Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Mathematical Analysis of Car & Bridge Interaction Using Law of Physics for Vibration Formulation

Authors: Avinash Gavel, Dr. H. R. Suryawanshi, Sudheshwar Singh

DOI Link: https://doi.org/10.22214/ijraset.2023.49288

Certificate: View Certificate

Abstract

Vibration is the natural & inherent property of resistance against disturbance in a Elasto-Plastic materials. The structure are often designed in the manner that they can sustain and maintain their superstructure under the influence of dead and live loads with the minimum disturbance of their inertia. The super-structures and tunnels are generally placed on the surface of load carrying columns in the form of simply supported beams. The integration method of which generates a continuous system which is the bridge super structure. So that Natural Frequency (time function Fn) and Response Function (space function) can be generated and programmed in MATLAB.

Introduction

I. INTRODUCTION

The first mathematical expressions were developed in the late 1990’s carrying out many experiments by C. E. Inglis for Tracks considering simply supported segments of a continuous system and S. Timoshenko for bridge super structures. In both of the cases the bridge is the integrated system of simply supported segments containing a lumped vehicle mass. The experiments of 1950’s were also lab dependent until the 1970’s. At that time computer was available for designing and simulating the bridge parameters. Dynamic analysis was firstly carried out in 1953 by K. H. Kinnier. After the year 1980’s standard composite materials like Portland cement, ceramics and RCC were being used extensively in place of steel bridges which were providing flexibility with complexity in material property and geometry. The advancement of new mathematical expression using Laplace and Newmark beta function provides accurate results of damped frequency and damping co-efficient for either side of the vehicle at each point of the bridge using Delta function.

Transport vehicle and bridge both reflects complex models in the real environment. At the point of interaction the damping systems and wheels diminish the value of vibration of assembly up to a very high limit. The structure itself behaves like a damper. During the analysis of vibration the vehicle is considered as a concentrated mass.

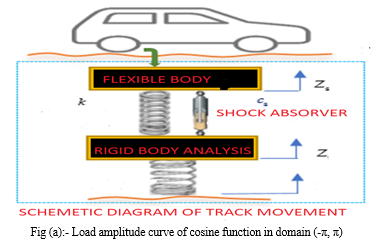

Figure (a) shows the effects of bumps over the vehicle and its mathematical model. The value of damping always varies from zero to unity. A wave has the nature of diminishing its amplitude with respect to time. The reduction of amplitude is inversely proportional to the frequency of vibration of the bridge as well as of the automobile also.

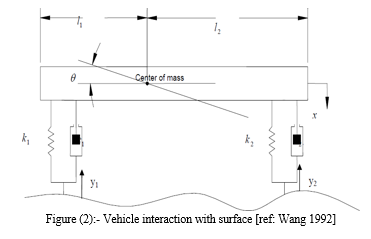

In Fig.2 represents the elastic behavior of an eccentric vehicle which has following parameters.

- Pitching angle (?).

- Eccentricity of support from the center of mass (l1 and l2 respectively).

- Deviation of mass -center (x).

- Lift of the tyre (y1 and y2) i.e. displacement of wheels in vertical direction.

- Equivalent stiffness (k1 and k2) and equivalent damping (c1 and c2 ) respectively for the automobiles front and rear elements

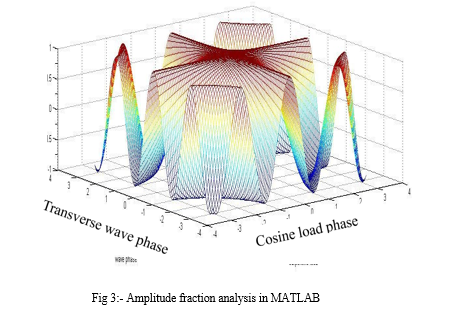

Figure 3.2 represents two perpendicular curvilinear co-ordinates representing highest amplitude of vibration at the center of bridge irrespective to the position of load for the first shape mode of vibration.

Explanation of parameters:- A complex vehicle structure is made up of robust assemblies and meeting parts having complex moving structures. The analysis commonly used for design considerations are:-

a. Unidirectional axle 2D model

b. Double axle 2D model with four degree of freedom.

c. 3 Dimensional models with seven degree of freedom.

