Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

Universal Turning Forklift

Authors: Khan Muniruzzama Najmuzzama, Khan Habib Sharif, Manihar Mohammad Shamim Roshan, Pandey Vishal Ramesh, M. A. Gulbarga

DOI Link: https://doi.org/10.22214/ijraset.2022.41995

Certificate: View Certificate

Abstract

We describe the development of robotic forklift intended to operate alongside human personnel, handling palletized materials within existing, busy, semi-structured storage facilities. The main objective of this project is to fabricate a Mechanical forklift for material handling in industries. In this project a Universal Turning Forklift is fabricated which runs to carry material from one place to another by using Android App. To use forklift, it requires one spot guide to guide a forklift driver because of less visibility. This project discusses how to integrate Android App based remote controlled technology into a forklift to make it wireless to increase visibility and human safety. Along with this the forklift designed in this project can move in a semi-circular path from left to right hence it becomes more easier for the user to setup the warehouse efficiently.

Introduction

I. INTRODUCTION

The development of technology has resulted in increment of the usage of robots to a great extent in many fields, such as exploration, medicine, agriculture, defense, rescue robots, family service robots and many more. As applications of robots have spread out, the level of intelligence and automation have also become higher and it is continuing to grow. In the industrial and factory environments, the interest of automation and intelligence has increased as well. The recent development of machinery has increased the production and manufacturing rates of industries resulting a need of faster material handling system. To fulfil the requirements, heavy material handling vehicles; forklifts, pallet movers, counter balanced electric stackers were introduced to factory floors. As the robotic technology and the demand to advance material handling systems rise, automatic guided vehicles which could handle the tasks of a manual forklift driver have become an innovative solution. Guided vehicles offer endless advantages over conventional material handling vehicles. First and foremost, the safety and the reliability of the GVs is one of the vital components of the system. Through sophisticated control architecture, GV`s could offer safe and predictable service. Their ability to work around the clock without any breaks and ability to operate in hazardous environments which humans may not be able to work comfortably are few of the many assets that GV`s provide compared with human drivers. Safety has the highest priority in manufacturing industries. Thus, navigating guided vehicles should be done cautiously as possible while maintaining the operation efficiently.

II. COMPONENTS

A. ESP Microcontroller

ESP32-WROOM-32 is a powerful, generic Wi-Fi + BT + BLE MCU module that targets a wide variety of applications, ranging from low-power sensor networks to the most demanding tasks, such as voice encoding, music streaming and MP3 decoding. At the core of this module is the ESP32-D0WDQ6 chip*. The chip embedded is designed to be scalable and adaptive. There are two CPU cores that can be individually controlled, and the CPU clock frequency is adjustable from 80 MHz to 240 MHz the user may also power off the CPU and make use of the low-power co-processor to constantly monitor the peripherals for changes or crossing of thresholds. ESP32 integrates a rich set of peripherals, ranging from capacitive touch sensors, Hall sensors, SD card interface, Ethernet, high-speed SPI, UART, I²S and I²C. The integration of Bluetooth, Bluetooth LE and Wi-Fi ensures that a wide range of applications can be targeted, and that the module is all-around: using Wi-Fi allows a large physical range and direct connection to the Internet through a Wi-Fi router, while using Bluetooth allows the user to conveniently connect to the phone or broadcast low energy beacons for its detection. The sleep current of the ESP32 chip is less than 5 µA, making it suitable for battery powered and wearable electronics applications. The module supports a data rate of up to 150 Mbps, and 20 dBm output power at the antenna to ensure the widest physical range. As such the module does offer industry-leading specifications and the best performance for electronic integration, range, power consumption, and connectivity. The operating system chosen for ESP32 is free RTOS with Lw IP; TLS 1.2 with hardware acceleration is built in as well. Secure (encrypted) over the air (OTA) upgrade is also supported, so that users can upgrade their products even after their release, at minimum cost and effort.

