Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Study The Behaviour of Box Type Bridge with Different Height and Same Width for the IRC Loadings

Authors: Sarvesh Dubey , Gaurav Tiwari , Abhay Kumar Jha, Barun Kumar, Rajesh Misra

DOI Link: https://doi.org/10.22214/ijraset.2022.47528

Certificate: View Certificate

Abstract

Box type bridge designing process starts with the hydraulic calculation for a particular site of crossing. In this process catchment area along with its critical length of the river and fall in level is marked on the toposheet available in 1:50000 scale for a region. After getting the required data design discharge is calculated by using different methods given in IRC: SP: 13-2004 (Guidelines for the Design of Small Bridges and Culverts) and then finally span arrangement is decided for the required site of crossing. Once the span is decided then design of structure takes place. Box Type Bridge is a monolithic structure generally used when the safe bearing capacity of the soil is ascertained to be very less. Different structural member act as whole to resist the characteristic load for which it is designed.

Introduction

I. INTRODUCTION

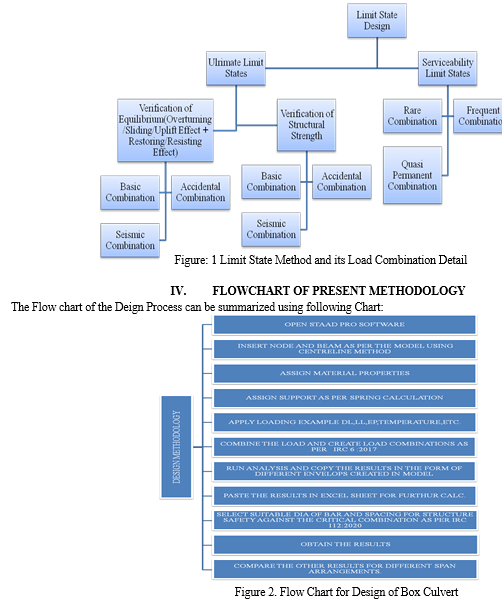

When a particular road is about to get constructed various number of structures are proposed in which around 60-80 % structures are generally box type structures. The reason behind this can be three-fold, one being easy to construct, two being economical and three boxes is a monolithic and a stable structure. When proposing a box type structure, same span arrangement along with different height, the result obtained is worth noting. The design of structure in present day is done using Limit State Method as per industrial practice. States beyond which the structure no longer fulfils the design criteria. Limit State Method is the combination of two state that is Ultimate Limit States and Serviceability Limit States. Limit State Method can be well understood through the following

II. LITERATURE REVIEW

Awad et al. (2008) This paper presents the results of a parametric study of wheel load distribution in four- sided precast concrete box culverts using three-dimensional finite element analysis (3D- FEA) as compared to the two-dimensional (2D) plane frame analysis. Maximum bending moments and deflections from the 3D-FEA results and the 2D frame analysis were computed and evaluated. Several concrete box culvert sizes were chosen with various span lengths, constant rise, and standard laying width. The culverts were subjected to various combinations of earth loading and AASHTO HS20 wheel loading applied at mid- span of the top slab. As the soil cover increases from 0 to 3 m, wheel loads are projected to the top slab using ASTM C890 procedure. The finite element results showed that the effect of wheel loading along mid-span is significant and that the edge loading condition for a single box is more critical than centre loading for soil cover less than 0.9 m. The earth loading tends to gradually dominate as the soil cover increases, which is expected based on geotechnical engineering practices. It was shown that the plane frame analysis and 3D-FEA gave similar results for long-span and non-standard box culverts. However, for short-span (3.6 m) concrete box culverts, the plane frame analysis was less conservative than the 3D-FEA by about 15% for moments; versus about 5% for long-span culvert (7.2 m). The results of this paper will assist bridge engineers in analysing and designing non-standard precast concrete box culverts and quickly replacing small bridges.

Chen et al. (2009) Concrete culverts in trenches have been widely used in expressways. Problems frequently take place because of improperly estimated vertical earth pressures on culverts. Different codes have been used in China to estimate the design load on culverts. In this study, a full-scale experiment and FEM simulation were conducted to evaluate the variation of vertical earth pressures and soil arching in backfill and to examine the accuracy of the methods recommended by different design codes including the prevailing Chinese General Code for Design of Highway Bridges and Culverts based on the linear earth pressure theory. The measured vertical earth pressures from the experiment were compared with those from the current theoretical methods. The variations of foundation pressure and settlement were also analyzed.

The FEM simulation investigated the key influencing factors on the vertical earth pressures including the height of the embankment fill, the width of the trench, the slope angle of the trench, the dimensions of the culvert, the properties of the backfill, and the elastic modulus of the foundation soil. This research reveals that soil arch formed when the backfill on the culvert reached a certain height, but it was unstable. The coefficient of the vertical earth pressure on the top of the culvert was significantly different from that recommended by the Chinese General Code for Design of Highway Bridges and Culverts.