In this, 2D model of vehicle has been used having properties stiffness (k), damping(c) and mass (m) matrices with the interactional behavior of bridge material. Mainly the lower order natural frequency is introduced which is the basic mode of vibration. The bridge is assumed to be made up of the simply supported segments of homogenous material. Mode superposition method is used to reduce the degree of freedom. The dynamic analysis is done with superposition of load along with the Euler Bernoulli beam theory.

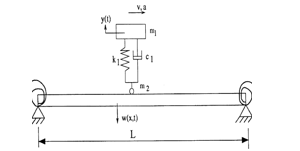

Here, w(x, t) is the uniform shape function of load density. L is the length of the structure.

V is the velocity of the vehicle a is the position of rear wheels.

Other terms have their usual meanings.

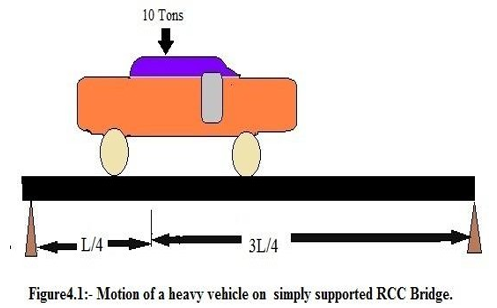

Figure (3) shows that the position of moving vehicle is the function of velocity and corresponding time. The vehicles as well as the bridge material also have damping properties. Unbalancing of vehicle and bridge are the result of relative motion between them because the point contact of

bridge and vehicle changes with time to time. The hysteresis is the accumulation of load with time duration and speed of the vehicle increasing successively day by day.

II. PROCEDURE

Assumptions made at different stages of superposition:

The bridge and the car both have to tackle the environmental parameters such as atmospheric pressure, speed of vehicle and density variation of air due to temperature and seasons etc. All the parameters could not be taken for the consideration. At the time of interaction of bridge and vehicle only material properties and surface properties are involved in the calculation of bridge vibration. At that instant positions of the rest parts of the vehicle other than the contact with bridge are considered as elements of lumped body. Assumptions made at different stage of superposition are as under: -

- The automobile is assumed to be a rigid body during the calculation of vibration of bridge so that only bridge variables are considered as variables at that time.

- The dead load is linear function of mass density for uniform propagation of amplitude function.

- There is no transverse motion in bridge other than longitudinal direction.

- The property of bridge (i.e. flexural rigidity EI and linear mass density ρ) remains constant during the motion of vehicle to evaluate length-time and length-density propagation.

- The property of vibration after impulsive loading will be treated as a cosine function over the L length of the vehicle.

III. REASON OF CONSIDERING COSINE WAVE

The simplification of the bridge model, using the cosine function (including general bridge parameters) with the basic vibration parameters is the easiest way of calculating amplitude of bridge vibration. It is impossible to analyze all the bridge parameters with a single bridge model because of different types and manners of loadings. Cosine function due to its following properties:

- Continuous function of space and time variables.

- Differentiability of the function at each position of vehicle.

- Single valued at each point of vibration.

- The maximum and minimum magnitude is unity thorough out the length.

- Whatever the domain (-∞, +∞), the range varies in the range [-1,1].

- The fundamental range is from (-π, π) in which at the point of interaction, the cosine function has highest load as well as deflection value.

- The maximum possible load value is considered at mid span interaction. All other points will be calculated in the fraction of maximum displacement due to cosine function.

IV. STEPS OF APPROACH

- Selection of standard elastio-plastic bridge material (i.e. concrete).

- Function of bridge vibration should be progressive within the length and unchanged to the surrounding. Wave equation is suitable under impulse load of vehicle with point contact of bridge and wheel for the bridge. Euler Bernoulli beam theory relates the material properties (EI and ρ) with the amplitude functions of front and rear wheels in the terms of time and position.

- Utilization of impulse loading under finite length span of bridge provides shape function of amplitude and time function of frequency for different modes. Laplace transform of integral provides an exact solution of space- time functions in orthogonal (free) co-ordinates.

- Location of the wheel is the time-velocity product, on the bridge. After crossing the bridge deflection of vehicle and bridge are independent to mutual interaction.

