Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Use of Plastic Waste in Concrete Pavement Construction

Authors: Nupur Dewangann, Shantam Ambastha, Rahul Dewangan, Rohit Patel, Aryan Singh Chandel, Tanishk Pandey

DOI Link: https://doi.org/10.22214/ijraset.2023.52823

Certificate: View Certificate

Abstract

The urbanization process contributes to the growth of solid waste generation and causes an increase in environmental impacts and failures in the management of solid waste. The number of dumps is a concern due to the limited implementation and safe disposal of this waste. The interest in sustainable techniques has been growing in relation to waste management, which is largely absorbed by the civil construction sector. This work aimed to review plastic waste, especially low density polyethylene (LDPE), that can be incorporated with construction materials, such as concrete, mortars mixtures, and paving. as a tool that allows the sustainability of products and processes to be enhanced in the long term. After analysing the recent literature, it was identified that studies related to plastic wastes in construction materials concentrate sustainability around the alternative destination of waste. Experimental investigation was carried out of to study various engineering properties such as workability, compressive strength, qualitative and quantitative study. It highlights various combinations of recycled plastic waste with normal grade concrete. This project investigates the influence of different percentage of shredded LDPE with concrete. Experimental result are holds good or bad as compared to normal concrete cured for 14 and 28 days. This study conducts the performance analysis and optimize the overall calculation for mix design.

Introduction

I. INTRODUCTION

The evolution of road industry and the tremendous surge in number of vehicles on roads has been a rationale that has promoted exploiting all viable available resources to build better roads of prolonged service life. Furthermore, the alarming rate of increased waste production is what underpin the efforts to investigate the potential incorporation of various by-products in road construction. The most dominant recycling materials that are in practice at present include plastic wastes which consists mainly of low density polyethylene (LDPE).

There are several ongoing researches and field studies that continues the investigation for better utilization of many recycled materials.

Aside from benefits and promising research recommendations and practical results obtained from using waste material as substitutions to natural raw materials, several barriers have road blocked the employment of recycled material by virtue of environmental concerns and the lack of real field experience with such materials.

Certain recycled material and waste by-products possess considerable salient properties over others and great benefits would be acquired when characterized properly and incorporated with some other construction materials. Recycling materials have been reported to be utilized in different composition in different layers of road structure from the top surfacing layer to the underneath layers.

The pro``cessing cost, the engineering properties, the evidence that demonstrate the viability of the material and its positive impact on the long-term performance of the road construction works are what characterizes and favors the use of that specific recycled waste material.

Many studies are there in which combination of plastic wastes in different forms are combined with concrete in order to find their influence in physical and chemical properties.

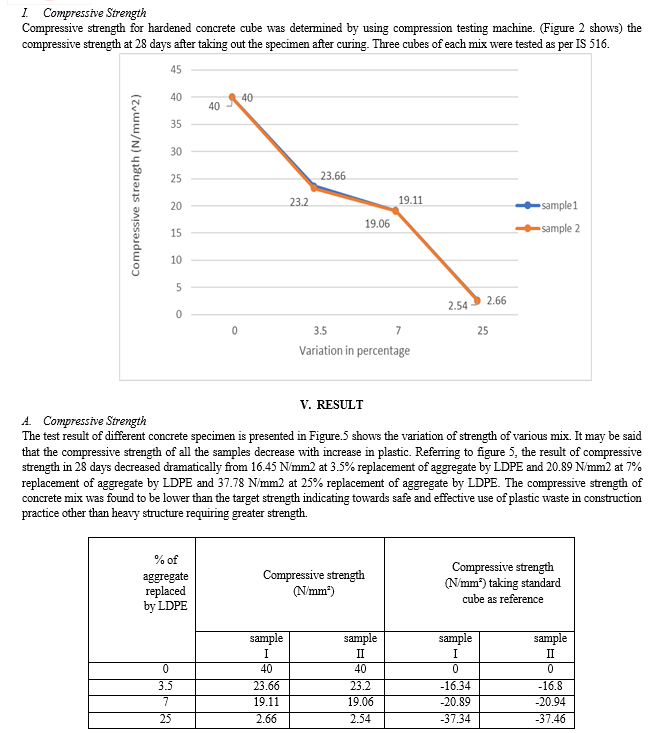

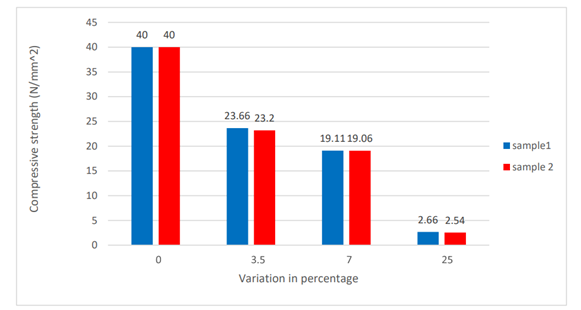

Here we have compared the change of compressive strength of concrete mixed with LDPE with respect to compressive strength of concrete of M40grade. The size of cube is 150x150x150 mm. Strength of concrete will be calculated after 28 days with different percentages of Ldpe by replacing the aggregate by weight.

