Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Modify and Convert Conventional Lathe Machine to Special Purpose Lathe Machine Operated using CNC Unit

Authors: Mr. Gaurav B. Nagare, Mr. Shubham S. Bachhav, Mr. Ajay N. Shelar, Mr. Vivek R. Chaudhari, Prof. Mugdha V. Bhadak

DOI Link: https://doi.org/10.22214/ijraset.2023.53227

Certificate: View Certificate

Abstract

Products are manufactured using modern technology nowadays that uses communication between computer software, hardware and firmware, and lathes play an important role in production. While manual machine lathes are more economical, they have to be made by skilled workers, which limits their precision and poor performance, on the other hand, CNC machines provide the accurate and good results needed, but cost a lot of money. This can be done using ARM. The processor is used to control the work of the lathe. Retrofit is a way to use new technologies and features to improve the performance and security of legacy systems. Since the machining process takes a long time, retrofit applications can be made on traditional lathes. Also, in this traditional turning job, the results are not the same as the result of the work piece depends on the skill of the operator. For this reason, a new design has been created to maintain this lathe and increase its lifespan. Rebuilding and remanufacturing often involves CNC rebuilds.

Introduction

I. INTRODUCTION

Traditional manual machines are time-consuming and labor intensive and manufacturers need to think and use new ways to make the machine more efficient by creating products with digital control systems. Retrofit is the process of replacing CNC, servo and spindle systems to extend the life of a machine tool. Rebuilding and remanufacturing often involves CNC rebuilds. Expected benefits include lower capital costs and increased uptime and availability from purchasing new machines. Investment is like any other investment.With all the financial costs and benefits, you can calculate theROI of CNC refurbishment, which is usually the lowest cost to improve the overall performance of the old machine. While some electrical assembly is usually done at the tuner's workplace, most of the work can be done on site at the machine, avoiding expensive machine assembly and shipping costs and reducing machine time.Today, products are manufactured using modern technology that uses communication between computer software, hardware and firmware, and machine tools play an important role in production. While manual lathes are more economical, they must be made by skilled workers, which limits their high performance and low performance, while CNC lathes are well done and results are good but require a lot of capital. Retrofit is a way to use new technology and features to improve the performance and security of legacy systems.Since the machining process takes a long time, retrofit applications can be made on traditional lathes. So in this traditional turning job, the result is not the same as the result of the workpiece depends on the skill of the operator. So this lathe has a new design that controls it and makes it last longer. Rebuilding and remanufacturing often involves CNC rebuilds. Therefore, the flexibility of traditional lathes based on the skills of previously experienced workers will be increased.

II. OBJECTIVES

- The retrofitting of a lathe machine is to improve the existing conventional lathe machine to provide it features of CNC machine with very lower cost than a new CNC Lathe machine.

- To get Increased productivity and improved control of machine.

- To Obtain Fast machining cycles, High accuracy and high feed-rate

- To reduce machine downtime during production.

- To increase accuracy and part finish due to controller Unit.

- To Eliminate additional tooling cost.

- The Up-gradation Package is less expensive and more readily justifiable.

III. SCOPE OF OUR PROJECT

- After modification of this conventional lathe machine to CNC, Multiple Required Machining Operation like Turing and Facing will be performed on one machine.

- In modified CNC Machining Operation will be performed one after another which will save Efforts, Man Power and Time.

- No Manual operation‘s will be required, all the machining Operations will performed by providing Programme to CNC.

- The manufactured product will have good precision due to no manual operation, so that, product rejection ratio will be very less.

IV. LITERATURE REVIEW

This chapter sets the background for up-coming sections. It is an assessment of the present state of art of wide and complex field of Research done in the field of advanced automation analysis of conventional lathe machines.

- Nagraj Patil and Arunkumar D T carried study that explores the use of computer hardware and firmware to upgrade traditional machines to semi-automatic lathe control machines. They focus on the mechanical and electronic components required for retrofitting traditional machines and highlight the use of a Digital Intelligence System (DIS) to accurately measure and shape high-end items. The chapter also discusses the importance of reducing costs while maintaining accuracy and dimensional strength. A lathe-mill RMT is introduced as a practical and budget-friendly solution. The chapter concludes by emphasizing the need for further research and testing of the proposed techniques.

