Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Performing of Concrete by Replacing Aggregate with Plastic Waste Generated During Covid19

Authors: Shivendra Mani Tripathi , Sunil Kumar

DOI Link: https://doi.org/10.22214/ijraset.2022.47308

Certificate: View Certificate

Abstract

Biomedical waste management is becoming increasingly important to satisfy sustainability goals and to meet the growing demand for medical services around the world. When considering recycling and incineration methods from an environmental perspective, over 80% of published Life Cycle Assessment studies believe recycling is better. Furthermore, among the many recycling methods, the use of various waste materials such as aggregates and fibers in the cement manufacturing process is considered to be an environmentally friendly, safe and reliable method. Useful. Nephrology, especially dialysis, is a major producer of polymer waste (BPW) in medical practice. After each treatment, 1.5-8 kg (400 kg / patient / year) of BPW is removed by burial or cremation. Most polymers are not biodegradable, so they accumulate inside. Previous studies have shown that incineration sterilization 49-60% BPW, autoclaving 20-37% and other sterilization methods 4-5%. Other methods, such as autoclaves and microwave ovens, are considered more environmentally friendly than incineration and produce the same waste after treatment. It must be disposed of by burning, increasing disposal costs and eliminating the need for waste. This study shows a positive relationship with the BPW environment through dialysis treatment and the participation of healthcare and industry partners in challenging situations. After each dialysis treatment, 1.5-8 kg (400 kg / patient / year) of total biomedical waste (BPW) is filled or stored. Additionally, this study will provide information to engineers, designers and construction managers on the use of reinforced concrete in BPW and equipment predictions based on current international standards and regulations.

Introduction

I. INTRODUCTION

Concrete plays an important role in the design and construction of our civil engineering and infrastructure. Its high strength and durability are used in infrastructure projects such as roads, bridges, airports, railways, tunnels and ports. Concrete has many disadvantages such as low tensile strength, low ductility, high weight and low energy absorption. Due to this weakness, structural engineers use primitive reinforcement to increase tensile strength and ductility. As a light weight aggregate, plastics such as syringes and saline bottles must be used in concrete. One of the goals of producing earthquake-resistant structures is to reduce the unit weight of concrete. Medical trash and infectious waste are examples of biomedical waste. Is it used to describe solid waste generated during the detection, treatment, research, production or testing of human or animal products? The hospital produces 545 kg of waste per month. Of this amount, 15% is classified as fly waste, which is 82 kilograms per month. Biomedical waste from hospitals, medical research services and other medical facilities is a major problem in India. The resulting waste has a negative impact on the environment and the human world. Waste management, treatment and disposal are a growing environmental concern, particularly in developing countries. Improper waste disposal can pollute the environment and create health risks. Proper collection, treatment and disposal of medical waste not only reduces the costs and disposal of unnecessary infectious waste, but also promotes a healthy environment and a high quality of life. Infectious waste, pathological waste, pharmaceutical waste, genotoxic waste, chemical waste, high quality metal waste, etc.

A. PPE Kit Waste

In half a century, plastic consumption has increased from 1.3 million tons in 1950 to 245 million tons in 2006. In recent years, plastic has been introduced into new fields of application such as automobiles, trains, transport, aviation, health and wellness. . etc., leading to an increase in consumption. The plastics crisis is worsening due to the ongoing COVID-19 pandemic, along with the waste of personal protective equipment (PPE). As the world moves on with vaccines and other control methods, we need to find sustainable ways to stay healthy and clean. The high standards of hygiene established during this pandemic are expected to continue for some time in our daily lives, including: B. Use of Personal Protective Equipment (PPE). The use of Personal Protective Equipment (PPE) has proven to be the most effective and efficient way to prevent the spread of COVID-19.

