Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Performance of SI Engine under the Effect of Magnetic Field by using CNG, Petrol and Ethanol

Authors: Mr. Virendra Nagture, Mr. Rohan Patil, Mr. Ashish Hol, Mr. Rushiraj Watekar, Prof. Nilesh Pawar

DOI Link: https://doi.org/10.22214/ijraset.2022.42162

Certificate: View Certificate

Abstract

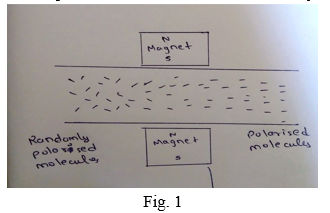

The invention resides within the field of treatment of hydrocarbon fuels in liquid or gaseous form, to extend the fuel-burning efficiency, by exposing the fuel in containment vessels or conduits to a shaped uniform field of force with a relentless directional flux. Hydrocarbon fuels have long branched geometric chains of carbon atoms which tend to fold over onto themselves and on adjoining molecules because of inter molecular electromagnetic attraction existing between like molecules or atoms. It is vital to grasp that in a very fluid that\'s subjected to an external field the electron excitation (magnetic moment) occurring, affects molecular orientation. because the axis of the electrons become aligned with the external magnetic flux, the momentum of the molecule not averages intent on zero, as within the normal case in molecules not possessing permanent dipole moments. This accommodation is attributed to the very fact that on the molecular level, a spinning electron subjected to an accurate amount of electromagnetic energy will captivate that energy and \"spinflip\" into an aligned state. When a magnetism is applied, the instant as seen by the electron excitation, causes the molecule to tend to align with the direction of the field of force. The momentum of the molecule not averages dead set zero because the axis of the electrons aligns with the external magnetic flux, because it does in molecules without permanent dipole moments. The fluctuating dipole moments under the influence of the external flux acquire a net attraction, which produces a stronger bonding with an oxygen ion. As a result of the complex fuel, molecules tend to uncluster, straighten and produce higher combustion efficiencies. the rise in combustion efficiency is because of the unfolding of the hydrocarbon molecules which produce an increased extent for more complete oxidation of the fuel. The unfolding of the fuel molecules is that the major effect of the dipole being off from its neutral state by the applied field of force. Increased combustion yields increased fuel efficiency, with lower hydrocarbon emissions from hydrocarbon-based fuel-burning apparatus. However, certain problems remain to be overcome, like whether to focus the force field con or directional alignment, determine flux strength, select appropriate magnetic materials and determine mounting arrangements for the best efficiency. The effect is to stop scaling from occurring on the inner walls of the conduit from the liquid flowing there through by forcing the molecules which might attach themselves to the inner walls of the conduit toward the middle of the conduit.

Introduction

I. INTRODUCTION

The application of the magnetic flux is vital in many aspects of research and practical applications. Over the past century, the necessity and development of micro-power devices have necessitated the necessity for studies to appear further into mediums that may enhance the combustion processes of fuels by optimizing system parameters. this is often essential to utilize the high specific energy content of liquid hydrocarbon fuels. Magnetic fields can affect fluids that may exhibit paramagnetic and diamagnetic behaviour (even if the fluid isn't electrically conducting), this means the potential ability of magnetic control of air flows and also combustion. Paramagnetism may be a result of unpaired electrons within an atom that may cause a dipole to create within the presence of a magnetic flux and, as a result, within the presence of a force field this effect causes the fluid to be drawn within the direction of skyrocketing field of force strength.

On the contrary, if the electrons are already paired, the atoms resist the formation of a dipole and this resistance causes the atoms to maneuver within the direction of decreasing force field strength, called diamagnetism. Paramagnetic behavior is about three orders of magnitude larger than diamagnetic behavior. Oxygen and air are samples of paramagnetic substances and are drawn towards higher force field strengths. Nitrogen, carbonic acid gas, and most hydrocarbon fuels are samples of diamagnetic substances and are repelled by stronger magnetic fields. Thus, the behaviour of those gases within the field suggests a replacement methodology of study and separation in gases, using the field. Conservation of fuel is that the key to any nation’s economic success; on the opposite hand, the limitation of pollution through such fuel combustion could be a must for the nation’s health. At a time when rising fuel costs are referring to the economy of the country, at the identical time rising pollution levels are playing havoc with the health of the multitudes.

