Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Review Paper on Lithely Arch Bridge

Authors: Divyani Rehapade, Sarita Harne

DOI Link: https://doi.org/10.22214/ijraset.2022.39933

Certificate: View Certificate

Abstract

In this we are studying modern technology of arch bridges i.e “Lithely Arch technology”. In this technology the blocks are precasted, blocks are jointed with screed concrete and lifted to a location by transporting them on site and again lifted to form arch bridge and then working towards the finishing. It also includes the study of reading the drawing, Bearing capacity, prepared all over detailed estimate and stability checks. Various IRC codes, IS codes is studied. The masonry arch is one of the oldest structural elements. Brick masonry arches have been used for hundreds of years. This technical note is an introduction to brick masonry arches. Many of the different types of brick masonry arches are discussed and a glossary of arch terms is provided. Material selection, proper construction methods, detailing and arch construction recommendations are discussed to ensure proper structural support, durability and weather resistance of the brick masonry arch. Lithely arch method is innovative, modern, economic and fastest method of construction of arch bridges. This method is invented in Maharashtra, India. Bridges constructed using this method are purely compressive in nature. This method utilizes precast units for construction of arch bridges. This method can be utilized for rehabilitation of old arch bridges in India very economically and with less time. The lithely arch is India\'s only Precast, Unreinforced Bridge solution and is developed on the lines of the conventional stone-mason built arch bridges. Arch bridges are the most reliable and time tested solution for medium span (5m to 20m) bridges. These bridges have been standing strong for centuries and while they were initially designed for 8-10 tons of load are carrying modern vehicular load without any distress.

Introduction

I. INTRODUCTION

Arch Bridges are used form ages. Lithely Arch technology is the derived version of stone arch bridges. Stone arch bridges required more time in construction, and it also required accurate stone cutting (skilled manpower). These limitations were overcome in the Lithely Arch bridge.

The lithely arch is based on the same principles of the conventional arch bridge and requires absolutely no maintenance once installed. the bridge is designed to have a service life of over 120 years, almost twice that of modern bridge solutions.

Modern arch infrastructure, through lithely arch, retains the core functionality of arch bridges, while eliminating all inconveniences.

These bridges are strong enough to hold 8-10 tons of load which can carry a modern vehicular load without any distress.

Masonry arch bridges are part of our heritage. To preserve our heritage and to utilize these bridges to their maximum capacity, understanding of arch bridges is vital. as no more masonry arch bridges are being constructed in modern times, engineers have forgotten the old thumb rule methods of their design and also there are no common software available which can analyse the arch bridges correctly taking into account effect of fill, spandrel walls etc. the design of these structures was based on empirical rules which were too conservative, this has resulted in structures with an inherent ability to withstand the applied loads and extreme weathering conditions. Masonry arch bridges form an integral part of the railway infrastructure. They are the oldest structure type of the railway bridge population with thousands still in service despite their age and the significant changes in loading conditions that have occurred since their construction. Today many masonry arches carry a load that is radically different from that when they were constructed.

II. OBJECTIVE

In absence of steel improves cost efficiency over conventional bridge solutions.

To minimize construction time by to rapid installation due to reliance on precast elements.

To calculate the detailed estimate and the design calculation of bridge.

To compare the structural, hydraulic and cost effectiveness of the various types of bridges with Lithely arch bridge.

To provide such type of design which have less maintenance cost and long service life.

III. LITERATURE REVIEW

1. Lithely Arch Bridge: A Review R.V. Popate Sheikh Md. Sabir R.H. Mohankar

a. The lithely arch system requires no steel reinforced. As a compression structure, it is self – supporting by virtue of its own weight, without any external support.

b. With the absence of steel rebar content, the possibilities for internal correction, rebar expansion, and the resultant concrete cracking are eliminated.

c. These factors result in a substantially lower carbon footprint and energy consumption during the construction and overall life span of the bridge

d. Lithely Arch method is very useful for rehabilitation of old arch bridges in India.

e. Lithely Arch method is easy, fastest and economical method than other methods of construction of arch bridges.