Ref : https://www.google.com/search?q=bio+medical+waste&rlz=1C1VDKB_enIN973IN973&sxsrf=ALiCzsZfi_0_Zp34OBTVW3OqTDL-GPGRjQ:1666080493785&source=lnms&tbm=isch&sa=X&ved=2ahUKEwi07f6_qen6AhXJRmwGHX_PBRMQ_AUoAXoECAIQAw&biw=1536&bih=714&dpr=1.25#imgrc=jDYrYX4EsLRo5M

Fig. 1 PPE kit Waste

Additionally, PPE equipment plays an important role in maintaining public health during the pandemic. Polypropylene is commonly found in PPE and can be pyrolyzed to make fuel. This is a chemical reaction that destroys plastic at high temperatures (300-400 degrees Celsius for 1 hour) without oxygen. During the degradation process, the long polymer chains are broken down into molecules with lower molecular weights. This process produces very valuable compounds that can be used as fuels and chemicals in a variety of applications. The National Department of Disaster Management has issued clear guidelines recommending that all concerned wear PPE when in contact with known or suspected cases of COVID-19. Using multiple layers of PPE leads to poor waste disposal, which is already an environmental problem. Developing countries that do not have biomedical waste disposal (common bio-medical waste treatment and disposal facility) facilities will face major waste management challenges during this pandemic. The Central Pollution Control Board of India has published guidelines for effective waste management specific to COVID-19, incorporating several methods for long-term use. With a population of 1.38 billion and a large number of cases, India can generate a lot of hospital waste. Workers become infected with improper disposal of drugs and masks. Therefore, in order to prevent the spread of infectious diseases, it is necessary to improve the separation of medical waste at source and to provide for more effective methods of treatment, protection and disposal. Since PPE is a single use item, more use creates more waste. Research shows that medical waste production increased from 40-50 tons per day to 247 tons per day during this pandemic. One of the disadvantages of using PSA kits is that isolated viruses lose their potency after purification. This opens up new opportunities to convert waste into valuable products compared to traditional incineration methods, leading to a more sustainable approach to waste management.

B. Medical Waste

Medical waste is part of the waste received from hospitals such as hospitals, clinics, dental clinics, blood banks, veterinary clinics / hospitals, as well as laboratories and laboratories. Pharmaceutical waste, also known as controlled pharmaceutical waste, refers to pharmaceutical waste contaminated with blood, milk or other potentially infectious substances. Medical waste is part of the waste received from hospitals such as hospitals, clinics, dental clinics, blood banks, veterinary clinics / hospitals, as well as laboratories and laboratories. Pharmaceutical waste, also known as controlled pharmaceutical waste, refers to pharmaceutical waste contaminated with blood, milk or other potentially infectious substances. Including pharmaceutical waste

Tissues, organs, and body parts are examples of human anatomical waste.

- Veterinary hospital animal excrement created during research

- Microbiology and biotechnology waste

- Sharp objects such as needles, syringes, skin fasteners and glass should be disposed of carefully.

- Antibiotics and cytotoxic agents

- Bandages, bandages, blood related items, tubes and catheters are examples of contaminated waste.

- Liquid waste from any infected location

- Chemical wastes and ash from incinerators

https://www.google.com/search?q=bio+medical+waste&rlz=1C1VDKB_enIN973IN973&sxsrf=ALiCzsZfi_0_Zp34OBTVW3OqTDL-GPGRjQ:1666080493785&source=lnms&tbm=isch&sa=X&ved=2ahUKEwi07f6_qen6AhXJRmwGHX_PBRMQ_AUoAXoECAIQAw&biw=1536&bih=714&dpr=1.25#imgrc=5349HDH8qvdAaM&imgdii=yV_UoN706EcqTM

C. Powdered PPE Kit Used in Concrete as Sand

Personal protective equipment (PPE), face masks, including gloves—was one of several socioeconomic outcomes used during the COVID-19 pandemic. As a consequence, this disposal sector has grown dramatically. Several studies that looked into waste management concerns from differing viewpoints, such as local authorities and trash collection firms. According to the findings of numerous studies, nearly 60percent of local authorities in the country region have implemented particular procedures for the processing and collecting of trash PPE. Due to the increased expenses of modifying collecting scheduling, 15% of trash collection businesses have used special collection schedules for waste created at quarantined collection stations, and 25% of waste PPE kit has been thrown in waste land fields, causing numerous infections. Use of PPE kit shows some advantages according to some research-

- The PPE materials are utilized in the trials are of excellent quality and thus are comfortable to manage with and work with.

