Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- Copyright

Repair of Cracks in Nicol Blocks of a Reinforced Earth Wall

Authors: Sowmik Islam

DOI Link: https://doi.org/10.22214/ijraset.2022.48277

Certificate: View Certificate

Abstract

Bangladesh\'s first access-controlled expressway is the Dhaka-Khulna (N-8) Expressway. The project consists of 8 lane road of 55 km length, 54 culverts, 20 underpasses, 2 interchanges, 4 major bridges, 25 minor bridges, and 5 flyovers. Teghoria Interchange of this project is structured with 19 Reinforced Earth Wall, out of which a crack appeared in a wall that has 146 meters length and 7 meters height. Detailed inspection and analysis were followed by repair and rectification work. The aim of this paper was to find out the likely causes of this crack, discuss detailed retrofitting methodology and bring forth some recommendation. This crack may form due to weak workmanship during compaction and installation of tendons of reinforced earth, environmental load, heavy-loaded vehicle travel above the RE wall etc. The specialist team of the consultants of the project and experts from development partner inspected the problem and worked out how to repair the cracked area. The development partner developed repair methodology and executed the crack repair work as well as the treatment plan under strict supervision of consultants. Surface preparation, preparation of precast veneer & epoxy-based mortar, placement and finishing work make up the treatment process.

Introduction

I. INTRODUCTION

Dhaka-Khulna (N-8) expressway Improvement Project is the first ever access controlled expressway of Bangladesh. This Highway from Jatrabari Intersection to Mawa and Patchchar to Bhanga connects the south western parts of Bangladesh with Dhaka through the long-cherished Padma Multipurpose Bridge. The project is led by Roads & Highways Department and implemented by Bangladesh Army. This road is a Part of National Highway N8 and the Annual Average Daily Traffic (AADT) of the road exceeded 30000 at many locations. The road comprises of 08 lanes including service roads at both sides. The project includes 05 flyovers, 20 underpasses, 02 interchanges, 04 railway over bridges, 4 major bridges, 25 minor bridges and 54 culverts also. One Major structure of this project is Teghoria Interchange. In this Interchange, there are more than 19 nos RE Wall, Total RE Wall Length 1332m, and Maximum length of RE Wall 170m. A crack appeared in a RE wall located at Chainage 4+805 to 4+810, which is included at Ch. 4+805 to 4+951 and total length is 146m, Hight-7.00m.

Based on the methodology sent by the Development Partner, the repairing/ rectifying work was conducted after detailed inspection and analysis.

II. TERMINOLOGY

- Interchange: An intersection or an at-grade junction is a junction where two or more roads converge, diverge, meet or cross at the same height, as opposed to an interchange, which uses bridges or tunnels to separate different roads. There can be different type of Interchange - Cloverleaf Interchange, Stack Interchange, Combination Interchange, Turbine Interchange, Trumpet Interchange, T and Y type Interchange.

- Reinforcement Earth Wall: Reinforced Earth retaining wall system is a fast and cost-effective solution for the construction of earth stabilized vertical walls for bridge and approaches for various underpasses. The facing system offers a natural aes-thetic appearance and can be casted in various shapes. Reinforced Earth retaining walls utilizes discrete concrete panels with joints provided between panels in order to enable the structure to accommodate differential settlement and dynamic loads. The Reinforced Earth system adopted in this project was composed of High Adherence GeoStrap which were connected to the facing panel by means of patented connectors, which were embedded inside the panels during panel casting. The high adherence reinforcing straps have high adherence edges to provide passive resistance. Design and construction of Reinforced Earth includes all dead and live loads and its combinations including seismic load. The connectors between the straps and the facing have been designed to provide high durability and easy installation. The structure has to be designed for a service life of 100 years.

- Tensar Modular Block: Tensar Modular Block Wall System is built by reinforcing soil mass with uniaxial geogrids. The high-efficiency connection between the facing and the geogrids is the best feature of this system. Blue moulded connectors are placed between blocks to provide it connection to geogrids. Tensar Modular Block wall is used to retain earth of high embankment, bridge abutment, and so on. Modular Block Wall consists of factory pre-cast concrete blocks as facing for the reinforced soil wall system.