II. REVIEW OF LITERATURE

- S. Vivek, P.Hari Krishna, T.D. Gunneswara Rao (2023) researched researched that when an effort is made to use the waste plastic as a partial replacement to fine aggregate and coarse aggregate in the preparation of concrete mix. The mechanical properties of concrete mix with and without plastic waste was determined and the conclusions are that the strength in compression of concrete mix with the addition of plastic waste decreases with increase in the percentage of plastic.

- M.A.A. Aldahdooh , A. Jamrah , Ali Alnuaimi , M.I. Martini, M.S.R. Ahmed , A.S.R. Ahmed concludes that their findings in this present study can contribute immensely toward the field of concrete technology and construction, where: The inclusion of the PWA tends to increase the water demand of GNC, which leads to a lower workability at a constant water content and also The highest compressive strength of GNC was found at 0.0% of [FA-PWAR] and at 0.0% of [FA-PWAR].

- Steve W.M. Supit , Priyono states from their experiment, it can be concluded that the size of the aggregate used affects the compressive strength of the pervious concrete where the 10–20 mm aggregate size generally provides a greater compressive strength than the 5–10 mm aggregate size. The use of smaller aggregate size lead to reduce the compressive strength of pervious concrete. When the plastic aggregate is involved, the optimum percentage of replacement using plastic waste as coarse aggregate in pervious concrete is 5%.

- Ibrahim Almeshal , Bassam A. Tayeh , Rayed Alyousef , Hisham Alabduljabbar , Abdeliazim Mustafa Mohamed , Abdulaziz Alaskar studied and concluded that Many researchers have exerted considerable effort to investigate the properties of mortar and concrete that contain plastic (recycled plastic). Their studies have produced different results (although the behaviour was often the same) depending on the type, size and proportion of plastic used. Concrete properties are reduced, but lightweight concrete is obtained. Plastic can thus be used in certain proportions in concrete, and research in this aspect continues.

- Khaja Musab Manzoor, Syed EhtishamUddin stated that in their experiment showed that the use of plastic waste and granite as a replacement for coarse aggregates in concrete can lead to a reduction in the self-weight of the resulting blocks. The proportion of granite in the mixture directly affected the self-weight of the blocks, with higher percentages resulting in increased weight. The compressive strength of the blocks showed a significant increase when about 20% of the coarse aggregates were replaced, but replacement beyond 25% led to decrease in strength.

- Md. Jahidul Islam, Md. Shahjalal, Niaz Md Ashraful Haque Based on the experimental program, the following conclusions can be drawn that the slump value increased up to 89%, with varying PP aggregate percentage and w/c ratio. The degree of workability of all PP concrete fell either in the high or very high category. Also averagely 5% and 10% density reduction can be achieved using 10% and 20% PP content.

- Sifatullah Bahij , Safiullah Omary , Francoise Feugeas , Amanullah Faqiri had results like Overall, the workability of concrete mixtures that contain waste plastic aggregates or fibers has been decreased as the amount of plastic wastes increased. Also Fresh and dry densities of the concrete containing both types of waste: plastic aggregates and plastic fibers have been decreased as the percentage of plastic wastes increased. Also concrete porosity and water absorption are remarkably enhanced as a higher amount of waste plastic aggregates being used in concrete mixtures.

III. OBJECTIVE

The objectives and scope of present study are:

- To study the compressive strength of cement concrete block by replacing aggregate (coarse + fine) by shredded LDPE in different percentages by weight.

- Use of industrial waste in a useful manner.

- To conduct compression test of concrete block on standard IS specimen size (150 x 150 x 150) mm.

- To provide economical construction material

- Provide safeguard to the environment by utilizing

IV. MATERIAL AND METHODS

All the materials are collected from various sources like suppliers and surrounding waste

A. Cement

In concrete mix, Ordinary Portland Cement of 53 grade was used in this project. Cement is a binder, a substance used in building that binds other materials together by setting, hardening, and adhering to them.

It has cohesive and adhesive properties in the presence of water. It is a product obtained by grinding clinker made by calcining raw materials consisting mainly of lime (CaO), silicates (SiO2), alumina (Al2O3), and iron oxides (Fe2O3). The standard density of cement is 1440 kg/m³. Care was taken to ensure that it was recent supply and free from adulteration.