B. L293D Motor Driver

The Device is a monolithic integrated high voltage, high current four channel driver designed to accept standard DTL or TTL logic levels and drive inductive loads (such as relays solenoids, DC and stepping motors) and switching power transistors. To simplify use as two bridges each pair of channels is equipped with an enable input. A separate supply input is provided for the logic, allowing operation at a lower voltage and internal clamp diodes are included. This device is suitable for use in switching applications at frequencies up to 5 kHz. The L293D is assembled in a 16-lead plastic package which has 4 center pins connected together and used for heatsinking The L293DD is assembled in a 20-lead surface mount which has 8 center pins connected together and used for heatsinking.

C. DC Geared Motors

These motors are simple DC Motors featuring gears for the shaft for obtaining the optimal performance characteristics. They are known as Center Shaft DC Geared Motors because their shaft extends through the center of their gear box assembly. These standard size DC Motors are very easy to use. Also, you don’t have to spend a lot of money to control motors with an Arduino or compatible board. TheL298N H-bridge module with onboard voltage regulator motor driver can be used with this motor that has a voltage of between 5 and 35V DC. This DC Motor – 100 RPM – 12Volts can be used in all-terrain robots and a variety of robotic applications. These motors have a 3 mm threaded drill hole in the middle of the shaft thus making it simple to connect it to the wheels or any other mechanical assembly. These DC Geared motors with robust metal/Plastic gearbox for heavy-duty applications, available in the wide RPM range (Check the list below) and ideally suited for robotics and industrial applications.

D. AMS1117 Voltage Regulator Module

This power supply module is based on the AMS1117 3.3V regulator. It is capable of regulating a wide range of input voltage (4.0 to 12V) down to a fixed 3.3V output at up to 1A (Vin = 4.5V). Standard 0.1″ header pins provide a means of connecting to its input and output terminals.

E. 12V Battery

12V 7.2AH SMF Battery Excellent cyclic performance and reliability Suitable for Solar, wind and normal UPS products Completely leak proof and maintenance free Superior Lead Calcium Alloy Grid with high density active materials.

F. HC SR04 Ultrasonic Sensor

The HC-SR04 ultrasonic sensor uses sonar to determine distance to an object like bats or dolphins do. It offers excellent non-contact range detection with high accuracy and stable readings in an easy-to-use package. From 2cm to 400 cm or 1” to 13 feet. Its operation is not affected by sunlight or black material like Sharp rangefinders are (although acoustically soft materials like cloth can be difficult to detect). It comes complete with ultrasonic transmitter and receiver module.

III. WORKING PRINCIPLE, IMPORTANCE & NECESSITY

A. Working Principle of Forklift

The machine entitled Automobile actuated trolley Works on the principle that the motive force of a 12 Volt battery and mechanical advantage of linkages is utilized for the auto-motion of the trolley along with the Load on the platform. In such a machine era of economic liberalization small industries are contributing in a big way to the growth of our country. Taking in to account the above contribution we have tried to help the small-scale industries by introducing a machine which will be a very much useful for them intending to make a light weight portable are multipurpose material handling device called as Hand lifter. This Hand lifter machine is a machine in which actual load is overcome by the worm and worm gearing, by actuating the lever, due to its high mechanical ratio and advantage however, lightly you operate the handle lever, the raising action you get on the trolley crane is consisting.

Its special features are:

- It raises the load of 1.5kg

- It is light in weight and hence it is portable.

- It requires very low maintenance,

- Its setting time is less.

- It required very low floor space area.

- Its manufacturing cost is also very low.

- The raising distance can be adjusted as per our requirement.

- It requires no power for its operations hence it can be used in the remote areas also.

- It is compact.

- Total height of Machine is 450mm.

- Weight of machine is 10kg (approx.).

B. Importance of Forklift

- Manually transporting heavy loads using your own strength alone makes for slow, laborious work. Most people aren't able to move very quickly while carrying weighty items; furthermore, a person generally can't carry as many things at once as a pallet truck or trolley. Using the right piece of material handling equipment allows you to transport your entire load swiftly and easily.

- It reduces the risk of injury.

- Manual handling injuries are awfully common these days - in fact, according to the HSE, manual handling (that is, transporting a load by your own bodily force) is the most common cause of back disorders in the workplace. Carrying heavy items by yourself can lead to chronic back pain and permanent musculoskeletal problems; you may also harm yourself and/or others if you accidentally drop the object you're carrying.