- Effective deviation of wheel is the function of position on the bridge and eccentric load due to own weight within the bridge.

- The shape function of wheels are valid from the entry of front wheel on the bridge i.e. (a/v), to the exit of rear wheel (l+a)/v from the bridge.

- Analysis of variation of natural frequency with density of bridge material and length using MATLAB.

- After the analysis of bridge, the eccentric load on the vehicle is also required to be quantified. This is carried out by calculating frequency of the standard vehicle using complex function and MATLAB. The input parameters are distance of wheel positions from center of gravity of vehicle, stiffness and damping co-efficient of front and rear wheels.

- The damping ratio is calculated with the help of complex roots of natural frequency of four wheels.

- These complex roots also provide the resultant of mode shape (plane) and its propagation from wave direction. Then transfer function is generated mathematically including all the parameters. Laplace function provides exact solution for load transfer ratio with Cremer rule.

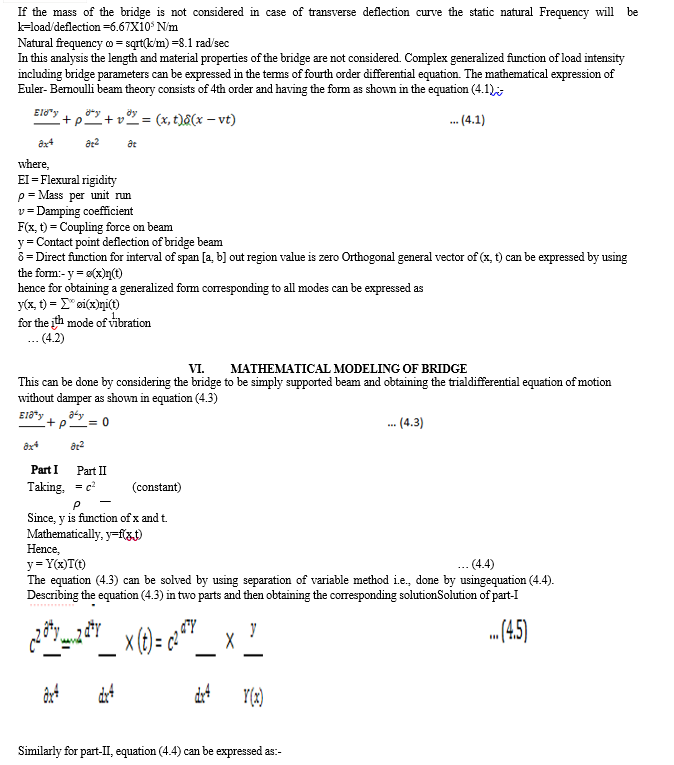

V. TRANSVERSE STATIC VIBRATION ANALYSIS

- There are two ways of analyzing vehicle vibration

- Stationery bridge and moving vehicle for analyzing vehicle behavior.

- Moving bridge carrying lumped vehicle mass.

The combination of these two ways of analysis will provide high degree of accuracy in analysis of each parameter of bridge design. For an example the static loading frequency is calculated by load per unit deflection. If a vehicle of 10 tons is moving on the concrete bridge. The static transverse deflection of bridge is 3/2 mm. then natural frequency can be calculated without considering the gravity load as following:

