Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Study of Composite Bricks from Sawdust and Cement

Authors: Ms. Mayuri Narsinge, Ms. Samruddhee Kamble, Mr. Jaydeep Saste, Ms. Rasika Kolte, Prof. Snehal Dethe

DOI Link: https://doi.org/10.22214/ijraset.2022.43523

Certificate: View Certificate

Abstract

Many timber producing countries generate more than 2 million m3 of sawdust annually. In developing countries, sawdust is often disposed of by open dumping, open burning, or dumping in landfills. The majority of wood sawdust wastes is accumulated from the countries all over the world and causes certain serious environmental problems and health hazards. This poses huge environmental challenges related to air pollution, greenhouse gas emission and destruction of plant and aquatic life. Finding from this experiment that sawdust can be used to make sawdust construction composites with good water absorption and strength characteristics. In this experiment concludes that partially replacing 10%, 20% and 30% of sawdust with sand and cement. Sawdust composites are also attractive for their low thermal conductivity, high sound absorption and good sound insulation characteristics. These findings indicate that increased utilization of sawdust composites in construction will mitigate against potential sawdust environmental pollution, conserve energy and reduce disposal costs. It shows a potential to be used for walls, wooden board substitute, economically alternative to the concrete blocks, ceiling panels, sound barrier panels, etc.

Introduction

I. INTRODUCTION

A. Information

Sawdust (or wood dust) is a by-product or waste product of wood working operations such as sawing, sanding, milling, planning, and routing. It is composed of small chippings of wood. These operations can be performed by woodworking machinery, portable power tools or by use of hand tools. Wood dust is also the by-product of certain animals, birds and insects which live in wood, such as the woodpecker and carpenter ant. The disposal of sawdust is often by open dumping, open burning, or dumping in landfills. Sawdust dumped in landfills increases the burden on landfill sites and burning it contributes to greenhouse gas emissions. Despite the air pollution and public health challenges associated with open burning, it is commonly practiced by saw millers as the easiest way to get rid of sawdust. When dumped on stream and river banks sawdust is transported by rainwater or wind into the surface water and can severely affect aquatic life. Moreover, sawdust indiscriminately dumped on land kills plant life and causes wood dust when blown into the atmosphere. Creating value from this waste stream would reduce disposal costs and create jobs. Additionally, utilizing wood-based products such as sawdust composites in construction contributes to climate change mitigation. Substituting steel, concrete, and other high energy manufactured products with sawdust composites has the potential to reduce the consumption of large amounts of fossil fuels. Considering that wood based products store carbon for the duration of their life cycle, the use of sawdust composites, accordingly, leads to reduced CO2 emissions and therefore mitigates against global warming. In some manufacturing industries it can be a significant fire hazard and source of occupational dust exposure. Sawdust, as particulates, is the main component of particleboard. Wood sawdust wastes are accumulated from different sawmills and would cause certain serious environmental problems and health hazards to man-kind if it remains in nature and would decompose. In most forest industry clusters, the volume of wood waste generated is very enormous and constitute a nuisance to the environment. In most cases, the wood waste piles up to form big heaps which disturb activities within the mills. The heaps of the waste are burnt for days, disturbing visibility and causing pollution, thereby endangering health of residents, motorists and passersby. Sawdust is one of the organic waste products being tested in a bid to produce bricks with enhanced heat insulation properties.

If we bear in mind the volume of trees that are felled every year (over 400 million m3 since the year 2000 in the European Union in the production of firewood for fuel, sawn wood, veneers, pulp and paper, one can imagine the huge amounts of sawdust generated during sawing. In chemical terms, sawdust is composed approximately of 60% carbon, 34% oxygen, 5% hydrogen and 1% nitrogen. The organic polymers of which it is composed are essentially cellulose and lignin. Wood is often treated with varnishes and resins, both during sawing and storage, so as to guarantee better conservation. Sawdust typically has variable grain sizes, colours and consistencies depending on the type of Wood being sawn.

B. Aims and objectives

- To prepare cement bricks by adding sand and wood saw dust in different volume proportions of ( 10%, 20%, 30%) sawdust.

