Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Study on Properties of Bituminus Mix Using the Combination of Shredded Plastic combined with Chemical Additives

Authors: Maruti Naik , Praveen Kumar P

DOI Link: https://doi.org/10.22214/ijraset.2022.40705

Certificate: View Certificate

Abstract

The design of a satisfactory bituminous mix is a complex task due to the wide variation in properties of its constituents such as bitumen, coarse and fine aggregate, filler, etc. The design also depends on the shape and gradation of the aggregates. Flexible pavement with bituminous surfacing is commonly used in Indian highways. Distress symptoms, such as cracking, rutting, etc., are increasingly caused earlier by high traffic intensity, over loading of vehicles and significant variations in daily and seasonal temperature of the pavement. Investigations have revealed that Plastic and sulphur modifier can be used to improve properties of bitumen and bituminous mixes to make it more suitable for road construction. The present investigation comprises of determining the Marshall test properties of Dense Bitumen macadam Using VG-30 grade penetration grade bitumen modified with Sulphur as Modifier. The study helps to ascertain the suitability of Sulphur as modifier which could minimize the consumption of VG-30 grade bitumen. Also there is considerable amount of savings in bitumen cost.

Introduction

I. INTRODUCTION

The quality of roads dictates the economy of a country and hence the quality of our life’s. Roads are vital for the transport of the goods and passengers. In India, road transport carries approximately 85% of passenger traffic and 70% of freight transport. But the construction of highways involves huge amount of the investment and mainly sixty percent of the highway project cost is associated with the pavement construction. Pavement is a durable surfacing of a road, airstrip, or similar area and the primary function is to transmit loads to the sub-base and underlying soil sub-grade. Around ninety percent of the Indian highways have a covered surface with bituminous layers which are constructed and maintained by using naturally available road aggregates and bitumen, a petroleum product, which being mixed at high temperatures to produce hot mix asphalt. Mix design for the different layers of the pavement can have a major impact on the performance, cost and sustainability of the bituminous surfaces.

II. OBJECTIVE OF STUDY

This study is conducted with the main objective.

- To conduct the basic tests on Materials, to find out the Job Mix Formula and Optimum Binder Content for DBM- II bitumen mix.

- To find out Marshall properties i,e; Stability, Flow value, VFB, VMA, and Percentage of voids for conventional mix and shredded plastic combined with sulphur DBM-II mix.

- To compare the Marshall test results of conventional mix and shredded plastic combined with sulphure additive for DBM-II mix.

- To compare the cost analysis of conventional mix and shredded plastic combined with sulphur additives of DBM-II.

III. LITREATURE REVIEW

- Poorna Prajna S and Mohamed Ilyas Anjum (2015) examined the influence of Sulphur colloidal powder as a modifier, comprised a mixture of 75% Sulphur and 25% acacia (gum Arabic) as well as determined the Marshall properties of bituminous mixes by using bitumen grade of 60/70 penetration binder and Sulphur modified bitumen.

- Aditya Kumar Das and Mahabir Panda (2017) assessed the suitability of sulphur as a bitumen modifier for road construction by leading the Marshall Stability Test on plain and sulphur modified bitumen specimens as per ASTMD 1559. The possessions of sulphur modified bituminous similar volume of air voids, the volume of bitumen, VMA, VFB, bulk density, flow, Marshall Stability, and Marshall Quotient values were examined

- Kumkum Priyadarsini and Jhunarani Ojha (2020) conducted experimental studies to determine the result of sulphur as a modifier on the belongings of binder along with ageing assessment. Sulphur had different with variable percentages from 1 to 9 per cent and the physical properties of the modified binder tested by unlike tests such as Ductility, Elastic Recovery, Viscosity, Penetration and Softening point. The optimum concentration of sulphur found to be 2%. Results showed that with increasing percentages of sulphur, penetration.

- Abdulgazi Gedik et al (2013) conducted a laboratory investigation, aims to examine the appositeness of sulphur as compare to neat bitumen and determine the practical application of the resulting bitumen modified with sulphur in flexible pavements. Materials such as neat bitumen binder (70/100 penetration grade) as well as sulphur- added bitumen (SAB) and aggregates of crushed quartz used in this research

IV. MATERIALs AND METHODOLOGY

A. Materials

- Fine Aggregate

a. Sieve 4.75mm Passing and retained on 75-micron sieve used as fine aggregate

b. Aggregate should be clean, durable and free from dust, organic and deleteriousmaterials

2. Coarse Aggregate

a. Crushed gravel, rock or any other hard material which retains on 4.75mm sieve be used as coarse aggregate complying IS:383

b. Aggregate should be clean, hard, durable and free from dust, organic anddeleterious materials Selected source of aggregates should have affinity for bitumen, for a bettercoating and binding property.