- The additives added might have a major influence on strength of concrete.

- The elements in PPE kits have such a lower specific gravity.

D. Glucose Bottle Used in Concrete as Aggregate

Cement producing also produces harmful gases including dust, which have the ability to degrade air quality and cause a variety of respiratory illnesses. As a result, various studies have been conducted in order to find a unique alternatives method of dealing with this environment issues. Plastic bottles were employed as the major component in the creation of concrete blocks, such as waste medical waste glucose bottles and waste plastic water bottles.

Some of the results obtained according to some studies -

- Medical plastics wastes such as glucose bottles, plastic waste containers, and others have been recognized as building material that can be discarded of.

- The medical glucose bottle trash is utilised to substitute the coarse aggregate because fine aggregate isn't really acceptable.

- The compressive strength and durability of concrete (including concrete) are essentially the same as that of standard concrete. However, if the plastic content is greater than 20%, the strength decreases significantly.

II. OBJECTIVES OF THE STUDY

- This study main objective is to reduce the hospital medical waste which is more hazardous to the environment.

- These medical waste increases the concrete workability, strength and also other properties of the concrete.

- Also to know the performance of medical waste as a partial replacements in concrete.

III. METHODOLOGY

In this research work using M-35 grade of concrete with some replacement material generated from medical waste like PPE kit, Glucose bottles. Material replacement with percentage variation likes 0%, 3% 6% and 9%.

A. Materials used

- Concrete

- Cement

- Aggregate

- Admixture

- PPE kit

- Glucose Bottles

B. Mix Formulation

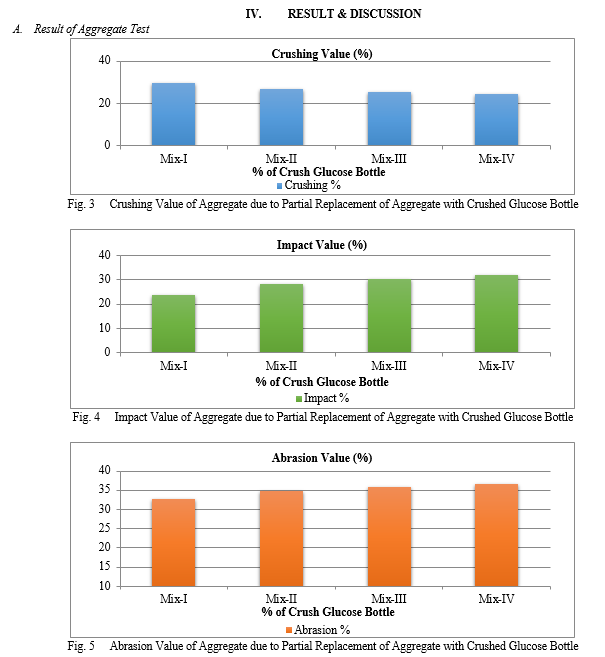

Table: 1 Mix for Testing of Corse Aggregate

|

S. No. |

% Crush Glucose Bottle |

Coarse Aggregate |

|

Mix-I |

0% |

100% |

|

Mix-II |

3% |

97% |

|

Mix-III |

6% |

94% |

|

Mix-IV |

9% |

91% |

Table: 2 Mix for Testing of Concrete at 0% replacement of Sand with varying % of CGB

|

S. No. |

% Crush PPE Kit |

% Crush Glucose Bottle |

Cement |

Sand |

Aggregate |

|

Mix-1 |

0% |

0% |

100% |

100% |

100% |

|

Mix-2 |

0% |

3% |

100% |

97% |

97% |

|

Mix-3 |

0% |

6% |

100% |

94% |

94% |

|

Mix-4 |

0% |

9% |

100% |

91% |

91% |

Table: 3 Mix for Testing of Concrete at 3% replacement of Sand with varying % of CGB

|

S. No. |

% Crush PPE Kit |

% Crush Glucose Bottle |

Cement |

Sand |

Aggregate |

|

Mix-1 |

3% |

0% |

100% |

97% |

100% |

|

Mix-2 |

3% |

3% |

100% |

97% |

97% |

|

Mix-3 |

3% |

6% |

100% |

97% |

94% |

|

Mix-4 |

3% |

9% |

100% |

97% |

91% |

Table: 4 Mix for Testing of Concrete at 6% replacement of Sand with varying % of CGB