2. Rehabilitation of arch bridges with lithely arch method Saurabh Vilas Joshi ,G. N. Kanade

Today arch bridges can be built very fast with advanced technologies and advanced materials. With help of new construction techniques now it has been possible to achieve economy during construction of arch bridges. Also these new arch bridges are durable and withstands in natural calamities due to advanced materials. Today arch bridges can be built for longer spans. Lithely Arch is a precast, modular, concrete arch bridge system. The bridges constructed using Lithely Arch technology are purely compressive in nature. Lithely Arch technology can be used for replacing, widening and strengthening old arch bridges. In this paper the rehabilitation of old arch bridge by lithely arch technique done safely.

3. Arch bridges – unlocking their potential

By taking full advantage of the attributes of the FlexiArch system, the full potential of (a) arch bridges can be unlocked and (b) multi-span arch viaducts can be achieved. The lack of corrodible reinforcement, expansion joints and bearings will minimize maintenance. As a consequence, a highly sustainable bridge infrastructure can be realised in the future.

4. Performance Comparison of Through Arch Bridge at Different Arch Positions Alika Koshi, Dr. Laju Kottalil

The behaviour of a fixed supported through arch bridge was studied by changing the arch positions. The parameter investigated is deformation. The deformation increase as the arch position goes downwards. Maximum deformation is showed by the bridge having its arch positioned below the deck level and the maximum deformation is found at the center portion. The positioning of arch at deck level shows lesser deformation compared to the other cases. But as the arch is positioned below the deck level, the deformation exceeds thus making it unstable.

5. Long Span ARCH Bridges in China Baochun CHEN

It is heavy, labor consuming and difficult to build and is not an economic bridge type to be considered at present in many cases. Compared with the other types of bridges in China at present, steel arch bridges are still very expensive to be built.

6. Stability Analysis of Special-Shape Arch Bridge Wen-Liang Qiu1,Chin- Sheng Kao *, Chang-Huan Kou , Jeng-Lin Tsai and Guang Yang

If a deck arch bridge tilts and becomes unstable, vertical column will tilt as a result of restraints of the girder. The horizontal component force produced thereby will accelerate the tilt of the bridge. This is anegative effect produced by non-directional force on arch bridge stability. Diagonally placed hangers tend to postpone the buckling of arch occurring and improve the overall structural stability. This is a positive effect provided to special-shape arch bridge stability by non-directional force. Increasing vertical rigidity of arch can effectively increase overall structural stability, increasing the lateral rigidity of arches can increase overall structural stability, but the impact is insignificant once a certain value is reached.

7. Probabilistic Model for Masonry Strength of Existing Structures Miroslav S´ykora*, Milan Holick´y*

For common existing structures, moderate consequences of failure and moderate costs of safety measures may often be assumed and in accordance with ISO 2394 the target reliability index reduces to 3.1 .

The theoretical design value (6.6 0 /00 fractile corresponding to the reliability index 3.1) is greater by about 25 % than the design value estimated in accordance with EN 1996-1-1. – Significant economic effects may be achieved when the probabilistic model of masonry strength is used.