Table 4.1 Properties of Coarse aggregates

|

SL No. |

Properties |

Method adopted |

Permissible limit (as per table 500-14 of MORTH) |

Obtained results |

Remarks |

|

1 |

Aggregate Impact value test (AIV) % |

IS:2386 (Part IV) |

30% |

24.85% |

Satisfactory |

|

2 |

Abrasion value |

IS:2386 (Part IV) |

35% |

19.97% |

Satisfactory |

|

3 |

Specific gravity |

IS:2386 (Part III) |

2.5-3.0 |

2.67 |

Satisfactory |

|

4 |

Water absorption |

IS:2386 (Part III) |

2% |

0.81% |

Satisfactory |

|

5 |

Shape test (CI) |

IS:2386 (Part I) |

35% |

17.07% |

Satisfactory |

3. Bitumen

a. It is a byproduct of Petroleum.

b. The selected bitumen should be a paving grade complying with penetration specified by MORTH 5th revision

c. VG-30 is used in the present project.

Table 4.2: Properties of Bitumen grade 2

|

Sl N o |

Name of the test |

Method adopted |

Permissible limit |

Obtained results |

Remarks |

|

1 |

Penetration test (mm) |

IS:1203-1978 |

60-70 |

64.32 |

Satisfactory |

|

2 |

Softening point, ºC |

IS:1205-1978 |

45-55 |

48 |

Satisfactory |

|

3 |

Flash & fire point, ºC |

IS:1209-1978 |

175 min |

276 and 300 |

Satisfactory |

|

4 |

Ductility, cm |

IS:1208-1978 |

75min |

96 |

Satisfactory |

|

5 |

Specific Gravity |

IS:1203-1978 |

0.99 min |

1 |

Satisfactory |

4. Additives: The Sulphur colloidal powder is brownish grey in colour and is a mixture of 75% sulphur and 25% acacia (gum Arabic), is utilized as a protective colloid and in addition shredded plastic is used.

B. Methodology

This stage in divided into three sections: - Testing of aggregates, testing of bitumen, testing of DBM with additive and without additive.

Table 4.3 Grading requirement for DBM

|

Grading |

I |

II |

|

Nominal size of aggregate (mm) |

40 |

25 |

|

Layer thickness (mm) |

80-100 |

50-75 |

|

IS Sieve size (mm) |

Cumulative % by weight of total aggregate passing |

|

|

45 |

100 |

100 |

|

37.5 |

95-100 |

100 |

|

26.5 |

63-93 |

90-100 |

|

19 |

- |

71-95 |

|

13.2 |

55-75 |

56-80 |

|

4.75 |

38-54 |

38-54 |

|

2.36 |

28-42 |

28-42 |

|

0.3 |

7-21 |

7-21 |

|

0.075 |

2-8 |

2-8 |

|

Bitumen content % by weight of total mix |

Min 4.0 |

Min 4.5 |

Table 4.4 Job Mix Formula for DBM-II

|

IS sieve (mm) |

Aggregate |

Aggregate |

Aggregate |

Obtained gradation (%) |

MORTH Specification |

|

|

A |

B |

C |

||||

|

26.5 down |

12.5 down |

6.3 down |

||||

|

3 5 |

25 % |

40 % |

Upper Limit |

Lower Limit |

||

|

26.5 |

100 |

100 |

100 |

100 |

100 |

90 |

|

19 |

84.6 |

100 |

100 |

94.65 |

95 |

71 |

|

13.2 |

16.79 |

99.03 |

100 |

70.44 |

80 |

56 |

|

4.75 |

0.30 |

4.51 |

99.87 |

41.19 |

54 |

38 |

|

2.36 |

0 |

1.91 |

85.59 |

34.75 |

42 |

28 |

|

0.3 |

0 |

0.96 |

29.15 |

11.90 |

21 |

07 |

|

0.00 |

0 |

0.56 |

4.95 |

2.12 |

8 |

2 |

Preparation of Marshall Specimen

Test Specimens Approximately 1200g of the aggregate consisting of different aggregate fractions are preheated to 175-190°C. The bitumen (plain/modified) was heated to 121-138°C and the first trial bitumen content was added to a preheated steel bowl. The mix was thoroughly mixed at mixing temperature about 154°C.