|

S. No. |

% Crush PPE Kit |

% Crush Glucose Bottle |

Cement |

Sand |

Aggregate |

|

Mix-1 |

6% |

0% |

100% |

94% |

100% |

|

Mix-2 |

6% |

3% |

100% |

94% |

97% |

|

Mix-3 |

6% |

6% |

100% |

94% |

94% |

|

Mix-4 |

6% |

9% |

100% |

94% |

91% |

Table: 5 Mix for Testing of Concrete at 9% replacement of Sand with varying % of CGB

|

S. No. |

% Crush PPE Kit |

% Crush Glucose Bottle |

Cement |

Sand |

Aggregate |

|

Mix-1 |

9% |

0% |

100% |

91% |

100% |

|

Mix-2 |

9% |

3% |

100% |

91% |

97% |

|

Mix-3 |

9% |

6% |

100% |

91% |

94% |

|

Mix-4 |

9% |

9% |

100% |

91% |

91% |

V. RESULT AND DISCUSSION

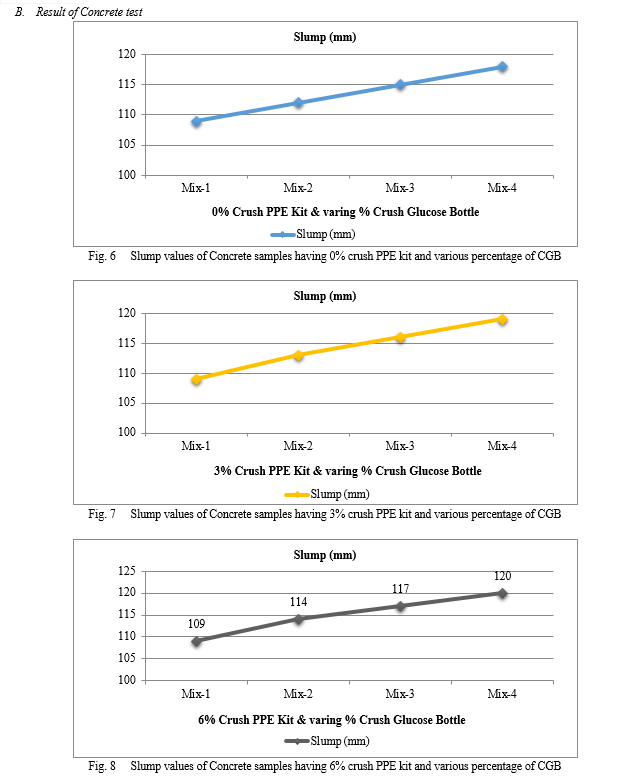

- Maximum value of Slump for Concrete samples having 0% crush PPE kit and 9% of CGB is 118mm. And minimum value of Slump for Concrete samples having 0% crush PPE kit and 0% of CGB is 109mm.

- Maximum value of Slump for Concrete samples having 3% crush PPE kit and 9% of CGB is 119mm. And minimum value of Slump for Concrete samples having 3% crush PPE kit and 0% of CGB is 109mm.

- Maximum value of Slump for Concrete samples having 6% crush PPE kit and 9% of CGB is 120mm. And minimum value of Slump for Concrete samples having 6% crush PPE kit and 0% of CGB is 109mm.

