Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Predictive Analysis to Prevent Fraud and Reduce Risk for Preserved Food Processing Industry

Authors: Radha ., Sreerambabu , Rajkumar , Santhosh

DOI Link: https://doi.org/10.22214/ijraset.2023.54998

Certificate: View Certificate

Abstract

This paper presents a blockchain-based traceability system for storing and retrieving product information in the agricultural supply chain, aiming to address issues such as centralized management, lack of transparency, untrustworthy data, and fragmented information. By leveraging blockchain technology\'s decentralized, tamper-proof, and traceable nature, the system enhances the transparency and credibility of traceability information. To alleviate the burden on the blockchain and enable efficient information retrieval, a dual storage structure comprising both an on-chain and off-chain component is employed to store traceability data. Moreover, the combination of blockchain technology and cryptography ensures the secure sharing of private information within the blockchain network. A reputation-based smart contract is devised to incentivize network nodes to contribute traceability data. The system\'s performance analysis and practical application demonstrate its ability to enhance query efficiency, safeguard private information, ensure data authenticity and reliability in supply chain management, and meet real-world application requirements.

Introduction

I. INTRODUCTION

The increasing globalization of food supply chains has resulted in greater separation between producers and consumers, leading to numerous challenges for the Food Safety and Traceability System (FSTS). Security, privacy, traceability, and other issues are among the significant hurdles faced by the FSTS. Over the past few decades, customers have expressed growing concerns about food safety, primarily due to instances of food safety accidents, misconduct, and disruptions in co-production processes caused by factors such as technology advancements, pollution, and obstructions.

The implementation of Food Safety and Traceability Systems (FSTS) is highly beneficial for consumers as it focuses on important aspects such as product recalls, removal of non-consumable items, and thorough investigation of the root causes of food safety issues. These safety measures effectively combat fraudulent activities and ensure the quality of products. Current food traceability systems predominantly adopt two architectural approaches: centralized and distributed. In a centralized structure, the involvement of a third-party official is necessary to supervise and control traceability operations. However, this centralized approach introduces a vulnerability to single-node attacks, thereby increasing the risks associated with data tampering and unauthorized disclosure.

In conclusion, the food safety traceability system using blockchain technology is that it offers significant potential to enhance and improve the overall safety and reliability of the food supply chain. Blockchain enables real-time visibility and transparency into food products' origin, quality, and journey. Consumers can access detailed information about the food they consume, including the entire food information. The immutability and decentralized nature of blockchain technology help build trust among consumers, as it reduces the risk of data tampering or fraudulent activities. By providing verifiable and auditable information, blockchain in stills confidence in the food supply chain.

II. PROPOSED METHODOLOGY

The proposed systems aim to enhance food safety transparency, build trust among consumers, and improve food supply chain efficiency by leveraging blockchain technology's immutability, transparency, and decentralized nature. While these systems hold promise, it is important to note that their implementation and adoption may vary depending on regulatory frameworks, industry collaboration, and technological advancements.

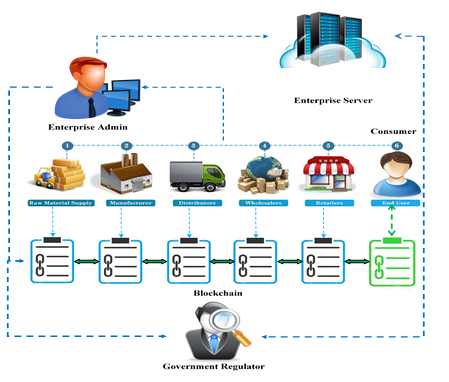

The proposed traceability system utilizes blockchain technology to enhance consumer trust in preserved food products by providing detailed information about the production, processing, transportation, and sales processes. This system enables law enforcement agencies to identify the responsible party in the event of quality and safety incidents. Blockchain traceability leverages blockchain's decentralized, non-tamperable, and traceable nature to ensure the authenticity and transparency of information within the traceability system.

By adopting a blockchain-based approach, the system manages and monitors food products' growth, processing, logistics, and sales information, ensuring comprehensive oversight of the entire product lifecycle. The preserved food products blockchain traceability system comprises the storage layer, service layer, interface layer, and application layer, facilitating effective and reliable traceability without compromising data integrity.

