Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

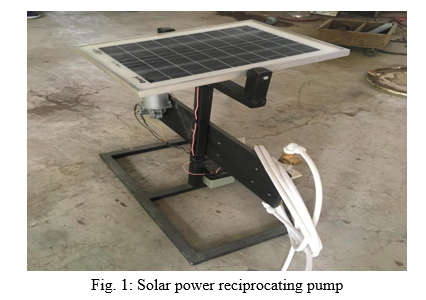

Solar Based Reciprocating Pump

Authors: Parag Akarte , Saurabh Vaidya, Vaibhav Ingole, Mahesh Pokale, Pujan Ghorad, Roshan Bunde

DOI Link: https://doi.org/10.22214/ijraset.2022.43443

Certificate: View Certificate

Abstract

The soul of India lives in the villages and the backbone of that soul is the agricultural sector Improvement in irrigation is necessary to strengthen the economic background in agriculture. In present times, more power is required for people to use new equipment. Solar energy must be used optimally to achieve the expected results that it is environmentally friendly and can be run with less power consumption than central pumps and fuel-based pumps. Its ultimate objective is to lift water from the level discharged through water resources. Therefore, electric energy is powered by the help of PV panels and batteries charged by the Sun rays and electric power is obtained to drive the DC motor Which provides power to the reciprocating pump with mechanical power to the connecting rod. The system consists of a single solar panel, battery, motor, crankshaft, exchange pump, valve and tank

Introduction

I. INTRODUCTION

A. Introduction to Non-Conventional Energy Sources

While fossil fuels will be the main fuels for thermal power, there is a fear that they will get exhausted eventually in the next century. Therefore other system based on non-conventional and renewable sources are being tried by many countries. These are solar, wind, geo-thermal, sea and bio-mass.

- Solar Energy: Solar energy can be major source of power. Its potential is 178 billion MW which is about 20000 times the world's demand but so far it could not developed on large scale. Sun's energy can be utilized as thermal and photovoltaic. The former is currently being used for steam and hot water production. A solar-based reciprocating pump is a pump that is powered by electricity generated by a solar cell that is available from sunlight collected in contrast to electricity or a diesel water run water pump. Nowadays many types of pumps have come. Positive Displacement A reciprocating pump is a class of positive pumps. It is used to serve various purposes. Such as washing, irrigation, sprinkling, oil extraction, sprinkler, other technology, water demand, system capacity and initial and long-term costs are incurred. Solar powered systems are considered for the use of other forms of alternative energy as they provide long-term and economic benefits.

B. The Application of Solar Energy

- Water for livestock.

- Drinking and Cooking WaterSupply.

- Solar drying of agricultural and animal products.

- Industries and commercial uses.

- Solar engines for water pumping.

- Food refrigeration.

- Solar electric power generation by solar ponds, steam generator.

- Solar photovoltaic cells.

II. LITERATURE REVIEW

A. Solar Powered Water Pump System

Abstract: This project will consist of a water pumping system to supply potable water to an orphanage located in the Chuluchosema community of Malawi, Africa. The water will be pumped from a nearby well up to a water tower located in the orphanage center. The pump will be powered by a solar panel that will capture the solar energy from the sun. This project is in association with Mercer’s University’s Master’s Program for Environmental Engineering and Mercer on a Mission. The water pump system will be built on Mercer’s campus and will then be sent to the orphanage in Malawi to be assembled permanently. The water pumping system will be built by materials that are sustainable enough to allow the system to function properly long after the student has installed the system and has left. The intent of this project is to provide a hands-on experience for the graduate student by working with various professors and manufacturers as well as different contacts from the developing country. The goal of this project is to supply potable water to an orphanage without the residents retrieving it from a well.Keywords: Malawi Solar Water Pump.

