Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

A Survey on Use of Non-Recyclable Waste in Construction

Authors: Prof. B. H. Chafekar, Mr. Suhan Kamble, Mr. Vedant Jadhav, Mr. Arya Dhankawade, Mr. Sujal Doshi

DOI Link: https://doi.org/10.22214/ijraset.2022.42694

Certificate: View Certificate

Abstract

Plastic waste is becoming extremely threatening to the environment due to their high quantities generated which pose serious harm to both the environment and its inhabitants. A major victim of this menace is the marine environment. Plastic wastes generated on land find their way to water bodies where they cause detrimental effects such as flooding and poisoning of the animals in the marine ecosystem. The plastics in the marine environment, which are ingested in fish, are also deleterious to human health if such fish are consumed. Cancer is a major disease that emanates as a consequence. In order to find an effective way to manage these wastes and improve the sustainability of our environment, this study, therefore, explores various approaches to recycling plastic wastes into new products. The critical threat of the presence of plastic wastes in our marine environment is also presented. The limitation of the use of plastic waste for construction applications alongside the prospects is discussed. It is concluded that the use of plastic wastes for construction applications will improve the sustainability of the environment significantly, and also serve as a reliable source of materials for construction purposes. In addition, the use of recycled plastic wastes as a component in cementitious composites has been found to be the most beneficial as it can be used to replace all solid components of the composite. Finally, areas for further studies are also presented.

Introduction

I. INTRODUCTION

A. Information

The items/material which used once are called non-recycle waste. It has very bad impact on Environment & humanity. The use of solid waste and recycled materials is becoming increasingly important in the construction practice for energy, natural resources, and environment conservation considerations. In the United States, significant quantities of waste are generated every year. The majority is landfilled at tremendous economic and environmental expense. One of the main reasons for low level of waste and recycled material utilization is the lack of quantified criteria to guide extensive use for a given waste material in special uses. The utilization of waste in the construction industry has two glaring dividends, one, environmental impact is addressed by disposal of the waste and second, the economic impact and this waste has the edge of being available large quantity, everywhere and at low value. Concrete3 being the widely used construction material in the world estimated up to 11 billion metric tons every year.

Typical concrete ingredients are cement, sand and coarse aggregate which are used universally for producing concrete. Due to the great utility of concrete, with the passing of each day these materials are getting deficient thus demanding for the alternatives.

It is off course a matter of serious concern for the civil engineers who are on the search of suitable materials which can fully or partially replace the typical concrete materials.

B. Items That Cannot Be Recycled

- Food-soiled Papers and Boxes: Contaminations can quickly be introduced into the recycling process when food contaminated materials are recycled. They stick to the machine used for recycling and end up delaying the task. Examples are pizza boxes, used paper plates, paper towels, and used napkins, etc.

- Plastic Grocery Bags: Contaminations can quickly be introduced into the recycling process when food contaminated materials are recycled. They stick to the machine used for recycling and end up delaying the task. Examples are pizza boxes, used paper plates, paper towels, and used napkins, etc.

- Rags and Cloth Material: Rags and cloth material cannot also be recycled; they are better deposited into the trash bin

- Glossy Material/ Plastic Coated Material: Glossy materials like juice boxes, chip boxes, frozen food boxes, and coffee cups cannot be recycled. They are lined with materials that make them hard to separate from paper.

- Styrofoam: Many recycling services in New Jersey do not accept recycling Styrofoam.

- Broken or Sharp Objects: A Broken object or sharp object should not be recycled as they can damage the machine used for recycling.

C. List of Materials which cannot be Recycle

II. LITERATURE SURVEY

- Youcef Ghernouti et al. The study presents the partial replacement of fine aggregate in concrete by using plastic fine aggregate obtained from the crushing of waste plastic bags. Plastic bags waste was heated followed by cooling of liquid waste which was then cooled and crushed to obtained plastic sand having finesse modulus of 4.7. Fine aggregate in the mix proportion of concrete was replaced with plastic bag waste sand at 10%, 20%, 30% and 40% whereas other concrete materials remain same for all four mixes. In fresh properties of concrete, it was observed from the results of slump test that with increase of waste content workability of concrete increases which is favorable for concrete because plastic cannot absorb water therefore excessive water is available. Bulk density decreases with increase of plastic bags waste. In harden state, flexural and compressive strength were tested at 28 days and reductions in both strengths with increasing percentage of plastic bag waste sand in concrete mix. Plastic waste increases the volume of voids in concrete which on other hand reduce the compactness of concrete simultaneously speed of sound in concrete is also decreased. Strength reduction in concrete mix was prime concern; however, they recommend 10 to 20% replacement of fine aggregate with plastic aggregate. Use of admixtures to address the strength reduction property of concrete with addition of plastic aggregate is not emphasized.