- The effect of cementious materials & curing condition on the compressive strength of concrete also analyzed for a period of 3, 7 & 28 days.

- To compare the obtained result of our manufacture brick with the standard brick.

C. Problem identification

- The weight of standard bricks is non uniform and heavy.

- The demand of wood and wood materials is increasing day by day and amount of waste material of wood is also increasing rapidly. There no specific and fix technique for recycling and disposed for waste material of wood.

II. LITERATURE SURVEY

A. A.Zziwa, S. Kizito1 , A. Y. Banana, J. R. S. Kaboggoza, R. K. Kambugu and O.E. Sseremba, “Production of composite bricks from sawdust using Portland cement as a binder”, 1 June 2006 : A study was conducted between October 2004 and April 2005 in Kampala District, with the objective of investigating the feasibility of making sawdust-cement composites using saw dust. A total of 48 bricks were made in the Faculty of Forestry and Nature Conservation laboratory based on volume ratios of sawdust to cement (3:2 and 2:1). Mass was measured using a weighing balance and density calculated from mass and volume of the bricks. The composites were tested for compressive strength using a universal testing machine, as they cracked due to compression. The mean compressive strength values were 1.61 N mm-2 and 1.986 N mm-2 for 50 x 50 x 50 mm composites with sawdust to cement ratios of 3:2 and 2:1 respectively; and 1.778 N mm-2 and 2.21N mm-2 for 100x100x100mm composites with sawdust to cement ratios of 3:2 and 2:1 respectively. Analysis of variance (ANOVA) indicated significant differences (P<0.05) in strength values of the two compositions. Soaked composites swelled irrespective of the cement to sawdust ratio. The compressive strength for the soaked bricks was approximately 40% of the dry weight strength. The composite bricks were found to be unfit for paving and medium heavy load wall construction. Due to their light weight, by imparting decorative mosaics they can be used for interior wall paneling and decoration, where minimal wetting is experienced.

B. David OriabureEkhuemelo, OwoichoAdemu, EmmanualTerzungwueTembe, “Physical and strength properties of bricks produced from portland cement and saw dust of DanieliaOliverii wood”, 2016: This study investigated the use of sawdust as partial replacement for sand in wood-concrete hollow blocks. Sharp sand, ordinary Portland cement (binder) and sawdust were used as raw materials. Sawdust was treated by boiling then sieved after drying using British Standard sieve of 3.35mm to remove sticky wood capable of causing pores. The quantities of sawdust used were 0%, 5%, 10%, 15% and 20%. A mixing proportion of 1:8 cement sand ratio, moulding machine with single 6” (450mm x 225mm x 150mm) mould and vibrated with 5.0KW power machine for adequate compaction were used. Wood-concrete block was cured for 28 days. The blocks produced were tested for compressive strength and water absorption.

The results showed that mean compressive strength of 100% sand was 2.81N/mm2 followed by 95% sand and 5% sawdust replacement with 1.58N/mm2 ; 90% Sand and 10% sawdust replacement with 0.55N/mm2 ); 85% sand and 15% sawdust replacement with 0.43 N/mm2 and 80% sand 20% sawdust replacement with 0.24N/mm2 . The result further showed that as the percentage of sawdust increased, the compressive strength decreased. At 28 days, the compressive strength of blocks with 5% SD replacement satisfied meets Ghana Building Code for non- load bearing walls.

The results also reveals that blocks with 80% sand 20% sawdust replacement level has the highest water absorption (23.72%) followed by 85% Sand and 15% sawdust replacement (20.40%); 90% sand and 10% sawdust replacement (18.0%); 95% sand and 5% sawdust replacement (12.12%) and 100% sand and 0% sawdust replacement (11.43%). It was concluded that 5% sawdust (8kg) replacement and cured 28 days could be used for non-load bearing walls. It was recommended that further research should be carried out to evaluate sawdust replacement level within the range of 1-4% to ascertain results that could be used for various other purposes.