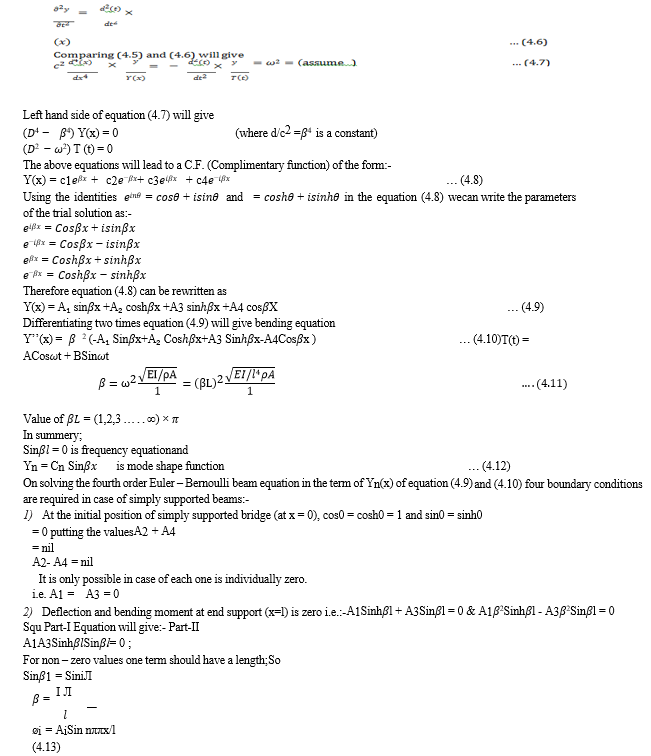

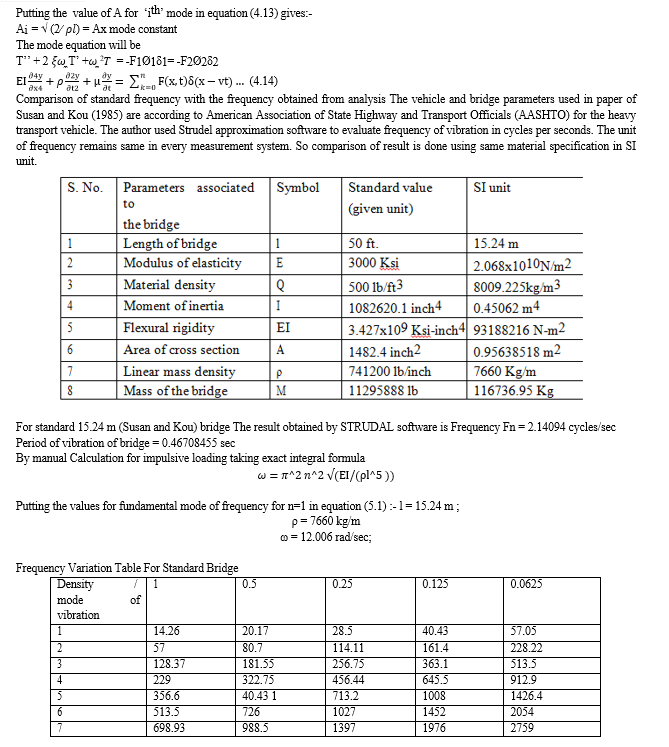

VII. RESULTS AND DISCUSSIONS

A. Natural Frequency

Graph between the natural frequency and the number of modes is plotted, it is shown in Figure (6.1). It represents; when the bridge of finite length vibrates under the loading condition the frequency of vibration increases with the increase in shape mode. Shape modes are the number of waves produced within the finite bridge length. Larger value of shape modes diminishes the amplitude of vibration. So the frequency of vibration is very high due to lower value of amplitude. Similarly if the bridge is moving in single mode then the value of amplitude will be high. So the damping effect should be high, so that instability of the vehicle due to vibration could be diminished up to optimum value. After the seventh mode of vibration the amplitude is diminished to a negligible value.

Table 6.2:- Span/frequency table of bridge for fundamental mode:-

|

Serial number |

Length of bridge (in meter) |

Natural frequency |

|

1. |

16 |

1.070 |

|

2. |

14 |

1.500 |

|

3. |

12 |

2.211 |

|

4. |

10 |

3.490 |

|

5. |

8 |

6.090 |

|

6. |

6 |

12.500 |

For the rear wheel components.

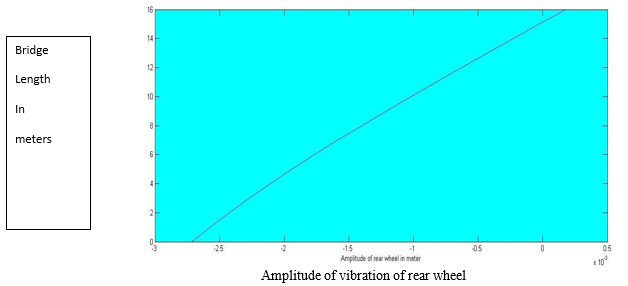

Here the position is the function of velocity of vehicle and instantaneous value of time. Using MATLAB program for standard length of 16 m for different velocity values

Velocity – displacement graph in the terms of amplitudes of each meters A2 (0, 0.0031, 0.0034, 0.007, -0.0036;-0.0014, 0.0021, 0.0037, -0.0014, 0.0036, 0.0007, 0.0034, 0.0031, 0.000)

Length amplitude graph For V = 30m/s.