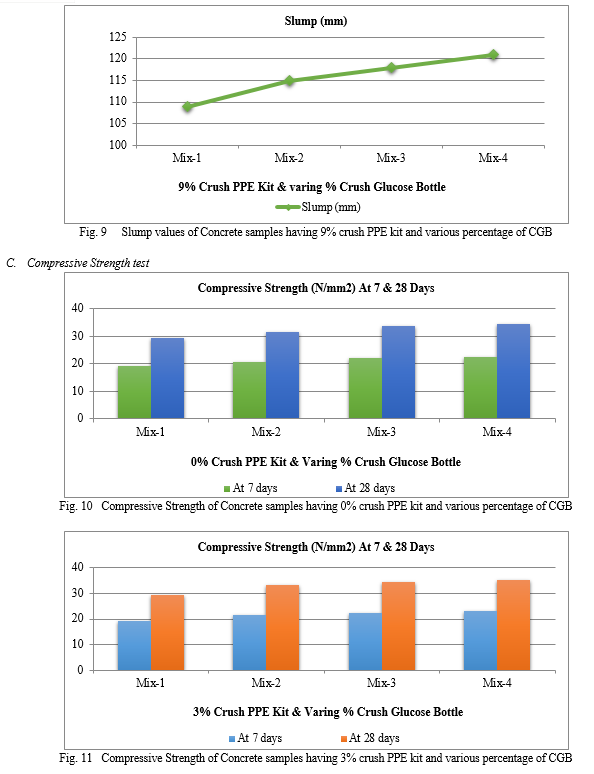

- Maximum value of Slump for Concrete samples having 9% crush PPE kit and 9% of CGB is 121mm. And minimum value of Slump for Concrete samples having 9% crush PPE kit and 0% of CGB is 109mm.

- Maximum value of Compressive Strength of 7days for Concrete samples having 0% crush PPE kit and 9% of CGB is 22.53N/mm2. And minimum value of Compressive Strength for Concrete samples having 0% crush PPE kit and 0% of CGB is 19.24 N/mm2.

- Maximum value of Compressive Strength of 28days for Concrete samples having 0% crush PPE kit and 9% of CGB is 34.46N/mm2. And minimum value of Compressive Strength for Concrete samples having 0% crush PPE kit and 0% of CGB is 29.42 N/mm2.

- Maximum value of Compressive Strength of 7days for Concrete samples having 3% crush PPE kit and 9% of CGB is 23.10N/mm2. And minimum value of Compressive Strength for Concrete samples having 3% crush PPE kit and 0% of CGB is 19.24N/mm2.

- Maximum value of Compressive Strength of 28days for Concrete samples having 3% crush PPE kit and 9% of CGB is 35.32N/mm2. And minimum value of Compressive Strength for Concrete samples having 3% crush PPE kit and 0% of CGB is 29.42N/mm2.

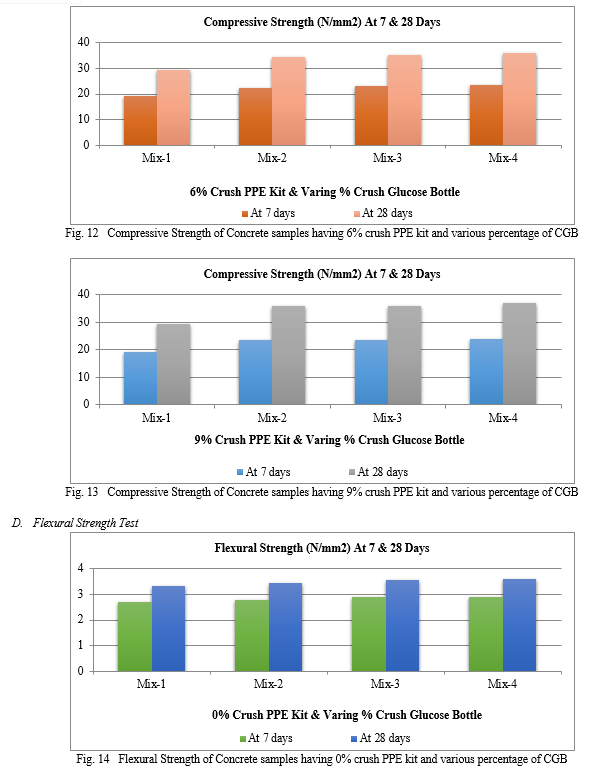

- Maximum value of Compressive Strength of 7days for Concrete samples having 6% crush PPE kit and 9% of CGB is 23.55N/mm2. And minimum value of Compressive Strength for Concrete samples having 3% crush PPE kit and 6% of CGB is 19.24N/mm2.

- Maximum value of Compressive Strength of 28days for Concrete samples having 6% crush PPE kit and 9% of CGB is 36.01N/mm2. And minimum value of Compressive Strength for Concrete samples having 3% crush PPE kit and 6% of CGB is 29.42N/mm2.