C. Mushtaq Ahmed, Mahzuz HMA, Rakash Kumar Mondal, Md.Sal-Shabil, “Production of Lightweight Bricks using Sawdust”, 24 July 2020 Clay bricks are widely used for building construction in Bangladesh. Due to rapid urbanization, use of clay bricks is increasing exponentially which leads to air pollution, as well as huge degradation of topsoil from the agricultural lands. Besides, clay bricks increase dead load of structure as they are heavy. In order to minimize these problems, techniques must be innovated for production of low-cost lightweight and eco-friendly bricks. In this study, an attempt was taken to assess the potentiality of locally available saw dust instead of clay to produce lightweight eco-friendly bricks. Total 16 different ratios of cement, saw dust and sand have been taken to prepare samples of saw dust bricks. Compressive strength, unit weight, water absorption rate, fire sensibility and cost of production per brick were analyzed for each type of bricks and compared. The result shows that the compressive strength of bricks was satisfactory for lower percentage of saw- dust. Unit weight of saw dust bricks were reduced by 2 – 42.8 % than that of clay brick and water absorption rate was very low. There was no significant difference between strength of burnt and the unburnt saw dust bricks. Price of saw dust bricks is not higher than that of clay bricks.

D. A. Abdullahi, M. Abubakar, A. Afolayan, “Partial Replacement of Sand with Sawdust in Concrete Production”, May 2013: In this study Sawdust as an air-entraining agent has no appreciable positive effect on the compressive strength of concrete. Variation in the compressive strength results is traceable to the fact that it is difficult to obtain sawdust which is not a mixture of several species. A possibility exists for the partial replacement of sand with sawdust in the production of lightweight concrete.

E. Darweesh H.H.M, Kenawy S.H, “Light-weight highly porous building bricks from sawdust”, 2020: The present study shows the possibility to produce Light-weight high porous building bricks with a high mechanical performance from the clay batches containing 0, 4, 8, 12 and 16%, wt. sawdust. The water absorption and apparent porosity of the prepared ceramic bodies were increased with the increasing of the sawdust content, while the bulk density was decreased. The results of compressive strength are in a good agreement with those obtained with water absorption, bulk density, and apparent porosity. Consequently, the optimum batch composition is that containing 12% wt. sawdust fired 1000 oC for 3 hours soaking times. The XRD analysis for the optimum brick batch fired at 1000 0C for 3 hours was detected walstromite phase (BaCa2Si3O9 Card No: 5177), the quartz phase was detected too in the sample containing 12 wt.% saw dust. The SEM of the sample has no additives fired up to 1000 oC for 3 hrs showed a large amount and volume of open pores the grains were clustered together forming cavities. The resulting light-weight high porous building bricks are suggested to use as isolating bricks for heat in hot countries and maybe even for cold in the cold countries.

III. PROPOSED METHODOLOGY

- First of all, we collect the information about cement sawdust brick.

- After that we discuss and study about it.

- After that we calculate the proportion of the material needed for making the bricks.

- As per the proportion we have taken the weight of material.

- After that we had made (10%, 20%, 30%) brick and one without sawdust.

- Then oil is applied to all sides of mould for proper finishing.

- After oiling process, we mixed the mixture of cement, fine Aggregate, sawdust with specific water cement ratio.

- After proper mixing of all this ingredients, it is placed in the mould and proper compaction is done to remove the air voids.

- After 24 hours the brick is de mould, and Curing is done at regular intervals of time.

- Then we tested the compressive strength of the bricks in UTM machine and record the results.