The focus, therefore, is continuously on, how best to save lots of fuel with a watch to reducing the elevated emissions levels. The dynamics of combustion of hydrocarbon fuel have forever been an issue of intense research the globe over as also the issues related to it like a decrease in equipment efficiency through unfinished combustion, consequent carbon deposits, and high emission levels. Efforts have always been on to attain the simplest possible burning and energy output from fuel combustion systems, the aim being to extend fuel efficiency and reduce exhaust emission levels. Traditional methods have always focused on the employment of additives to realize the means which ends up in a recurring cost and poor impact on the lifetime of the combustion systems within the future. Today Hydrocarbon fuels have a natural deposit of carbon residue, that clogs carburettors and fuel injectors, resulting in reduced efficiency and wasted fuel. Knocking, stalling, loss of horsepower, and significantly decreased mileage are very obvious. This results from the unfinished combustion of hydrocarbon fuel. so as to market the entire combustion of hydrocarbon fuels, oxygen must saturate the fuel molecules. Hydrocarbon fuels possess large clustering molecules that tend to bunch up into groups, preventing complete oxygen penetration. For this reason, 100% combustion doesn't occur. Various institutions have conducted exhaustive research into the employment of permanent magnetic fields in alleviating these problems currently related to hydrocarbon fuel combustion. the sector success of those devices and continuous research has now given thanks to fusion technology and better availability of magnetic fields which promises to relinquish rapid and effective results for rising fuel efficiency and reducing exhaust emissions.

II. PROBLEM STATEMENT

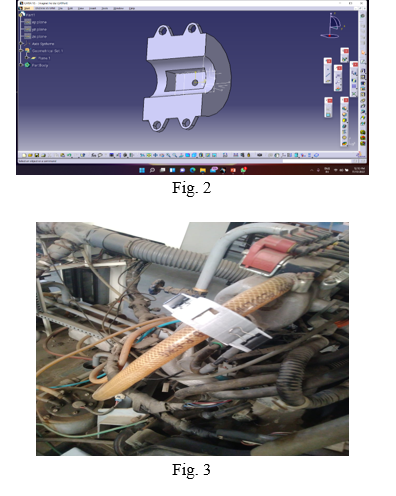

The performance of the SI engine can be increased by using magnetic flux. While going through the literature survey it’s been observed that there is scope for using magnets in IC engines for complete combustion. As of now, maximum work has been carried out only on IC engines with a single magnet fitted on the fuel line only.

Following are some gaps in current research work:

- By correct fuel-burning parameters through proper magnetic flux an internal combustion engine is getting maximum energy per liter as well as an environment with the lowest possible level of toxic emission.

- Magnetic field significantly improved the molecular excitement of fuel and turbulence in a petroleum-based fuel so that re-polymerization is more effective.

- Unburned hydrocarbon and oxides of nitrogen cause toxic emission, Pre-ignition, loss of horsepower, and greatly decreased mileage on cars are minimized by using magnetic effect by fitting magnets on the fuel line, before fuel injector as well as over air inlet pipe, around the engine block, on high tension cords from Ignition coil up to spark plug.

III. LITERATURE REVIEW

- ScienceDirect 2016: Alternative fuels for IC Engines by Choongsi Bae, Jaeheu Kim

- P. Govindasamy & S. Dhandapani: Reduction of NOx Emission in Bio Diesel Engine with Exhaust Gas Recirculation & Magnetic Fuel Conditioning.Vol.8,No.5,(2007),PP.533-542

- P. Govindasamy and S. Dhandapani, performance and emissions achievements by magnetic energizer with a single-cylinder two-stroke catalytic spark ignition engine, Journal of Scientific and Industrial Research, 66, (2007), 457-463

- S. Jain and S.Deshmukh, Experimental investigation of magnetic fuel conditioner in I. C. Engine, IOSR Journal of Engineering 2(7)(2012),27-31

- P.Govindswami and S.Dhandapani, Experimental investigation of cyclic variation of combustion parameters in catalytically activated and magnetically energized 2-stroke SI Engine, Journal of Energy and Environment,6(2007),45-59.

- Increased combustion yields increased fuel efficiency with lower hydrocarbon emissions from hydrocarbon-based fuel-burning apparatus. The focus of the magnetic field in opposition or directional alignment, determine magnetic field strength, select appropriate magnetic materials and determine mounting arrangements for better efficiency. Earlier attempts have proven to be less than satisfactory, producing only limited results as can be seen from the discussion of the teachings of the several patents.