Mohankar and Ronghe (2010) Presenting on "Analysis and Design of Underpass RCC Bridge" and stating that the Underpass RCC Bridge is very rarely implemented in bridge construction but is being used for traffic movement. Presented is an analysis of the RCC bridge underpass. In this case, we take the fixed end condition into account when analysing the RCC bridge underpass. In this study, FEM results are presented. Comparative force analysis between 3D and 2D models is provided for fixed end conditions.

Demane and Cholekar (2013) A parametric study on a RCC underpass bridge with soil structure interaction was conducted. Analysing the interaction of soil and structure during the modelling of a RCC bridge. Presented is an analysis of the RCC bridge underpass. An illustration of the interaction between soil structure and the concrete of this RCC underpass bridge is shown by considering its fixed ends and its different sections. The model is compared with results based on different forces considering a fixed end condition.

Kattimani and Shreedhar (2013) Culverts are required to be provided under earth embankment for crossing of water course like streams, Nallas etc across the embankment, as road embankment cannot be allowed to obstruct the natural water way. The culverts are also required to balance the flood water on both sides of earth embankment to reduce flood level on one side of road thereby decreasing the water head consequently reducing the flood menace. Culverts can be of different shapes such as arch, slab and box. These can be constructed with different material such as masonry (brick, stone etc) or reinforced cement concrete. Concrete culverts in trenches have been widely used in expressways. Box type structure with single cell or multiple cells can be effectively employed as Underpasses, Grade Separator, and Minor Bridges or as a Flyover also. This paper deals with study of some of the design parameters of box culverts like angle of dispersion of live load, effect of co-efficient of earth pressure and depth of cushion provided on top slab of box culverts. Depth of cushion, coefficient of earth pressure for lateral pressure on walls, width or angle of dispersion for live loads on box without cushion and with cushion for structural deformation are important items where opinion of the designers vary and need to be dealt in much detail. By the studies on cushion depth it is feasible to design box type of structure with 0 meter or no cushion which shall be safe for cushion loads which may become a necessity at future date due to change in road profile. From the study it is seen that the moments for no cushion are higher than the moments for a cushion of 5 meters.

Chen and Liang (2014). The performance of embankment installation (EI) and trench installation (TI) culverts has been investigated through experimental, numerical, and analytical methods. However, there are few studies on the performance of trapezoidal TI (TTI) culverts. Therefore, this study was performed to investigate the complex soil-structure interaction and to provide reference for the design of TTI culverts. First, field tests were conducted to measure the vertical earth pressure on the TTI culvert. Then, numerical simulations were performed to investigate the performance of TTI culverts. With the validation of the numerical model, parametric studies were carried out to investigate the important influencing factors (i.e., the slope angle of the trench, the bottom width of the trench, the culvert dimensions, and the stiffness of backfill adjacent to the culvert) on the culvert performance. This study reveals that the vertical earth pressure on the TTI culvert is significantly different from that on EI and TI culverts. The magnitude of the vertical earth pressure and deformation of the TTI culvert are influenced by the soil arches as long as the backfill is high enough. Generally, it is suggested that soil arch effects should be considered in the design of TTI culvert.

Tikate and Tande (2015) Reinforced concrete box culverts are widely used throughout the world to provide safe and relatively economical structures for the conveyance of water, vehicles, utilities, or pedestrians. Although single cell or multicell box culverts are rather simple structures, the loadings applied to these structures during their construction and subsequent service life can be complex. Problems frequently take place because of improperly estimated load of cushion on culverts and considered coefficient of earth pressure. Depth of cushion, coefficient of earth pressure for lateral pressures on walls, width or angle of dispersion for live loads on box culvert without cushion and with cushion for structural deformations are important items where opinion of the designers vary and need to be considered in much detail. Therefore, for live load, an attempt is made to study the effects of cushion, co-efficient of earth pressure (Ka) and width/angle of dispersion (θ).

Finite element method simulation was conducted to evaluate the effect of the variation of cushion depth, coefficient of earth pressure, width or angle of dispersion on the structural behavior of the three- dimensional box culvert and to examine the accuracy of FEM by comparing the FEM results with IS Code methods. The calculated bending moments, shear forces from the FEM were compared with those from the current theoretical methods which showed close correlation.

It is recommended to design box culvert structure without cushion condition along with Coefficient of earth pressure (Ka) = 0.5 & Angle of dispersion (θ) = 450 which will perform safely even in additional cushion loads which may come due to change in road profile. This work guides engineers using IS code in evaluating box culvert behavior under different cushion depths so that they can decide up to what depth of cushion, the box culvert need not be reconstructed during widening of roads. By the studies on cushion depth it is feasible to design box type of structure with 0 meter or no cushion which shall be safe for cushion loads which may become a necessity at future date due to change in road profile.

