Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Study and Performance Characteristics of Gasoline Direct Injection Engine Using Alternative Fuels

Authors: Suryaprakash A, Kumaravel K, Kulandaivel D, Ramesh K

DOI Link: https://doi.org/10.22214/ijraset.2023.48746

Certificate: View Certificate

Abstract

Biogas is the one of the best alternative fuel for IC engines. However some improvements and different techniques are still needed. In this research biogas with petrol fuelled Gasoline Direct Injection (GDI) engine performance was to be studied. The current study shows that biogas with petrol using GDI engine, particularly beneficial to reach interesting conversion efficiencies. It allows a significant boost in energy conversion from biogas compared to existing system.

Introduction

I. INTRODUCTION

It is a well-known fact that a significant percentage of the greenhouse gases produced are given by automobile engines from the transportation sector. Due to rise in carbon footprint and the depletion of fossil fuels, automobiles industries are banking on alternative strategies to meet the stringent emission norms. To tackle this issue, two main strategies are trending in the automotive sector for over a decade. This first strategy is to utilize various generations of biofuels at optimized levels along with conventional fuels.

Additionally, various gaseous fuels like compressed natural gas, liquefied petroleum gas and hydrogen are used as fuel in the engine. The second strategy is to calibrate the engine with the help of various tuning techniques and optimization approaches for ideal engine output characteristics. Using the optimized engine calibration process the overall output of the engine can be improved in the form of reduced emission levels and improved fuel economy. Conventional engines can be switched to be operated with biogas, hydrogen along with diesel or petrol with very less modification. Worldwide research is focussed on appropriate technology as well as alternative fuel that would be used in these existing internal combustion engines with no or less emissions. In the last few decades, various alternative fuels have been proposed, targeting at cleaner and sustainable energy source in order to counteract the consequences of the emission from SI and CI engines

The present performance test focuses on the utilization of biogas as alternative fuel in SI engine. Utilization includes the optimized performance of SI engine by the use of biogas as alternative fuels. Indeed, there is review articles published on different strategies and alternative fuels for SI engine with some reviews on blending of additives with biodiesel. Given a multitude of these reviews, it is an apt time to make an attempt to compile and analyse the research studies focussing on the influence of potential gaseous fuels induction on the combustion performance and emission characteristics of a SI and CI engine.

II. GASEOUS FUEL AS AN ALTERNATIVE

Gaseous fuels have been emerging as attractive alternative energy resource to replace petrol and diesel fuel either partially or completely in SI and CI engine. The injection of gaseous fuel in SI and CI engine under dual fuel mode is not a new technology, it has been investigated by many researchers with widespread success. Usually, gaseous fuels are mixed with the intake air during the suction stroke of dual fuel engine, either through manifold injection or through direct injection into the cylinder. Depending upon the availability of fuels, dual fuel engines be switched to either dual fuel mode or single fuel mode. In dual fuel mode, a small amount of fuel should be sprayed to an ignition source due to high auto-ignition temperature of the fuel. Usually, the quantity of fuels required for adequate ignition is around 10-20% of the quantity required for single fuel mode operation. The main objective of a dual fuel technology is to reduce the expending of fossil fuels with increased replaced by alternative renewable fuels, which are economically viable and environmental friendly.

A. Biogas as an Alternative Fuel

The utilization of biogas in IC engines is a more economical and a easiest way. Thousands of engines are operated on sewage works, landfill sites and other biogas installations. The engine sizes range from 45 kW on small farms up to several MW on large-scale landfill sites.

Power generation from landfill gas using spark ignition engines, dual fuel engines and gas turbines has been successfully demonstrated in the UK for engine sizes ranging from about 0.5 to over 4 MW. In the US as of 1990, 117 landfill methane power plants were in operation, each a few megawatts in size. For large scale applications diesel engines are standard. Engine power should depend on the rate of production of the biogas produced from the biogas plant. For an engine/generator set, assuming the engine efficiency is 30% and the generator efficiency about 70%, the gas production rate required to produce 1 kW of electricity is 0.56 m3/hr.

III. LITRATURE SURVEY

Ragadia Sadiq Y., have found the piston crown geometry that affects the compression ratio for the scrubbed bio gas and raw bio gas in a spark ignition engine. By testing the engine with raw bio gas and scrubbed bio gas and these results were compared to gasoline test results. Finally, the engine performance is increased by increasing the compression ratio of the engine.

Eui-Chang Kwon., bio gas fueled internal combustion engine tested by modifying in engine and using carbon dioxide dilution. These results are compared to the test results from normal IC engine, the engine performance is reduced when using carbon dioxide dilution.

Chandra R., using methane enriched bio gas, bio gas and CNG for compression ignition engine. The results such as brake power output, specific gas consumption and thermal efficiency are high when compared to normal engine performance.