B. Experimental Study Of Solar Water Pump BY:- Master of Science ErinWilliamson

Abstract: Bio resource Engineering Solar water pump studies for small-scale Irrigation is a well established procedure on many farms in western Canada and is practiced on various levels around the world. It allows diversification of crops, while increasing crop yields. However, typical irrigation systems consume a great amount of conventional energy through the use of electric motors and generators powered by fuel. The overall objective of this research was to determine the feasibility of using photovoltaic (PV) modules to power a water pump for a small-scale drip irrigation system in Montréal (Québec, Canada). The study involved field observations, as well as computer simulations of global solar radiation and PV electrical output. Field observations involved a summer and winter installation of two amorphous silicon 42 W PV modules, directly connected to a 12 V surface water pump. The parameters monitored were voltage, current, back-of-panel temperature, pressure, and flow. These observed parameters were used to determine PV electrical output and volume of water pumped. Site latitude, elevation, and panel tilt were applied to the solar radiation and PV electrical output models, along with the following meteorological data: daily average, maximum, and minimum temperatures, and global solar radiation. Daily solar radiation prediction showed a linear correlation of 0.69 with the observed daily values, over the years 2000 to 2005. The correlation coefficient was improved to 0.91, when 7 day moving averages of both the observed and predicted solar radiation data were used. PV electrical output and volume of water pumped were monitored between August 2005 and May 2006. Both the power and water output observations were less than expected. However, the predicted daily PV electrical output ranged from 1.0 MJ d-1 in the summer to approximately 0.6 MJ d-1 in the winter. As expected, an increase in power caused an increase in the volume of waterpumped.

A solar powered water pumping system is made up of two maincomponents,

- Solarpanels:

- Photovoltaicmodule

2. Pumps:

- Centrifugal

- Reciprocatingpump

There are two basic types of solar powered water pumping systems,

- Batterybased

- Solar direct

-

- A variety of factors must be considered in determining the optimum system for a particularapplication.

- Battery based water pumping system consists of photovoltaic(PV) panels charge controller, batteries, pump controller and DC waterpump,

-

- Water supply for home orcabin.

- Pumping atnight

III. WORKING PRINCIPLE

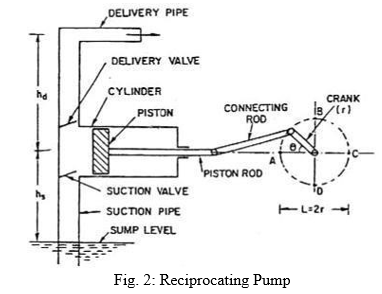

Reciprocating pumps are those which cause the fluid to move using one or more oscillating pistons, plungers or membranes (diaphragms).To 'Reciprocate' means 'To Move Backwards and Forwards'.

A 'RECIPROCATING' pump therefore, is one with a forward and backward operating action. The simplest reciprocating pump is the 'Bicycle Pump', which everyone at some time or other will have used to re-inflate their bike tyres. Reciprocating- type pumps require a system of suction and discharge valves to ensure that the fluid moves in a positive direction. Pumps in this category range from having "simplex" one cylinder, to in some cases "quad" four cylinders or more. Most reciprocating-type pumps are "duplex" (two) or "triplex" (three) cylinder. Furthermore, they can be either "single acting" independent suction and discharge strokes or "double acting" suction and discharge in both directions. The pumps can be powered byair,

Steam or through a belt drive from an engine or motor. This type of pump was used extensively in the early days of steam propulsion (19th century) as boiler feed water pumps. Reciprocating pumps are now typically used for pumping highly viscous fluids including

Concrete and heavy oils, and special applications demanding low flow rates against high Resistance.

Reciprocating pump is a positive displacement pump, which causes a fluid to move by trapping a Fixed amount of it then displacing that trapped volume into the discharge pipe. The fluid enters a Pumping chamber via an inlet valve and is pushed out via outlet valve by the action of the piston or diaphragm. They are either single acting; independent suction and discharge strokes or Double acting; suction and discharge in both directions.

During the suction stroke the piston moves left thus creating vacuum in the Cylinder. This vacuum causes the suction valve to open and water enters the Cylinder. During the delivery stroke the piston moves towards right. This increasing pressure in the cylinder causes the suction valve to close and delivery to open and water is forced in the delivery pipe. The air vessel is used to get uniform discharge.

Reciprocating pumps are self-priming and are suitable for very high heads at low flows. They deliver reliable discharge flows and is often used for metering duties because of constancy of flow rate. The flow rate is changed only by adjusting the rpm of the driver.