SHA-256, a secure hashing algorithm, is an unkeyed cryptographic function used to generate a 256-bit hash output from an input of variable length. It guarantees that each block in the blockchain ledger receives a distinct hash value, as no two input values can yield the same hash output. Even a minor alteration in the input results in a significantly different output, ensuring that the hash value remains unpredictable based on the input values, thereby enhancing its security.

By leveraging the self-executing capabilities of smart contracts, the food safety transparency and traceability system on blockchain technology can automate processes, ensure compliance, enable efficient traceability, enhance overall transparency and trust in the food supply chain and monitor the entire food details.

III. THE TRACEABILITY SYSTEM BASED ON BLOCKCHAIN

Blockchain can be considered a distributed database consisting of blocks arranged in chronological order. Each block contains comprehensive information about network activity from the moment it is appended to the chain. All data within the blockchain is accessible to the public, enabling any user to contribute data in the form of a transaction, which is a distinct and identifiable data package within the system. Users can verify and duplicate this data whenever necessary, while its immutability ensures that no alterations can be made. Consequently, the blockchain serves as an unchangeable historical record that can be shared among all system nodes. By utilizing blockchain, trust can be established without the requirement of a centralized authority. Instead, trust is attained through a "mining process" that guarantees the security and validity of the information incorporated into the chain among the nodes in the system.

- Data should be kept as concise as possible.

- Sensitive information about enterprises should not be included in the blockchain.

- The system should incorporate mechanisms to ensure the quality and legitimacy of uploaded data.

- The system should be resistant to spam attacks.

- It should guarantee the accessibility of shared data exclusively among enterprises within a specific supply chain while preventing access by unauthorized entities.

- Data within the system must be tamper-proof.

The overall cost of the system should be appropriately managed and controlled.

The smart contract acts as a bridge between the physical world and the Blockchain network, enabling the collection of data and the updating of traceable variable logs. Our goal is to deploy a Blockchain network and utilize it to evaluate the functionality of our proposed smart contract. The network comprises two organizations with two and three transactional endpoints referred to as Peers. These Peers are responsible for submitting transactions to the network via a dedicated channel. Additionally, a Peer can simultaneously join multiple channels, and each transaction initiated by a Peer must specify the target network and smart contract.

These technologies enable the collection of relevant data in the food supply chain system, such as object or individual identification tags and environmental sensing capabilities. However, it's crucial to recognize that attackers can manipulate or tamper with the collected data, leading to the dissemination of false information regarding environmental conditions. This misinformation can result in product damage or destruction due to erroneous identification of dynamic environmental factors. To mitigate such risks, a secure monitoring and reporting system based on IoT is being developed to ensure the quality of perishable goods throughout the SCM process, particularly during transportation, without the need for human intervention. This system aims to provide a comprehensive digital representation of valuable assets to all stakeholders involved, starting from raw material suppliers to end-users or consumers. In the proposed blockchain-based SCM, each stakeholder becomes part of a Blockchain node, allowing them to engage in Blockchain transactions and contribute to its ongoing maintenance. Upon joining the Blockchain, every node receives a unique public/private key pair to facilitate secure cryptographic operations by the Blockchain's architectural framework.

The suggested system offers a secure monitoring and reporting solution based on Blockchain frameworks, which aims to replace traditional and costly supply chain management mechanisms. This system enables stakeholders to enhance the quality of perishable goods while ensuring privacy and security.

IV. REQUIREMENT ANALYSIS AND SYSTEM ARCHITECTURE

A. FSC Dashboard

The application layer comprises two components: the business system and the application service system. The business system is built on the blockchain platform, primarily utilized for acquiring and overseeing critical data within the grain supply chain. On the other hand, the application service system enables the retrieval and monitoring of supply chain information for all participants involved. Within the business system, there are distinct modules, namely the coding module, blockchain interaction module, data processing module, and monitoring module.

- Blockchain Interaction: This facilitates data interaction and the deployment of smart contracts. Data interaction encompasses the establishment of a suitable blockchain platform for querying essential information in the supply chain. Smart contract deployment guarantees the authenticity of data and enhances the supply chain information management system through the verification of contracts for all participants involved in the supply chain.

