Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Stabilization of Red Clay Soil using Rice Straw

Authors: Anusuri Uma Maheswari, M. Pavan Kumar, Pooja Kumari, G.V. Tanuj Varma, G. Haritha, M. Venu Gopal, P. Gayatri, B. Divya

DOI Link: https://doi.org/10.22214/ijraset.2022.44576

Certificate: View Certificate

Abstract

Infrastructure projects such as highways, railways, water reservoirs etc, requires earth materials in very large quantities. The foundation should have sufficient strength to support any land based structure. The soil surrounding the foundation plays a very important role. The strength of soil should be maintained according to the loading conditions. One of the most important aspect for construction purpose is to improve the soil strength i.e; stabilizing soil. Here, in this paper, soil stabilization is done by mixing of soil with the chemical treated rice straws fibers. The main motive of this analysis is to find out the utilization of waste rice straw fiber materials in foundation construction without open burning of waste so we can reduce the pollution which create by the open burning of rice straw in the fields.

Introduction

I. INTRODUCTION

Different types of soil present in India and every soil has its own characteristics. Some soils have good physical and mechanical properties and some soils have good fertility characteristics. According to the point of view of a geotechnical engineer, the soil should have good bearing capacity but such type of soil is not present in overall country so the soil reinforcement word has been introduce to solve this problem. Soil reinforcement can be define as the inserting of a strengthen material into the soil to increase the bearing capacity and stability characteristics of soil.

Soil stabilization involves the use of stabilizing agents (binder materials) in weak soils to improve its geotechnical properties such as compressibility, strength, permeability and durability. The components of stabilization technology include soils and or soil minerals and stabilizing agent or binders (cementitious materials). Soil stabilization aims at improving soil strength and increasing resistance to softening by water through bonding the soil particles together, water proofing the particles or combination of the two Usually, the technology provides an alternative provision structural solution to a practical problem.

Agricultural residue burning is a very big issue in worldwide because it creates lots off negative impact on our environment. It creates air pollution by increasing the amount of carbon in environment due to burning which cause climatic changes and global warming. The rice straw burning is a cause of methane emission. In this study we are analyzing rice straw because Rice straw ash have the good concentration of SiO2 as 40.07% .and 27.5% content of K2O.

II. LITERATURE REVIEW

- Nidhi Gautam, Sohit Agrawal, Mukesh Pandey, Nikhil Nandwani (2020),“ Effect of Mixing of Rice Straw to Enhance the Characteristics of Soil”: In this paper, soil reinforcement analysis completed with the mixing of soil with the powder produced from burning of rice straws fibers (parali) by an specific method. The main motive of this analysis is to find out the utilization of waste rice straw fiber materials in foundation construction without open burning of waste so we can reduce the pollution which create by the open burning of rice straw in the fields. They finally concluded that use of rice straw ash in soil improved the bearing strength of soil on in foundation construction and in slope stability as well.

- Serin Issac, Neethu Elizabeth John (2018), “Stabilization of Expansive Kuttanad clay using Lime treated Rice straw fibres”: In this thesis, a detailed study is undertaken to study the effect of Rice Straw as a reinforcement material in Kuttanad clay used as a pavement material. The study is intended to investigate the strength behaviour of the soil reinforced with randomly included Rice Straw fibres. The samples were reinforced with untreated Rice Straw. The untreated Rice Straw was added to soil in addition with Lime also. The reinforced soil samples were then subjected to Unconfined Compressive Strength, Light Compaction and California Bearing Ratio tests to study the effect of fibre reinforcement on Kuttanad clay. Different percentages of Rice Straw fibres (0.25%, 0.5%, 0.75%, and 1%) are added to the 6% lime stabilized soil. They found that maximum CBR value of 5.095 is obtained for 0.5% Rice Straw at optimum lime content of 6%.

- Aditya Kumar Anupama, Praveen Kumar and G D Ransinchung R N (2013), “Use of Various Agricultural and Industrial Waste Materials in Road Construction”: The main objective of this investigation is to assess the usefulness of agricultural and industrial waste as a soil admixture, and focused to improve the engineering properties of soil to make it capable of lower layer of road construction. Present investigation describes the behavioral aspect of soils mixed with industrial waste materials viz. fly ash (FA), rice husk ash (RHA) & bagasse ash (BA) and agricultural waste material rice straw ash (RSA) to improve the load bearing capacity of the soil. Clayey soil has been considered using four different types of stabilizer viz. FA, BA, RHA & RSA ranging from 5 to 35% by weight of soil. The physical and chemical properties of these stabilizers were ascertained and compared. Admixing of all these stabilizers improve soaked CBR values substantially and dramatic reduction in dry density was observed.