Porpatham E., testing the SI engine performance when changing the compression ratio for the engine while using bio gas. In this test test thermal efficiency is increased when increasing the compression ratio above critical level and also brake power and thermal efficiency also increased in this test.

Chinmay dehri., testing bio gas in dual fuel engine and investigating the emission analysis. In this test brake thermal efficiency and exhaust gas temperature are deteriorated to between 2% to 20% while specific fuel consumption is increased to 36% by using gaseous fuel in dual fuel engine and the emission is increased significantly when compared to diesel engine performance

Mindaugas Melaika., using bio gas/ethanol in dual fuel engine. In this test combustion rate is accelerated in biogas/ethanol. These results are compared to bio gas single fuel engine. In biogas/ethanol dual fuel engine test complete combustion takes place. So the carbon dioxide, carbon monoxide and hydrocarbons are reduced. And the combustion efficiency is increased when compared to single fuel engine. Finally NOx is reduced when compared to ethanol single fueled engines and overall efficiency is high in biogas/ethanol fueled engines.

Ydav S D., testing 100% bio gas fueled SI engine with emissions test. The emission from the pure biogas fueled engine is lower when compared to existing petrol engine limit without exhaust gas treatment. Before testing this engine, the compression ratio is varying from 9:1 to11:1 without any tendency to auto-ignition.

Jingdang Huang., using bio gas fueled SI engine at different mixtures of bio gas and the test is done from rich mixture to lean mixture. In this test NOx is increased when the presence of carbon dioxide. And engine power, thermal efficiency is reduced while the operating cylinder pressure is less, also unburnt hydrocarbon is increased without complete combustion. By avoiding these emissions, compression ratio is increased.

M.s. Gad., this paper aims of the paper is to describe physical and chemical of biodiesel blend with diesel fuel. Thermal efficiency of biodiesel blend with diesel is lower than compared with diesel fuel. Specific fuel consumption of biodiesel blend with diesel is high. Unburnt CO and HC were reduced and NOx emission is slightly increased in biodiesel fuel blend when compared with diesel duel engine.

TABLE 1

Average composition of biogas

|

ELEMENT |

COMPOSITION (%) |

|

Methane |

30-80% |

|

Carbon dioxide |

2-45% |

|

Nitrogen |

0-10% |

|

Ammonia |

0-0.5% |

|

Moisture |

2-8% |

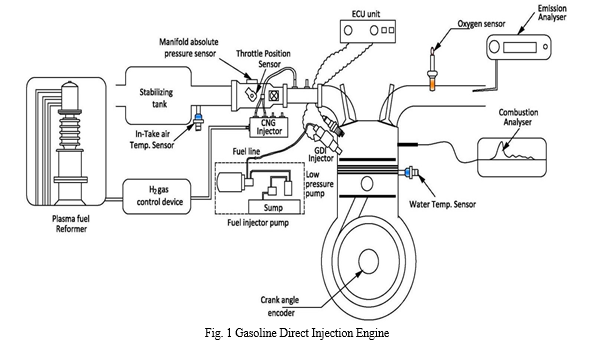

IV. GASOLINE DIRECT INJECTION ENGINE

This engine was run with a help of gasoline and fuel was directly injected into the combustion chamber. So this engine known as petrol direct injection engine. This engine had two types of charging modes for fuels distributed to throughout the combustion chamber.

- Homogeneous charge mode.

- Stratified charge mode.

A. Gasoline Direct Injection Engine Specification

TABLE 2

GDI engine specifications

|

Engine type |

Single cylinder engine |

|

Bore x Stroke |

80 x110 mm |

|

Displacement |

484 CC |

|

Compression ratio |

9:1 |

|

Injection angle |

Through 145?.2' bTDC |

|

Combustion chamber |

Hemisphere open type |

|

Piston |

Flat - bowl piston |

|

Ignition type |

Coil on plug |

|

Injector |

Inward swirl |

|

Nominal power/speed |

3.7 kW/1500 ± 100 rpm |

|

Max. Torque |

23.55m |

|

Type of cooling |

Water cooling |

- Objectives of the GDI engine: Superior power to traditional MPI engines with extremely low fuel consumption that surpasses even diesel engines. The distinction between the new GDI and the current MPI The fuel injection system, which took the role of the carburetion system for conventional engines, supplies the fuel. One of the most popular methods now is MPI, or multi-point injection, which injects fuel into each intake port. Since the fuel and air mix before entering the cylinder, even with MPI engines there are limits to the fuel supply responsiveness and the combustion management. By creating an engine where gasoline is directly injected into the cylinder as in a diesel engine and, in addition, where injection timings are meticulously managed to fit load circumstances, Mitsubishi set out to push those limitations. The GDI engine achieved the following outstanding characteristics

a. By permitting burning of ultra-lean mixture supply extremely accurate fuel supply management can be used to achieve fuel efficiency that is higher than that of diesel engine

b. The GDI engine's extremely effective intake and relatively high compression ratio give performance and response that are superior to those of traditional MPI engines.