- Pramod S. Patil.et al. This study presents the use of plastic recycled aggregate as replacement of coarse aggregate for production of concrete. They used forty-eight specimen and six beams/cylinders casted from variable plastic percentages (0, 10, 20, 30, 40 and 50%) used as replacement of coarse aggregate in concrete mixes. They have conducted various tests and observed decrease in density of concrete with increase percentage of replacement of aggregate with recycle plastic concrete. They also reported decrease in compressive strength for 7 and 28 days with increase in percentage of replacement of coarse aggregate with recycle plastic aggregate. They have recommended feasibility of replacing 20 % will satisfy the permissible limits of strength. Again, these researchers limited their research to only compressive strength property and no work was carried out to study the other important properties of concrete. Their research also lacks use of various admixtures in concrete to cater for the loss in strength.

- Khilesh Sarwe. [2014] This study presents the results of addition of waste plastics along with steel fibers with an objective to seek maximum use of waste plastic in concrete. Two different categories of mix were casted in cubes (150mm x 150mm x 150mm), one with varying percentages of plastic wastes (0.2%, 0.4%, 0.6%, 0.8% and 1% weight of cement) and another mix of plastics waste/steel fibers (0.2/0.1, 0.4/0.2, 0.6/0.3, 0.8/0.4 and 1/0.5 % by weight of cement) to study the compressive strength at 7- and 28-days strength. The combine mix of plastic waste and steel fibers has shown more strength as compare to concrete mix prep only with plastic waste. He has reached to conclusion that a plastic waste of 0.6% weight of cement when used with steel fiber of 0.3 % (weight of cement) has shown the maximum compressive strength. This study has really focused on addressing the issue of reduced compressive strength with addition of plastic waste. Steel fibers when used along with plastic wastes will affect all the properties of concrete but the researcher only focused on compressive strength property which is insufficient to give clear picture of concrete behavior.

- Raghatate Atul M. The paper is based on experimental results of concrete sample casted with use of plastic bags pieces to study the compressive and split tensile strength. He used concrete mix by using Ordinary Portland Cement, Natural River sand as fine aggregate and crushed granite stones as coarse aggregate, portable water free from impurities and containing varying percentage of waste plastic bags (0%, 0.2%, 0.4%, 0.6% 0.8% and 1.0%). Compressive strength of concrete specimen is affected by the addition of plastic bags and with increasing percentage of plastic bag pieces compressive strength goes on decreasing (20% decrease in compressive strength with 1% of addition of plastic bag pieces). On other hand increase in tensile strength of concrete was observed by adding up to 0.8% of plastic bag pieces in the concrete mix afterward it starts decreasing when adding more than 0.8% of plastic bags pieces. He concluded that utility of plastic bags pieces can be used for possible increase in split tensile strength. This is just a basic study on use of plastic bags in concrete. More emphasis was required by varying the shape and sizes of plastic bags to be use in concrete mixes.

- R L Ramesh et al. They have used waste plastic of low density poly ethylene as replacement to coarse aggregate to determine its viable application in construction industry and to study the behavior of fresh and harden concrete properties. Different concrete mix were prepared with varying proportions (0%, 20%, 30% & 40%) of recycle plastic aggregate obtained by heat treatment of plastic waste (160-200 centigrade) in plastic granular recycling machine. A concrete mix design with 1: 1.5: 3 proportions was used having 0.5 water/cement ratio having varying proportion of plastic aggregate as replacement of crushed stone. Proper mixing was ensured and homogeneous mixture was prepared. A clear reduction in compressive strength was reported with increase in percentage of replacing plastic aggregate with crushed aggregate at 7, 14 and 28 days of casted cubes (80% strength achieved by replacing waste plastic up to 30%). The research highlights the potential application of plastic aggregate in light weight aggregate. Their research was narrowed down to compressive strength of concrete with no emphasis given to flexural properties of concrete. They suggest future research scope on plastic aggregate with regard to its split tensile strength to ascertain its tensile behaviour and its durability aspects for beams and columns.

III. PROPOSED METHODOLOGY

As Non recycle wastes like plastic bags, glass bottles, etc., cannot be broken down by decomposers, their disposal poses a big problem. Non-biodegradable wastes can be managed by practicing the concept of 3Rs Reduce, Reuse, and Recycle.

A. Reduce

We need to reduce the amount of waste generated by consuming more and throwing away less. We often buy more things than we really need. Nowadays, disposable items have become popular, for example, ballpoint pen, plastic bag, disposable napkins etc. We are using them frequently without giving a thought to their hazardous effects.