- Roshan N. Shirke, Makarand B. Khalde, Devang M. Prajapati, Punam S. Tonde, and Prof. L. M. Rathod conducted research on converting a conventional lathe into a semi-automatic CNC machine. In traditional small workshops and industries, operations like turning, milling, and drilling are performed using conventional lathes. However, modern technologies like computer software, hardware, and firmware have made it possible to achieve more accuracy and better finishing using CNC machines. As a result, CNC machines are increasingly important in modern industrialization. To modernize traditional lathes, the researchers proposed retrofitting them into semi-automatic CNC machines. This involved replacing and adding some parts to the conventional lathe. As a result of the retrofitting, the production rate increased compared to using a conventional lathe. The retrofitted semi-automatic CNC was also suitable for mass production and did not require skilled labor. Since it is computer-controlled, it eliminated the danger to workers. Furthermore, the cost of retrofitting a conventional lathe into a semi-automatic CNC machine was four times less than buying a new CNC machine on the market.

- Perry S. Koradiya, Aman H. Kania, Himanshu S. Wankhede, Parth A. Patel, form this research paper we get the information of the how they reduce the cost of CNC machine by converting the conventional lathe machine into CNC operated lathe machine. While manual lathe machines are economical, they require skilled workers for accuracy and efficiency. On the other hand, CNC machines offer the can get required output but require a large capital investment. So the researchers developed automation in conventional lathe machines by retrofitting stepper-based methods, making it a suitable CNC trainer for students. They retrofitted bench lathe machine was developed by replacing or removing components from the conventional lathe machine, resulting in a higher production rate and accuracy of the manufactured parts. While the machine cost is higher than a standard lathe machine, it is a cost-effective option for mass production. Additionally, the retrofitted lathe machine we can manufacture the complex parts that are not possible to manufactured in the conventional lathe machine. The cost of this retrofitted CNC training is approximately 4 times lower than the standard CNC machine.

- Sutarman, Haryono EdiHermawan, and Sarmidi, done the work on, CNC (Computer Numerical Control) milling and turning machining processes used in Xintai Indonesia. A CNC machine tool is a computer-controlled machine that uses command data code in the form of numbers, letters, and symbols following the ISO standard. These machines are more accurate, precise and suitable for mass production. They are designed to support production and require a high level of complexity, reducing operator intervention during machine operation. The cutting process of a CNC machine tool involves processing a workpiece as the object being processed. The program can be modified to process a new job. CNC is an automation system for machine tools that operates according to programmed instructions in numeric code stored on a storage medium. There are two types of CNC machines, namely Lathes (Turning Machines) and machinery frais (Milling Machines). The operation of a CNC machine tool involves cutting the workpiece using a chisel instructed by the CNC (Computer Numerical Control) to drive a chisel on a machine tool on the workpiece. The coordinate system of CNC milling and turning machines includes three axes: X, Y, and Z. The X-axis is a moving horizontal axis, the Y-axis is a transverse axis, and the Z-axis is a vertical axis that moves. Programming language in CNC machine tools including the giving instructions in one block to another block using code letters, numbers, and symbols (Numerical System). The computer device in CNC machines is called the Machine Control Unit (MCU), which translates the code language into the appropriate for the movement on the shape of the workpiece. The codes of language in CNC machine tools are called G and M codes, which are standardized by ISO and International Standards.

V. PROBLEM STATEMENT

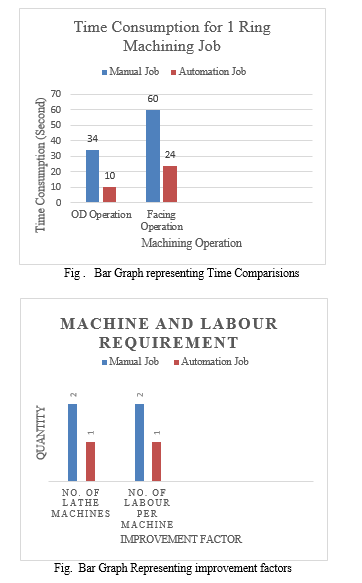

The Project Work Focuses on Removing the Manual Machining Job Work on Lathe Machine‘s in the Industry which currently consists of different Manual Operations like OD Turning and Facing on Rings required for Gear Manufacturing and has many issues, we are going to Modify and Convert Conventional Lathe Machine to Special Purpose CNC Operated Lathe Machine using CNC Computer Unit and Components according to the Industry Requirements.

