Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Project on Preparation of Plastic Road Using Single Used Waste Plastic

Authors: Nabin Kumar Sahoo, Biswojeet Tarai, K. Abhinash Mohanta, Devranjan Kumar, Prasad Tarasankar Panigrahi, Shibani Hota, Abhijit Mangaraj

DOI Link: https://doi.org/10.22214/ijraset.2022.42556

Certificate: View Certificate

Abstract

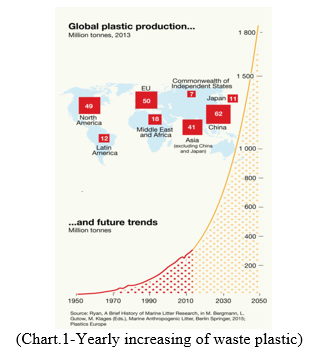

Plastics are non-biodegradable materials and means to degrade our environment. The waste plastic and its disposal are a major threat to the environment, which results in pollution and global warming. The utilization of plastic waste in bituminous mixes enhances its properties and also its strength. In addition, it will also be a solution to plastic disposal & various defects in pavement i.e., pot holes, corrugation, ruts, etc. the waste plastic used are poly-ethylene, poly-styrene, poly-propylene. There are two processes available for the mixing of plastic in bituminous mix such as wet process and dry process. The waste plastic is shredded & coated over aggregate & mixed with hot bitumen and resulted mix is used for pavement construction is known as the dry process. But in wet process waste plastic is ground and made into shredded form; various percentage of plastic is mixed with the bitumen and study the durability of the roads laid out with shredded plastic waste is much more compared with roads with asphalt with the ordinary mix which is the objective of the present study. The use of the innovative technology not only strengthened the road construction but also increased the road life as well as will help to improve the environment and also creating a source of income. It’s economical and eco-friendly. In this project, we have discussed about the bitumen with plastic properties to be considered in design of pavement, pavement design, and process of construction flexible pavement.

Introduction

I. INTRODUCTION

Plastics are non-biodegradable materials. The waste plastic and its disposal are a major threat to the environment, which results in pollution and global warming. The utilization of plastic waste in bituminous mixes enhances its properties and also its strength. In addition, it will also be a solution to plastic disposal & various defects in pavement i.e., pot holes, corrugation, ruts, etc. the waste plastic used are poly-ethylene, poly-styrene, poly-propylene.

There are two processes available for the mixing of plastic in the bituminous mix as the wet process and the dry process. The waste plastic is shredded & coated over aggregate & mixed with hot bitumen and the resulted mix is used for pavement construction is known as the dry process. But in wet process waste plastic is ground and made into shredded form. The use of the innovative technology not only strengthened the road construction but also increased the road life as well as will help to improve the environment and also creating a source of income. It’s economical and eco-friendly. In this project, we have discussed about the bitumen with plastic properties to be considered in design of pavement, pavement design, and process of construction flexible pavement.

II. MATERIALS REQUIRED

This chapter describes the methodology and materials used to achieve the objectives. The main materials characterized in the present study are bitumen, plastic, and aggregate; the experimental methodology followed for the characterization of these materials is discussed.

- Bitumen: Bituminous materials used in highway construction are broadly classified into bitumen and tar. bitumen is a material obtained by fractional distillation of crude petroleum as an end product.it is a non-crystalline solid or viscous material having adhesive properties, which keeps the materials in the road mix bound together under strong bonds. Bituminous materials were used for the construction of roads, preserving timber, and waterproofing stone walls. Nowadays, they are extensively used for the surfacing of road and airport pavements. The main purpose of bitumen in flexible pavements is to strongly bind and hold the other pavement components together and provide a smooth and levelled surface for the moving vehicles.

- Waste Plastic: Plastics are usually classified by their chemical structure of the polymer's backbone and side chains. There are two types of plastics: thermoplastics and thermosetting polymers. Thermoplastics are the plastics that do not undergo chemical change in their composition when heated and can be moulded again and again. The properties of plastics are defined chiefly by the organic chemistry of the polymer. such as hardness, density, and resistance to heat, organic solvents, oxidation, and ionizing radiation. Improving environmental sustainability, roads made with Plastics are found more durable and cost-effective. Plastic roads mainly use plastic carry bags, disposable cups, and bottles that are collected from garbage dumps as an essential ingredient of the construction material.