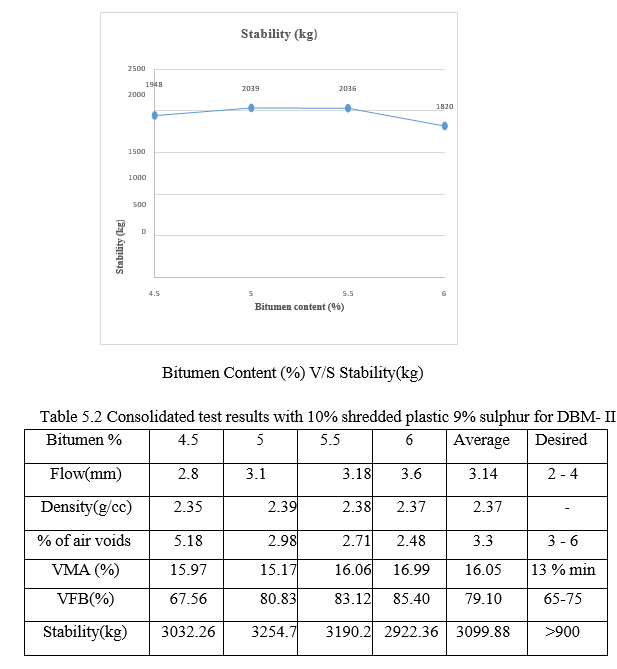

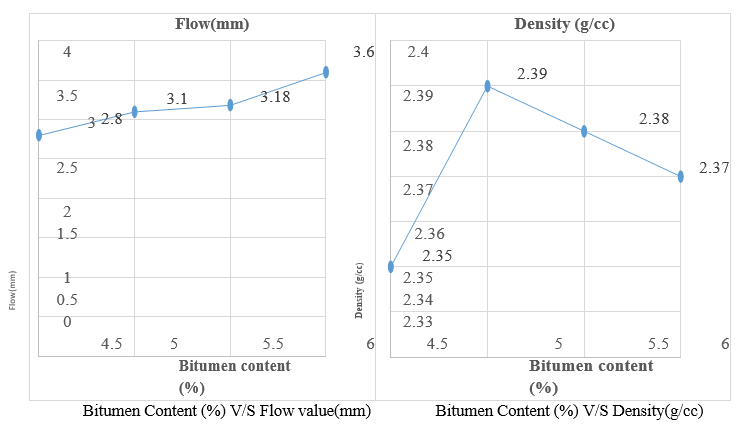

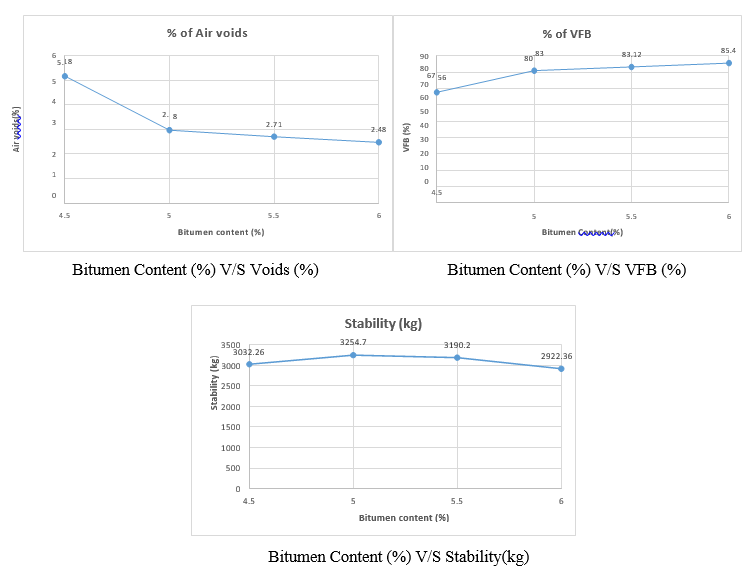

The mix was compacted in a preheated Marshall mould by applying 75 blows on each side of the specimen. Specimens were prepared at bitumen content 4.5%, 5%, 5.5%, 6% and weight of dry mix modified using plastic 8%, 10%, and 12% and sulphur at 9% weight of bitumen respectively.