These pumps deliver a highly pulsed flow. If a smooth flow is required then the discharge flow system has to include additional features such as accumulators. An automatic relief valve set at a safe pressure is used on the discharge side of all positive displacement pumps.

The performance of a pump is characterized by its net head h, which is defined as the change in Bernoulli head between the suction side and the delivery side of the pump. H is expressed in equivalent column height ofwater.

The air vessel is used to get uniform discharge. Reciprocating pumps are self-priming and are suitable for very high heads at low flows. They deliver reliable discharge flows and is often used for metering duties because of constancy of flow rate. The piston connected to the connecting rod will move in linear direction. If crank moves outwards then the piston moves towards its right and create vacuum in the cylinder. The flow rate is changed only by adjusting the rpm of the driver. These pumps deliver a highly pulsed flow.

If a smooth flow is required then the discharge flow system has to include additional features such as accumulators. An automatic relief valve set at a safe pressure is used on the discharge side of all positive displacement pumps. The performance of a pump is characterized by its net head h, which is defined as the change in Bernoulli head between the suction side and the delivery side of the pump. H is expressed in equivalent column height ofwater.

IV. PARTS

- 10 WATT SOLARPANNEL

- 12 VOLTBATTERY

- 12 VOLT MOTOR WITH SPEED REDUCTIONGEARBOX

- CIRCULARDISC

- CONNECTINGROD

- PISTONCYLINDER

- SUPPLYPIPES

- SUMP AND OVERHEADTANK

- BASE FOR SUPPORTING THESYSTEM

A. Calculation

L=LENGTH OF STROKE R= RADIUS OF THE DISC. L=2R

L=150mm, thus radius is L/2= 50mm. Thus diameter of the disc is 100mm.

- Disc: - The circular disk of 120mm diameter and 3mm thickness is used to convert rotary motion of the gear box to reciprocating motion for piston andcylinder.

- Connecting rod: - A connecting of 220mm is used to connect the disk and the piston with a special attachment to provide reciprocating motion. The center hole distance is250mm.

