Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Review: Wastewater Treatment in Different Industries

Authors: Bharat Chandra Pandey, Sangita Gupta

DOI Link: https://doi.org/10.22214/ijraset.2022.46245

Certificate: View Certificate

Abstract

Wastewater treatment is a process used to remove contaminants from wastewater and convert it into an effluent that can be returned to the water cycle. Once returned to the water cycle, the effluent creates an acceptable impact on the environment or is reused for various purposes (called water reclamation). The treatment process takes place in a wastewater treatment plant. There are several kinds of wastewater which are treated at the appropriate type of wastewater treatment plant. For domestic wastewater (also called municipal wastewater or sewage), the treatment plant is called a sewage treatment plant. For industrial wastewater, treatment either takes place in a separate industrial wastewater treatment plant, or in a sewage treatment plant (usually after some form of pre-treatment). Further types of wastewater treatment plants include agricultural wastewater treatment plants and leachate treatment plants. Processes commonly used in wastewater treatment include phase separation (such as sedimentation), biological and chemical processes (such as oxidation) or polishing. The main by-product from wastewater treatment plants is a type of sludge which is usually treated in the same or another wastewater treatment plant. Biogas can be another by-product if anaerobic treatment processes are used. Treated wastewater can be reused as reclaimed water. The main purpose of wastewater treatment is for the treated wastewater to be able to be disposed or reused safely. However, before it is treated, the options for disposal or reuse must be considered so the correct treatment process is used on the wastewater. Performance of state owned sewage treatment plants, for treating municipal waste water, and common effluent treatment plants, for treating effluent from small scale industries, is also not complying with prescribed standards. Thus, effluent from the treatment plants, often, not suitable for household purpose and reuse of the waste water is mostly restricted to agricultural and industrial purposes. The development of innovative technologies for treatment of wastewaters from various industries is a matter of alarming concern for us. Although many research papers have been reported on wastewater pollution control studies, but a very few research work is carried out for treatment of wastewater of steel industries, especially in reference to development of design of industrial effluent Treatment Plants (ETP) system. Another beneficial aspect of this research work will be recycling, reuse of water and sludge from steel industry The whole technologies for treating industrial wastewater can be divided into four categories: - Chemical, Physical, Biological and mathematical approaches.

Introduction

I. INTRODUCTION

Water is constantly moving on the Earth between the atmosphere, ocean, rivers and streams, snowpack’s and ice sheets, and underground. Water availability, both as surface water and groundwater, is essential for agriculture, human consumption, industry, and energy generation. Water is one of the most vital natural resources for all life on Earth. Major source for irrigation is groundwater [1]. Water use can mean the amount of water used by a household or a country, Commercial water use includes fresh water for motels, hotels, restaurants, office buildings, other commercial facilities, and civilian and military institutions. Domestic water use is probably the most important daily use of water for most people [2]. Domestic use includes water that is used in the home every day, including water for normal household purposes, such as drinking, food preparation, bathing, washing clothes and dishes, flushing toilets, and watering lawns and gardens. Industrial water use is a valuable resource to the nation's industries for such purposes as processing, cleaning, transportation, dilution, and cooling in manufacturing facilities. Major water-using industries include steel, chemical, paper, and petroleum refining. Industries often reuse the same water over and over for more than one purpose. Irrigation water use is water artificially applied to farm, orchard, pasture, and horticultural crops, as well as water used to irrigate pastures, for frost and freeze protection, chemical application, crop cooling, harvesting, and for the leaching of salts from the crop root zone. Mining water use includes water for the extraction of naturally occurring minerals; solids, such as coal and ores; liquids, such as crude petroleum; and gases, such as natural gas [3]. The category includes quarrying, milling (such as crushing, screening, washing, and flotation), and other operations as part of mining activity. A significant portion of the water used for mining, about 32 percent, is saline.

A. Wastewater Sources

- Human waste (urine) often mixed with used toilet paper or wipes; this is known as black-water if it is collected with flush toilets.

- Washing water also known as greywater.

- Surplus manufactured liquids from domestic sources (drinks, pesticides, lubricating oil, paint, cleaning etc.)