Here are some tips for reducing wastes:

- Use fountain pen in place of a ballpoint pen,

- Use old newspapers for packaging, and

- Use cloth napkins in place of disposable ones.

B. Reuse

We can reuse certain things for more than one purpose. If we reuse them for other purposes, we can help in reducing the waste. Here are some of the tips for reusing things:

- Small jars and bottles can be cleaned to keep some other kitchen stuffs.

- One should prefer glass bottle to metal can when buying juice or soft drink. The bottles can be refilled.

- Old clothes can be made into other usable items like cushion cover, handkerchief, etc.

- Old mobile phones can be donated to friends or family

C. Recycle

The process by which waste materials are used to make new products is called recycling. Materials like glass, metal, plastic, and paper are collected, separated, and recycled to make new things.

Recycling of Plastics

Bucket, bottle, toy, shoe, bag, pen, and comb are a few things made of plastic. Use of plastics has become a major concern nowadays because they are non-biodegradable and release harmful gases upon heating or burning. They can also contaminate foodstuffs. If eaten by animals, plastics can choke and kill them. Therefore, one should reduce and reuse plastic items as far as possible. When plastic items are to be discarded, they should be recycled to make new things.

Not all the plastics generated are recycled, hence causing much damage to life on Earth. In many places in India, plastics are totally banned seeing its adverse effects on the environment.

Some of the ways to reduce, reuse, and recycle plastics are as follows:

- Paper, cotton, and jute bag should be preferred over plastic bags.

- Some disposable plastic containers and jars can be used to grow plants.

- Empty bottles can be refilled for storage of water or any other liquid stuff. Think about the number of times you buy a bottle of water when you are out. Instead, you can fill the used bottle and carry it whenever you are out.

- Zip foils can be reused after cleaning thoroughly each time after storing foodstuffs.

Recycling of paper

Paper is made from trees and trees are essential for our survival on Earth. So, even if paper is biodegradable, depletion of trees at a fast pace is a big concern. Therefore, to save trees we must use paper carefully. Some of the ways to save paper are:

a. We should always write on both sides of paper sheets.

b. Unused pages from old notebooks can be torn off and made into a new notebook for doing rough work and other miscellaneous work.

c. We can also reuse envelopes and covers by using stickers to write new addresses.

d. We can also make fresh paper from old newspapers.

By now, we know how harmful garbage accumulation can be. But, by following the 3Rs concept, we can manage the garbage generated in our surroundings so that it is beneficial to the environment.

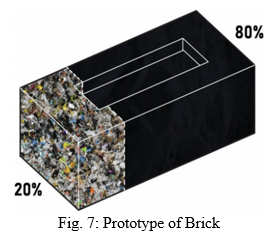

D. Details of Designs & Working and Process

- Plastic Brick: This brick is made of non-recycle plastic waste. It is made by mixing cement, fine aggregate, shredded plastic, & water in appropriate ratio.

a. Details & Designs of Plastic Brick

- Size of Brick: 19 × 12 × 8 cm [ L × W × H]

- Compressive Strength of Brick (N/mm^2): 61 kn

- Price of Brick in Market: Rs. 10/- to Rs. 16/-

- Ratio of Mixing: [ 1:3] where the mix comprised of 20% small and medium sized plastic flakes plus 80% fine aggregate and a water to cement ratio.

b. Prototype of Brick

c. . Resource required for making plastic-based bricks

- Brick Mold

- Coarse Sand / Fine aggregate

- Cement

- Shredded Plastic

- Water

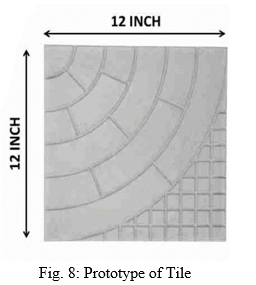

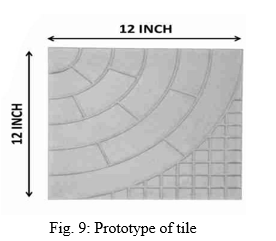

2. Demolition Waste Tile: This brick is made of non-recycle plastic waste. It is made by mixing cement, fine aggregate, shredded plastic, & water in appropriate ratio.

a. Details & Designs of Demolition Waste Tile:

- Size of Tile: 30cm × 30cm [ L × B]

- Compressive Strength of Tile (N/mm^2): 135 kn

- Price of Tile in Market: Rs. 20 - Rs. 30

- Ratio of Mixing: [ 1:3] where the mix comprised of 20% small and medium sized plastic flakes plus 80% fine aggregate and a water to cement ratio.