- Picking up the materials from the warehouse shelves, carrying to the open yard and loading in the trucks,

- Unloading the material from trucks, carrying to the shelves, and placing in the correct bin of shelves.

C. Necessity of Forklift

Fork lift is the material handling device with the flat and wheeled robust platform having four wheels. Among four wheels two wheels is having steering arrangement to change the direction of the trolley. The wheels are installed with the band-type friction brakes to break the motion of the vehicle whenever required. It is installed with the worm and worm gear operated lifting crane on it which is power driven through electric motor. As this trolley is a low velocity material handling device, it can be installed with the band operated shoe brakes. It will definitely become one of the most popular automobile trolleys in the world of material handling field. The material handling is specialized activity for a modem manufacturing concern. The main purpose of material handling is to achieve an effective and economical handling system right from the introduction of raw material to the time when products are finally put to use. It has been estimated that about 50- 75 percent of the cost of the production is spent in material handling. As the majority of time of production is spent in material handling before and after the production. This cost can be reduced by proper selection, operation and maintenance: "Material handling" refers to the moving of materials from the storeroom to the machine to the next during the process of manufacturing." The material can be referred as the techniques employed to move, transport, and store or distribute materials with or without the aid of mechanical appliances. It may also be defined as the "Art and science of moving, packing and storing of products in any form". Its general objectives can be summarized in the aphorism "Getting the right goods safety to the right place at right time at right cost".

IV. DESIGN & CALCULATION

A. Dc Geared Motors

A DC motor is any of a class of rotary electrical motors that converts direct current (DC) electrical energy into mechanical energy. The most common types rely on the forces produced by magnetic fields. Nearly all types of DC motors have some internal mechanism, either electromechanical or electronic, to periodically change the direction of current in part of the motor. DC motors were the first form of motor widely used, as they could be powered from existing direct-current lighting power distribution systems. A DC motor's speed can be controlled over a wide range, using either a variable supply voltage or by changing the strength of current in its field windings. Small DC motors are used in tools, toys, and appliances. The universal motor can operate on direct current but is a lightweight brushed motor used for portable power tools and appliances. Larger DC motors are currently used in propulsion of electric vehicles, elevator and hoists, and in drives for steel rolling mills. The advent of power electronics has made replacement of DC motors with AC motors possible in many applications.

B. Types of DC Geared Motor

- Brushed.

- Brushless (BLDC)

- Planetary Gear Motors.

- Spur Gear Motors.

- Stepper.

- Coreless & Coreless Brushless.

- Servo.

- Gear heads.

C. Voltage Regulator Module

A voltage regulator module (VRM), sometimes called processor power module (PPM), is a buck converter that provides microprocessor and chipset the appropriate supply voltage, converting +3.3 V, +5 V or +12 V to lower voltages required by the devices, allowing devices with different supply voltages be mounted on the same motherboard. On personal computer (PC) systems, the VRM is typically made up of power MOSFET devices. Most voltage regulator module implementations are soldered onto the motherboard. Some processors, such as Intel Haswell and Ice Lake CPUs, feature some voltage regulation components on the same CPU package, reduce the VRM design of the motherboard; such a design brings certain levels of simplification to complex voltage regulation involving numerous CPU supply voltages and dynamic powering up and down of various areas of a CPU

D. Rope Drive

A rope drive is a form of belt drive, used for mechanical power transmission. Rope drives use a number of circular section ropes, rather than a single flat or vee belt. The first multiple rope drive was a 9-rope drive of 200 bhp produced by Coombe Barbour for their Falls Foundry, Belfast, in 1863. James Coombe experimented first with circular ropes laid from leather strips, then from manila hemp. The idea of using rope drives had arisen from his earlier, 1856, experiments in using a rope drive together with an expanding vee pulley, as part of a Van Doren or Variomatic transmission.