- Aggregate: The commonly used aggregates i.e., sand, gravel, and crushed rocks such as granite, basalt, quartz, sandstone, and limestone. These aggregates whose particles are larger than 4.75 mm are termed coarse aggregate The aggregate gives volume, stability, resistance to wear or erosion, and other desired physical properties to the finished product. Aggregates form the major portion of pavement structure and they form the prime materials used in pavement construction.

III. TEST

A. Test on Aggregate

The following testes ware carried out for coarse aggregate,

- Crushing Test: The crushing value test of aggregate provides the resistance of an aggregate sample to crushing under gradually applied compressive load.

- Impact Test: The aggregate impact test is carried out to evaluate the resistance to the impact of aggregates. The property of a material to resist impact is known as toughness.

- Los Angle Abrasion: Los Angeles abrasion test is a preferred one for carrying out the hardness property of aggregate and has been standardized in India.

Results of the tests conducted on aggregates,

|

Sl no. |

Tests |

Result |

|

01 |

Crushing test |

16.14%. |

|

02 |

Impact test |

22.53% |

|

03 |

Los angel abrasion test |

32.34% |

|

04 |

Water absorption test |

3.1% |

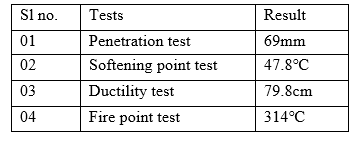

B. Test on Bitumen

The following tests were conducted for bitumen,

- Penetration Test: It measures the hardness or softness of bitumen by measuring the depth in tenths of a millimeter to which a standard loaded needle will penetrate vertically in 5 seconds.

- Softening Point Test: The softening point of various bitumen grades generally lies between 35? to 70?. The softening point of between to be used for road construction at a place where the maximum temperature is 40? should be greater than the 40?

- Ductility Test: The property of bitumen allows it to undergo deformation or elongation is called ductility of bitumen.

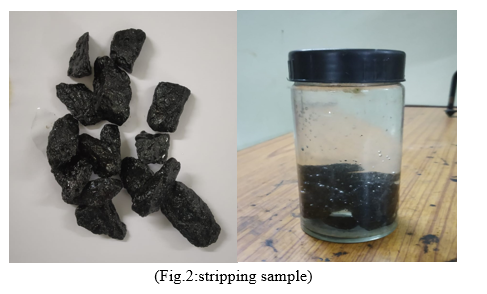

IV. STRIPPING VALUE TEST OF BITUMEN MIX

The stripping value of an aggregate is determined as the ratio of the uncovered area observed visually to the total area of aggregate, expressed as %. The principle of the test is by immersing aggregate fully coated with binder in water maintained at 40°C temperature for 24 hours. IRC has specified maximum stripping value of aggregates should not exceed 5%.

|

Sl no. |

Type of aggregate |

Time |

Stripping% |

|

01 |

Plain Bitumen Coated Aggregate |

24hr |

5% |

|

02 |

Waste plastic coated aggregate |

47hr |

Nil |

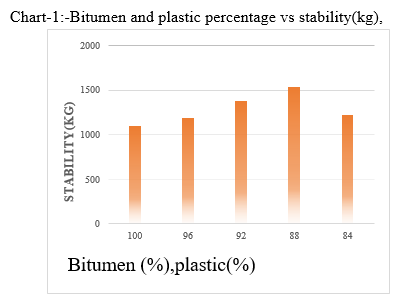

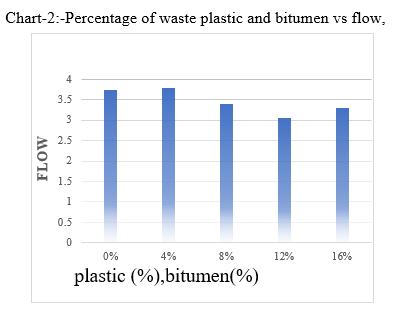

V. MARSHALL TEST

Marshall stability test will be done for measuring how well an asphalt mixture will perform and the maximum load it can support. The sample needed is From Marshall stability graph, select proportions of coarse aggregates, fine aggregates and filler in such a way, so as to fulfill the required specification. The total weight of the mix should be 1200g.