III. MATERIALS

A. Red Clay Soil

Red soils, generally called red clay soils, the red color of which results from the presence of iron oxide. It is considered an eco-friendly material, with many industrial, cosmetic, and architectural uses. Red soils, occupying about 66 percent of the State’s land area, are formed from granites, gneisses. The red clay soil sample is collected from Chaitanya Engineering College, kommadi, Visakhapatnam.

B. Rice Straw

Rice straw is a rice by-product produced when harvesting paddy. Each kg of milled rice produced results in roughly 0.7–1.4 kg of rice straw depending on varieties, cutting-height of the stubbles, and moisture content during harvest. Rice straw is separated from the grains after the plants are threshed either manually, using stationary threshers or, more recently, by using combine harvesters. The rice straw is collected from local shops.

IV. EXPERIMENTAL WORK

Soil sample location: Chaitanya Engineering College, Kommadi, Visakhapatnam,.

Rice Straw: Collected from local retailers

A. Mix Proportions

Rice Straw cleaned and dipped in NaOH solution and then dried it for some time and later used in soil sample.

Table 1: Proportion of Soil Samples

|

Sample No. |

Identification of Soil Samples |

% Rice Straw Added |

|

1. |

RCS0.0S |

0% |

|

2. |

RCS0.5S |

0.5% |

|

3. |

RCS1.0S |

1.0% |

|

4. |

RCS1.5S |

1.5% |

|

5. |

RCS2.0S |

2.0% |

|

6. |

RCS2.5S |

2.5% |

|

7. |

RCS3.0S |

3.0% |

???????B. Tests Conducted on Soil Specimen

- Specific Gravity Test on Soil: It is defined as the ratio between weight of soil solids to weight of equal volume of water. It is measured with the help of Pycnometer.

- Wet Sieve Analysis: This test is carried out for separating fine grains from coarse grains by washing the soil specimen on a 75-micron sieve mesh.

- Dry Sieve Analysis: This test is carried out on particles coarser than 75 microns. Samples (with fines removed) are dried and shaken through a set of sieves of descending size. The resulting data is presented as a particle’s distribution curve with grain size along x-axis (log scale) and percentage passing along y-axis (arithmetic scale).

- Liquid Limit: The Liquid Limit, also known as the upper plastic limit, is the water content at which soil changes from the liquid state to a plastic state. It is the minimum moisture content at which a soil flows upon application of very small shear force.

- Plastic Limit: The Plastic Limit, also known as the lower plastic limit, is the water content at which a soil changes from the plastic state to a semisolid state. The moisture content at which any increase in the moisture content will cause a semi-solid soil to become plastic. This limit is defined as the moisture content at which a thread of soil just crumbles when it is carefully rolled out to a diameter of 1/8 inch.

- Water Content determination by Oven Drying Method: The water content (w) of a soil sample is equal to the mass of water divided by the mass of solid, The moisture content of a soil sample is defined as the mass of water in the sample expressed as a percentage of the dry mass, usually heating at 1050C.

- Field Dry Density by Core Cutter Method: This method is comparatively accurate one in this method a core cutter (cylinder with cutting edge) is pushed into the ground with rammer blows. The cutter is then dug out of the ground, any soil protruding from its ends is trimmed off so that the volume of the soil contained within it is just equal to its own volume.

- IS Light Weight Compaction: The proctor compaction test is a laboratory method of experimentally determining the optimal moisture content at which a given soil type will become most dense and achieve its maximum dry density.

- California Bearing Ratio Test: CBR value of a soil is an index which is related to its strength, modulus of sub grade reaction, modulus of resilience and plasticity index. California bearing ratio is the ratio of force per unit area required to penetrate in to a soil mass with a circular plunger of 50mm diameter at the rate of 1.25mm / min.