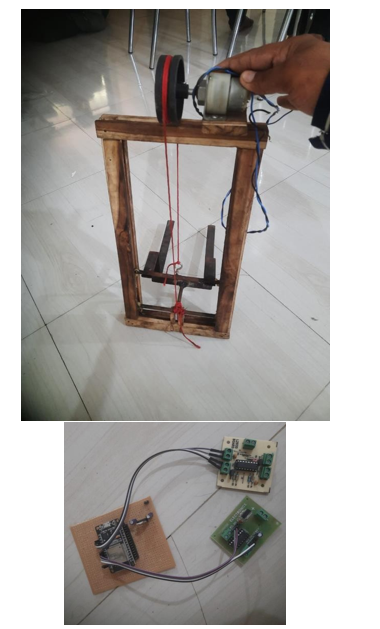

V. METHODOLOGY

A. Introduction

- ESP32 Microcontroller is used in this system.

- The reason behind using ESP32 Microcontroller is it has inbuilt Wi-Fi module which makes it suitable for our operation.

- Various peripherals such as motor drivers, sensors etc. are connected to the ESP32 microcontroller for operation.

- L298N Motor Driver is used to drive motors connected to the chassis for movement of the vehicle.

- An ultrasonic sensor is used to detect any obstacle in front of the vehicle.

- A DC Geared motor is used for the vertical axial movement of the forklift.

- Another motor is used for moving the forks from left to right and vice versa in semi-circular direction.

- Commands for operation of the vehicle are provided through a custom- made Android App that sends command over wi-fi to the vehicle.

- Android App is designed using Kordula Android App Development Platform.

- The vehicle is battery operated using a 12V DC Rechargeable Battery.

B. How Do We Make Universal Turning Forklift?

GENERAL PROCEDURE IN MACHINE DESIGN

The general steps to be followed in designing the machine are as followed:

- Preparation of a statement of the problem indicating the purpose of the machine.

- Selection of groups of mechanism for the desire motion.

- Calculation of the force and energy on each machine member.

- Selection of material.

- Determining the size of component drawing and sending for manufacture. Preparation of component drawing and sending for manufacture.

- Manufacturing and assembling the machine.

- Testing of the machine and for functioning.

VI. ADVANTAGES, LIMITATIONS & APPLICATION OF FORKLIFTS

A. Advantages

- The forklift mechanism is modified to move in a semi-circular path which provides ease of access to the controller or user.

- The system can be wirelessly controlled using an Android App which resolves the issues of accidents due to less visibility.

- Modified system also has almost same power requirements to the conventional one even after adding advanced features to the system.

B. Limitations

- Requires additional materials for modification in the conventional system which increases cost of the system.

C. Applications

- Material Loading Unloading in Factories, Industries Etc

VII. OBSERVATION

Observed that the universal turning forklift needs some of the updates / upgrades for better working. Whereas the project universal turning forklift is working fine.

Conclusion

As we seen the above problem regarding material handling in warehouse, the proper remedy for that problem is necessary. By seeing those problem our team has decided to modify the ordinary forklift and giving the name as \"universal turning forklift\'. What we did is, we modify the fork which is mainly responsible for taking the loaded pallet. The design of fork is changed and by using spur gear and pinion arrangement fork is turn about its axis by 180 degre. Because of that when forklift travel in warehouse having gathering space and at that time forklift does not need to take turn during lifting load. Universal turning forklift only has to stable at its place and driver turn the fork and lift the loaded pallet and come back to normal position and follow the straight path.

