energy in another way or to save energy. This project involves the construction and use of the foot operated washing machine. The next pages in the paper include the constructions of foot operated washing machine, its raw material, its operation , benefits of the foot washing machine in terms of the actual electronic washing machine save time, water, electricity and not very expensive. His main expectation is exercises with the application of the foot to wash the cloths.

Introduction

I. INTRODUCTION

The project covers one of the daily activities of the washing clothes but solves many other problems with her as well. We wash our garments either by hand or using electric washing machines. Over the years, this has been a process that requires a lot of efforts and time. The project aims to solve the problem so many people have encountered in their daily lives. In rural areas and undeveloped countries, where electrical power is unavailable and expensive, electric washing machines become almost impractical. It uses a simple mechanism that utilizes a chain drive and converts human power into mechanical energy to wash cloth. The foot operated washing machine permits human beings to wash clothes in a more efficient manner with less effort and

strain than using hand/manual washing.

The project has the following objectives:

- Low-cost and low maintenance.

- It should operate with less water.

- It will be easy to repair when things go wrong.

- Easy to operate and maintain as readily available parts.

- Women do not have to be in contact with soapy water which may damage there hands.

- Another way to reuse energy that we don’t utilize during exercise.

II. LITERATURE REVIEW

A. Pedal Powered Washing Machine (PPWM)

By: Adarsh Ranjan, Kushagra Sharan, Sudeep Mazumdar

This project not only covers one of the daily household activities (laundry), but also solves many other problems related to it. We all wash by hand or use an electric washing machine.

This project aims to solve the problems that many people face in their daily lives. In rural areas where electricity is not available and expensive, electric washing machines are almost impractical. The main goal is to provide the product with another way to wash clothes when there is no electricity .but this project has more Product and manufacturing cost. this also has intricate shape.it also require more maintenance due to more mechanical arrangements.

B. Design and Fabrication of Pedal Powered Washing Machine

By: Gaurang Bhatawadekar, Budye Salman, Nilesh Chiplunkar, Swapnil Devrukhakar, Singh Akashdeep Rajendra Mane

The pedal power washing machine is different from any other method of the cleaning device. The community may be reluctant to try a new machine.

They have carry out a trial period in groups such as women's associations that are familiar with pedal drivers. they have achieved our goal of building a low-cost, manually operated pedal-operated washing machine that uses locally available materials to easily perform the required cleaning and rinsing functions.

C. Design and Analysis of a Pedal Operated Washing and Drying Machine

by: Hakizimana E*, Masengesho P, Cyusa O, Niyigena M

This washing machine is made from easily available parts at rural area thus, does not required to import any part or component. It uses the parts of bicycle for precision parts. therefore it is inexpensive and easy to build. this machine can also runs without electricity. we can easily perform washing and rinsing cycle on it. peoples in the city can be use this for exercise as well as washing clothes thus utilizing energy.

D. Pedal Operated Washing Machine using 4-bar Crank Mechanism

by: Blair Fargose, Mihir Raorane, Manas Dhumal, Chinmay Khanvilkar, Prathamesh Bidaye

In this pedal operated washing machine they have designs using 4 bar crank mechanism and bevel gear arrangement to transfer power. they have done calculation, modelling and analysis of their machine. From that they concluded that there machine will work smoothly and effectively. their machine allows cloths to wash faster.

E. Design & Fabrication of Pedal Operated Multi Purpose Machine

by: Yash Hiragar, Ketul Dantani, Gautam Prajapati, Rixit Kakani

This project aims to develop pedal operated multipurpose machine. this machine can be operated when electricity is not available. There main objective is to make machining operation cost effective and eco friendly.it can run with zero operating cost. unskilled worker can also operate this machine. This machine can perform drilling & grinding operation on materials like wood, aluminium & steel which having less hardness & thickness.

F. Pedal Power Generation: An Implementation Of Stationary Bike Generator

by Ron Edward Guia, Aodrel Dave Ilagan, Lorenz Gerald Sauz, Engr. Favis Joseph Balinado

This study shows the design and development of an alternative source of electricity in supplying one household that is in rural areas. With the use stationary bike, the user can be productive in different ways beside of being active in cardio workout but also productive in such away the calorie burned upon using the pedal can produce a certain amount of voltage that is a part of power.

G. Design And Fabrication Of A Foot Operated Washing Machine

By : Chetan rajoria, Deepali Gautam, harsh Rajput, Abhinav vats, amit singh

The current research project aims to solve the problem of electric supply to people because of which many in rural area are unable to wash clothes. Nowadays there is electric supply which is provided in most parts of the world but we cannot neglect those who don’t have access to electricity. In India most of village and hilly areas are suffering from lack of electricity supply. So, to overcome above problem we select the washing machine, which is operated manually. It requires no power supply. It is a machine which use the power generated by human pedalling and with the use of bevel gears and shaft converts the pedalling motion into required rotary motion of the inner drum of washing machine. This is a low cost project and can be transported very easily.