V. RESULTS AND ANALYSIS

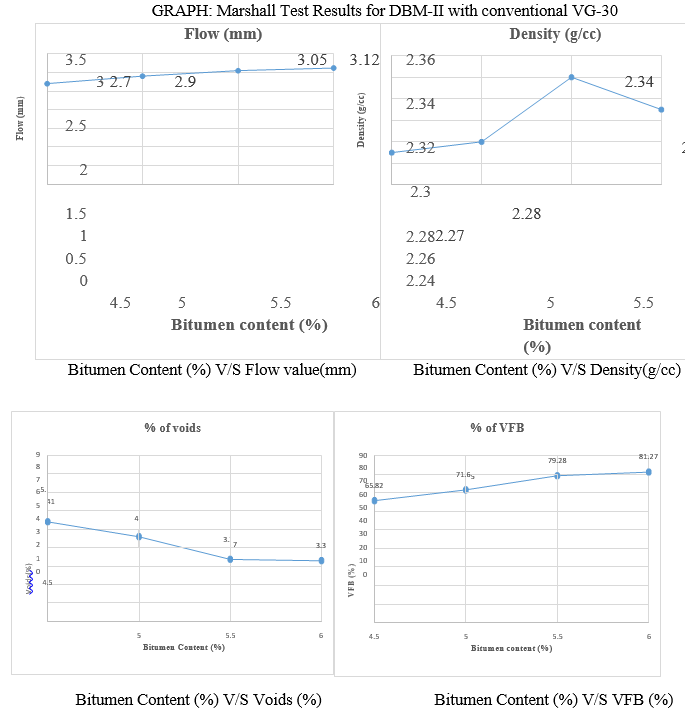

The Marshall Stability test was conducted on the prepared specimens as per ASTM D 1559 to determine the stability and flow values. The Marshall Test properties such as bulk density, Volume of air voids, volume of bitumen, voids in Mineral aggregates, etc were determined, shown in Table 5.1

Table 5.1 Consolidated test results of conventional bitumen mix DBM- II

|

Bitumen % |

4.5 |

5 |

5.5 |

6 |

Average |

Desired |

|

Flow(mm) |

2.7 |

2.9 |

3.05 |

3.12 |

2.97 |

2 - 4 |

|

Density(g/cc) |

2.27 |

2.28 |

2.34 |

2.31 |

2.3 |

- |

|

% of voids |

5.41 |

4.6 |

3.37 |

3.3 |

4.17 |

3 - 6 |

|

VMA (%) |

15.83 |

16.23 |

16.27 |

17.62 |

16.48 |

13% min |

|

VFB (%) |

65.82 |

71.65 |

79.28 |

81.27 |

74.5 |

65-75 |

|

Stability(kg) |

1948.00 |

2039.00 |

2036.00 |

1820.00 |

1960.75 |

>900 |

A. Cost Estimate

The appropriate cost and savings in cost of DBM mix for 1km road is shown in the table 5.4

Table 5.4

|

Parameters |

Length (m) |

Breadth (m) |

Depth (m) |

Volume (m3) |

Density (kg/m3) |

Wt. in MT |

OBC |

Bitumen in MT |

Rate/MT |

Amount In Rs |

|

Conventional |

1000 |

7.5 |

0.05 |

375 |

2310 |

866.25 |

5.25 |

45.47 |

60000 |

2728200 |

|

10% Plastic and 9% Sulpuhur |

1000 |

7.5 |

0.05 |

375 |

2380 |

892.5 |

5.25 |

40.93 |

60000 |

2455800 |

Table 5.5 Total cost of Additives in Rupees

|

Parameters |

Rate of additives /MT in Rupees |

Wt in MT |

Cost in Rupees |

|

10% Plastic |

15000 |

4.54 |

68100 |

|

9% sulphur |

20000 |

3.68 |

73600 |

Conclusion

Following Conclusions are drawn on the basis of laboratory investigation. 1) Basic properties of Coarse aggregates, Bitumen is tested and the materials satisfies the Standard Specifications of MORTH (5th revision). 2) The Job Mix Formula is done meeting the desired gradation of MORTH and the Optimum Binder Content (OBC) for DBM Grade-II among conventional bitumen is 5.25% and for modified bitumen is 4.9%. 3) Marshall Test Properties like Stability, flow value, Volume of voids, VMA, and VFB for conventional mix of DBM- II are 2037.5Kg, 2.97mm, 3.98%, 16.25% and 74.46% respectively and for 10% of plastic and 9% sulphur added DBM-II are 3210.21Kg, 2.88mm, 3.42%, 15.33% and 74.91% respectively. 4) Marshall values of stability of 10% plastic and 9 % sulphur added mix is approximately 57% greater than conventional bitumen mix. 5) The Modified bitumen saves 10.84% cost is bitumen, when compare with conventional bitumen.

References

[1] Poorna Prajna S and Mohamed Ilyas Anjum (2015) examined the influence of Sulphur colloidal powder as a modifier. [2] Aditya Kumar Das and Mahabir Panda (2017) assessed the suitability of sulphur as a bitumen modifier for road construction by leading the Marshall Stability Test on plain and sulphur modified bitumen specimens. [3] Kumkum Priyadarsini and Jhunarani Ojha (2020) conducted experimental studies to determine the result of sulphur as modifier on the belongings of binder along with ageing assessment. [4] Abdulgazi Gedik et al (2013) conducted a laboratory investigation, aims to examine the appositeness of sulphur as compare to neat bitumen.

Copyright

Copyright © 2022 Maruti Naik , Praveen Kumar P. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET40705

Publish Date : 2022-03-09

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online