A. Objectives

- The present invention is to provide a method and apparatus to improve the combustion of fuels to achieve more complete combustion thereby significantly improving combustion efficiency in internal combustion engines.

- To provide a method and apparatus to reduce the formation of exhaust pollutants due to more ideal and complete combustion conditions and to further combust any remaining unburnt fuel as they exit the combustion process.

- To make practical and economical changes to new and existing internal combustion system configurations to save fuel and reduce world usage of petroleum and other combustion resources.

- To investigate the performance and emission characteristics of SI engine under application of magnetic field on alternative fuel.

IV. WORKING

- When hydrocarbon fuel (methane molecule) is combusted, the primary to be oxidized are the hydrogen atoms (or precisely electrons on their outer shells). Only then, are the carbon atoms subsequently burned (CH4+ 2O2 = CO2+ 2H2O). Since it takes less time to oxidize hydrogen atoms in an exceedingly high-speed combustion process, in normal conditions a number of the carbon are going to be only partially oxidized; this is often to blame for the unfinished combustion. Oxygen combines with hydrogen readily; however, the carbon-oxygen reaction is much less energetic. we must always detain mind: that oxygen always incorporates a valence of minus two. The valence of carbon, on the opposite hand, may be plus or minus because of the configuration of its four electrons within the outer shell, which needs a complete of eight electrons for completion. The optimum combustion efficiency (performance) obtained from the Magnetizer application on fuel is first indicated by the quantity of increase in greenhouse gas (CO2) produced, which has been validated by state emissions control devices.

Furthermore, because the pollutants decrease, the combustion efficiency increases. The drop of HC & CO emissions is well proven by comparative gas flue analysis & opacimeter emissions tests. The stoichiometric tests indicate a discount in hydrocarbon HC (unburned fuel) approx. 75 - up to 92% and CO (CO) up to 99.9%, thanks to the Magnetizer use. Remember, as HC goes down, mileage goes up. This leads to a scientifically measurable emission reduction/combustion efficiency ratio and a mean increase in mileage of 15-25%. Since the Fuel Energizer saves fuel by increasing combustion efficiency, less CO is being emitted; thereby, less fuel is being employed. In principal, all-time low fuel savings occur within the range velocity of the utmost torque, when the very best increase of horsepower will be noted (about 10 HP); the unit gives a trade-off between driving a Porsche versus Volkswagen.

2. Altering the spin properties of the outer shell ("valence") electron enhances the reactivity of the fuel (and related combustion process). the upper energized spin state of hydrogen molecules clearly shows a high electrical potential (reactivity), which attracts additional oxygen. Combustion engineering teaches that additional oxygenation increases combustion efficiency; therefore, by altering the spin properties of the H2molecule, we will produce to its torque and enhance the reactivity of the hydrocarbon fuel and ameliorate the related combustion process. The unit's extremely strong field of force, with sufficient density to own the specified effect on fluid passing through it, substantially changes the isomeric sort of the hydrocarbon atom from its para-hydrogen state to the upper energized, more volatile, ortho state, thus attracting additional oxygen. Fuel structure and properties, such as e.g. electrical conductivity, density, viscosity, or light extinction are changed; its macrostructure is beneficially homogenized.