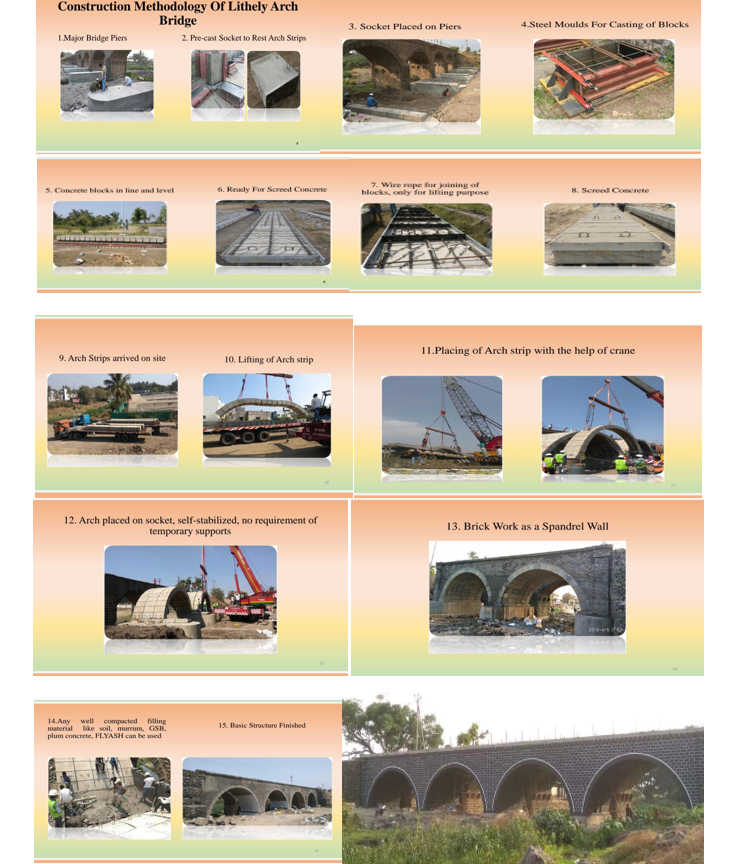

IV. CONSTRUCTION METHODOLOGY OF LITHELY ARCH BRIDGE

Footings must be prepared on each side of the structure. the attendant crane lifts each LITHELY ARCH strips and lowers it into position over the precast sockets laying a top the foundation / pier top the lithely strips arrive on site completely flat , laying upon flatbed transporters. The components includes the required number of arch strips based on the scope of the project, ready for lifting and placing in position precast concrete sockets act as the surface on which individual lithely arch strips are placed . These sockets are placed in line and level a top the piers, prior to the commencement of the erection activity. Once all strips have been poisoned and placed, block masonry spandrel walls are constructed up to the road top level. Spandrels do not carry ant traffic load but act as a permanent shuttering for the poured plum concrete acting as the back fill to the lithely arch strips .the bridge is then ready for roadway finishing and any railing protection that may require.

- Steel Molds for casting of concrete blocks: The blocks which used in strip are made from concrete. For casting those blocks steel mold have been used. Steel mold will make as per the design of size of the block. Steel mold are used to get smooth surface and sharp corners.

- Concrete blocks line and leveled : After the casting of blocks , the blocks are lied into in series. Blocks lied in series where gives length of the strip which used for arch.

- Wire Rope for lifting: generally, the rope which will used in arch bridge it made of ferrous. Wire is consisting of numbers of small diameter. steel wire known as tendons. These wire rope isnot part of structural member in the arch bridge. The main use of wire rope is to lift the arch strip.

- Arch strip before screed and after screed: Successfully placing of the wire rope on the arch strip the top surface of the strip should be cover with the screed concrete. Screed it is the small thickness layer of concrete on the top of the strip of arch that is to cover the wire rope and the top surface.

- Lifting of arch: From the casting place the arch strip will be transported to the site location by the transporter vehicle after the reaching the site the arch strip will be lifted by the cranes. During the lifting process, some precaution should be taken to account the arch strip will lifted in the proper manner. The blocks in the arch strip should not get damaged.

- Arch placed on socket stabilized, no support required: Due to the design of the arch strip and the socket they both will balance their centre of mass. Design of socket will give the stabilized condition to the arch. Total weight of the strip will transfer to the socket and then to the foundation. All the strips will arrange parallel o each other.

- Back filling procedure 60% rubble, 40% concrete: After them construction of both spandrel walls back filling will be done. It is used to fill the space between the arch and provide the level surface for the transportation. Also the main purpose of the filling is to increase the weight of the bridge. In this back filling 60% rubble and 40% concrete will be used and compact using vibrator. Generally, old arch bridges murrum was used but as we know that concrete stronger than murrum , hence concrete eliminated the murrum . Concrete will effectively bind the rubble at high load it cannot allow to displace the rubble.