- Urban rainfall runoff from roads, roofs, sidewalks/pavements (contains oils, animal feces, litter, gasoline/petrol, diesel or rubber residues from tires, metals from vehicle exhausts, etc.)

- Highway drainage (de-icing agents, rubber residues, particularly from tires)

- Storm drains (may include trash)

- Manmade liquids (disposal of pesticides, used oils, etc.)

- Industrial waste

- Industrial site drainage (silt, sand, alkali, oil, chemical residues)

- Industrial wastewater: waterborne waste generated from a variety of industrial processes, such as manufacturing operations, mineral extraction, power generation, or water and wastewater treatment.

- Cooling water, released with potential thermal pollution after use to condense steam or reduce machinery temperatures by conduction or evaporation [4].

- Leachate: precipitation containing pollutants dissolved while percolating through ores, raw materials, products, or solid waste.

- Return flow: the flow of water carrying suspended soil, pesticide residues, or dissolved minerals and nutrients from irrigated cropland.

- Surface runoff: the flow of water occurring on the ground surface.

B. Reuse Of Waste Water & Disposal

- Agricultural wastewater reuse.

- Redirecting drain water (Grey wastewater systems)

- Recycling dirty aquarium water.

- Collect shower water.

- Trap rainwater.

- The use of coarse filtration.

II. ENVIRONMENTAL IMPACT ASSESSMENT (EIA)

Environmental Impact assessment (EIA) is the assessment of the environmental consequences of a plan, policy, program, or actual projects prior to the decision to move forward with the proposed action. In this context, the term "environmental impact assessment" (EIA) is usually used when applied to actual projects by individuals or companies and the term "strategic environmental assessment" (SEA) applies to policies, plans and programmes most often proposed by organs of state. It is a tool of environmental management forming a part of project approval and decision-making. Environmental assessments may be governed by rules of administrative procedure regarding public participation and documentation of decision making, and may be subject to judicial review [5].

It is the term used for the assessment of the environmental consequences (positive and negative) of a plan, policy, program, or concrete projects prior to the decision to move forward with the proposed action. In this context, the term "environmental impact assessment" (EIA) is usually used when applied to concrete projects by individuals or companies and the term "strategic environmental assessment" (SEA) applies to policies, plans and programmes most often proposed by organs of state (Fischer, 2016). Environmental assessments may be governed by rules of administrative procedure regarding public participation and documentation of decision making, and may be subject to judicial review.

Purpose of EIA

The purpose of the assessment is to ensure that decision makers consider the environmental impacts when deciding whether or not to proceed with a project.

The International Association for Impact Assessment (IAIA) defines an environmental impact assessment as "the process of identifying, predicting, evaluating and mitigating the biophysical, social, and other relevant effects of development proposals prior to major decisions being taken and commitments made".

EIAs are unique in that they do not require adherence to a predetermined environmental outcome, but rather they require decision makers to account for environmental values in their decisions and to justify those decisions in light of detailed environmental studies and public comments on the potential environmental impacts purpose of Environmental Impact Assessment (EIA) is to identify and evaluate the potential impacts (beneficial and adverse) of development and projects on the environmental system[6]. It is an useful aid for decision making based on understanding of the environment implications including social, cultural and aesthetic concerns which could be integrated with the analysis of the project costs and benefits. This exercise should be undertaken early enough in the planning stage of projects for selection of environmentally compatible sites, process technologies and such other environmental safeguards.

While all industrial projects may have some environmental impacts all of them may not be significant enough to warrant elaborate assessment procedures [7]. The need for such exercises will have to be decided after initial evaluation of the possible implications of a particular project and its location. Industrial wastewater treatment covers the mechanisms and processes used to treat wastewater that is produced as a by-product of industrial or commercial activities.

After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment[8]. Most industries produce some wastewater although recent trends in the developed world have been to minimise such production or recycle such wastewater within the production process. However, many industries remain dependent on processes that produce wastewaters.

There are three different types of wastewater treatment process are ETP, STP and CETP. It is estimated that every year 1.80 million people die due to suffering from waterborne diseases.