Marshall stability result:-

|

SL. NO. |

WASTE PLASTIC (%) |

BITUMEN (%) |

STABILITY (kg) |

FLOW (mm) |

|

01 |

0 |

100 |

1100 |

3.23 |

|

02 |

4 |

96 |

1185 |

3.28 |

|

03 |

8 |

92 |

1374 |

3.35 |

|

04 |

12 |

88 |

1532 |

3.43 |

|

05 |

16 |

84 |

1217 |

3.48 |

A. Stability

Stability (kN) is gradually increases with the increase in the percentage of waste plastic as the partial replacement for bitumen possess high crushing strength than the conventional bitumen mixes up to a certain limit then after in a decreasing manner. The optimum amount of waste plastic is 12%.

B. Flow

Flow(mm) value increase with the increase in waste plastic content up to 12%, then the flow value gradually increases, but the maximum and minimum tolerance of flow in between (3%-4%) .

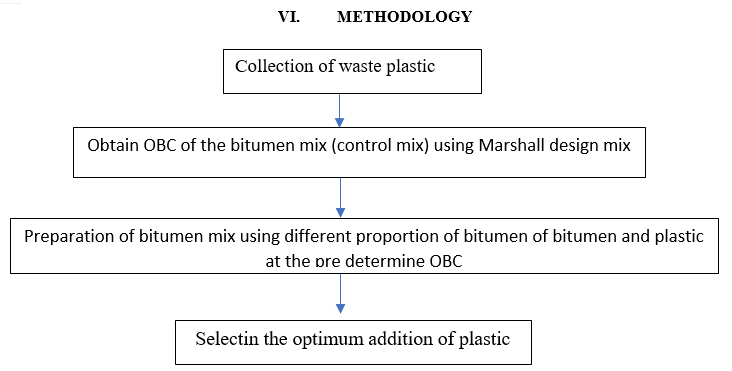

VII. FIELD TRAIL

There are two processes for constructing flexible pavement using waste plastic,

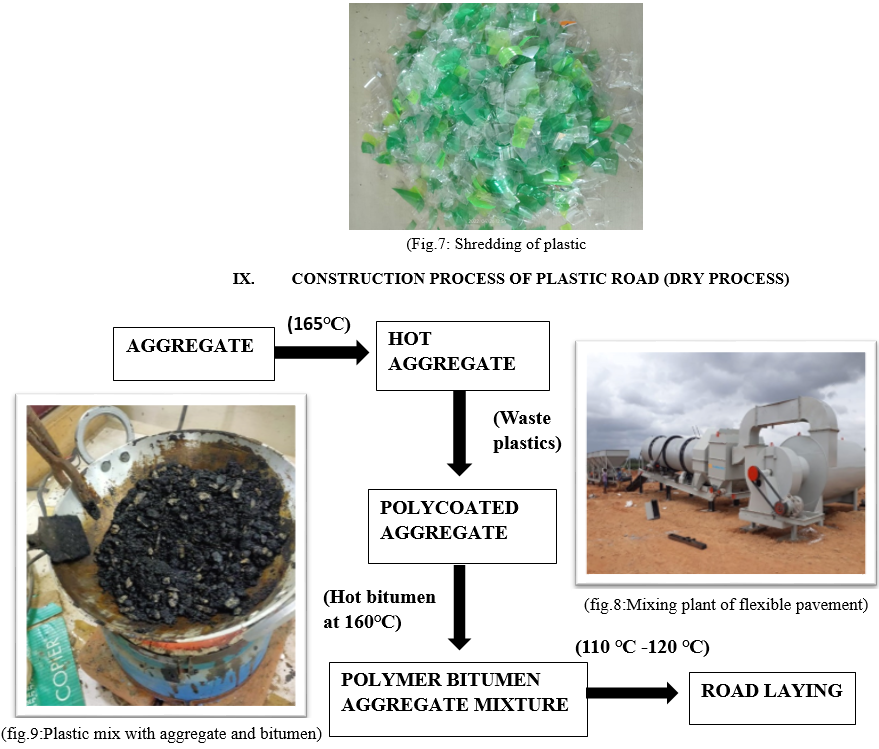

A. Dry Process

For the flexible pavement, hot stone aggregate (170) is mixed with hot bitumen (160° C) and the mix is used for road laying. The aggregate is chosen on the basis of its strength. porosity and moisture absorption capacity as per IS coding. The bitumen is chosen on the basis of its binding property, penetration value and viscoelastic property. The aggregate. when coated with plastics improved its quality with respect to voids, moisture absorption and soundness. The coating of plastic decreases the porosity and helps to improve the quality of the aggregate and its performance in the flexible pavement. It is to be noted here that stones with 2% porosity only allowed by the specification.