References

[1] Panara, K.S., Mishra, V.R., Patel, A., Patel, T.B., Dhivar, K.R. (2015). Construction of battery operated forklift. International Journal of Science Technology and Engineering, 2(4): 1-5. [2] Allwyn, L.M., Karan, K.N., Ganesh, A.B., Prathamesh, B.G., Omkar, K.S., Abhijeet, N.N. (2018). Design and development of mechanical forklift. International Research Journal of Engineering and Technology, 5(3): 1125-1136. [3] Sachin, U.S., Tushar, S.S., Sachin, L.S., Prashant, K.R. (2014). Design, development and modelling of forklift. International Journal of Engineering Research and Technology, 3(4): 1234-1238. [4] Wade, R.R., Waghchore, R.K. (2018). Battery operated 3 wheel drive forklift for industrial warehouse. International Journal for Scientific Research and Development, 5(12): 670-673. [5] Wang, Y., Zhao, D.X., Wang, L., Zhang, Z.X., Wang, L.L., Hu, Y.J. (2016). Dynamic simulation and analysis of the elevating mechanism of a forklift based on a power bond graph. Journal of Mechanical Science and Technology, 30: 4043-4048. https://doi.org/10.1007/s12206-016-0817-y [6] Kumar, N.K., Arun, M., Kumar, K.R. Sabiranathan, R., Yuvaraj, K. (2015). Design and fabricated pneumatic operated forklift. International Journal of Engineering Research and Science and Technology, 4(1): 291-296. [7] Pan, L., Du, Q.L., He, C.S. (2015). Design research on hydraulic system of working device of a forklift. 5th International Conference on Advanced Design and Manufacturing Engineering ICADME (2015), pp. 1813-1817. [8] Kim, S., Choi, S., Lee, J., Hong, S., Yoon, J. (2013). A study of hybrid propulsion system on forklift trucks. 2013 World Electric Vehicle Symposium and Exhibition, IEEE, Barcelona, Spain. https://doi.org/10.1109/EVS.2013.6914737 [9] Roskam, R. (2018). Development of a forklift for research and education in mechatronics. 2nd International Conference on Mechatronics Systems and Control Engineering, 21-23: 17- 21. https://doi.org/10.1145/3185066.3185070 [10] Jagtap, K.S., Londhe, S.D., Khujat, S.M., Koli, P.S., Desai, A.A. (2018). Design and fabrication of battery operated remote controlled articulated forklift. International Journal of Advance Research in Science and Technology, 7(1): 809-813. [11] Kumar, K.S., Reddy, A.S., Reddy, G.S.K., Reddy, G.S.S. (2018). Fabrication of mini forklift using Wi-Fi module. Journal of Emerging Technologies and Innovative Research, 5(9): 613-617. [12] Abdellatif, M., Shoeir, M., Talaat, O., Gabalah, M., Elabably, M., Saleh, S. (2018), Design of an autonomous forklift using Kinect. MATEC Web of Conferences, 153: 1-5. https://doi.org/10.1051/matecconf/201815304005 [13] Vaidya, A., Rotliwala, K., Prajapati, M., Patel, N., Rajpurohit, R. (2016). Design of Pedal operated wheel drive forklift. International Journal of Design and Manufacturing Technology, 9(1): 17-22. [14] Salunke, G., Bell, P., Chore, S., Ghatol, C., Vaishnav, S. (2018). Designing of hydraulic forklift circuit in automation studio using manufacturer’s catalogue. International Journal of Current Engineering and Technology, 8(5): 1210-1219. https://doi.org/10.14741/ijcet/v.8.5.3 [15] Shen, Y., Chu, B. Liu, D.C., Zhu, C.A. (2015). Optimization of steering system of forklift vehicle for idle performance. Mathematical Problems in Engineering, Hindawi, 2015: 1-9. http://dx.doi.org/10.1155/2015/313182 Websites [1] https://www.static- contents.youth4work.com/y4w/Documents/Portfolio/692f759e-a439-4047- 86f0-ab212113fddb.pdf [2] https://pdfcoffee.com/design-and-development-of-forkliftfinal-project- report-pdf-free.html [3] https://www.irjet.net/archives/V5/i9/IRJET-V5I9209.pdf [4] https://www.researchgate.net/publication/283438687_Construction_of_Batt ery_Operated_Forklift [5] https://www.ijert.org/research/design-development-and-modelling-of- forklift-IJERTV3IS041632.pdf [6] https://www.slideshare.net/sathiskumar359778/4remote-control-mini- forklift

Copyright

Copyright © 2022 Khan Muniruzzama Najmuzzama, Khan Habib Sharif, Manihar Mohammad Shamim Roshan, Pandey Vishal Ramesh, M. A. Gulbarga. This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET41995

Publish Date : 2022-04-29

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online