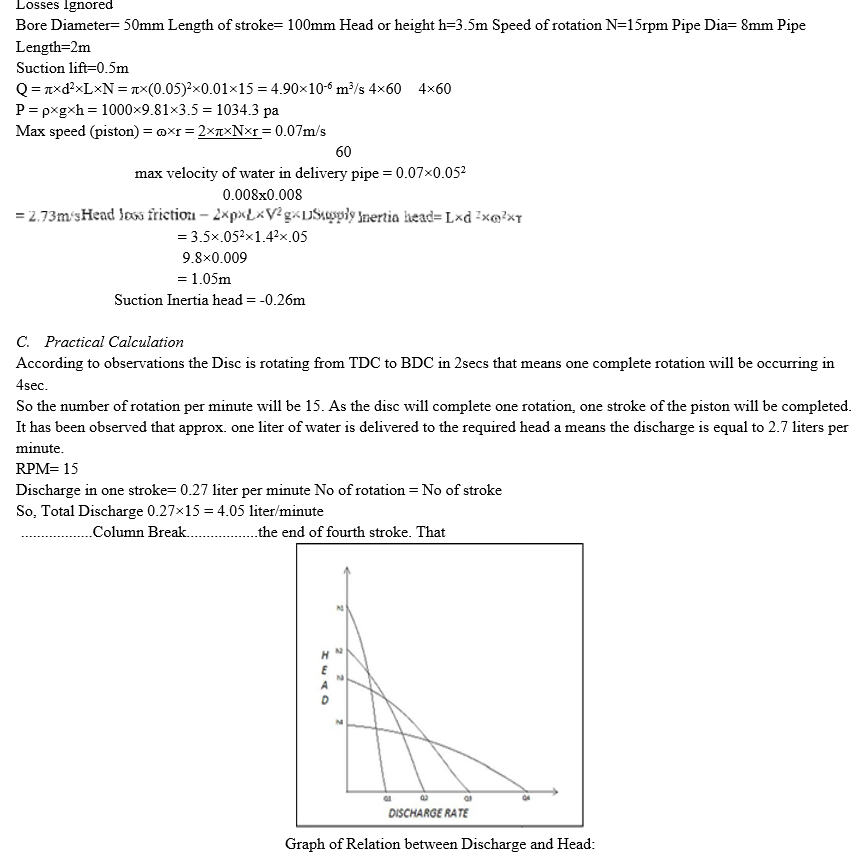

B. Theoretical Calculations:

V. ADVANTAGES AND DISADVANTAGE

A. Advantages

- Solar-powered Water Systems are practical in flat terrain where the sunshines.

- Solar-powered water pumps can be placed in or next to the pond or other source of water and the water can be pumped where it isneeded.

- Solar water pumping is clean andefficient.

- Solar electric water pumping cuts down on waste because it’s based on natural cycles. Your panels give the most pumping power on the sunniest days---when you need the mostwater.

- Solar power is clean. You never have to worry about polluting the groundwater or air with a gas-poweredpump.

- Solar-powered water systems take very little maintenance because they only have a few moving parts. They have long life---usually 20 to 40 years. And solar water systems never run out of fuel as long as the sun isshining.

B. Disadvantages

- Relatively high initialcost

- Lower output in cloudyweather

Conclusion

The method used here to build solar powered water pumping system is cost effective comparatively to an electrically operated hydraulic pump. Since here non-conventional energy is used to achieve the required head. Discharge obtained from the observations is 2.7liters per minute. The reciprocating pump built by us is built with the help of simple and easily available materials still we have successful to demonstrate the worth of a reciprocating pump. This device serves its purpose to some extent, but with proper course of actions, it can perform still better.

References

[1] Deshmukh Priyanka, Hotkar Pradnya, Shelke Dnyaneshwari and Anupma Kamboj, “PV Based Solar Water Pumping System”, International Engineering Research Journal (IERJ) Volume 2 Issue 2 Page 744-746, 2016, ISSN2395-1621.. [2] BrianD.Vick&R.NolanClark,“16DeterminingtheOptimumSolarWaterPumpingSystemforDomesticUse,Livestock Watering or Irrigation”, Proceedings of the 4th Renewable Energy Policy and Marketing Conference, Buffalo, New York, May11. [3] AI Abdelkerim, MMR Sami Eusuf, MJE Salami, A. Aibinu and M A Eusuf, “Development of Solar Powered Irrigation System”, 5th International Conference on Mechatronics (ICOM’13) IOP Publishing IOP Conf. Series: Materials Science and Engineering 53(2013) [4] S. Harishankar, R. Sathish Kumar, Sudharsan K.P, U. Vignesh and T. Viveknath, “Solar Powered Smart Irrigation System”, International Journal of Emerging Technology and Advanced Engineering, ISSN 2231-1297, Volume 4, Number 4 (2014), pp. 341-346,© Research IndiaPublications [5] Mohit Bansal, Tushar Bhatia, Sanchit Srivastava, Shivangani Gupta & Tripti Goyal, “ Automatic Solar Powered Water Pumping Using Zigbee Technology”, The International Journal Of Engineering And Science (IJES), Volume -3, Issue- 3, Pages- 41-46, 2014,ISSN (e): 2319 – 1813 ISSN (p): 2319 –1805. [6] B.Kavitha, S.Karthikeyan & B.Iswarya, “Design of solar PV water pumping system using BLDC drive using sensorless method”, International Journal of Emerging Technology and Advanced Engineering,ISSN 2250-2459, ISO 9001:2008 Certified Journal, Volume 3, Issue 7, July2013. [7] K. B. Rohit, Prof. G. M. Karve & Prof. Khatri, “Solar Water Pumping System”, International Journal Of Innovative Research In Electrical, Electronics, Instrumentation And Control Engineering,Vol. 4, Issue 4, April2016.

Copyright

Copyright © 2022 Parag Akarte , Saurabh Vaidya, Vaibhav Ingole, Mahesh Pokale, Pujan Ghorad, Roshan Bunde. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET43443

Publish Date : 2022-05-27

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online