H. Design and Fabrication of a Pedal Operated Power Generator

By: Anyanwu s. Ikechukwu, ashinze e. Anthony

In conclusion, this project was designed to serve as a model/prototype to meet specific need in our locality. The device can also serve as an alternative power source in extreme case scenario even in urban centres. Since the device is manually operated, it can be used in areas where there is no power supply and would always be readily available. The device is environmentally friendly as it produces no waste in the process of its operation, and the device work with little or no noise. The system proved efficient since even with a minimum peddling speed, the system produced enough voltage required to charge the battery in order for the system to be usable by almost anybody at anytime.

I. Development of a Human Powered Pedal Washing Machine

By: M A Fajobi, E Y Salawu, J Azeta, J O Dirisu, O O Ajayi, P Onwordi

Human powered pedal washing machine has been designed using materials suitable for its application. An existing bicycle was used as the pedal and other parts of the machine such as the drum, the frame was fabricated using galvanized steel. The material selection was put into consideration, such as corrosion because of the machine’s involvement with water. The human powered pedal washing machine was tested with a used dirty Laboratory coat.

The peddling washing was first done for the first 15 minutes, using water and sunlight detergent soap. The washing testing was done on cloth and it was excellent because the cloth was clean. The human powered pedal washing machine performed well with all the designed parts functioning well. This is an eco-friendly machine, maintenance cost free, energy conservation machine and highly sustainable for underdeveloped nations of the world.

III. PROBLEM STATEMENT

The problems that we are currently facing in current trends:

- High cost of electricity powered washing machines.

- It require electricity to run electric washing machines, it can’t be run if there is power cut-off.

- Water requirement is more for washing.

- Manually washing of clothes can cause detergent to come in contact with human hands which may cause allergic reactions to there hands.

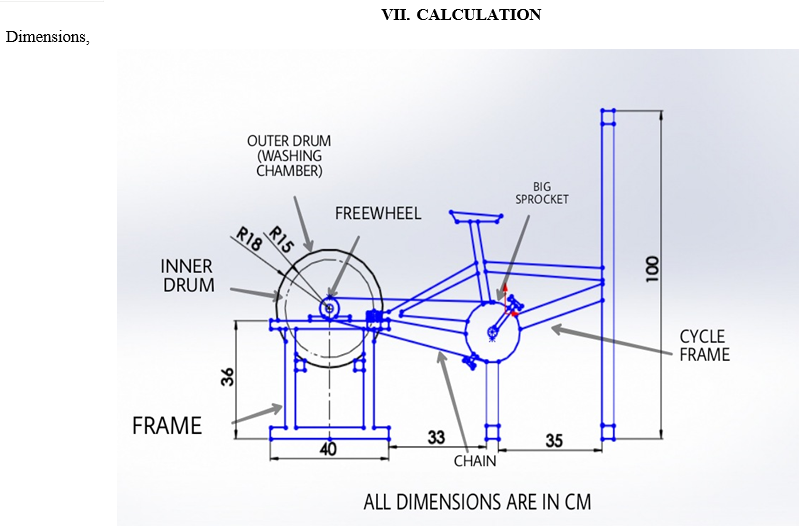

IV. FABRICATION METHODOLOGY

- First, as the inner drum was open from one side we have to close that side of the drum so we cut a plate of same diameter as the inner drum and welded it to the drum. Then on the outer and inner drum we cut the door. Then on the outer drum we created a hole on both sides on its centre which will be greater than the shaft diameter. And then on the inner drum shaft was welded by argon welding on both the sides and also hinges and latches were welded for opening and closing the door. As the washing chamber was as tank it was open from one side so argon welding was done to close that opening.

2. Then for the frame MS pipes were cut using the hack saw as per the required sizes for the main frame of the machine. First the side frame were welded together and then the bottom parts were welded to the side frame and was made sure that is stands still without any wobble then two more square pipes were welded to give support to the drum so is cannot be moved while operating the machine. And after the welding we made sure that there were any wobbling even after the load of the drum is placed. Then on the side frame at top side holes were drilled so that the plummer block can be fitted on that spot.

3. A cycles centre frame was cut which will works as the driving parts main frame, then from the cycles rare hub was cut and it was fitted on to the left side of the shaft. Then cut section of the cycle frame was welded to the stand and then the handle was welded to it. The on the main frame bolt arrangement was made so that the cycles frame can be removed or attached easily. And after all the fittings were completed we painted the both the frame of the machine.

V. WORKING

First of all open the outer and inner drum doors. put the clothes in inner drum and close the door of inner drum. Then fill 8 to 9 litre water for 1.5 kg clothes and add some detergent as per requirement. Then close the outer drum and then sit on seat provided on cycle frame. Then start cycling slowly at the begin, then rear freewheel also starts rotating due to chain sprocket arrangement. then inner drum also starts rotating which creates turbulence between clothes. when pedalling at a rate of 30rpm the inner drum rotate with speed of 90rpm.after about 6 to 7 mins of continuous pedalling the washing cycle gets completed. Then remove the soapy water by opening the drain valve located at the bottom of outer drum. Then add about 2 to 3 litre water for rinsing cycle, it requires faster pedalling rate i.e. when pedalling at 60rpm, at that time inner drum rotates at about 180rpm. Then approx. after 5min rinsing of cycle get completed. then remove the clothes from the washing machine.