B. Sand

Sand is made up of small, loose pieces of rock, soil, minerals, and even gemstones. It may also contain the remains of living things. Sand particles called grains, are smaller than gravel. They are larger than particles of mud or clay. Sand is used of 2.36mm passed particles.

Sand is obtained from supplies for laboratory work in Civil Engineering department. Sand is an important building material. It abundantly occurs in nature and is formed by the decomposition of rocks. Sand particles consists of small grains of silica (SiO2). It forms major ingredient in concrete. Lime mortar cement mortar etc.

C. Aggregates

The fine aggregates used are clean sharp sand and the virgin coarse aggregates are crushed boulder of maximum size of 20mm, both obtained from supplies for laboratory work of Civil Engineering department of Shri Shankaracharya Technical Campus Bhilai.

- Fine Aggregate: This is the aggregate for which its size ranges between 4.75mm to 0.075mm. This are also called sand. This are the natural particles that the mining process can generate. It consists of particles of the crushed stones or the sandy material.

- Coarse Aggregate: This aggregate have a size of more than 4.75mm. These aggregates are used in the construction of concrete structures. Such aggregates include river gravel and stone particles made from rock stratum.

D. LDPE (Low density Polyethylene) waste

Ldpe waste consist of milk pouches, water pouches , food packet , plastic bags and many other types of plastic waste having low density is collected.

Then washed properly two to three times by hand, then after drying properly and collection of around 10 kg of the waste, it is shredded collectively using industrial shredder machine.

E. Calcium Chloride (CaCl2)

Calcium Chloride is the most effective accelerator for concrete because of its strength and quality. Concrete is produced at an estimated rate of 9 BILLION cubic yards per year.

It is the most widely consumed substance on Earth, second only to water. If the temperature drops below 70 degrees, the setting of ready mix concrete slows down.

The effects are most significant in the 30 to 50 degree range. Calcium Chloride is used in cold weather ready mix concrete to improve this process.

Using Calcium Chloride in concrete produces an accelerated rate of hydration in cement. It warms the concrete mixture and allows workability of placement in cold weather. By using Calcium Chloride in ready mix, it develops high early strength.

F. Experimental studies

Test Set-up: In present experimental work, various concrete mix batches have been prepared such as, normal concrete - 0% replacement, 3.5% replacement, 7% replacement and 25% replacement of aggregate by LDPE. The testing is conducted on Universal Testing machine after 28 days.

G. Evaluation of Compressive Strength

Compressive strength is the most common test conducted on hardened concrete, partly because it is an easy test to perform, and partly because most of the desirable characteristic properties of concrete are qualitatively related to its compressive strength. To evaluate the compressive strength cubes of size 150 mm x 150 mm x 150 mm were casted using C.I. mold. A test was conducted on the cubes of grade M40 at 28 days.

Total four concrete mix batches were tested in which one mix was of normal aggregate concrete at 0% replacement and others at 3.5%, 7% and 25% aggregate replacement.

VI. ACKNOWLEDGMENT

We would like to express our proud sense of deepest gratitude to our guide and motivator Ms. Nupur Dewangan [Assistant professor], Civil Engineering Department, Shri Shankaracharya Technical Campus, Bhilai for his valuable guidance, sympathy and cooperation for providing necessary facilities and source during the entire project of this project. We wish to convey our sincere gratitude to all the facilities of Civil Engineering Department who have enlightened us during our studies. The facilities and co-operation received from the faculties of Civil Engineering Department is thankfully acknowledged. We express our thanks to all those who helped us in one way or other. Last, but not least, we would like to thank the authors of various research articles and books that wore referred to.

Conclusion

From the experimental work study of compressive strength of concrete, the following conclusion can be made:- 1) Using plastic wastes in concrete construction have to been found to be an appropriate solution to the problems of dumping hundreds of thousands tones of industrial and environmental waste. 2) Mixing plastic in concrete decreases its self-weight making it light weighted concrete. 3) This study shows that the compressive strength decrease as the amount of plastic content increases. 4) It was also found that as we increase the amount of plastic , workability of concrete decreases