VI. STUDIES AND FINDINGS

- Retrofitting Technique: Discuss the process of retrofitting, which involves adding a CNC unit to a conventional lathe machine to enhance its capabilities and functionality.

- Benefits of Conversion: Highlight the advantages of converting a conventional lathe machine to a CNC-controlled special purpose lathe. These benefits may include improved accuracy, higher productivity, increased automation, and the ability to perform complex machining operations

- Performance Evaluation: Explore studies that measure and compare the performance of converted CNC lathe machines with conventional lathes. Look for findings related to factors such as accuracy, repeatability, surface finish quality, and energy efficiency.

- Design Considerations: Discuss important design considerations when modifying the lathe machine, such as motor and power calculations, CNC unit selection, structural modifications, tooling and cutting parameters, safety considerations, and space and ergonomics.

- Application-specific Modifications: Highlight case studies or research papers that focus on converting lathe machines for specific applications or industries. This can include modifications tailored for tasks like thread cutting, contour turning, micro-machining, or high-speed machining.

- Cost-effectiveness: Evaluate the economic aspects of the conversion process, considering the initial investment, operational costs, maintenance requirements, and potential productivity gains. Discuss studies or reports that analyze the cost-effectiveness and return on investment of converting conventional lathe machines to CNC-controlled special purpose machines.

- Human Factors and Training: Address the impact of the conversion on operators' skills, training requirements, and work ergonomics. Discuss findings related to operator proficiency, training methods, and the ease of use of the modified machines

VII. MODIFICATIONS REQUIRED ON CURRENT LATHE MACHINE

- Removal of Lead Screw Shaft from Lathe Machine as we will require Ball Screw Shaft and the Feed will be Provided by Guiding Carriage on Ball Screw Shaft.

- As Lead Screw is Removed, we do not require the Apron and Saddle anymore due to removal of manual Operations, the apron and Saddle are removed.

- The Feed Gear Box which is connected to Lead Screw is also removed from the Lathe Machine, also the Gear System which Transmits Power to Feed Gear Box is Removed from Head Stock.

- The Carriage will be Mounted above a Plate, the Ball Nut will be mounted below this Plate, the Ball Nut will Slide on Ball Screw and Transmit Feed to Carriage and Tool Post.

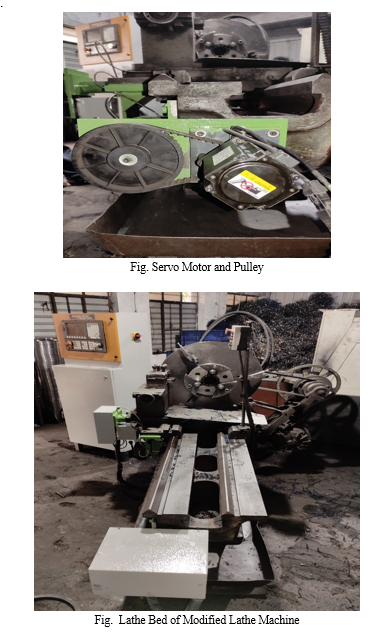

- Pulley System via Timing Flat Belt will be used to Transmit Power from Servo Motor to both main Ball Screw Shaft and Cross Slide Ball Screw Shaft.

- This System will be Mounted on a Plate which will fit on the Carriage for Cross Slide Ball Screw and for Main Ball Screw this system will be mounted on a Plate below the Tailstock

- Further Addition of Components and Mountings will be carried out during the assembly of New Components on the Lathe Machine.

A. List of New Components Required

- Delta CNC Controller Unit.

- AC Servo Motors & Servo Drives. (P = 0.75 KW for X Axis & P = 0.75 KW for Z Axis).

- Electronic Panel Board.

- All necessary Cables and Electrical Components.

- Ball Screws Shaft. (30 mm X 200 cm for X Axis & 25 mm X 60 cm for Z Axis.)