- Maximum value of Compressive Strength of 7days for Concrete samples having 9% crush PPE kit and 9% of CGB is 24.08N/mm2. And minimum value of Compressive Strength for Concrete samples having 9% crush PPE kit and 0% of CGB is 19.24N/mm2.

- Maximum value of Compressive Strength of 28days for Concrete samples having 9% crush PPE kit and 9% of CGB is 36.83N/mm2. And minimum value of Compressive Strength for Concrete samples having 3% crush PPE kit and 9% of CGB is 29.42N/mm2.

- Maximum value of Flexural Strength of 7days for Concrete samples having 0% crush PPE kit and 9% of CGB is 2.914 N/mm2. And minimum value of Flexural Strength for Concrete samples having 0% crush PPE kit and 0% of CGB is 2.693 N/mm2.

- Maximum value of Flexural Strength of 28days for Concrete samples having 0% crush PPE kit and 9% of CGB is 3.604 N/mm2. And minimum value of Flexural Strength for Concrete samples having 0% crush PPE kit and 0% of CGB is 3.330 N/mm2.

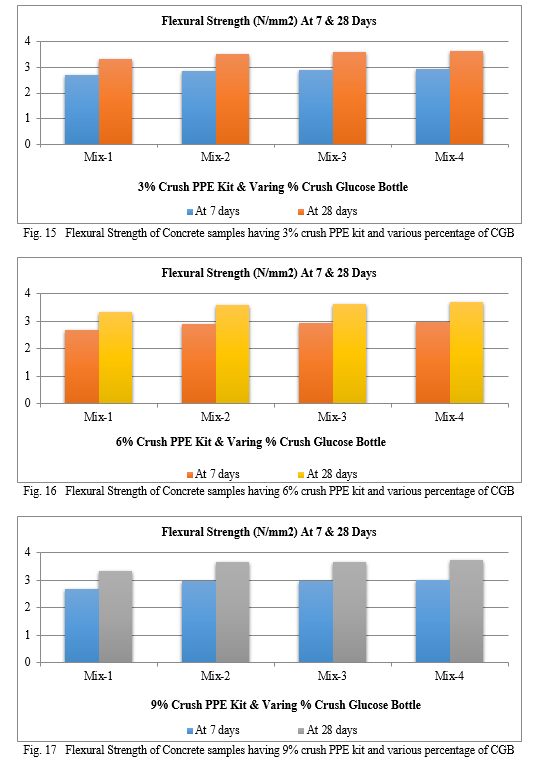

- Maximum value of Flexural Strength of 7days for Concrete samples having 3% crush PPE kit and 9% of CGB is 2.951 N/mm2. And minimum value of Flexural Strength for Concrete samples having 3% crush PPE kit and 0% of CGB is 2.693 N/mm2.

- Maximum value of Flexural Strength of 28days for Concrete samples having 3% crush PPE kit and 9% of CGB is 3.649 N/mm2. And minimum value of Flexural Strength for Concrete samples having 3% crush PPE kit and 0% of CGB is 3.330 N/mm2.

- Maximum value of Flexural Strength of 7days for Concrete samples having 6% crush PPE kit and 9% of CGB is 2.980 N/mm2. And minimum value of Flexural Strength for Concrete samples having 3% crush PPE kit and 6% of CGB is 2.693 N/mm2.

- Maximum value of Flexural Strength of 28days for Concrete samples having 6% crush PPE kit and 9% of CGB is 3.685 N/mm2. And minimum value of Flexural Strength for Concrete samples having 3% crush PPE kit and 6% of CGB is 3.330 N/mm2.

- Maximum value of Flexural Strength of 7days for Concrete samples having 9% crush PPE kit and 9% of CGB is 3.013N/mm2. And minimum value of Flexural Strength for Concrete samples having 9% crush PPE kit and 0% of CGB is 2.693 N/mm2.

- Maximum value of Flexural Strength of 28days for Concrete samples having 9% crush PPE kit and 9% of CGB is 3.726N/mm2. And minimum value of Flexural Strength for Concrete samples having 3% crush PPE kit and 9% of CGB is 3.330 N/mm2.