V. TEST RESULTS

Table 2: Liquid Limit values of soil samples with varying percentages of Rice Straw

|

Soil Sample |

Liquid Limit |

|

RCS0.0S |

27.00% |

|

RCS0.5S |

29.39% |

|

RCS1.0S |

30.73% |

|

RCS1.5S |

32.00% |

|

RCS2.0S |

29.05% |

|

RCS2.5S |

28.00% |

|

RCS3.0S |

27.90% |

Table 3: Plastic Limit values of soil samples with varying percentages of Rice Straw

|

Soil Sample |

Plastic Limit |

|

RCS0.0S |

22.58% |

|

RCS0.5S |

25.51% |

|

RCS1.0S |

27.66% |

|

RCS1.5S |

29.13% |

|

RCS2.0S |

27.38% |

|

RCS2.5S |

25.03% |

|

RCS3.0S |

24.67% |

Table 4: Grain Size Analysis by Dry Sieve Method

|

S.No. |

IS Sieve

|

Mass of Soil Retained (gms) |

Mass of Percentage of Soil Retained (%) |

Cumulative Percentage of Mass of Soil Retained (%) |

Finer (%) |

|

1. |

4.75 mm |

42 |

4.2 |

4.2 |

95.8 |

|

2. |

2.80 mm |

24 |

2.4 |

6.6 |

93.4 |

|

3. |

2.36 mm |

10 |

1 |

7.6 |

92.4 |

|

4. |

1.40 mm |

30 |

3 |

10.6 |

89.4 |

|

5. |

1.18 mm |

30 |

3 |

13.6 |

86.4 |

|

6. |

600 µ |

208 |

20.8 |

34.4 |

65.6 |

|

7. |

300 µ |

312 |

31.2 |

65.6 |

34.4 |

|

8. |

150 µ |

262 |

26.2 |

91.8 |

8.2 |

|

9. |

90 µ |

48 |

4.8 |

96.6 |

3.4 |

|

10. |

75 µ |

14 |

1.4 |

98.0 |

2.0 |

|

11. |

Pan |

20 |

2 |

100 |

0 |

Table 4: Grain Size Analysis by Wet Sieve Method

|

S.No. |

IS Sieve

|

Mass of Soil Retained (gms) |

Mass of Percentage of Soil Retained (%) |

Cumulative Percentage of Mass of Soil Retained (%) |

Finer (%) |

|

1. |

4.75 mm |

0 |

0 |

0 |

100 |

|

2. |

2.80 mm |

10 |

1 |

1 |

99 |

|

3. |

2.36 mm |

0 |

0 |

1 |

99 |

|

4. |

1.40 mm |

20 |

2 |

3 |

97 |

|

5. |

1.18 mm |

20 |

2 |

5 |

95 |

|

6. |

600 µ |

136 |

13.6 |

18.6 |

81.4 |

|

7. |

300 µ |

208 |

20.8 |

39.4 |

60.6 |

|

8. |

150 µ |

226 |

22.6 |

62.0 |

38 |

|

9. |

90 µ |

76 |

7.6 |

69.6 |

30.4 |

|

10. |

75 µ |

14 |

1.4 |

71.0 |

29 |

|

11. |

Pan |

290 |

29 |

100 |

0 |

Table 5: IS Light Weight Compaction Test values of soil samples with varying percentages of Rice Straw

|

Soil Sample |

Maximum Dry Density (MDD) gm/cc |

Optimum Moisture Content (OMC) % |

|

RCS0.0S |

2.30 |

12% |

|

RCS0.5S |

2.10 |

4.0% |

|

RCS1.0S |

2.10 |

4.0% |

|

RCS1.5S |

2.00 |

6.0% |

|

RCS2.0S |

1.90 |

4.5% |

|

RCS2.5S |

1.90 |

6.0% |

|

RCS3.0S |

1.70 |

6.0% |

Table 6: California Bearing Ratio test values of soil samples with varying percentages of Rice Straw

|

Soil Sample |

CBR @ 2.5 mm Penetration(%) |

CBR @ 5.0 mm Penetration(%) |

|

RCS0.0S |

3.19 |

2.43 |

|

RCS0.5S |

3.60 |

3.00 |

|

RCS1.0S |

7.80 |

6.98 |

|

RCS1.5S |

14.61 |

13.70 |

|

RCS2.0S |

8.22 |

8.06 |

|

RCS2.5S |

7.98 |

7.67 |

|

RCS3.0S |

7.34 |

7.00 |

???????

???????