3. Hydrocarbon molecules form clusters called "associations." it's been technically possible to reinforce van der Waals' discovery thanks to the applying of the Magnetizer, a high power, permanent magnetic device, strong enough to interrupt down, i.e. de-cluster these HC associations. They become normalized & independent, distanced from one another, having bigger surfaces available for binding (attraction) with more oxygen (better oxidation). a straightforward analogy is of burning coal dust and a coal brick. There, where one aims at higher efficiency, during the combustion process, one should provide a molecule greater access to oxygen. within the case of burning of powdered coal dust, adding oxygen may even cause explosions. Thus, with our fuel energizer, the oxygenation and combustion efficiency increase. Fuel is more active and dynamic, and also the combustion process faster and more complete. These "new” hydrocarbon molecules have yet one more important characteristic: they not only dissolve and eliminate carbon varnish within the combustion chambers, on the surface of jet nozzles, spark plugs, and exhaust pipes but don't allow new and harmful deposits to reform. Furthermore, the energizer's work ensures better performance of carburettor or fuel injectors, makes start-ups easier, considerably increases driving dynamics, etc. the ability and torque within the whole range of rotational velocity of the crankshaft also go up. De-clustering of hydrogen molecules, within the combustion chamber, increased saturation & reactivity of the fuel mixture with oxygen is achieved, leading to more complete oxidation of the first hydrogen element and further oxidation of carbon ©, the secondary fuel element, since, in accordance with van der Waals discovery of a weak clustering force, there's a awfully strong binding of hydrocarbons with oxygen in such magnetized fuel, which ensures optimal burning of the mixture within the engine chamber. The charged fuel, so to talk, swells, thickens, and desires a bigger quantity of air, which is definitely remedied by adjusting the change in air/fuel ratio in carburised cars. once we attach the Magnetizer unit to the gas line of an automobile (before carburettor, in tandem series, placed 1/4" apart, or in mechanical system Systems - on the pipage to the injectors + before the injection pump; ensure it's not involved with the engine's metal parts), we see a direct (approx. after 5 min., 4-5 miles/6-8 kms upon start-up) visit unburned hydrocarbons and carbon monoxide gas thanks to the magnetic conditioning of the fuel which makes it more reactive. As explicitly stated in our instructions, upon the Magnetizer installation (5-10 minutes thereafter) engine will undergo the so-called "Stabilization Period", i.e. the time of the gradual disappearance of prior carbon varnish sediments and also the total magnetic saturation of all ferromagnetic metal parts of the feeding system between the installed energizer and also the combustion chamber so as to totally activate fuel. The initial saturation lasts a couple of weeks (even though within the past we received positive reports already after 2-3 days upon installation), while the complete engine cleaning from the carbon residue lasts about 30 to 70 days (old engines). On passenger cars, this implies about 1,000-1,125 miles (1600-1800 kms) driven (depending on vehicle class, age, internal cleanliness of its engine, driving habits, etc.), on trucks - about 1,250-2,000 miles (2,000-3,200 kms).

When after a month from the correct installation, the improvement is not readily apparent, it is caused by too little amount of oxygen in the fuel mixture. One has then to change the dirty or oiled air filter and adjust the carburettor in order to increase the amount of air in the mixture (make it leaner) or adjust the fuel pressure of a diesel pump to restore the O2 level to where it was prior to the energizer's installation. Fuel-injected cars are self-adjustable, with the exception of quite rare cases when the lambda (excess air) probe has been worn out (needs replacement) and the system "overrides" the Magnetizer's action.

Conclusion

This is a device for fuel processing with the purpose of its preparation (modification) for the more effective combustion in the internal-combustion engine. At its designing the necessary condition for the reception of the effect of decoupling fuel hydrocarbon circuits and their keeping in such condition for the period, necessary for the technological process of fuel-burning is considered. The invention is related to the technical equipment where the effective utilization of the fuel by internal-combustion engines and reduction of ecologically harmful exhausts at their work is required. A number of devices for \"magnetization\" of the liquids (fuel) are known, having the general and common purpose to pass the liquid through a magnetic field and “magnetizing” it. Such devices have a number of lacks: 1) non-technological designs 2) passage of liquid past the active zone of the magnetic field 3) contact of magnets with liquid 4) presence of joints of details requiring hermetic sealing The offered design has a concrete purpose. The purpose of the invention is to increase the efficiency of fuel combustion of fuel in the internal-combustion engine (petrol and diesel) with improvement of their ecological characteristics. Thus, the design is compact and reliable. Processing (modification) of fuel before its reception into the combustion chamber of the internal-combustion engine, occurs in the channel of the fuel pipe with to variable cross-section. The positive effect is reached at a molecular level in a volume of the channel of the fuel pipe with variable polarization by a magnetic field. As an elementary particle of liquid (molecule, ion) in a magnetic field is influenced by Lorentz\'s force aspiring to turn it perpendicularly, in a volume of fuel pipe with variable polarization resonant magnetostriction effects arise, braking the hydrocarbon “chains” of fuel, leading the fuel structure to a condition in which oxidizing process at combustion proceeds much more effectively, with reduction of harmful emissions. Research at test stands a specialized design office of engines, at the application of the device in the system of fuel delivery of forced automobile petrol & diesel engines. The greatest effect is achieved at the installation of the device in the immediate proximity to the executive operation point of the unit (in front of the carburettor, injector, spray).In this case, the effect of the greatest structural reorganization of molecules of the fuel is kept while preparing for effective burning. Fuel, when passing the fuel pipe, satisfies conditions of the Joule’s effect (at an increase of magneton deformation magnetic conductivity increases). As well as in any magnetostrictive effects if there is a change of sizes in the volume of polarization - a change of magnetization is unavoidable. In this section, the magnetic intensity - a condition of conformity to Gillman’s effect - is also amplified. The diamagnetic filling is applied for reduction of dispersion of magnetic stream and reduction of external magnetic influences. The fuel stream passes 5 critical sections with the magnetic stream constantly compressing it, with alternation of field direction. Approximately 1/6 of fuel streams receive 3 “turns” for 180o and 5/6 of fuel “is turned” 4 times for 90o and one for 180o Thus, in the offered device, the preparation of fuel occurs before the burning process, the time of oxidizing processes is determined basically by the speed of chemical reactions of fuel burning. In its turn, the speed of chemical reactions of burning depends on the condition of hydrocarbon compounds. Increasing the speed of chemical reactions of burning as a result of the reorganization of fuel at the molecular level raises the useful capacity of the internal-combustion engine and, finally, increases the efficiency of fuel use, and also considerably improves the ecology of exhaust. For the preparation of fuel before it\'s burning the offered device, in such performance carries out the most effective destruction of “hydrocarbon chains” (hydrogen compounds) and keeps them in such condition during the period, necessary for the process of the most effective burning of fuel.