VI. FUTURE SCOPE OF THE WORK

- For forward this study also used higher grade of concrete.

- As a replacement material silica fume, Metakaoline and copper slag are may be used in concrete.

- Non-destructive testing on same mix samples prepared from same or different grade of concrete also taken in future.

Conclusion

1) The compressive strenght of the concrete with varying replacement of sand and course aggregate of 3,6,9 % resepectively are found to be increase in comparision to the value of standard comcrete of M30 > As a replacement material silica fume metakaoline and copper slag may be used in concrete 2) Medical plastics wastes such as glucose bottles, plastic waste containers, and others have been recognized as building material that can be discarded of. The medical glucose bottle trash is utilised to substitute the coarse aggregate because fine aggregate isn\'t really acceptable. 3) The compressive strength and durability of concrete (including concrete) are essentially the same as that of standard concrete. However, if the plastic content is greater than 20%, the strength decreases significantly. 4) The compressive strenght of the concrete with varying replacement of sand and course aggregate of 3,6,9 % resepectively are found to be increase in comparision to the value of standard comcrete of M30 5) As a replacement material silica fume metakaoline and copper slag may be used in concrete. 6) Medical plastics wastes such as glucose bottles, plastic waste containers, and others have been recognized as building material that can be discarded of. 7) The medical glucose bottle trash is utilised to substitute the coarse aggregate because fine aggregate isn\'t really acceptable. 8) The compressive strength and durability of concrete (including concrete) are essentially the same as that of standard concrete. However, if the plastic content is greater than 20%, the strength decreases significantly

References

[1] Tao Liu “Comparative study of mechanical properties between irradiated and regular plastic waste as a replacement of cement and fine aggregate for manufacturing of green concrete” publishing in 2021. [2] Marcin Koniorczyk “Performance of concrete containing recycled masks used for personal protection during coronavirus pandemic “publishing in 2022. [3] Harish T. Mohan” A sustainable approach for the utilization of PPE biomedical waste in the construction sector”2022 [4] Priyanka Yadav “Strength Analysis by Utilization of Plastic PET Bottles In Concrete Material, publishing in 2022 [5] Elamaran Manoharan, Norazli Othman, Roslina Mohammad, “A Review of Hazardous Compounds Present in Construction Waste Materials” publishing in 2021. [6] Pooja Lamba “Recycling/reuse of plastic waste as construction material for sustainable development: a review” publishing 2021 [7] Lubna K. Hamada “Sustainable Approach for Recycling Medical Waste Needles to Partially Replace Aggregate in Lightweight Concrete Production “publishing in 2021. [8] Saman Rahimireskati “Prediction of the Mechanical Performance of High-Strength Concrete Containing Biomedical Polymeric Waste Obtained from Dialysis Treatment”, publishing in 2021. [9] T.Sai Ram Reddy “Comparative study on partial replacement of cement with Hospital waste ash Coal dust and Rice husk ash “publishing in 2021. [10] Huynh Thi My Dung “Possibility Of Using Recycled Waste Medical-Glass As Fine Aggregate In Normal-Strength Concrete”, Publishing In 2021 [11] Saman Rahimireskati “Prediction of the Mechanical Performance of High-Strength Concrete Containing Biomedical Polymeric Waste Obtained from Dialysis Treatment” publishing in 2021. [12] Saman Rahimireskati, Kazem Ghabraie, Estela Oliari Garcez & Riyadh AlAmeri “Improving sorptivity and electrical resistivity of concrete utilising biomedical polymeric waste sourced from dialysis treatment”, publishing in 2021. [13] Maria Rashidi” Towards Eco-Flowable Concrete Production” publishing in 2020. [14] Prof. Saurabh Kasliwal “Utilization of Biomedical Waste Plastic Fibers In Concrete”, publishing in 2020m [15] Ammu B Crusho “Medical Plastic Waste Disposal by Using in Bituminous Road Construction”. Publishing in 2019.

Copyright

Copyright © 2022 Shivendra Mani Tripathi , Sunil Kumar. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET47308

Publish Date : 2022-11-04

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online