- NICOL Block: Modular Block Wall System is a proven solution in making retaining walls and bridge abutments. This wall system is built by reinforcing soil mass with uniaxial geogrids. The high efficiency connection between the facing and the geogrids is the best feature of this system. With this feature, it can allow rapid and economical construction, reduction of conventional construction time, avoidance of the need for specialist skills and often the utilization of site-won materials. Hence, cost of constructing this kind of wall system is surely cheaper than the conventional wall systems.

- Tensile Strength: The tensile strength of concrete is its capacity to resist cracking or breaking under tension. The tensile strength in very-high- strength concrete often is no higher than 10 MPa as in the conventional high-strength concrete. For use as a protective material, both tensile and compressive strength are important properties.

- Epoxy Based Mortar: Grout is a thick fluid which is used to fill gaps or used as underpinning in being structures. Grout is generally a admixture of water, cement and sand, and is employed in pressure grouting, bedding rebar in masonry walls, connecting sections of pre-cast concrete, filling voids, and sealing joints similar as those between penstocks.

III. METHODOLOGY

The data has been gathered thorough physical survey and experiments which gained by quantitative methodology. With the Descriptive and experimental result the research could make the conclusion. The study presents a practical approach based on scientific research and technology development for repairing of cracks in nicol blocks.

IV. GOALS AND OBJECTIVES

The main goal of the research was to establish a method to repair the cracks in nicol block.

The objectives are following:

- Identify the Longitudinal Cracks on the surface of some modular blocks.

- Treatment of the cracked blocks.

V. DESCRIPTION OF TEGHORIA INTERCHANGE

This interchange connects Jatrabari to Mawa Express Highway and Babu Bazar Link Road together. This a Trumpet type of Interchange. The trumpet interchange allows for interchange of secondary two-way streets to a multi-lane roadway with minimal traffic mix. It takes the place of a T-intersection which is often used when a roadway ends at the intersection of another roadway.

A. Statement of Problem

Longitudinal Cracks were found on the surface of some modular blocks of reinforcement earth wall at Tegoria Interchange Bridge abutment-3.

- The height of this RE wall is maximum in this location.

- Rain water might be seeped to the RE wall filling because of this crack.

B. Joint Inspection

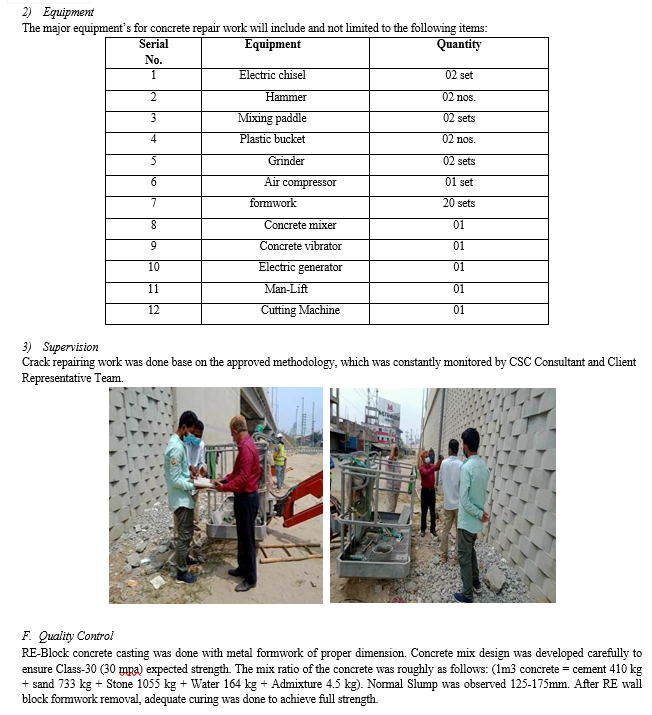

The site inspection was done jointly by technical advisers, international team leader, deputy team leader, senior material engineer, Senior Bridge engineer, client's executive to analyse the problem in depth and work out how to repair the cracked area.