A large part of these deaths can be indirectly attributed to improper sanitation [9]. Wastewater treatment is an important initiative which has to be taken more seriously for the betterment of the society and our future. Wastewater treatment is a process, wherein the contaminants are removed from wastewater as well as household sewage, to produce waste stream or solid waste suitable for discharge or reuse.

III. EFFLUENT TREATMENT PLANTS (ETP)

ETP is one type of waste water treatment method which is particularly designed to purify industrial waste water for its reuse and it is aim to release safe water to environment from the harmful effect caused by the effluent. Industrial effluents contain various materials, depending on the industry. Some effluents contain oils and grease, and some contain toxic materials. Effluents from food and beverage factories contain degradable organic pollutants. Since industrial waste water contains a diversity of impurities and therefore specific treatment technology called ETP is required. Treatment Plants or (ETPs) are used by leading companies in the pharmaceutical and chemical industry to purify water and remove any toxic and non-toxic materials or chemicals from it. These plants are used by all companies for environment protection.

An ETP is a plant where the treatment of industrial effluents and waste waters is done. The ETP plants are used widely in industrial sector, for example, pharmaceutical industry, to remove the effluents from the bulk drugs.

A. Requirement of Effluent Treatment Plant

- For the removal of high amounts of organic compounds, debris, dirt, grit, pollution, toxic, non-toxic materials and polymers etc. from industrial effluent.

- To clean industry effluent and recycle it for further use.

- To reduce the usage of fresh/potable water in Industries.

- To cut expenditure on water procurement.

- To meet the Standards for emission or discharge of environmental pollutants from various Industries set by the Government and avoid hefty penalties.

B. Treatment Methods of Effluent Treatment Plant

Treatment levels:

1. Preliminary Treatment: Physical separation of big sized impurities like cloth, plastics, wood logs, paper, etc. Common physical unit operations at Preliminary level are:

a. Screening: A screen with openings of uniform size is used to remove large solids such as plastics, cloth etc. Generally maximum 10mm is used.

b. Sedimentation: Physical water treatment process using gravity to remove suspended solids from water.

c. Clarification: Used for separation of solids from fluids.

d. Primary Treatment Level Purpose: Removal of floating and settleable materials such as suspended solids and organic matter.

e. Methods: Both physical and chemical methods are used in this treatment level.

f. Chemical Unit Processes: Chemical unit processes are always used with physical operations and may also be used with biological treatment processes. Chemical processes use the addition of chemicals to the wastewater to bring about changes in its quality. Example: pH control, coagulation, chemical precipitation and oxidation.

g. pH Control: To adjust the pH in the treatment process to make wastewater pH neutral. For acidic wastes (low pH): NaOH, Na2CO3, CaCO3 or Ca(OH)2. For alkali wastes (high pH): H2SO4, HCl.

2. Secondary Treatment Level Methods: Biological and chemical processes are involved in this level.

Biological Unit process: To remove, or reduce the concentration of organic and inorganic compounds. Biological treatment process can take many forms but all are based around microorganisms, mainly bacteria. Aerobic Processes Aerobic treatment processes take place in the presence of air (oxygen). Utilizes those microorganisms (aerobes), which use molecular/free oxygen to assimilate organic impurities i.e. convert them in to carbon dioxide, water and biomass. Anaerobic Processes the anaerobic treatment processes take place in the absence of air (oxygen). Utilizes microorganisms (anaerobes) which do not require air to assimilate organic impurities. The final products are methane and biomass.

3. Tertiary / Advanced Treatment Purpose: Final cleaning process that improves wastewater quality before it is reused, recycled or discharged to the environment. Mechanism: Removes remaining inorganic compounds, and substances, such as the nitrogen and phosphorus. Bacteria, viruses and parasites, which are harmful to public health, are also removed at this stage. Methods: Alum: Used to help remove additional phosphorus particles and group the remaining solids together for easy removal in the filters. Chlorine contact tank disinfects the tertiary treated wastewater by removing microorganisms in treated wastewater including bacteria, viruses and parasites. Remaining chlorine is removed by adding sodium bisulphate just before it's discharged.