- Timing Pulleys & Belts.

- Fitting Plates for Part Mountings.

- Ball Bearings.

- Miscellaneous fasteners, etc

- Lubrication System for Ball Screw shaft.

B. Use of Simulation software

There are numbers of software available which can mimic the process involved in our research work and can produce the possible result. One of such type of software is Auto CAD, Ansys. We have using delta CNC software for creating a program for specific operation with the help of G-code and M-code, you can get program of G & M codes from online of our project and it easies the process of paper writing.

VIII. ACKNOWLEDGMENT

Acknowledgement is a sweet and short way to express gratitude. I take these opportunity heartfelt thanks to all those who have guided, supported and encouraged me to complete my research work. Indeed the words at my command are not adequate to convey the depth of my feeling and gratitude to my project guide prof. M.v. Bhadak, for her most valuable and inspiring guidance with his friendly nature, love and affection, for his attention and magnanimous attitude right from the first day, constant encouragement, enormous help and constructive criticism throughout the course of this investigation and preparation of this manuscript.We are also thankful to (project coordinator), for counselling generous guidance and useful suggestions; special thanks are tendered to , head of mechanical department. Taken deep appreciation is being rendered to dr. K. N. Nandurkar, principal, k.k wagh institute of Engineering Education and Research, Nashik, for providing the facilities during my studies. I would like to thank the entire staff members of Mechanical Department for timely help and inspiration for completion of the dissertation. My vocabulary fail to get words expressed for my respect and sense of gratitude to my beloved parents, colleagues and friends who always wanted my success, inspired me with their love and affections and for the sacrifice made by them to shape my career.

Conclusion

Modifying a conventional lathe machine to a special purpose lathe machine using a CNC unit is a complex and challenging process that requires careful planning, design, and execution. It involves evaluating the existing machine, identifying the requirements for the special purpose machine, designing and installing the CNC unit, modifying the lathe machine, testing the CNC unit, and training the operators. To ensure success, it is essential to work with experienced professionals who have the knowledge, skills, and expertise to guide and support the project from start to finish. By following a systematic and collaborative approach, a conventional lathe machine can be transformed into a versatile and efficient special purpose lathe machine that can meet the unique needs of different industries and applications. As we upgrade the traditional lathe to automatic CNC upgrade, the production Rate has increased compared to the previous production cost. It will be suitable for mass production. When we use the computer control code, the danger to employees is eliminated. Dimensional accuracy is far superior to conventional lathes. User friendly as shown by the programming code. Advanced lathe manufacturing also ensures repeatability and dimensional stability of manufactured parts by working with high precision. Advanced lathes produce the same quality for all workpieces and shorten lead times. It is safer to work on a powerful lathe.

References

[1] Nagraj patil, arunkumar d t, advance automation analysis of modern conventional lathe machine, journal of emerging technologies and innovative research (jetir) 2019 jetir january2019, volume 6, issue 1 www.jetir.org (issn-2349-5162) , pp.134-138. [2] Roshan n. Shirke, makarand b. Khalde, devang m. Prajapati,punam s. Tonde, prof. L. M. Rathod,conversion of conventional lathe into semi-automatic cnc, international engineering research journal (ierj), volume 3, issue 3, , 2019, pp.5374-5376. [3] Perry s. Koradiya, aman h. Kania, hemanshu s. Vankhede, parth a. Patel, chinmay k. Desaiconversion of a conventional bench lathe to cnc machine, international journal of engineering andtechnical research (ijetr) issn: 2321-0869 (o) 2454-4698 (p) volume-8, issue-12, december2018, pp.19-23 [4] Sutarman, haryono edihermawan, sarmidi, computer numerical control (cnc) milling andturning for machining process in xintai indonesia, quest journals journal of research in mechanical engineering, volume 3 ~ issue 5 (2017), issn(online) : 2321-8185, pp. 01-07

Copyright

Copyright © 2023 Mr. Gaurav B. Nagare, Mr. Shubham S. Bachhav, Mr. Ajay N. Shelar, Mr. Vivek R. Chaudhari, Prof. Mugdha V. Bhadak. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET53227

Publish Date : 2023-05-28

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online