III. PRINCIPLES OF DESIGN

The design of structure in present day is done using Limit State Method as per industrial practice. States beyond which the structure no longer fulfils the design criteria. Limit State Method is the combination of two state that is Ultimate Limit States and Serviceability Limit States. Limit State Method can be well understood through the following Figure.

V. MODELLING

- Box type minor bridge is modelled and analysed in Staad Pro considering one meter strip of box.

- The results viz., shear force and bending moment are then taken into consideration for design obtained from the Staad pro.

- Loads are taken from the classifications as mentioned in IRC :6-2017

- Design of structure is done considering the IRC : 112-2020.

- The results are then compared for economy and durability.

VI. ACKNOWLEDGMENT

This work was completed with the grants and facilities of Lakshmi Narain College of Technology, Bhopal (M.P.). Authors are thankful to this institute and faculties for extending this cooperation.

Conclusion

Based on the above study following conclusions can be made: 1) All the structure components are analysed using Staad Pro Software and Designed using Excel and Codal provisions. 2) Structure is Designed using LSM Method. 3) IRC Codes shall be followed for load and its combination for all the analysis. 4) All the models are designed and results are then compared

References

[1] Amita H. Bhujade, Sandeep Gaikwad (2020),” Design of RCC Box Culvert with Comparative Study for Cushion and without Cushion Condition” \"ISSN No: 0932-4747. [2] Awwad, Elie | Mabsout, Mounir | Sadek, Salah | Tarhini, Kassim\"Parametric study of load distribution in four-sided concrete box culverts\" Journal: Bridge Structures, vol. 4, no. 2, pp. 99-107, 2008 [3] Chaithra U, Chandrakant Jadekar, Channaveeresha Havanagi, Charankumar Kamble, R Shanthi Vengadeshwari, 2021, Parametric Study on Single Cell Box Culvert Design Considerations-A Review, INTERNATIONAL JOURNAL OF ENGINEERING RESEARCH & TECHNOLOGY (IJERT) NCACE – 2020 (Volume 09 – Issue 01), [4] Chen, Baoguo & Sun, Liang. (2014). Performance of a Reinforced Concrete Box Culvert Installed in Trapezoidal Trenches. Journal of Bridge Engineering. 19. 120-130. 10.1061/(ASCE)BE.1943-5592.0000494. [5] Chen, Baoguo & Zheng, Jun-jie & Han, Jie. (2009). Experimental study on concrete box culverts in trenches. Frontiers of Architecture and Civil Engineering in China. 3. 73-80. 10.1007/s11709-009-0008-3. [6] Gong, Yafeng; Ma, Yulin; Tan, Guojin; Bi, Haipeng; Pang, Yunze;Experimental Study and Numerical Simulation on Failure Process of Reinforced Concrete Box Culvert , Advances in Civil Engineering; New York Vol. 2020, (2020). DOI:10.1155/2020/5423706 [7] Hoyoung Seo, Ph.D., P.E., M.ASCE; Timothy A. Wood, Ph.D.; Amir Hossein Javid; and William D. Lawson, Ph.D., P.E., M.ASCE , Journal of Bridge Engineering /Volume 22 Issue 10 - October 2017. [8] IRC: 112:2020-Code of Practice for Concrete Road Bridges [9] IRC: 5:2015-Standard Specifications and Code of Practice for Road Bridges (Section-I General Features of Design) [10] IRC: 6:2017-Standard Specifications and Code of Practice for Road Bridges (Section-II Loads and Load Combinations) [11] IS 456: 2000 “Plain and Reinforced Concrete Code of Practice” [12] Komal S.Kattimani, R.Shreedhar (2013) , “Parametric Studies Of Box Culverts” ISSN (Online): 2320-9364, ISSN (Print): 2320-9356 [13] Krihnaraju N., “Design of Bridges”, Fifth Edition [14] M V Afanador Arias, J S Pacheco-Posada , and N Afanador Garc´?a. (2022) “Numerical simulation of box culverts subjected to different physical actions and design” regulations doi:10.1088/1742-6596/2153/1/012002 [15] Mohankar.R.H & Ronghe.G.N (2010) “Analysis and Design of Underpass RCC Bridge”, International Journal of Civil and Structural Engineering, Volume 1, No 3, 2010, ISSN 0976 – 4399.

Copyright

Copyright © 2022 Sarvesh Dubey , Gaurav Tiwari , Abhay Kumar Jha, Barun Kumar, Rajesh Misra. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET47528

Publish Date : 2022-11-18

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online