Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Experimental Study on Light Weight Concrete by Using Light Expanded Clay Aggregate (LECA)

Authors: Arivalagan S, Dinesh Kumar K S A

DOI Link: https://doi.org/10.22214/ijraset.2022.48111

Certificate: View Certificate

Abstract

This study examined the structural behavior of Lightweight concrete (LWAC) using lightweight aggregates (Light expanded clay aggregates LECA) and normal weight aggregates, aims to investigate on concrete mix M25 by the effect of partially and fully replacement of the coarse aggregate by LECA with various percentage such as 20%, 40%, 60%, 80% and 100%. Analysis of this concrete was done in fresh state as well in hardened state to evaluate mechanical properties of concrete. This paper concentrated on performance parameters such as compressive strength, splitting tensile strength of the light weight concrete using LECA. The Lightweight concrete density varies from 40% - 100% replacement of LECA such as 1996kg/m3-1597kg/m3. It reduces the weight of concrete and cost of concrete by reducing the aggregate cost and produces economical system.

Introduction

I. INTRODUCTION

Light-weight concrete can be defined as a type of concrete which includes an expanding agent in that it increases the volume of the mixture while giving additional qualities like lessened the dead weight. It’s lighter than the conventional concrete. The required properties of the light-weight concrete will have a bearing on the best type of light Expanded Clay Aggregate to use. The Structural light weight concrete as we call is a concrete whose density varies from 1400 to 2000 kg/m3.The literatures have thrown a light on influence of palm oil clinker, coconut shell, ceramic waste, Light expanded clay aggregate concrete to reduce the density of structural concrete member. It reduces the weight of concrete and cost of concrete by reducing the aggregate cost and produces economic infrastructure system. Light- weight concrete cubes, cylinders are casted and tested for determining compressive strength, split tensile strength, and obtain the results are compared with the control specimens.

II. AIMS AND SCOPE

To determine the consistency, setting time and fineness of the cement

To cast the cubes and cylinder for compressive strength and split tensile strength.

To study examined the structural behavior of Lightweight concrete (LWAC) using lightweight aggregates (Light expanded clay aggregates LECA) and normal weight aggregates, Aims to investigate on concrete mix M25 by the effect of partially and fully replacement of the coarse aggregate by LECA with various percentage such as 20%, 40%, & 60%,Analysis of this concrete was done in fresh state as well in hardened state to evaluate mechanical properties of concrete.

This project is concentrated on performance parameters such as compressive strength, splitting tensile strength of the light weight concrete using LECA.

III. ABOUT LECA (LIGHT EXPANDED CLAY AGGREGATES)

A. Lightweight Aggregate (LWA)

LWA as the name suggests have lower bulk density as compared to normal weight aggregates. There are many variations in the definition given for LWA in different codes of practice. BS 3797 defines coarse LWA as aggregates having a loose bulk density of 250–1000 kg/m3, whereas ACI 213R defines LWA as aggregates with a dry loose weight not exceeding 880 kg/m3. The AS 2758: Part 1 defines LWA as aggregates having loose bulk density of less than 1200 kg/m3. LWA can generally be classified into four types, namely (i) naturally occurring aggregates, (ii) artificially produced aggregates, (iii) aggregates from industrial by-products and (iv) organic aggregates.

B. Natural Building Material

LECA is a natural material and a LECA building is a healthy building, so that is LECA has been used in competition projects for allergy-friendly, healthy homes.

Used as a thermal-insulation material in houses, LECA has been saving energy for more than 50 years, and is now a standard component in low-energy development projects all over the world.

The Main Benefits of LEC are High insulation capacity ,Excellent drainage properties, Non combustible, Resistance to heat and frost, Low capillarity, Low bulk density, Easy to spread and compact, large load bearing capacity, Deformation resistance, Inert and chemically neutral, Resistant to fungus, rot, insect and pest, Constant and high quality of the lightweight material.

Properties of Leca Aggregate are Lightness, Thermal Insulation, Sound Insulation, Fire Resistance, Non-Decomposability and Water Absorption.

IV. LITERATURE SURVEY

Mahyar Arabani, et-al, Light Expanded Clay Aggregate (LECA) was used as a part of fine aggregate for improving mechanical properties of porous asphalt. To conduct the experiment in this research, three different mixtures of stone material and LECA (0, 10 and 20 percent LECA) were used.