Conclusion

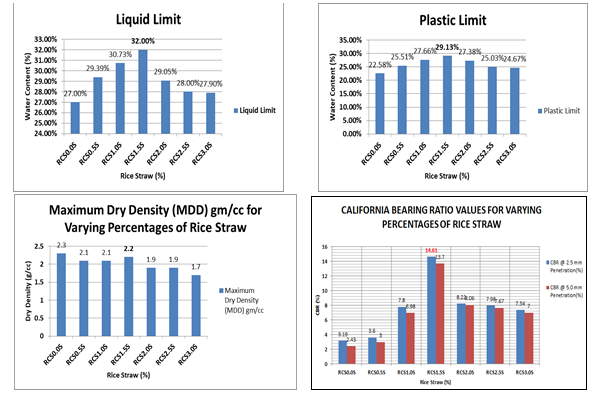

On the basis of present experimental study, the following conclusions are drawn: A. Based on Liquid Limit test on soil sample, with rice straw of 0%, 0.5%, 1.0%, 1.5%, 2.0%, 2.5% and 3% the increase in liquid limit value was found to be 27.00%, 29.39%, 30.73%, 32.00%, 29.05%, 28.00% and 27.90%. But beyond 1.5% the liquid limit value decreases to 27.90% at 3% rice straw. (illustrated in Chart-1). B. Based on Plastic Limit test on soil sample, with rice straw of 0%, 0.5%, 1.0%, 1.5%, 2.0%, 2.5% and 3% the increase in plastic limit value was found to be 22.58%, 25.51%, 27.66%, 29.13%, 27.38%, 25.03% and 24.67%. But beyond 1.5% the plastic limit value decreases to 24.67% at 3% rice straw. (illustrated in Chart-2). C. Based on IS Light Weight Compaction test on soil sample, with rice straw of 0%, 0.5%, 1.0%, 1.5%, 2.0%, 2.5% and 3% the increase in maximum dry density value was found to be 27.00%, 29.39%, 30.73%, 32.00%, 29.05%, 28.00% and 27.90%. But beyond 1.5% the maximum dry density value decreases to 27.90% at 3% rice straw. (illustrated in Chart-3). D. Based on California Bearing Ratio test on soil sample, with rice straw of 0%, 0.5%, 1.0%, 1.5%, 2.0%, 2.5% and 3%, the CBR value @ 2.5mm penetration was found to be 3.19%, 3.60%, 7.80%, 14.61%, 8.22%, 7.98% and 7.34% and CBR value @ 5.0 mm penetration was found to be 2.43%, 3.00%, 6.98%, 13.70%, 8.06%, 7.67% and 7.00% . But beyond 1.5% the CBR value @ 2.5mm penetration was found to be decreases to 7.34%, CBR value @ 5.0 mm penetration was found to be decreases to 7.00% at 3% rice straw. (illustrated in Chart-4). E. Overall it can be concluded that fiber reinforced soil can be considered to be good ground improvement technique specially in engineering projects on weak soils and the optimum % of rice straw was found to be 1.5%.

References

[1] Nidhi Gautam, Sohit Agrawal, Mukesh Pandey, Nikhil Nandwani ,“ Effect of Mixing of Rice Straw to Enhance the Characteristics of Soil”, International Journal of Innovative Technology and Exploring Engineering (IJITEE), vol 9, issue 8, June 2020, pp:656-658. [2] Serin Issac, Neethu Elizabeth John, “Stabilization of Expansive Kuttanad clay using Lime treated Rice straw fibres”, International Journal for Research in Applied Science & Engineering Technology (IJRASET), vol 6, issue 2, Feb 2018. [3] B. C Punmia, Seventh Edition, “Soil mechanics and foundation”, Luxmi Publication, New Delhi, (2017). [4] Aditya Kumar Anupama, Praveen Kumar and G D Ransinchung R N, “Use of Various Agricultural and Industrial Waste Materials in Road Construction”, Proceedings of the 2nd Conference of Transportation Research Group of India (2nd CTRG), IIT Roorkee,India, (2013) 264-273. [5] Junjun LIU, Chanjuan JIA and Chunxia HE, “Flexural properties of Rice Straw and Starch Composites”, Proceedings of the AASR Conference on Modeling, Identification and Control China, (2012) 89-94. [6] IS: 2720 (Part – 3), 1980 – Determination of Specific gravity. [7] IS: 2720 (Part – 4), 1965 – Determination of Sieve analysis. [8] IS: 2720 (Part – 5), 1985 – Determination of Liquid limit and plastic limit. [9] IS: 2720 (Part – 7, 8), 1980 – Determination of water content – Dry density of water reaction using light compaction and using heavy compaction. [10] IS: 2720 (Part – 31), 1990 – Determination of CBR

Copyright

Copyright © 2022 Anusuri Uma Maheswari, M. Pavan Kumar, Pooja Kumari, G.V. Tanuj Varma, G. Haritha, M. Venu Gopal, P. Gayatri, B. Divya. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET44576

Publish Date : 2022-06-19

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online