IV. TESTING AND RESULTS

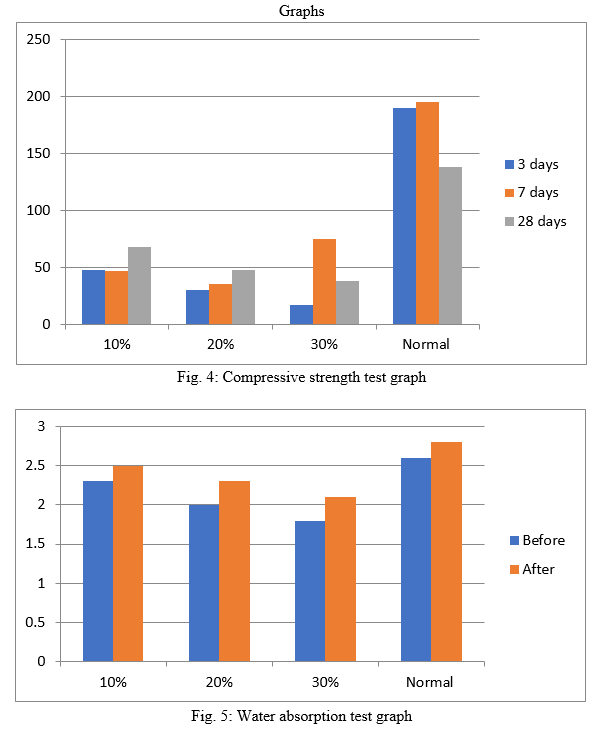

- Compressive Strength Test: Compressive strength test, mechanical test measuring the maximum amount of compressive load a material can bear before fracturing. The test piece, usually in the form of a cube, prism, or cylinder, is compressed between the platens of a compression-testing machine by a gradually applied load.

2. Water Absorption Test: The water absorption test determines the water absorption rate of both the outer and inner concrete surfaces. The test involves the measurement of the increase of mass of concrete samples resulting from the absorption of water as a function of time when only one face of the specimen is exposed to water.

V. FUTURE ENHANCEMENT

Sawdust is a recyclable waste and a raw material that is readily available and easily accessible in many timber producing countries. It can be collected and transported at minimal cost and energy when compared with the cost and energy required in exploiting natural resources. Value addition to this waste by incorporating it in the production of construction composites will address the quest for eco-friendly and energy efficient materials in building and construction contribute to a pollution-free environment and create employment.

Conclusion

As we know many timbers producing countries generate sawdust as a waste annually. This waste is disposed by open damping, burning or land filling which may be causes certain serious environmental problems and waste hazards. In this project we cast bricks using the sawdust waste. We added sawdust in certain proportion for manufacturing bricks and carried out on it. Sawdust was added as 10%, 20% and 30% replacement of cement for manufacturing bricks. From test results we conclude that for 10% replacement of cement with sawdust we get sufficient compressive strength. As we are suggesting using this bricks for partition purpose the obtained strength is sufficient. Also percentage of water absorption for 10% mix is minimum.

References

[1] A.Zziwa, S. Kizito1 , A. Y. Banana, J. R. S. Kaboggoza, R. K. Kambugu and O.E. Sseremba, Production of composite bricks from sawdust using Portland cement as a binder, Vol.12 No. 1 June 2006 URL: https://www.researchgate.net/publication/228467151 [2] David OriabureEkhuemelo, OwoichoAdemu, EmmanualTerzungwueTembe, Physical and strength properties of bricks produced from portland cement and saw dust of DanieliaOliverii wood, Vol. 12 N° 4 2016 URL: https://www.researchgate.net/publication/312218200 [3] Mushtaq Ahmed, Mahzuz HMA, Rakash Kumar Mondal, Md.Sal-Shabil, Production of Lightweight Bricks using Sawdust, 2020 URL:https://www.researchgate.net/publication/343214282_Production_of_Lightweight_Bricks_Using_Saw_Dust [4] A. Abdullahi, M. Abubakar, A. Afolayan, Partial Replacement of Sand with Sawdust in Concrete Production, 2013 URL:https://www.researchgate.net/profile/MahmudAbubakar/publication/264346663_Partial_Replacement_of_Sand_with_Sawdust_in_Concrete_Production/links/53d937190cf2e38c6331f3fe/Partial-Replacement-of-Sand-with-Sawdust-in-Concrete-Production.pdf [5] Darweesh H.H.M, Kenawy S.H, Light-weight highly porous building bricks from sawdust, 2020 URL:http://www.discoveryjournals.org/engineering/current_issue/2020/v17/n47/A15.pdf

Copyright

Copyright © 2022 Ms. Mayuri Narsinge, Ms. Samruddhee Kamble, Mr. Jaydeep Saste, Ms. Rasika Kolte, Prof. Snehal Dethe. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET43523

Publish Date : 2022-05-29

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online