B. Major Characteristics Of The GDI Engine

Lower fuel use and increased production A fuel spray that is ideal for two combustion modes The GDI engine uses special Mitsubishi techniques and innovations to deliver more output while using less gasoline. Two combustion modes are used to accomplish this ostensibly contradictory and challenging task. In other words, injection timing varies according to engine load.

Fuel is injected late in the compression stroke, just like in a diesel engine, to accommodate the load conditions needed for typical urban driving. As a result, a perfect stratified air-fuel combination is formed, leading to an ultra-lean combustion. Fuel is injected during the intake stroke when travelling at fast speeds. This makes it possible to produce more power with a homogenous air-fuel mixture similar to that seen in traditional MPI engines.

- Ultra-Lean Combustion Mode: The Mitsubishi GDI engine operates in ultra-lean combustion mode for reducing fuel consumption under the majority of typical driving circumstances up to speeds of 120km/h. In this mode, ignition takes place at an ultra-lean air-fuel ratio of 30 to 40 when fuel injection occurs at the end of the compression stroke (35 to 55, included EGR).

- Superior Output Mode: Fuel injection occurs during the intake stroke when the GDI engine is running at greater loads or speeds. This ensures a homogenous, cooler air-fuel mixture, minimising the chance of engine knocking, and enhances combustion.

V. FACTORS CONSIDERING FOR THE STUDY OF BIOGAS FUELLED GDI ENGINE

A. Major Characteristics Of The GDI Engine

The following factors play vital role on the performance of the engine when the engine runs by using biogas with petrol. This factor should also have to all other conventional fuels. In past research, methane enrichment, hydrogen addition was made to improve the engine efficiency. So these factors are to be considered for GDI engine

- Effect of Setting Maximum Brake Torque: The pressure development in the SI engine cylinder was impacted by changes in spark timing in relation to the top centre. The work transfer from the piston to the gases in the cylinder at the end of the compression stroke is too great if combustion begins too early in the cycle; conversely, if combustion begins too late, the peak cylinder pressure is reduced and the work transfer from the gas to the piston during the expansion stroke is reduced. There is a specific spark timing that, at a given speed, mixture composition, and flow rate, produces the most engine torque. Maximum brake torque timing, also known as MBT timing, is achieved when the magnitudes of these two opposing trends just barely offset one another. Lower torque is produced by timing that is either advanced or retarded from this optimum. Testing was done with various spark advance angles, ranging from 12 to 26 bTDC with a 2-degree increment at each start of injection angle (SOI). According to the test results, the engine produced its greatest amount of brake torque at a particular spark advance one such SOI angle is 18 which is obtained. It was noted that before achieving MBT at each SOI, a maximum 10% loss of torque was detected against a reduction of 9.8% in average speed. When the spark angle moved closer to the region of MBT at each of the SOI, a minimum 1% loss of torque was recorded against a 1% reduction in speed. Maximum torque generated for 70, 140, and 160 rpm when the engine was run at 16 ohms, 18 ohms, and 20 ohms of spark advance.

- Effect of Hydrogen Addition: According to the analysis shown above, determining how HRG addition affects combustion time is crucial to determining how well hydrogen extends the lean limit. Combustion time decreased as hydrogen fraction rose at a particular equivalency ratio. This demonstrated that the addition of hydrogen could really hasten the spread of flames.

- Effect of Compression Ratio: The compression ratio is varied in all other engines based on fuel combustion rate and required power. This compression ratio is varies from engine to engine for various fuels. In previous research, different compression ratios like 11.9 to 15.4 are to be used for testing. This different compression ratio helps to find the best engine performance for gasoline engines.

Conclusion

The present study serves as a gateway between environmental issue and energy requirement for society. A detail analysis on utilization of alternative fuel reveals the following conclusion. Through the calorific value of biogas is less compared to fossil fuel the area of research should focus to increase the same by using advanced techniques. The engine performance of the gasoline engine was reduced when using biogas as secondary fuel. This should be evaluated and suitable engine was to be selected. Gasoline Direct Injection (GDI) engine has low fuel consumption and higher thermal efficiency. A performance of the GDI engine was best when compared to other Port Fuel Injection (PFI) engine performance.