- Completed open for traffic

A. Construction Steps of Lithely Arch Bridge

V. FUTURE SCOPE

By lithely arch bridge technology we can minimize the weight of overall bridge,each unit is light weighted and construction procedure is also simple.

Rehabilitation of arch bridges carried out by lithely arch method is more economical than rehabilitation of carried out by replacing bridge with R.C.C beam bridge method.

Conclusion

A. Cost Effectiveness Absence of steel improves cost efficiency over conventional bridge solutions. The lithely arch system requires no steel reinforced. As a compression structure, it is self –supporting by virtue of its own weight, without any external support. With the absence of steel rebar content, the possibilities for internal correction, rebar expansion, and the resultant concrete cracking are eliminated. These factors result in a substantially lower carbon footprint and energy consumption during the construction and overall life span of the bridge. B. Reliability The lithely arch is based on the same principles of the conventional arch bridge and requires absolutely no maintenance once installed. The bridge is designed to have a service life of over 120 years, almost twice that of modern bridge solutions. C. Timeless Rapid installation due to reliance on precast elements. D. Highway Safe The lithely arch has designed as per specifications of the MORTH (Ministry of Road Transport Highways) and IRC-6 Loading (70R) with a Load Carrying Capacity of Class 70R and Class AA. E. Wide Implementation The lithely arch is suitable for use in Culverts, Minor and Major Bridges, Submersible and High Level Bridges, Animal Crossings, Railway over Bridges and Railway under Bridges. F. Varying Span The lithely arch is readily available for spans ranging from 6-15m with ongoing tests for 20m+ spans

References

[1] Modern Arch Infrastructure, Nagpur [2] IRC : 6-2016 ( Standard Specifications And Code Of Practice For Road Bridges) [3] IRC: 24-2001(Standard Specifications And Code Of Practice For Road Bridges) [4] IS 6403-1981: ‘Code of practice for determination of bearing capacity of shallow foundation’ [5] Saurabh Vilas Joshi, G. N. Kanade ,(2019) “Rehabilitation of arch bridges with lithely arch method” , International Journal of Advance Research and Development. [6] A. Long, Gupta, A., Mc Polin, D. Courtenay & Cook, J. (2018). “Adapting The Flexiarch For Widening a Complex Arch Bridge”. © Proceedings of ICE - Bridge Engineering, [1700007]. [7] A. Long, and Nanukuttan, S. (2016). “Arch Bridges – Unlocking Their Potential”. – Journal of Engineering and Computational Mechanics, © ICE Proceedings [1600018]. DOI: 10.1680/jencm.16.00018. [8] Sykora M, Holicky M. “Probabilistic Model For Masonry Strength Of Existing Structures”, Engineering Mechanics, 2010” [9] Ali Ura, Seref Oruc. Adem Dogangu, Iskender Tuluk (2008), “Turkish Historical Arch Bridges And Their Deterioration\'s And Failures”, International Journal of Engineering Failure Analysis15 (2008) ©Elsevier Ltd. pp. 43-53. [10] The Assessment of Highway bridges and structure departmental advice note BA16/97(AMD No 2, 2001), Section 3- Assessment of masonry Arch Bridge by the Modification MEXE Method. [11] Gilbert M, Hobbs B (1995) Impact Testing of Masonry Walls. 7 Proceedings of the British Masonry Society 97 - 100 UK. London. [12] Choo, B.S. Contie, M.G. Gong, N.G. , “\'Analysis of Masonry Arch Bridges by a Finite Element Method”, Developments in Structural Engineering Spon 1990” [13] Heyman, J, “The Masonry Arch\' Ellis Horwood 1982” [14] Dr. C. Melbourne, “The assessment of masonry arch bridges

Copyright

Copyright © 2022 Divyani Rehapade, Sarita Harne. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET39933

Publish Date : 2022-01-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online