The graph drawn between the rear wheel amplitude of vibration and the length of the bridge represents that for 16m bridge and moving vehicle of 30 km/hr. the fluctuation in amplitude varies symmetrically with the length of the bridge. It is from downward 2.7mm to the upward 0.5 mm because the front wheel has applied the compressive load on the bridge surface. The effect of the front wheel is dominant at the first half of bridge.

Conclusion

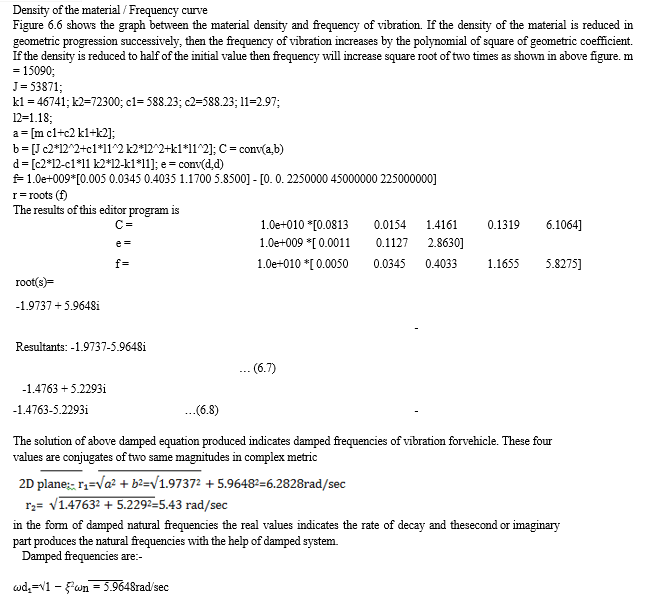

Based on the research work carried out following conclusions can be made:- A. For the bridge 1) The orientations of natural frequency of the bridge using standard Concrete having length of 16 meters and linear weight variation is found to be function of 2.5th order of its length. Its fundamental frequency is 12.006 rad/sec which deviates, 10.47% from the actual solution of Susan and Kou (1985). 2) The Amplitude function of vibration with respect to length is symmetric about the both ends and is highset at the mid span i.e., 3.7 mm for 40 kph velocity. It represents whatever the position (v.t) is the maximum deflections occurs at the centre of bridge. 3) Front wheel amplitude at eight equal segments of bridge A1{0.0031,0.0034,0.0007,- 0.0026,-0.0036,-00014,0.0021,0.0037 and symmetrically reduces to zero.}*10-3 m. Irrespective to the loading point mid span always has maximum deflection due to highest bending moment and tendency of load towards the center. B. For The Tyres 1) Using convolution theorem and energy method in the program of MATLAB the damped frequency magnitude are 6.2828 rad/sec and 5.45rad/sec. for standard 4.2m effective length. 2) The values of shape modes are [0.14<34.64°,-0.101<-30° for the damped natural frequency of [-1.4763-5.2293i,-1.9737-5.968i]. 3) The value of damping ratios calculated according to real and imaginary parts are 0.31 and 0.27 which are closer to the standard value of 0.3. C. Compound Effect 1) The amplitude of the vibration reduces with the density or length variation of the vehicle at constant flexural rigidity. 2) The vehicle should have the gravity center as near as possible to the midpoint for equal phase angle. It will provide geometrical balance during vibration.