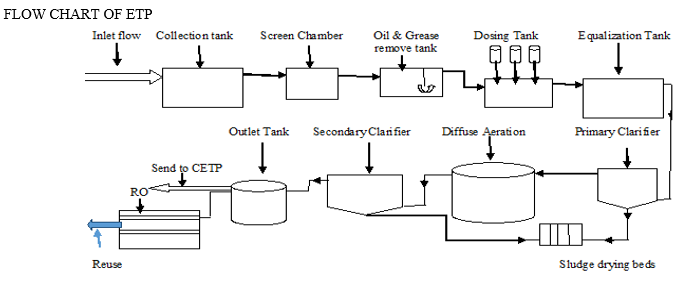

IV. ETP PLANT OPERATION

The ETP Plant works at various levels and involves various physical, chemical, biological and membrane processes to treat waste water from different industrial sectors like chemical, drug, pharmaceutical, refineries, dairy, ready mix plants & textile etc.

- Screen Chamber: Remove relatively large solids to avoid abrasion of mechanical equipments and clogging of hydraulic system.

- Collection Tank: The collection tank collects the effluent water from the screening chamber, stores and then pumps it to the equalization tank.

- Equalization Tank: The effluents do not have similar concentrations at all the time; the pH will vary time to time. Effluents are stored from 8 to 12 hours in the equalization tank resulting in a homogenous mixing of effluents and helping in neutralization. It eliminates shock loading on the subsequent treatment system. Continuous mixing also eliminates settling of solids within the equalization tank. Reduces SS, TSS.

- Clarriflocculator: In the clarriflocculator the water is circulated continuously by the stirrer. Overflowed water is taken out to the aeration tank. The solid particles are settled down, and collected separately and dried; this reduces SS, TSS. Flocculation provides slow mixing that leads to the formation of macro flocs, which then settles out in the clarifier zone. The settled solids i.e. primary sludge is pumped into sludge drying beds. ETP Plant Operation

- Aeration Tank: The water is passed like a thin film over the different arrangements like staircase shape. Dosing of Urea and DAP is done. Water gets direct contact with the air to dissolve the oxygen into water. BOD & COD values of water is reduced up to 90%.

- Clarifier: The clarifier collects the biological sludge. The overflowed water is called as treated effluent and disposed out. The outlet water quality is checked to be within the accepted limit as delineated in the norms of the Bureau of Indian standards. Through pipelines, the treated water is disposed into the environment river water, barren land, etc.

- Sludge Thickener: The inlet water consists of 65% water + 35 % solids. The effluent is passed through the centrifuge. Due to centrifugal action, the solids and liquids are separated. The sludge thickener reduces the water content in the effluent to 40% water + 60% solids. The effluent is then reprocessed and the sludge collected at the bottom.

- Screening: Screening is the filtration process for the separation.

V. MATERIALS & METHODS

Methodology: In this research paper the treatment technologies adopted for treating sewage are as follows:

- Activated Sludge Process

- Chlorination

- Filtration

Sewage treatment is the process of removing contaminants from wastewater and house hold sewage, both runoffs (effluents), domestic, commercial and institutional. It includes physical, chemical, and biological processes to remove physical, chemical and biological contaminants. Its objective is to produce an environmentally safe fluid waste stream (or Treated Effluent) and a solid waste (or treated sludge) suitable for disposal or reuse .The treatment of waste water is not only important for our own health but also to keep our environment clean and healthy in a sewage treatment plant, the activated sludge process is a biological process that can be used for one or several of the purposes like oxidizing carbonaceous biological matter, oxidizing nitrogenous matter: mainly ammonium & nitrogen in biological matter, removing phosphate, driving off entrained gases such as carbon dioxide, ammonia, nitrogen generating a biological floc that is easy to settle, generating a liquor that is low in dissolved or suspended material. The process involves air or oxygen being introduced into a mixture of screened and primary treated sewage or industrial wastewater combined with organisms to develop a biological floc which reduces the organic matter content of the sewage. The combination of wastewater and biological mass is commonly known as mixed liquor. In all activated sludge plants, once the sewage or wastewater has received sufficient treatment, excess mixed liquor is discharged into settling tanks and the treated supernatant is run off to undergo further treatment before discharge. Part of the settled material, the sludge, is returned to the head of the aeration system to re-seed the new sewage entering the tank. This fraction of the floc is called return activated sludge. Excess sludge is called surplus activated sludge is removed from the treatment process to keep the ratio of biomass to food supplied in the wastewater in balance, and is further treated by digestion, either under anaerobic or aerobic conditions prior to disposal. Activated sludge refers to biological treatment processes that use a suspended growth of organisms to remove BOD and suspended solids. This process requires an aeration tank and a settling tank. Clarifiers are settling tanks built with mechanical means for continuous removal of solids being deposited by sedimentation. Disinfection of sewage is necessary for healthy rivers and streams .Microorganisms are present in large numbers in sewage and waterborne disease outbreaks have been associated with sewage- contaminated water supplies.