- Data Processing Interaction: The primary objective of this module is to cater to the diverse data interaction channels utilized by data producers within the supply chain. Its purpose is to enable all participants to engage in activities such as data synchronization, data chaining, and data visualization, among other functionalities.

- Monitoring: This module oversees the entire life cycle of the grain supply chain and monitors the overall system operations. By analyzing the supply chain data stored in the database, it facilitates tracing, risk assessment, prediction, and early warning capabilities.

- Privacy Protection: The privacy protection model primarily focuses on implementing rights controls for system users, encryption and decryption of private information, and key generation. Additionally, it identifies key information generated at each stage of the grain supply chain and generates corresponding codes for the uploaded data. These codes facilitate convenient data archiving and querying.

- Smart Contract: The preservation of the food supply chain involves various stages, including production, collection, food processing, and shipping/delivery to wholesalers in the market. One of the persistent challenges in supply chain management (SCM) is the accurate identification, traceability, and real-time tracking of goods In the proposed blockchain-based SCM, each stakeholder becomes part of a Blockchain node, allowing them to engage in Blockchain transactions and contribute to its ongoing maintenance. Upon joining the Blockchain, every node receives a unique public/private key pair to facilitate secure cryptographic operations by the Blockchain's architectural framework.

The suggested system offers a secure monitoring and reporting solution based on Blockchain frameworks, which aims to replace traditional and costly supply chain management mechanisms. This system enables stakeholders to enhance the quality of perishable goods while ensuring privacy and security.

B. Enterprises

For the key stakeholders within the food supply chain, the collection and organization of data about the supply chain play a vital role in acquiring market insights, analyzing shifts in supply and demand, and enhancing operational efficiency and profitability. Grain supply chain enterprises have specific requirements that must be met: firstly, the blockchain-based data sharing should incorporate access controls to prevent the unauthorized disclosure of sensitive information; secondly, the blockchain system should be user-friendly, facilitating easy deployment and seamless operation.

- Traceability Information: The purpose of this module is to gather crucial traceability information generated during the production, storage, and distribution stages of food. It can operate in both automated and manual modes, enabling the identification and creation of comprehensive event data related to the movement of food within the supply chain.

- Blockchain: The blockchain module serves two primary functions. Firstly, it facilitates data interaction, encompassing the uploading of essential traceability information onto the blockchain, accessing on-chain data, and verifying event information. Secondly, it offers users the choice to become either a full blockchain node or a lightweight blockchain node, allowing them to decide whether or not to engage in blockchain maintenance activities.

- Information Extraction: The main purpose of this module is to retrieve information from the traceability database for uploading onto the blockchain, while also ensuring the verification of the enterprise identity during any event information interaction. It aims to confirm whether the requester initiating the request for event information is a legitimate participant within the supply chain.

C. Distributor

Before reaching the retailer, the finished product often undergoes several stages of distribution. Among these stages, the distributor assumes the role of storing processed agricultural products and supplying them to retailers in batches. Key information such as company details, product selling time, price, and other relevant data are securely stored in a blockchain. Similar to the quality supervision bureau's approach, a hash value is stored in the blockchain to guarantee the integrity of subsequent data and prevent any unauthorized modifications.

D. Retailer

The retailer procures processed produce from the distributor and subsequently sells it to consumers in smaller quantities. Essential details regarding the retailer, selling time, quantity sold, and other relevant information are meticulously recorded in a blockchain. Similar to the previous scenario, the hash value is also documented in the blockchain to ensure data integrity and prevent unauthorized modifications.

E. Consumer

The objective of the supply chain information management system is to offer consumers access to comprehensive supply chain details regarding the products they purchase, ensuring the integrity and traceability of the information. The system needs to prevent data tampering, thereby enhancing its credibility. Additionally, consumers should have the ability to manage their data access rights to safeguard sensitive information from being exposed.

The purpose of this module is to establish a connection between the client and the system, enabling the client to request information from the blockchain and validate the authenticity of the information. To reduce the user's maintenance expenses, a lightweight node is employed for this module. Furthermore, a cache database is implemented to store the relevant food traceability data that users request.