VI. FABRICATED MODEL

For inner drum,

Diameter of inner drum= 30cm

Length of inner drum= 42cm

Volume of inner drum = 29688cm3 = 30litre

For outer drum,

Diameter outer drum= 36cm

Length of outer drum= 50cm

Volume of outer drum = 50893cm3 = 50litre

For big sprocket and rear gear freewheel,

Big sprocket diameter =

Rear sprocket diameter =

No. of teeth on big sprocket = 42

No. of teeth on rear sprocket = 14

Gear ratio= No. of teeth on big sprocket = 42 = 3

No. of teeth on rear gear 14

No. of teeth on rear gear 14

Water required for 1kg laundry = 5-6 litre

Maximum weight of cloth that can be wash= 3kg

Average weight of human= 60

Average rpm can human produce at big sprocket = 60rpm

Average rpm at inner drum = 180rpm

Average power transferred by human during pedalling = 125kw (assumed)

VIII. RESULT

Observations made while testing of washing machine:-

|

Trial no. |

Load (in kg) |

Washing time (in min) at average 90 rpm |

Rinsing time (in min) at average 180 rpm |

Total time (in min) |

|

1 |

1.5 |

7 |

5 |

12 |

|

2 |

2.5 |

8 |

5 |

13 |

|

3 |

3 |

9 |

6 |

16 |

IX. FUTURE SCOPE

- Increasing capacity, so that more clothes can be washed, thus utilizing the wasted energy.

- The energy wasted during washing can be utilized in most fruitful way by using it in another household machine which would work simultaneously as the washing goes on. Load on the new machine would be such that entire energy is consumed and not wasted. The excess energy can be used to generate electricity to charge battery. It can be used to operate pedal powered pumps. Many machines operated on pedal power have been developed such as, Cassava graters, Coffee/grain hullers, cracking of oil palm nuts, Potter's wheels, Flexible shaft drive for portable grinders, saws, etc., Tire pumps, Sewing machines.

- Designing and Implementing the Drain Valve mechanically A normal washing machine uses an electronic control valve in the drainage system to control the flow of waste water out. This valve can be designed mechanically using bicycle brakes. The brakes would block the rubber outlet pipe when the clothes are being washed, rinsed or dried. The blockage would open to make the waste water flow out after a washing cycle or during drying.

- We can use gear shifter as used in gear cycle to vary speed.

Conclusion

We have made foot operated washing machine with the use of chain and sprocket mechanism. this project can be feasible in our day to day life. middle class family can also afford this. operation time for this product is also less without applying much great efforts.it also consumes less water. Also strain of washing clothes on women’s get reduce. from this we are concluding that this concept can be use at rural as well as urban areas.

References

[1] Adarsh Ranjan, Kushagra Sharan, Sudeep Mazumdar, Pedal Powered Washing Machine (PPWM)INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH, VOLUME 3, ISSUE 11, NOVEMBER 2014 [2] Gaurang Bhatawadekar, Budye Salman, Nilesh Chiplunkar, Swapnil Devrukhakar, Singh Akashdeep, Design and Fabrication of Pedal Powered Washing Machine, International Journal of Engineering Research and General Science, Volume 3, Issue 1, January-February, 2015 [3] Hakizimana E, Masengesho P, Cyusa O, Niyigena M, Design and Analysis of a Pedal Operated Washing and Drying Machine, : journal of applied mechanical engineering [4] Blair Fargose, Mihir Raorane, Manas Dhumal, Chinmay Khanvilkar, Prathamesh Bidaye, Pedal Operated Washing Machine using 4-bar Crank Mechanism, international journal for research in engineering application and management, volume 07, issue 02, may 2021 [5] Yash Hiragar, Ketul Dantani, Gautam Prajapati, Rixit Kakani, Design & Fabrication of Pedal Operated Multi-Purpose Machine, international journal of science technology and engineering, volume 4, issue 10, April 2018 [6] Ron Edward Guia, Aodrel Dave Ilagan, Lorenz Gerald Sauz, Engr. Favis Joseph Balinado, Pedal Power Generation: An Implementation Of Stationary Bike Generator, laguna journal of engineering and computer studies, volume 4, no 3, October 2020 [7] Chetan rajoria, Deepali Gautam, harsh Rajput, Abhinav vats, amit singh, Design And Fabrication Of A Foot Operated Washing Machine, international journal of trend in scientific research and development, volume 2, issue 4 [8] Anyanwu s. Ikechukwu, ashinze e. Anthony, Design and fabrication of a pedal operated power generator, innovative systems design and engineering, volume 7, no 3, 2016 [9] M A Fajobi, E Y Salawu, J Azeta, J O Dirisu, O O Ajayi, P Onwordi, Development of a human powered pedal washing machine, 6th international conference on advance engineering and technology

Copyright

Copyright © 2022 Omkar A. Mandavkar, Tejas P. Komawar, Dipesh R. Gawad, Shubham V. Gupta, Shaikh Abdul Bari. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET41296

Publish Date : 2022-04-07

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online