Conclusion

The successful implementation of wastewater reuse options in a water resources management programme requires careful planning, economic and financial analyses, and the effective design, operation, and management of wastewater reclamation, storage, and distribution facilities. Technologies for wastewater reclamation and purification have developed to the point where it is technically feasible to produce water of almost any quality, and advances continue to be made. Current water reclamation strategies incorporate multiple measures to minimize the health and environmental risks associated with various reuse applications. A combination of source control, advanced treatment process flow schemes, and other engineering controls provides a sound basis for increased implementation of water reuse applications. The feasibility of producing reclaimed water of a specified quality to fulfil multiple water use objectives is now a reality owing to the progressive evolution of technologies and the understanding of health and environmental risks. However, the ultimate decision to harvest reclaimed wastewater is dependent on economic, regulatory, and public policy factors reflecting the demand and need for a dependable water supply and water pollution control facing the mega-cities.The problems associated with wastewater reuse arise from its lack of treatment. The challenge thus is to find such low-cost, low-tech, user friendly methods, which on one hand avoid threatening our substantial wastewater dependent livelihoods and on the other hand protect degradation of our valuable natural resources. The use of constructed wetlands is now being recognized as an efficient technology for wastewater treatment. Compared to the conventional treatment systems, constructed wetlands need lesser material and energy, are easily operated, have no sludge disposal problems and can be maintained by untrained personnel. Further these systems have lower construction, maintenance and operation costs as these are driven by natural energies of sun, wind, soil, microorganisms, plants and animals. Hence, for planned, strategic, safe and sustainable use of wastewaters there seems to be a need for policy decisions and coherent programs encompassing low- cost decentralized waste water treatment technologies, bio-filters, efficient microbial strains, and organic / inorganic amendments, appropriate crops/ cropping systems, cultivation.

References

[1] Alqahtani, R., Nelson, M. I. & Worthy, A. L., A mathematical Model for the biological treatment of industrial wastewater in a reactor cascade. CHEMECA 2011(pp. 1-11). [2] L. D. Robescu et. al., Mathematical modeling of Sharon Biological Wastewater treatment Process, U. P. B. Sci. Bull. Series D, 74(1), 2102, pp. 229-236. [3] Anonymous. 2004. NATP – MM project report on ‘Use of Urban and Industrial Effluent in Agriculture’ CSSRI, Karnal 132001, India. [4] Journal of environmental Management, vol. 88, issue 3, August 2008, pp. 437-447. [5] Industrial wastewater reuses potential – internet (web) [6] Waste Management Strategies for industries. [7] U.S. Environmental protection Agency, Design criteria for Mechanical, Electric and Fluid system and Washington, D. C.,1974. [8] Raj kumar Agrawal and Piyush Kant Pandey, Productive recycling of basic oxygen furnace sludge in integrated steel plant. Journal of scientific and industrial Research, vol. 64, sept. 2005, pp. 702-706. [9] B. Das, S. Prakash, P.S.R. Reddy, VN Mishra, An overview of utilization of slag and sludge from steel industries, Resources, Conservation and Recycling Vol. 50, Issue1, March 2007, pp. 40-57.

Copyright

Copyright © 2022 Bharat Chandra Pandey, Sangita Gupta. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET46245

Publish Date : 2022-08-09

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online