References

[1] Aciu, C., Ilutiu-Varvara, D.-A., Manea, D.-L., Orban, Y.-A., Babota, F., 2018. Recycling of plastic waste materials in the composition of ecological mortars. Procedia Manuf. 22, 274–279. https://doi.org/10.1016/j.promfg.2018.03.042. [2] Afroughsabet, V., Ozbakkaloglu, T., 2015. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 94, 73–82. https://doi.org/10.1016/j.conbuildmat.2015.06.051. [3] Akçaözog, K., Atis, C.D., 2013. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Composites: Part B 45, 721–726. https://doi.org/10.1016/j.compositesb.2012.09.012. [4] Akçaözo?lu, S., Akçaözo?lu, K., Atis , C.D., 2013. Thermal conductivity, compressive strength and ultrasonic wave velocity of cementitious composite containing waste PET lightweight aggregate (WPLA). Compos. B Eng. 45, 721–726. https://doi.org/10.1016/j.compositesb.2012.09.012. [5] Al-hadithi, A.I., Hilal, N.N., 2016. The possibility of enhancing some properties of self-compacting concrete by adding waste plastic fibers. J. Build. Eng. 8, 20–28. https://doi.org/10.1016/j.jobe.2016.06.011. [6] Albano, C., Camacho, N., Hernández, M., Matheus, A., Gutiérrez, A., 2009. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manage. 29, 2707–2716. https://doi.org/10.1016/j.wasman.2009.05.007. [7] Aldahdooh, M.A.A., Jamrah, A., Alnuaimi, A., Martini, M.I., Ahmed, M.S.R., Ahmed, A.S.R., 2018. Influence of various plastics-waste aggregates on properties of normal concrete. J. Build. Eng. 17, 13–22. https://doi.org/10.1016/j.jobe.2018.01.014. [8] Aljerf, L., 2015. Effect of thermal-cured hydraulic cement admixtures on the mechanical properties of concrete. Interceram – Int. Ceram. Rev. 64, 346–356. https://doi.org/10.1007/BF03401142. [9] Almeshal, I., Tayeh, B.A., Alyousef, R., Alabduljabbar, H., Mustafa Mohamed, A., Alaskar, A., 2020. Use of recycled plastic as fine aggregate in cementitious composites: a review. Constr. Build. Mater. 253,. https://doi.org/10.1016/j.conbuildmat.2020.119146 119146. [10] Alqahtani, F.K., Ghataora, G., Dirar, S., Khan, M.I., Zafar, I., 2018. Experimental study to investigate the engineering and durability performance of concrete using synthetic aggregates. Constr. Build. Mater. 173, 350–358. https://doi.org/10.1016/j.conbuildmat.2018.04.018. [11] Ashwini, M.B.T., 2016. Partial replacement of E-plastic Waste as Coarse-aggregate in concrete. Procedia Environ. Sci. 35, 731–739. https://doi.org/10.1016/j. proenv.2016.07.079. [12] Azhdarpour, A.M., Nikoudel, M.R., Taheri, M., 2016. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete; [13] A laboratory evaluation. Constr. Build. Mater. 109, 55–62. https://doi.org/10.1016/j.conbuildmat.2016.01.056. [14] Bhogayata, A.C., Arora, N.K., 2018. Impact strength, permeability and chemical resistance of concrete reinforced with metalized plastic waste fibers. Constr. Build. Mater. 161, 254–266. https://doi.org/10.1016/j.conbuildmat.2017.11.135. [15] Bhogayata, A.C., Arora, N.K., 2017. Fresh and strength properties of concrete reinforced with metalized plastic waste fibers. Constr. Build. Mater. 146, 455–463. https://doi.org/10.1016/j.conbuildmat.2017.04.095. [16] Bui, N.K., Satomi, T., Takahashi, H., 2018. Recycling woven plastic sack waste and PET bottle waste as fiber in recycled aggregate concrete: an experimental study.Waste Manage. 78, 79–93. https://doi.org/10.1016/j.wasman.2018.05.035. [17] Cobîrzan, N., Balog, A.-A., Aciu, C., Ilut iu–Varvara, D.A., 2014. Sustainable uses of zeolitic tuff as building materials. Procedia technology 12, 542–547. https://doi.org/doi: 10.1016/j.protcy.2013.12.527. [18] Coppola, B., Courard, L., Michel, F., Incarnato, L., Scarfato, P., Di Maio, L., 2018. Hygro-thermal and durability properties of a lightweight mortar made with foamed plastic waste aggregates. Constr. Build. Mater. 170, 200–206. https://doi.org/10.1016/j.conbuildmat.2018.03.083. [19] Daniel, W., Pawel, ?., Gabriel, R., 2016. Application of fibres from recycled PET bottles for concrete reinforcement. J. Build. Chem. 1, 1–9. https://doi.org/10.17461/j.buildchem.2016.101. [20] F. Welle Twenty years of PET bottle to bottle recycling: an overviewhttps://www.sciencedirect.com/science/article/pii/S0921344911000656 [21] M. Patel et al. Recycling of plastics in Germany https://www.sciencedirect.com/science/article/pii/S0921344999000580 [22] P.M. Subramanian at Plastics recycling and waste management in the US https://www.sciencedirect.com/science/article/pii/S092134499900049X

Copyright

Copyright © 2023 Nupur Dewangann, Shantam Ambastha, Rahul Dewangan, Rohit Patel, Aryan Singh Chandel, Tanishk Pandey . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET52823

Publish Date : 2023-05-23

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online