F. Government And Regulatory Agencies

Governments and regulatory agencies bear the primary responsibility for macro control over the entire supply chain and ensuring the safety of grain. Hence, the establishment of a comprehensive information management system for the grain supply chain is crucial in enhancing the government's management capabilities and operational efficiency. Governments and regulatory agencies must utilize the information management system to meticulously record all trading information within the grain supply chain. This approach facilitates effective supervision of the entire grain supply chain and guarantees food safety.

Conclusion

The main objective of this paper is to develop and implement a product traceability system that leverages blockchain\'s non-tampering and traceable properties. Additionally, the paper discusses the design of storage and query mechanisms for the system. To address the challenges posed by the increasing data load and insufficient private security in blockchain-based traceability systems, the paper proposes a combined on-chain and off-chain data storage approach using both a database and blockchain. In this approach, the publicly accessible information intended for consumers is stored in the local database along the supply chain. Its hash value, obtained through the SHA256 algorithm, is uploaded to the blockchain system. On the other hand, private information, encrypted using asymmetric cryptographic algorithms, is stored in the blockchain for sharing with relevant companies. This storage method takes into consideration the encryption requirements for corporate private information and the need for public supervision of supply chain public information, while also alleviating the data load pressure on the blockchain. In future work, to develop deeper into cross-chain technology, aiming to establish connections between multiple blockchain networks. Additionally, investigate a novel consensus mechanism specifically tailored for traceability purposes. Our objective will be to assess the resilience and identify potential enhancements through the application of these algorithms.

References

[1] M. Rogerson and G. C. Parry, ‘‘Blockchain: Case studies in food supply chain visibility,’’ Supply Chain Manage., Int. J., vol. 25, no. 5, pp. 601–614, May 2020. [2] H. Wu, J. Cao, Y. Yang, C. L. Tung, S. Jiang, B. Tang, Y. Liu, X. Wang, and Y. Deng, ‘‘Data management in the supply chain using blockchain: Challenges and a case study,’’ in Proc. 28th Int. Conf. Comput. Commun. Netw. (ICN), Jul. 2019, doi 10.1109/ICCCN.2019.8846964. [3] R. V. George, H. O. Harsh, P. Ray, and A. K. Babu, ‘‘Food quality traceability prototype for restaurants using blockchain and food quality data index,’’ J. Cleaner Prod., vol. 240, Dec. 2019, Art. no. 118021. [4] A. Shahid, U. Sarfraz, M. W. Malik, M. S. Iftikhar, A. Jamal, and N. Javaid, ‘‘Blockchain-based reputation system in the agri-food supply chain,’’ in Advanced Information Networking and Applications (Advances in Intelligent Systems and Computing), vol. 1151, L. Barolli, F. Amato, F. Moscato, T. Enokido, and M. Takizawa, Eds. Cham, Switzerland: Springer, 2020,doi 10.1007/978-3-030-44041-1_2. [5] D. Mao, Z. Hao, F. Wang, and H. Li, ‘‘Novel automatic food trading system using consortium blockchain,’’ Arabian J. Sci. Eng., vol. 44, no. 4, pp. 3439–3455, Apr. 2018. [6] Y. Maleh, ‘‘Secure anti-counterfeiting pharmaceuticals supply chain system using composable non-fungible tokens,’’ in Blockchain for Cybersecurity and Privacy: Architectures, Challenges, and Applications, Boca Raton, FL, USA: CRC Press, 2020, pp. 243–258. [7] Weber, I., Xu, X.., Riveret, R., Governatori, G., Ponomarev, A., & Mendling, J., Untrusted business process monitoring and execution using blockchain. International Conference on Business Process Management. 2016. 329-347. [8] R. V. George, H. O. Harsh, P. Ray, and A. K. Babu, ‘‘Food quality traceability prototype for restaurants using blockchain and food quality data index,’’ J. Cleaner Prod., vol. 240, Dec. 2019, Art. no. 118021. [9] A. Shahid, U. Sarfraz, M. W. Malik, M. S. Iftikhar, A. Jamal, and N. Javaid, ‘‘Blockchain-based reputation system in the agri-food supply chain,’’ in Advanced Information Networking and Applications (Advances in Intelligent Systems and Computing), vol. 1151, L. Barolli, F. Amato, F. Moscato,

Copyright

Copyright © 2023 Radha ., Sreerambabu , Rajkumar , Santhosh . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET54998

Publish Date : 2023-07-25

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online