C. Reason for Crack

- Concrete is a brittle material with a relatively low tensile strength. The principle of RE Wall is load on roadway should be carried by compacted sand / earth reinforced with tendon but will not be shared by concrete blocks. If there is any circumstance when earth cannot adequately bear the induced load it will ultimately pass to the concrete blocks that are not designed to bear it.

- When the tensile stress induced by either traffic or environmental loading or both exceeds the tensile strength of concrete crack may occur and also for the defective manufacture it may happen.

- Heavy loaded vehicles like (crane, mixture truck, and transporter) etc always passes by the road above RE wall block.

- The structural damage might have been caused by vibration or impact from external source, though the possibility of such phenomenon is very less.

D. Treatment Method

The development partner (China Harbour Engineering Company) submitted the treatment method for these problems. The total work is finished by this treatment method given below:

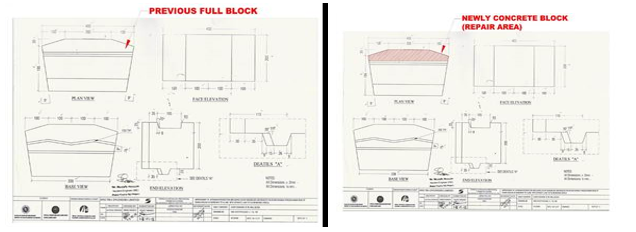

- Crushing, Cracking and Surface Damage of Individual Blocks: Localised damage to the face such as cracking or crushing of individual blocks is unlikely to cause any threat to overall structural stability (Referenced from “Guidelines for the maintenance of Tens Artech Modular Block Retaining walls”). If the depth of the damage is 40-50mm generally, the detail procedures of repairing are as follows:

a. Surface Preparation

- The damaged block(s) in question should be broken back with a mechanical chisel to a depth of 40mm to 50mm.

- Cleaning the dust with air compressor and water.

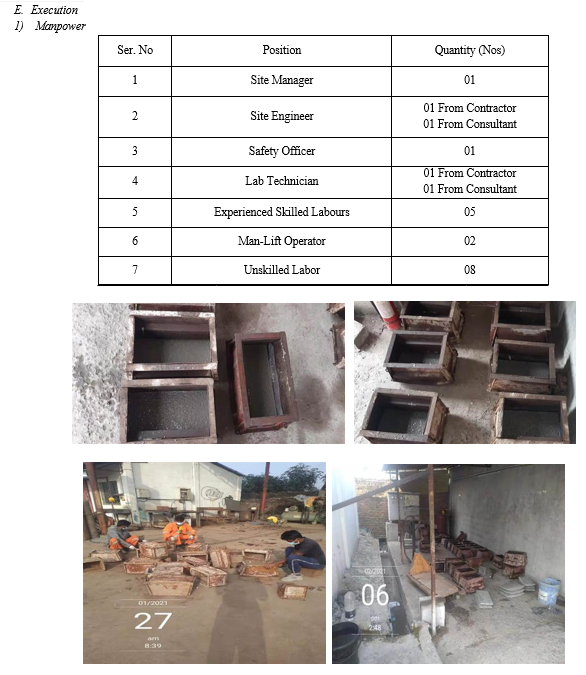

b. Precast Veneer

- Cleaning the steel formwork.

- Marking thickness of formwork to match the depth of chipped block.

- Close formwork after sealing the gaps in the formwork by the most appropriate method (sponge, water plug, etc.).

- Pouring concrete.

- The formwork shall be removed when the concrete strength meet with requires.

- The surface of veneer shall be covered by Geotextile after remove the formwork.

- Curing using water.

- Precast veneer shall be grinding by electric grinder.

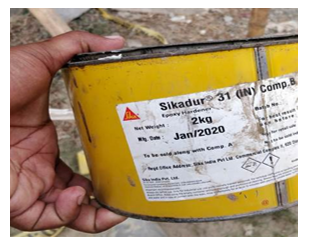

c. Mixing epoxy based mortar (Sikadur?R -31IN):

Mixing epoxy-based mortar under the product date sheet Sikadur?R -31IN.

d. Repair

- Apply mixed epoxy-based mortar to the replacement veneer and the prepared face of damaged block.

- “Glue” the replacement veneers on to the prepared face of damaged block.

e. Finishing

Protruded epoxy-based mortar shall be cleaned.