The results of moisture susceptibility tests demonstrated that adding LECA to porous asphalt mixture can increase resistance against moisture damage in this mixture. Serkan Suba, the effect of using fly ash in high strength lightweight aggregate concrete produced with expanded clay aggregate on physical and mechanical properties of the concrete was investigated and in order to determine the effect of use of fly ash in expanded clay aggregated concretes on bond strength, lightweight concrete mixtures of 350, 400, 450kg/m3 cement content and of 0, 10, 20 and 30% fly ash replacement were prepared. V.Khonsari, E.Eslami & Ah.Anvari, The expanded perlite aggregate (EPA) has a wide range of uses, generally due to its properties of extremely low bulk density, high brightness, high absorption, low thermal and acoustical conductivity, and non-flammability and the test results indicated a linear relationship between the compressive strength and splitting-tensile strength for steel fibrous. Sivakumar and B.Kameshwari, Experimental investigation on concrete mix M20 is done by replacement of cement with fly ash, fine aggregate with bottom ash and coarse aggregate with Light Expanded Clay Aggregate (LECA) at the rate of 5%, 10%, 15%, 20%, 25%, 30% and 35% and The results shows that 5% replacement of cement with fly ash, fine aggregate with bottom ash and coarse aggregate with Light Expanded Clay Aggregate (LECA) was found to be good performance in compressive strength. Sachin Paul and Ganesh Babu, this paper investigates the mechanical properties of light weight Geopolymer concrete produced by replacing normal coarse aggregate by Light weight expanded clay aggregates (LECA). Structural use was although limited to 60% replacement of coarse aggregate by LECA with a density of 1700kg/m3. On replacement of coarse aggregate by LECA by 40%, both split tensile strength and flexural strength decreased by about 35%, but still very much within structural limits.Thomas Tamu et al, to study the properties such as compressive strength and tensile strengths of lightweight concrete.

Expanded Polystyrene (EPS) beads are used as partial replacement to coarse aggregates with 5,10,15,20,25,30% Increase in the EPS beads content in concrete mixes reduces the compressive and tensile strength of concrete. It is used for non-structural applications, like wall panels, partition walls, etc.

V. EXPERIMENTAL INVESTIGATION

A. Materials

- General: Concrete is an artificial stone like material having an excellent resistance to compression. It resembles the principal asset of natural stone and is usually cast in place in a plastic condition. The composition of concrete is determined by the properties of the constituent materials, which are binding material (e.g. cement), fine aggregate (e.g. sand), coarse aggregate (e.g. gravel), fly ash, water and super plasticizer to harden in forms of the shape and dimensions of the desired structure.

- Cement: Cement is the binding material. In this study 43 grade of OPC confirming to the requirements of IS 8112-1989 has been used. The physical properties of cement: Specific gravity is 3.14, Specific surface area is 310 kg/m2 and the Fineness modulus is 4%. Normal consistency of cement is 34%, initial and final setting time is 30 min and 60 min respectively.

- Aggregates: Aggregates are the fine aggregate and coarse aggregate. The River sand as the fine aggregate and coarse aggregates from crushed rock conforming to the requirements of IS 383- 1970.

Table 1:Properties of Coarse Aggregate, Fine Aggregate Table 2 : Properties of LECA

|

Property |

Fine aggregate |

Coarse aggregate |

|

Specific gravity |

2.65 |

2.68 |

|

Fineness modules |

2.83 |

7.04 |

|

Water absorption |

1.5% |

0.85% |

|

Bulk density(kg/m3) |

1481 |

1659 |

|

Impact value |

- |

29.41% |

|

Property |

LECA |

|

Specific gravity |

0.44 |

|

Fineness modules |

5.99 |

|

Water absorption |

10% |

|

Bulk density(kg/m3) |

357 |

|

Impact value |

16.5% |

4. LECA Aggregates: LECA means Light Expanded Clay Aggregate. LECA consists of small, lightweight, bloated particles of burnt clay. The thousands of small, air-filled cavities give LECA its strength and thermal insulation properties. The base material is plastic clay which is extensively pretreated and then heated and expanded in a rotary kiln. Finally, the product is burned at about 1100°C to form the finished LECA product. In this study 4mm – 10mm sizes and 480 kg/m3is used to that of the normal concrete. Therefore more deflection is there in lightweight concrete.

5. Potable Water: Water is an important ingredient because it actively participates in the reaction with cement. It ensures workability. However, good quality concrete can be made with water that would pass normal standards for drinking water.

6. Super Plasticizer: Super plasticizer based on conplast SP430 (G) produced by fosroc with specific gravity 1.22 and dosage of super plasticizer 0.5% of cement weight used in leca concrete.