References

[1] Ragadia Sadiq.Y, Rajesh C. Iyer, (2019). Experimental investigation on the influence of compression ratio and piston crown geometry on the performance of biogas fuelled small spark ignition engine. Renewable Energy 146 (2020) 997-1009 [2] Suleyman Simsek, Smaset Uslu, (2020). Investigation of the impacts of gasoline, biogas and LPG fuels on engine performance and exhaust emissions in different throttle positions on SI engine. Fuel 279 (2020) 118528. [3] Eui-Chang Kwon, Kyeongsoo Song, Minsoo Kim, Youhwan Shin, Sun Choi, (20017). Performance of small spark ignition engine fuelled with biogas at different compression ratio and various carbon dioxide dilution. Fuel 196 (2017) 217-224. [4] Chandra.R, Vijay.V.K, Subbarao.P.M.V, Khura.T.K. performance evaluation of a constant speed IC engine on CNG, methane enriched biogas and biogas. Applied Energy 88 (2011) 3969-3977. [5] Porpatham.E, Ramesh.A, Nagalingam.B, (2011). Effect of compression ratio on the performance and combustion of a biogas fuelled spark ignition engine. Fuel 95 (2012) 247-256. [6] Chinmay Deheri, Saroj Kumar Acharya, Dhirendra Nath Thaoi, Ambica Prasad Mohanty, (2019). A review on performance of biogas and hydrogen on diesel engine in dual dual mode. Fuel 360(2020) 116337. [7] Mindaugas Melaika, Gills Herbilion, Petter Dahandler, (2020). Spark ignition engine performance, standard emission and particulates using GDI, PFI-CNG AND DI-CNG systems. Fuel 293(2021) 120454. [8] Sanjay Dnyanu Yadav, (2013). Characteristics of biogas operated automotive SI engine to reduce exhaust emission for green development. DOI: 10.4271/2013-26-0012 [9] Jingdang Huang, R. J. Crookes, (2000). Assessment of simulated biogas as a fuel for the spark ignition engine. Fuel Vol. 77, No. 15, pp. 1793–1801, 1998. [10] M.S. Gad, R. El-Araby , K.A. Abed , N.N. El-Ibiari , A.K. El Morsi G.I. El-Diwani, (2017). Performance and emission characteristics of C.I engine fueled with palm oil/palm oil methyl ester blended with diesel fuel. Egyptian Journal of Petroleum 27 (2018) 215–219 [11] Saiful Bari, (1996). Effect of carbon dioxide on the performance of biogas/diesel dual-fuel engine. [12] Awogbemi, Omojola, Adeyemo, Sunday Babatunde, (2015). Development and Testing of Biogas-Petrol Blend as An Alternative Fuel for spark ignition engine. https://www.researchgate.net/publication/281832384. [13] A. Vijin Prabhu, A. Avinash, Kathirvel Brindhadevi, Arivalagan Pugazhendhi, (2020). Performance and evaluation of dual fuel CI engine using preheated biogas-air mixture. Science of the Total Environment 754 (2021) 142389. [14] M. Feroskhan, Saleel Ismail, M. Gopinatha Reddy, A. Sai Teja, (2018). Effect of charge of preheating of a biogas-diesel dual fuel CI engine. https://doi.org/10.1016/j.jestch.2018.04.001. [15] Seung Hyun Yoon, Chang Sik Lee, (2011). Experimental investigation on the combustion and exhaust emission characteristics of biogas=-biodiesel dual fuel combustion in a CI engine. Fuel Processing Technology 92 (2011) 992–1000. [16] J. Zareei, M. Haseeb, K. Ghadamkheir , S.A. Farkhonde, A. Yazdani, K. Ershov, (2020). The effect of hydrogen addition to compressed natural gas on performance and emission of a DI diesel engine by a numerical study. https://doi.org/10.1016/j.ijhydene.2020.09.027. [17] Aman Hiraa, Shailendra Singh, (2012). Performance and emission characteristics of CI engine using blends of ethanol and biodiesel with diesel. [18] V. Jose Ananth Vino*, R. Solomon and S. Sreenath, (2013). Performance analysis of spark ignition engine fueled with methanol/petrol fuel blend. [19] T. Korakianitis,1, A.M. Namasivayam, R.J. Crookes, (2010). Natural gas fueled spark ignition and compression ignition engine performance and emissions. Progress in Energy and Combustion Science 37 (2011) 89-112. [20] K.A. Subramanian, Vinaya C. Mathad, V.K. Vijay, P.M.V. Subbarao, (2013). Comparative evaluation of emission and fuel economy of an automotive SI engine fueled with methane enriched biogas and CNG using chassis dynamometer. Applied Energy 105 (2013) 17–29.

Copyright

Copyright © 2023 Suryaprakash A, Kumaravel K, Kulandaivel D, Ramesh K. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET48746

Publish Date : 2023-01-20

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online