If depth of the damage is more than 40-50mm, the detail procedures of repairing are as follows:

f. Surface Preparation

- The damaged block(s) in question should be broken back with a mechanical chisel to a depth of 40 to 50mm.

- The tongue at the bottom of the precast veneer or the tongue on the existing block from the higher layer are to be cut off with an electric grinder so that the precast veneer can be inserted deeper.

- Cleaning the dust with air compressor and water.

g. Precast Veneer

h. Mixing epoxy based mortar (Sikadur?R -31IN)

- Chemical Base: Epoxy Resin

- Packaging: Part A: 2 kg, Part B: 1kg 3 kg x 2 sets, Part A: 4 kg, Part B: 2kg 6 kg x2sets, Part A: 20 kg, Part B: 10kg 30 kg x 1 set

- Colour: Grey Paste

- Shelf Life: 12 months from date ofproduction

- Storage Conditions: Store properly in original unopened sealed and undamaged.

- Packaging: Dry conditions at temperatures between + 5°C and +40°C. Protect from direct sun light.

- Density: Part A+B Mixed: 1.80 ± 0.1 kg/L at30°C

- Company Name: Sika India Pvt.Ltd.

i. Repair

j. Finishing

2. Horizontal gaps between adjacent layers of blocks: Settlement of RE walls are likely to achieve an equilibrium by 4 months continuous monitoring at Ramp B (close to abutment 3 of Teghoria Interchange Bridge) and Ramp D (close to abutment 0 of Link Road Flyover).

If the gap only 20-25mm, the detail procedures of repairing are as follows:

a. Surface preparation

Cleaning sundries from the gaps between adjacent layers.

b. Mixing epoxy based mortar (Sikadur?R -31IN):

Mixing epoxy based mortar under the product date sheet Sikadur?R -31IN.

c. Repair

Filling the gap with epoxy-based mortar and matching the hexagonal shape at surface by precision trowelling.

d. Finishing

Protruded epoxy-based mortar shall be cleaned.

If the gap is large say 40-50mm, the detail procedures of repairing are as follows

e. Surface Preparation

- Making room for insertion of a matching horizontal precast veneer by using an electric grinder cutting through tongue of the existing upper block if necessary.

- Cleaning sundries from the gaps between adjacent layers.

f. Veneer Preparation

- Casting blocks.

- The blocks shall be grinded by electric grinder.

- Marking slicing line of blocks to match the horizontal gaps between layers of blocks.

- The blocks shall be sliced horizontally to obtain a horizontal veneer element.

g. Mixing epoxy based mortar (Sikadur?R - 31IN)

- Chemical Base: EpoxyResin

- Packaging: Part A: 2 kg, Part B: 1kg 3 kg x2sets, Part A: 4 kg, Part B:2kg 6 kg x2sets, Part A: 20 kg, Part B:10kg 30 kg x 1set

- Colour: GreyPaste

- Shelf Life: 12 months from date ofproduction

- Storage Conditions: Store properly in original unopened sealed and undamaged.

- Packaging: Dry conditions at temperatures between +5°C and +40°C. Protect from dir- ect sun light.

- Density: Part A+B Mixed: 1.80 ± 0.1 kg/L at30°C

- Company Name: Sika India Pvt.Ltd.

h. Repair

- Apply mixed epoxy-based mortar to the horizontal veneer.

- Insert the horizontal veneer to fill horizontal gaps between blocks.

i. Finishing

Conclusion

1) Strict adherence to precise workmanship must be maintained while compacting reinforced earth or installing tendons. 2) Overloading on the roadway must be restricted by any means to avoid unexpected stress on RE Wall. 3) Concrete blocks used on RE wall must be of required compressive strength to survive external impact. 4) The Service Road used next to the RE wall should be kept safe. 5) Construction of safe guide walls next to the RE wall so that the Heavy vehicle dose not hit. 6) No big Trees can be Planted along the RE wall. 7) Care should be taken to ensure that the drainage/Rain water does not seep inside the wall.

Copyright

Copyright © 2022 Sowmik Islam. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET48277

Publish Date : 2022-12-21

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online