- Plastic waste like bags, bottles, etc are cut into size between 2.36mm and 4.75mm using shredding machine.

- The aggregate mix is heated to 170' and then it is transferred to mixing chamber.

- Similarly the bitumen is to be heated up to a maximum of 160°.

- At the mixing chamber, the shredded plastics waste is added over the hot aggregate.

- The plastics waste coated aggregate is mixed with hot bitumen.

B. Wet Process

Waste plastic is ground and made into powder: 6 to 8% plastic is mixed with the bitumen. Plastic increases the melting point of the bitumen and makes the road retain its flexibility during winters resulting in its long life. Use of shredded plastic waste acts as a strong "handing agent" for tar making the asphalt last long. By mixing plastic with bitumen the ability of the bitumen to withstand high temperature increases. The plastic waste is melted and mixed with bitumen in a particular ratio. Normally, blending takes place when temperature reaches 45.5° C but when plastic is mixed, it remains stable even at 55° C.

The vigorous tests at the laboratory level proved that the bituminous concrete mixes prepared. Using the treated bitumen binder fulfilled all the specified Marshall mix design criteria for surface course of road pavement. There was a substantial increase in Marshall Stability value of the mix, of the order of two to three times higher value in comparison with the untreated or ordinary bitumen. Another important observation was that the bituminous mixes prepared using the treated binder could withstand adverse soaking conditions under water for longer duration.

- Waste plastics by direct mixing with hot bitumen at 160°C.

- Mechanical stirrer is needed.

- Addition of stabilizers and proper cooling.

- Since the wet process require a lot of investment and bigger plants, for better or easy construction process we prefer dry process.

VIII. HOW TO USE

A. Segregation

Plastic waste collected from various sources must be separated from other waste. Maximum thickness of 60 microns.

B. Collection Of Plastic Waste

Waste plastic is collected from roads, garbage trucks, dumpsites or compost plants, or from school collection programs, or by purchase from ragpickers or waste-buyer.

C. Cleaning Process

Plastic waste gets cleaned and dried. Waste plastic litter in the form of thin-film carry-bags, use-and-throw cups, PET bottles, etc. these are sorted, de-dusted, washed if necessary.

D. Shredding Process

Plastic waste which is cleaned is cut into a size between 2.36 mm and 600 microns and of maximum size 2.36 mm in length and 2.00 mm in width using a shredding machine.

Conclusion

Plastics increase the melting point of the bitumen. The use of these plastics in road construction is an innovative technology that not only strengthens the road but also increases road life. The analysis in this paper reveals Durability, strength and cost. It is hoped that in near future we will have strong, durable, and eco-friendly roads which will relieve the earth from all types of plastic waste.

References

[1] Dr. S.S.Verma, “Road from Plastic state.”,ScienceTech Entrepreneur, March 2008 Gianni A.K. Modi, A.J., “Bio Enzymatic Soil Stabilizers for Construction of Rural Roads”, International Seminar on Sustainable Development in Road Transport, New Delhi-India 8-10November 2001. [2] Sherwood, P. T. (1995). “Alternative materials in road construction. “Thomas Telford Publications, London, 1995. [3] Tara Sen, Umesh Mishra, “Usage of Industrial Waste Products in Village Road Construction,” International Journal of Environmental Science and Development, Vol. 1, No. 2, June 2010. [4] \"Roads Made of Plastic Waste in India? Yes! Meet the Professor Who Pioneered the Technique\". The Better India. 2 February 2016. Retrieved 23 October 2019. [5] \"One Lakh Kilometres of Roads in India Are Being Made From Plastic Waste, Is This The Solution To End Plastic Crisis? | World Environment Day\". NDTV-Dettol Banega Swasth Swachh India. 5 June 2018. Retrieved 23 October 2019. [6] \"India has built 21,000 miles of road ways using plastic waste\". 20 December 2019.7. \"Say Hello to the Latest Technology in Civil Engineering: Plastic Road - Industry Tap\". Industry Tap. 14 November 2015. Retrieved 16 November 2015

Copyright

Copyright © 2022 Nabin Kumar Sahoo, Biswojeet Tarai, K. Abhinash Mohanta, Devranjan Kumar, Prasad Tarasankar Panigrahi, Shibani Hota, Abhijit Mangaraj. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET42556

Publish Date : 2022-05-12

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online