References

[1] “Mechanical Vibration”, by S. Graham Kelly edition:1 [2] Aswani M. Panicker and Alice Mathai (2013), “Free vibration analysis on FRP bridges’ American Journal of Engineering Research e-ISSN : 2320-0847 p-ISSN : 2320-0936 Volume-4 pp-47-5. [3] Augusztinovicz F., rki F. Ma´, Gulya´ s K., Nagy, Fiala P., Gajda´ tsy P.(2006), “isolation requirement for steel road bridge”, Journal of Sound and Vibration 293 953. [4] Bar?s- Sevim a,b,n, Alemdar Bayraktar b, Ahmet Can Altunis -ik b, Sezer Atamt¨ urkt ¨ ur c, Fatma Birinci (2011), “Finite element model calibration effects on the earth quake response of masonry arch bridges”, Finite Elements in Analysis and Design 47 621–634. [5] Concrete specification AASHTO (American Association of State Highway and Transportation Officials). [6] Errikssson Per and ”Vibration response of light weight padestrain bridge” Sweden 2013 Master’s Thesis 2013:51 [7] Higher engineering mathematics by Dr. B.S. Grewal -14062011 [8] Ghaffer and Ahmed (1982), “Suspension bridge vertical vibration ”. American Society of Civil Engineering V-108: EM6 p. 4 [9] Gonzalez A. ?, Cantero D.1, O Brien E. J. 2, (2011) “Dynamic increment on force due to heavy vehicles crossing a highway bridge”, Computers and Structures 89 2261–2272 47-455. [10] Ivanovic´ S. Z? , Pavic A., Reynolds P. (2005) , “Vibration serviceability of footbridges under human- induced excitation: a literature review” Journal of Sound and Vibration 279 1–74. [11] Jeffrey Kinlan (2012), “Structural Comparison of a Composite and Steel Truss Bridge” by An Engineering Research Project Submitted to the Graduate. [12] Liu K., Reynders E., DeRoeck G., Lombaert G. (2009) , “Vibrations of steel–concrete composite beams with partially degraded connection and applications to damage detection”, Journal of Sound and Vibration 320 101–124. [13] Luis Lorax “Stuructural design of bridge” (2008), ISSN 1103-4297, ISRN KTH/BKN/B—263 Structural Engineering. [14] Lv1 Na and Liang Fan1 (2014), “Optimization of Quickly Assembled Steel-Concrete Composite Bridge Used in Temporary”, Modern Applied Science; Vol. 8, No. 4; 2014 ISSN 1913-1844 E-ISSN 1913-1852. [15] Michaltsos G.T., Sarantithou E., Sophionopolos D. S. (2005) , “vibration of simply supported open cross- section steel beams under moving loads” Journal of Sound and Vibration 280 479–494. [16] Mistuhiro Yoshimuraa, Qingxiong Wub, Kazuo Takahashib, Shozo Nakamurab, Kazuyoshi Furukawa (2006), “Vibration analysis of sakai bridge”, Journal of Sound and Vibration 290 388–409. [17] Paolo Clemente1, Mehmet ÇELEBI2, Giovanni Bongivanni1, Dario Rinaldis1]” (2004) Seismic Analysis of indiano Cable-stayed bridge”. 13th World Conference on Earthquake Engineering Vancouver, B.C., Canada August 1-6 Paper No. 3296. [18] Qin J.W. a, Law b,n S.S., Yang Q.S. a, Yang N. ,”Pedestrian–bridge dynamic interaction, including human participation”, Journal of Sound and Vibration 332 (2013) 1107–1124. [19] Rainer, J. H. and Pernica (1979) ,“Dynamic testing of modern concrete bridge” Canadian Journal of Civil Engineering Vol.6 [20] Rajesh F. Kale1, Gore2 N.G., Salunke3 P.J. (2014) , “MATLAB optimization of bridge superstructure”, International Journal of Research Engineering and Technology EISSN-2319 -1163; PSSN:- 2321-7308. [21] Samali B., Li J., Crews K.I. (2007), “Load Rating of Impaired Bridges Using a Dynamic Method”, Electronic Journal of Structural Engineering Special Issue: Loading on Structures. [22] Sauvik Banerjeez, Fabrizio Riccib, Ernesto Monacob, Ajit Malc (2009), “A wave propagation and vibration-based approach for damage identification in structural components”, Journal of Sound and Vibration 322 167–183. [23] Sebastia´n Machadoa,b P., V?´ctor Cort?´ H., Neza B. (2009), “Dynamic stability of thin-walled composite beams under periodic transverse excitation”, Journal of Soundand Vibration 321220–241.

Copyright

Copyright © 2023 Avinash Gavel, Dr. H. R. Suryawanshi, Sudheshwar Singh. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET49288

Publish Date : 2023-02-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online