VI. RESULT AND DISCUSSION

A. Compressive Strength

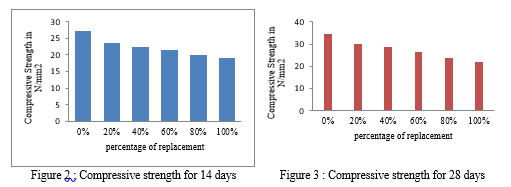

Compressive strength results of 28.56N/mm2, 26.40N/mm2 and strength reduction of 17.36% and 23.69% where for LECA40 & LECA60 respectively these replacement percentage due to made up light weight concrete with densities varying from 1400- 2000kg/m3. This mix can also be used for structural purposes.

B. Split Tensile Strength

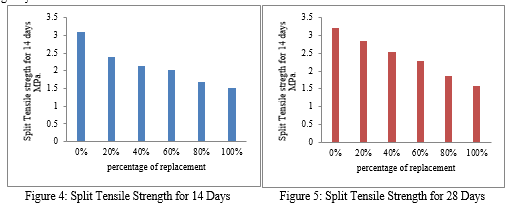

Split tensile strength results of 2.53N/mm2,2.28N/mm2. A replacement of 40% and 60% of LECA resulted in a decrease of split tensile strength by 20.93% and 28.75%.

Conclusion

Based on the experimental results of this study the following conclusion can be drawn. The density of concrete is found to decrease with the increase in percentage replacement of normal aggregate by Light Expanded Clay Aggregate. Compressive Strength and split tensile strength of concrete is found to decrease from 34.60 to 21.77 MPa and 3.20 to 1.5 MPa respectively with increase, in LECA content from 0% to 100% The LECA concretes when replaced with 40% and 60% of coarse aggregates shown better results, when compared to conventional concrete.

References

[1] Siamak Boudaghpour, and Shervin Hashemi, A Study on Light Expended Clay Aggregate (LECA) in a Geotechnical View and it Application on Greenhouse and Green roof Cultivation.International Journal of Geology, Volume 2, 2008 [2] O. Arioz , K.Kilinc1,et al, A Preliminary Research On The Properties of Lightweight Expanded Clay Aggregate, J. Aust. Ceram. Soc. 44 [1] (2008) 23-30. [3] Serkan Suba, The effects of using fly ash on high strength lightweight concrete produced with expanded clay aggregate. Scientific Research and Essay Vol. 4 (4) pp. 275-288, April, 2009. [4] V.Khonsari, E.Eslami & Ah.Anvari, Effects of expanded perlite aggregate(EPA) on the mechanical behavior of light weight concrete.Korea Concrete Institute 2010. [5] Payam Shafigh*, S. Vahid Razavi and Mohsen Kobraei, An investigation of the flexural behaviour of reinforced lightweight concrete beams, International Journal of the Physical Sciences. 2414-2421, 18 May, 2011. [6] A.Sivakumar* and P. Gomathi, Pelletized fly ash lightweight aggregate concrete: A promising material, Journal of Civil Engineering and Construction Technology Vol. 3(2), pp. 42-48,February 2012. [7] Sachin Paul and Ganesh Babu, Mechanical Properties of Light Weight Aggregate Geopolymer Concrete Using Light Weight Expanded Clay Aggregate.Transactions on Engineering and Sciences, Vol.2, Issue 10, October 2014[12] M.S. Shetty, Concrete Technology, S.Chand & Company Ltd.,2005, New Delhi. [8] S.Sivakumar1 and B.Kameshwari2, Influence of Fly Ash, Bottom Ash and Light Expanded Clay Aggregate in Concrete. [9] Thomas Tamu et al., Partial Replacement of Coarse Aggregates By Expanded Polystyrene Beads In Concrete.Construction and Building Materials, Vol-3, 2014. [10] Mahyar Arabani1, Gholam Hossein Hamedi2, Hasan Jaefari3 , Evaluating the Effects of Light Expanded Clay Aggregate on Mechanical Properties of Porous Asphalt.Current Advance in Civil Engineering [11] Super plasticizer based on conplast SP430 (G). [12] Application for LWA can be calculated from BS-3797[34] , ACI 213R[37],AS2758:PART 1 [38] [13] For cement fineness and consistency IS 8112-1989. [14] Aggregates IS 383-1970 [15] Mix proportion refered code IS 10262-1982 and IS 456-2000.

Copyright

Copyright © 2022 Arivalagan S, Dinesh Kumar K S A. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET48111

Publish Date : 2022-12-13

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online