b. Prototype of Tile

c. Resource Required for Making:

- Tile Mold

- Coarse Sand and Fine aggregate

- Cement

- Demolition Waste (Brick and Concrete waste)

- Water

3. Carbon Tile: This brick is made of non-recycle plastic waste. It is made by mixing cement, fine aggregate, shredded plastic, & water in appropriate ratio.

a. Details & Designs of Carbon Tile

- Size of Tile: 30cm × 30cm [ L × B]

- Compressive Strength of Tile (N/mm^2): 129 kn

- Price of Tile in Market: Rs. 20 - Rs. 30

- Ratio of Mixing: [ 1:3] where the mix comprised of 20% small and medium sized plastic flakes plus 80% fine aggregate and a water to cement ratio.

b. Prototype of Tile

c. Resource Required for Making

- Tile Mold

- Coarse Sand and Fine aggregate

- Cement

- Carbon

- Water

IV. FUTURE ENHANCEMENT

The plastic bricks used for further in construction projects due to its light weight and economic purpose. The plastic use in the many forms in the construction like bricks, tiles, road pavements etc. When plastic used for this construction, the structures will be more economics and it have enough strength, durability, economic, high resistance of water and less wastage of materials.

Conclusion

In this Capstone Project, we understood the various problems on field which cannot be studied from the book but by experiencing and facing the problem on filed we can crack them. In this we have understood the real importance of Capstone Project. We faced many problems while doing the Capstone Project but with the help of MR. B. H Chafekar we managed to complete. We have learned so many new and different things from this project of Non-Recycle Waste is an important issue that needs governmental action quickly. At present there is very little awareness exists regarding this issue in our society. The practices of bringing forth waste are too risky not only for today but they could be dangerous for our future generation. After completing the Capstone Project, it is going to help me in different ways to become a successful civil engineer in life.

References

[1] J. Jambeck, B. Denise, A.L. Brooks, T. Friend, K. Teleki, J. Fabres, Y. Beaudoin, A. Bamba, J. Francis, A.J. Ribbink, T. Baleta, H. Bouwman, J. Knox, C. Wilcox, Challenges and emerging solutions to the land-based plastic waste issue in Africa, Mar. Policy 96 (2018) 256–263, doi:http://dx.doi.org/10.1016/j. marpol.2017.10.041. [2] P. Singh, V.P. Sharma, Integrated plastic waste management : environmental and improved health approaches, Procedia Environ. Sci. 35 (2016) 692– 700, doi:http://dx.doi.org/10.1016/j.proenv.2016.07.068. [3] EPA, Summary of Expert Discussion Forum on Possible Human Health Risks From Microplastics in the Marine Environment, EPA Reports, (2015) . https://www.epa.gov/trash-free-waters/epa-reports. [4] D. Lazarevic, E. Aoustin, N. Buclet, N. Brandt, Plastic waste management in the context of a European recycling society: comparing results and uncertainties in a life cycle perspective, Resour. Conserv. Recycl. 55 (2010) 246–259, doi:http://dx.doi.org/10.1016/j.resconrec.2010.09.014. [5] A. Alassali, M. Abis, S. Fiore, K. Kuchta, Classi?cation of plastic waste originated from waste electric and electronic equipment based on the concentration of antimony, J. Hazard. Mater. 380 (2019) 120874, doi:http://dx.doi.org/10.1016/j.jhazmat.2019.120874. [6] D. Xanthos, T.R. Walker, International policies to reduce plastic marine pollution from single-use plastics (plastic bags and microbeads): A review, Mar. Pollut. Bull. 118 (2017) 17–26, doi:http://dx.doi.org/10.1016/j.marpolbul.2017.02.048. [7] A.L. Andrady, Assessment of environmental biodegradation of synthetic polymers, J. Macromol. Sci. Part C- Polym. Rev. 34 (1994) 25–76, doi:http://dx. doi.org/10.1080/15321799408009632. [8] G. Swift, Degradable polymers and plastics in land?ll sites, in: encycl, Polym. Sci. Technol., American Cancer Society (2015) 1–13, doi:http://dx.doi.org/ 10.1002/0471440264.pst457.pub2. [9] I. Kyrikou, D. Briassoulis, Biodegradation of agricultural plastic ?lms: a critical review, J. Polym. Environ. 15 (2007) 125–150, doi:http://dx.doi.org/ 10.1007/s10924-007-0053-8.

Copyright

Copyright © 2022 Prof. B. H. Chafekar, Mr. Suhan Kamble, Mr. Vedant Jadhav, Mr. Arya Dhankawade, Mr. Sujal Doshi. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET42694

Publish Date : 2022-05-14

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online