References

[1] Internal Combustion Engine Fundamentals. Heywood, John B McGraw-Hill [2] Internal Combustion Engines: Applied Thermo sciences, 2nd Edition, Colin R. Ferguson, Allan T. Kirkpatrick. [3] “Internal Combustion Engines Analysis and Practice”, Obert E.F., International Text Books Co., Scrantron, Pennsylvania. [4] “Automotive Engines”, William H.Crouse McGraw-Hill. [5] “Automotive technology: A system approach”, Erjavec, Thomson learning series. [6] “Heat release analysis of lean-burn catalytic combustion in a four-stroke spark-ignited engine.” International Journal of Combustion Science and Technology. N. Nedunchezhian. 2000 vol.155. pp. 181-200. [7] “Experimental Investigation on Electronic Fuel Injection in four- Stroke SI Engine using Virtual Instrumentation Technique”, International Journal of Engineering Education, Robinson Y & S.Dhandapani Vol.21,2005. No.1, pp 55-62. [8] Investigation of pollution monitoring and its control for the Indian petrol light-duty vehicles applications to meet emission regulations”. International Journal of Enviromedia S.V.Saravanan. vol.4 pp.821-826 2006. [9] “An Experimental Investigation on the effect of Magnetic flux to reduce emissions and improve combustion performance in a four-stroke catalytic coated spark ignition engine”, KSAE International Journal of Automotive Technology”, Paper No. E 2006079. P.Govindasamy, S.Dhandapani Vol.8,November5,Year2007. [10] S.Dhandapani, P. Govindasamy “Economizer for four- stroke engine” Motor India Auto Journal, S.Dhandapani, P. Govindasamy Vol. 46, No.10, May2002, pp 29-31 [11] Combustion stability and control analysis of scooter engine, JSAE Small Engine Technology Conference.Wisconsin, Manivel.R, Dhandapani.S USA.2003.SAE 2003-32-0009/20034309. [12] “Experimental Investigation on an embedded system controlled Electronic Fuel Injection of LPG in a four-stroke Spark Ignited Engine” Y. Robinson, S. Dhandapani, International Mechanical Engineering Conference and Expo 2004 (IMECE 2004), Dec 5-8, 2004, 13ELECTRONIC FUEL INJECTION SYSTEM FOR A SINGLE-CYLINDER SPARK-IGNITED FOUR-STROKE ENGINE-DEVELOPMENTS, EXPERIMENTAL AND THEORETICAL INVESTIGATIONS - 2006. - Y. ROBINSON.

Copyright

Copyright © 2022 Mr. Virendra Nagture, Mr. Rohan Patil, Mr. Ashish Hol, Mr. Rushiraj Watekar, Prof. Nilesh Pawar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET42162

Publish Date : 2022-05-02

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online